Beruflich Dokumente

Kultur Dokumente

07 Bubble Break

Hochgeladen von

Web Logueando0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

190 Ansichten25 SeitenThis document provides a tutorial for modeling bubble breakup and coalescence in a bubble column reactor using a population balance approach coupled with an Eulerian multiphase model. The tutorial demonstrates how to set up a two-phase bubble column problem using six bubble size bins to represent the bubble size distribution. It describes using the discrete method and Luo breakup and coalescence kernels to compute the bubble size distribution over time as bubbles break up and coalesce due to turbulence and collisions in the column.

Originalbeschreibung:

1

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document provides a tutorial for modeling bubble breakup and coalescence in a bubble column reactor using a population balance approach coupled with an Eulerian multiphase model. The tutorial demonstrates how to set up a two-phase bubble column problem using six bubble size bins to represent the bubble size distribution. It describes using the discrete method and Luo breakup and coalescence kernels to compute the bubble size distribution over time as bubbles break up and coalesce due to turbulence and collisions in the column.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

190 Ansichten25 Seiten07 Bubble Break

Hochgeladen von

Web LogueandoThis document provides a tutorial for modeling bubble breakup and coalescence in a bubble column reactor using a population balance approach coupled with an Eulerian multiphase model. The tutorial demonstrates how to set up a two-phase bubble column problem using six bubble size bins to represent the bubble size distribution. It describes using the discrete method and Luo breakup and coalescence kernels to compute the bubble size distribution over time as bubbles break up and coalesce due to turbulence and collisions in the column.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 25

Tutorial: Modeling Bubble Breakup and Coalescence in a

Bubble Column Reactor

Introduction

The purpose of this tutorial is to provide guidelines for solving the ow break-up, and

coalescence of gas bubbles in a gas-liquid bubble column reactor using a population balance

approach coupled with the Eulerian multiphase model. The population balance approach

is used to solve for bubble ow and size distribution in an axisymmetric bubble column for

a population of six dierent bubble sizes.

This tutorial demonstrates how to do the following:

Set up a two-phase, unsteady bubble column problem for an air-water bubble column

using the Eulerian multiphase model.

Enable and set up a population balance model with six bubble sizes.

Solve the case using appropriate solver settings and solution monitors.

Postprocess the resulting data for bubble size distribution.

Prerequisites

This tutorial is written with the assumption that you have completed Tutorial 1 from

ANSYS FLUENT 13.0 Tutorial Guide, and that you are familiar with the ANSYS FLUENT

navigation pane and menu structure. Some steps in the setup and solution procedure will

not be shown explicitly.

This tutorial assumes that you are familiar with the use of the Eulerian multiphase mixture

model. This tutorial does not cover the mechanics of using this model, but focuses on

setting up the population balance problem for bubble size distribution and solving it. For

details on Eulerian multiphase model, refer to Section 26.5, Setting Up the Eulerian Model

in ANSYS FLUENT 13.0 Users Guide.

The population balance module is provided as an add-on module with the standard ANSYS

FLUENT licensed software. A special license is required to use the population balance

module. For a comprehensive overview of the ANSYS FLUENT population balance model

and its application in solving multiphase ows involving a secondary phase with a size

distribution, refer to ANSYS FLUENT 13.0 Population Balance Model Manual.

c ANSYS, Inc. January 24, 2011 1

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

Problem Description

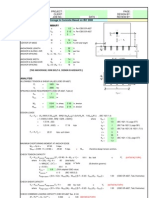

Figure 1 shows the schematic representation of the air-water bubble column of diameter of

0.29 m and height of 2 m. Air is injected into the water column through an inlet at the

bottom, which has a diameter of 0.23 m, with a constant velocity of 0.02 m/s. The initial

diameter of the injected air bubbles is 3 mm. Model this column as a 2D, axisymmetric

column.

Figure 1: Problem Schematic

Strategy

The injection of air causes the development of a turbulent ow pattern in the liquid column,

which transports the bubbles throughout the column. Due to the eects of turbulence and

collisions between individual bubbles, the bubbles breakup and coalesce with each other.

As a result, bubbles with a range of sizes are formed in the bubble column. The size

distribution of the bubbles, plays a critical role in any mass transfer and reactions that

may occur between the air and the liquid, as in a Fischer-Tropsch synthesis process. Hence

resolving the bubble size distribution is an important task in the CFD analysis of bubble

column reactors. This can be accomplished using the population balance model in ANSYS

FLUENT.

1. In this tutorial, you will set up the two phase ow problem using the Eulerian mixture

multiphase model.

(a) Enable the population balance model using the TUI commands.

(b) Use the specialized dialog box for this model to dene the size distribution prob-

lem.

2 c ANSYS, Inc. January 24, 2011

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

(c) Select the discrete method with six size bins to represent the the bubble size

distribution.

(d) Set the volume ratio to 4 with a minimum size of 0.001911 m or 1.911 mm. The

six size bins correspond to the bubble diameters 0.012, 0.00756, 0.004762, 0.003,

0.00189, and 0.001191 metres respectively.

(e) Choose the size bins such that the inlet bubble size of 3 mm, i.e. 0.003 m, lies

in the middle of the bin sizes.

(f) Enable the aggregation and breakage kernels and choose the Luo model.

(g) Set up and solve the ow and population balance problem in transient mode

until an equilibrium solution is reached.

(h) Finally, use the postprocessing capabilities to analyze the ow and resulting size

distribution.

2. Use the population balance model for solving multiphase ow problems where the

secondary phase has a size distribution such as droplets, bubbles or crystals, which

evolves and changes with the ow due to phenomena like nucleation, growth, aggre-

gation or coalescence, and breakage.

The population balance model uses a balance equation, similar to the mass, energy and

momentum balance, to track the changes in the size distribution. The size distribution

can be determined using one of the four approaches:

The discrete method.

The inhomogenous discrete method.

The standard method of moments.

The quadrature method of moments.

3. Use the discrete method to compute the bubble size distribution. Here, the range of

particle sizes in the particle size distribution is divided into a nite number of intervals

or discrete bin.

The bubble sizes chosen for the bins have to be in geometric progression with the

ratio of bubble volumes of adjacent size bins, or volume ratio, set to an integer

power of 2. Thus the bubble diameters are in geometric progression with a size

ratio which is the cube root of an integer power of 2.

A transport equation is solved for each bin with a corresponding scalar, which

represents the volume fraction of gas in that bin. Thus, the sum of the scalars

for all the discrete bins is equal to the gas phase volume fraction.

Source terms in the transport equation account for the birth and death of bubbles

in each size bin, when they enter or leave the bin due to breakup and coalescence.

These terms are computed using specic models or kernels which are published in

the scientic literature. In this tutorial, you will use the breakup and coalescence

kernels for bubble columns developed by Luo et.al. [1]

After solving the transport equations for the scalars, calculate the value of the

number density function for each size bin. This is the volume fraction of each

bin i.e. the scalar value, divided by the volume of a single bubble, yielding the

c ANSYS, Inc. January 24, 2011 3

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

number of bubbles per unit volume or number density. The values of the number

density function for all size bins give the bubble size distribution.

The transport equations from the population balance model and the momentum

equations are coupled due to user-dened drag based on Sauter mean diameter

computed from the obtained size distribution. Both the number density function

and the Sauter diameter are available in ANSYS FLUENT for postprocessing.

Specialized postprocessing functions for the population balance model have been

added to ANSYS FLUENT.

4. Report and plot volume and surface averages of the size distribution. You will also

compute the statistical moments of the size distribution, which represent aggregate

quantities such as the total number of bubbles or the total bubble surface area per

unit volume.

For details about the population balance model and its application to bubble column

reactors, refer to [1] and [2].

Setup and Solution

Preparation

1. Copy the mesh le (bubcol new2.msh.gz) to your working folder.

2. Use FLUENT Launcher to start the 2D double precision 2ddp version of ANSYS FLU-

ENT.

For more information about FLUENT Launcher see Section 1.1.2, Starting

ANSYS FLUENT Using FLUENT Launcher in ANSYS FLUENT 13.0 Users Guide.

The Display Options are enabled by default. Therefore, after you read in the mesh, it

will be displayed in the embedded graphics window.

Step 1: Mesh

1. Read the mesh le (bubcol new2.msh).

File Read Mesh...

As the mesh le is read, ANSYS FLUENT will report the progress in the console.

Step 2: General Settings

1. Dene the solver settings.

General

(a) Select Transient from the Time list.

(b) Select Axisymmetric from the 2D Space list.

4 c ANSYS, Inc. January 24, 2011

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

2. Check the mesh.

General Check

3. Rotate the mesh display.

Display Views...

(a) Select axis from the Mirror Planes list to enable the symmetry.

(b) Click Camera... to open the Camera Parameters dialog box.

i. Drag the indicator of the dial with the left mouse button in the counter-

clockwise direction until the upright view is displayed (see Figure 2).

Figure 2: Mesh Display

ii. Click Apply and close the Camera Parameters dialog box.

(c) Click Apply and close the Views dialog box.

4. Close the Mesh Display dialog box.

Step 3: Models

1. Enable Eulerian multiphase model.

Models Multiphase Edit...

(a) Select Eulerian from the Model list.

(b) Click OK to close the Multiphase Model dialog box.

2. Enable turbulence model.

Models Viscous Edit...

(a) Select standard k-epsilon from the Model list.

(b) Click OK to close the Viscous Model dialog box.

c ANSYS, Inc. January 24, 2011 5

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

Step 4: Materials

1. Copy a new material from the materials database.

Materials Create/Edit...

(a) Click FLUENT Database... to open the FLUENT Database Materials dialog box.

i. Select water-liquid (h2o<l>) from the FLUENT Fluid Material list.

ii. Click Copy and close the FLUENT Database Materials dialog box.

(b) Click Change/Create and close the Create/Edit Materials dialog box.

Step 5: Phases

1. Dene the primary phase (water-liquid).

Phases phase-1-Primary Phase Edit...

(a) Enter water-liquid for Name.

(b) Select water-liquid from the Phase Material drop-down list.

(c) Click OK to close the Primary Phase dialog box.

2. Similarly, dene the secondary phase (air).

Step 6: Operating Conditions

1. Specify the following operating conditions

Boundary Conditions Operating Conditions...

(a) Enable Gravity and set the Gravitational Acceleration to a value of -9.81 m/s

2

in

the X direction.

(b) Enable Specied Operating Density and retain a value of 1.225 kg/m

3

for Oper-

ating Density.

(c) Click OK to close the Operating Conditions dialog box.

Step 7: Population Balance Model Setup

1. Enable the population balance model.

(a) Enter the TUI command, define models addon-module, in the console.

(b) Enter 5 for the module number to enable the Population Balance model.

The GUI now changes and an item is added to the Models menu.

6 c ANSYS, Inc. January 24, 2011

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

2. Set the parameters for the population balance model.

Models Population Balance Edit...

(a) Ensure that Discrete is selected from the Method list.

(b) Ensure that Geometric Ratio is selected from the Denition list.

(c) Ensure that air is selected from the Phase drop-down list.

(d) Enter 6 for Bins, 2 for Ratio Exponent, and 0.001191 m for Min in the Bins group

box.

(e) Click Print Bins to print the discrete bubble sizes for each bin.

(f) Enable Aggregation Kernel and Breakage Kernel from the Phenomena group box.

c ANSYS, Inc. January 24, 2011 7

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

(g) Select luo-model from the Aggregation Kernel and Frequency drop-down lists.

Leave the surface tension requested by the model as default.

(h) Click OK to close the Population Balance Model dialog box.

In the Secondary Phase dialog box, the Diameter property changes to sauter-mean

i.e. the Population Balance model is automatically set to calculate the Diameter

for the mean bubble size.

Step 8: Boundary Conditions

1. Set boundary conditions for inlet.

Boundary Conditions vinlet

(a) Select air from the Phase drop-down list and click Edit....

i. Click the Momentum tab.

A. Select Magnitude, Normal to Boundary from the Velocity Specication

Method drop-down list.

B. Enter 0.02 m/s for the Velocity Magnitude.

ii. Click the Multiphase tab.

A. Enter 1 for the Volume Fraction.

B. Ensure that Specied Value is selected from the Boundary Condition drop-

down lists for all the Population Balance variables.

C. Enter 1 for Bin-3-fraction and retain the default value of 0 for the other

variables in the Boundary Value group box.

D. Click OK to close the Velocity Inlet dialog box.

8 c ANSYS, Inc. January 24, 2011

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

(b) Select mixture from the Phase drop-down list and click Edit....

i. Click the Momentum tab and select Intensity and Hydraulic Diameter from

the Specication Method drop-down list.

ii. Enter 5 % for Turbulent Intensity and 0.145 m for Hydraulic Diameter.

iii. Click OK to close the Velocity Inlet dialog box.

2. Set the boundary conditions for the outlet.

Boundary Conditions outlet

(a) Select air from the Phase drop-down list and click Edit....

i. Click the Multiphase tab and enter 1 for Backow Volume Fraction.

ii. Set the value of Bin-3-fraction to 1 and retain 0 for the other variables in the

Boundary Value group box.

iii. Click OK to close the Pressure Outlet dialog box.

(b) Select mixture from the Phase drop-down list and click Edit....

i. Select Intensity and Hydraulic Diameter from the Specication Method drop-

down list.

ii. Enter 5 % for Backow Turbulent Intensity and 0.145 m for Backow Hydraulic

Diameter.

iii. Click OK to close the Pressure Outlet dialog box.

Step 9: Solution

1. Set the solution method parameters.

Solution Methods

(a) Ensure that Phase Coupled SIMPLE is selected from Scheme drop-down list in

Pressure-Velocity Coupling group box.

(b) Retain the default settings for the Spatial Discretization parameters.

2. Retain the default values for Under-Relaxation Factors.

Solution Controls

3. Initialize the solution.

Solution Initialization

(a) Enter 0.1 (m

2

/s

2

) for Turbulent Kinetic Energy and 0.25 (m

2

/s

3

) for Turbulent

Dissipation Rate in the Initial Values group box.

(b) Enter 1 for air Bin-3-fraction.

(c) Click Initialize.

4. Mark the region for adaption.

Adapt Region...

c ANSYS, Inc. January 24, 2011 9

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

(a) Retain selection of Inside from the Options list and Quad from the Shapes list.

(b) Enter the values for the coordinates as shown in the following table:

Parameter Value

X Min 1.8

X Max 2.0

Y Min 0

Y Max 0.145

(c) Click Mark to select the region for adaption.

(d) Close the Region Adaption dialog box.

5. Patch the selected regions.

Solution Initialization Patch...

(a) Select air from the Phase drop-down list.

(b) Select Bin-3-fraction from the Variable list and enter 1 for Value.

(c) Select hexahedron-r0 for Registers to Patch.

(d) Click Patch.

(e) Select Volume Fraction from the Variable list and set Value to 1.

(f) Click Patch and close the Patch dialog box.

6. Set surface point.

Surface Point...

(a) Enter x0 (m) = 1.5 and y0 (m) = 0.

(b) Keep New Surface Name as point-5 and click Create.

7. Create a surface monitor for Bin-0-fraction.

Monitors (Surface Monitors) Create...

(a) Enable Plot and Write.

10 c ANSYS, Inc. January 24, 2011

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

(b) Enter surf-mon-1.out for the File Name.

(c) Select Time Step from the X Axis drop-down list.

(d) Select Time Step from the Every drop-down list.

(e) Select Vertex Average from the Report Type drop-down list.

(f) Select Population Balance Variables... and Bin-0-fraction from the Field Variable

drop-down list.

(g) Select air from the Phase drop-down list.

(h) Select point-5 from the Surfaces list.

(i) Click OK to close the Surface Monitor dialog box.

8. Create a surface monitor for Bin-3-fraction.

Monitors (Surface Monitors) Create...

Set the parameters as shown in the following dialog box.

9. Create a surface monitor for Bin-5-fraction.

Monitors (Surface Monitors) Create...

Set the parameters as shown in the following dialog box.

c ANSYS, Inc. January 24, 2011 11

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

10. Save the initial case le (bubcol new2-initial.cas.gz).

When using the population balance model, the settings do not get applied to the solver.

In order to get appropriate results, you need to exit ANSYS FLUENT and read the case

le in a new session (so that the settings are applied).

11. Exit ANSYS FLUENT.

Step 10: Calculation

1. Read the case le (bubcol new2-initial.cas.gz) in a new ANSYS FLUENTsession.

2. Initialize the solution and patch the regions. Repeat Step 9: 35.

3. Set the time stepping parameters.

Run Calculation

(a) Enter 0.01 s for Time Step Size.

(b) Enter 5000 for Number of Time Steps.

(c) Enter 100 for Max Iterations/Time Step.

(d) Click Calculate.

The scaled residuals are as shown in Figure 3. Figures 4-6 show the plots of con-

vergence history of Bin-0-fraction, Bin-3-fraction, and Bin-5-fraction, respectively.

4. Save the case and data les (bubcol new2.cas/dat.gz).

12 c ANSYS, Inc. January 24, 2011

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

Figure 3: Scaled Residuals

Figure 4: Convergence History of Bin-0-fraction

c ANSYS, Inc. January 24, 2011 13

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

Figure 5: Convergence History of Bin-3-fraction

Figure 6: Convergence History of Bin-5-fraction

14 c ANSYS, Inc. January 24, 2011

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

Step 11: Postprocessing

1. Display the lled contours of air volume fraction.

Graphics and Animations Contours Set Up...

(a) Select Phases... and Volume fraction from the Contours of drop-down list.

(b) Select air from the Phase drop-down list.

(c) Disable Auto Range from the Options list and enter 0 for Min and 0.1 for Max.

(d) Click Display (see Figure 7).

Figure 7: Contours of Volume Fraction of Air

The changes in phase from inlet to outlet, and areas with low volume fraction as

well as dead zones can be observed.

2. Create a vector plot for water velocity and observe the recirculation patterns.

Graphics and Animations Vectors Set Up...

(a) Select Velocity and water-liquid from the Vectors of and Phase drop-down lists

respectively.

(b) Click Display (see Figure 8).

c ANSYS, Inc. January 24, 2011 15

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

Figure 8: Water Velocity Vector Colored by Velocity magnitude of Water

3. Create a contour plot of population balance for air phase.

(a) Select Population Balance Variables... and Bin-0-fraction from the Contours of

drop-down lists.

(b) Select air from the Phase drop-down list.

(c) Enter 0 for Min and 1 for Max.

(d) Click Display (see Figure 9).

Figure 9: Contours of Bin-0-fraction for Air Phase

4. Calculate the moments of the bubble size distribution for the uid region and the

outlet.

16 c ANSYS, Inc. January 24, 2011

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

Report Population Balance Moments...

(a) Increase Number Of Moments to 4.

(b) Ensure that uid is selected from the Cell Zones list and click Print. The values

of the moments are printed in the ANSYS FLUENT window are as shown:

>

Population Balance Moments over Surface(s) (default-interior)

Moment Number Moment

------------------------- ------------------------

0 1489889.2

1 5600.0782

2 27.479965

3 0.19211298

Population Balance Moments over Volume(s) (fluid)

Moment Number Moment

------------------------- ------------------------

0 1483171.4

1 5582.8814

2 27.470498

3 0.19260043

5. Plot the volume averaged discrete number density function distribution for dierent

bubble sizes for the uid volume.

Report Population Balance Number Density...

(a) Select Volume Average from the Report Type list.

(b) Select Discrete Number Density from the Fields list.

c ANSYS, Inc. January 24, 2011 17

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

(c) Select Histogram from the Plot Type list.

Histogram is enabled only after you select Discrete Number Density from the Fields

list.

(d) Select uid from the Cell Zones list.

(e) Click Print to print the values in the ANSYS FLUENT console. The values printed

in the console are as shown:

>

Number Density for Discrete Method

Particle Diameter Number Density

------------------------- ------------------------

0.012004528 66031.477

0.0075623785 76371.661

0.004764 114764.32

0.0030011319 1216879.3

0.0018905946 4335.9113

0.001191 4788.7544

(f) Click Plot to plot the histogram of the volume averaged number density distri-

bution with bubble diameter (see Figure 10).

Figure 10: Volume Averaged Number Density Distribution Histogram

You can also plot the length and volume based number density distribution.

18 c ANSYS, Inc. January 24, 2011

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

6. Create a surface x=1 with x-coordinate equal to 1.

Surface Iso-Surface...

(a) Select Mesh... and X-Coordinate from the Surface of Constant drop-down list.

(b) Enter 1 for Iso-Values.

(c) Enter x=1 for New Surface Name.

(d) Click Create.

(e) Close the Iso-Surface dialog box.

7. Plot the surface averaged discrete number density function distribution for dierent

bubble sizes for the surface at x=1.

Report Population Balance Number Density...

(a) Select Surface Average from the Report Type list.

(b) Select Discrete Number Density from the Fields selection list.

c ANSYS, Inc. January 24, 2011 19

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

(c) Select Histogram from the Plot Type list.

(d) Select x=1 from the Surfaces list.

(e) Click Print to print the values in the ANSYS FLUENT console.

The values printed in the console are as shown:

Number Density for Discrete Method

Particle Diameter Number Density

--------------------------------- ------------------------

0.1941455 0.65229802

0.077046692 125.01903

0.030576 2729.8223

0.012134094 29808.771

0.0048154183 2617.7323

0.001911 940.51139

(f) Click Plot to plot the histogram of the surface averaged number density distri-

bution with bubble diameter (see Figure 11).

Figure 11: Surface Averaged Number Density Distribution Histogram

20 c ANSYS, Inc. January 24, 2011

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

8. Plot the distribution along the central axis of the bubble column for each scalar.

Plots XY Plot Set Up...

(a) Select Population Balance Variables... and Bin-3-fraction from the Y Axis Function

drop-down lists.

(b) Select air from the Phase drop-down list.

(c) Select axis from the Surfaces list.

(d) Click Axes... to open the Axes - Solution XY Plot dialog box.

i. Disable Auto Range from the Options list.

ii. Enter 1.8 for Maximum and click Apply.

iii. Close the Axes-Solution XY Plot dialog box.

(e) Click Plot (see Figure 12).

You can see the initial bubble size distribution.

Figure 12: Distribution of Bubble Size Along the Axis for Bin-3-fraction

The Bin-3-fraction (initial bubble size) decreases from inlet to outlet.

(f) Close the Solution XY Plot dialog box.

Breakup and coalescence are irrelevant in the freeboard region, which does not

contain water.

9. Create and plot a custom eld function that calculates the fraction of air contained

in a bubble size corresponding to Bin-3-fraction.

Dene Custom Field Functions...

c ANSYS, Inc. January 24, 2011 21

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

(a) Select Population Balance Variables... and Bin-3-fraction from the Field Functions

drop-down lists.

(b) Select air from the Phase drop-down list.

(c) Click the Select button to include this variable.

(d) Click the multiplication sign x.

(e) Select Phases... and Volume fraction from the Field Functions drop-down list and

click the Select button.

(f) Enter discrete-size-3-fraction for New Function Name.

(g) Click Dene to create the function.

(h) Close the Custom Field Function Calculator dialog box.

10. Plot the contours of the custom eld function discrete-size-3-fraction.

Graphics and Animations Contours Set Up...

(a) Select Custom Field Functions... and discrete-size-3-fraction from the Contours of

drop-down list.

(b) Disable Auto Range and enter 0 for Min and 0.04 for Max.

(c) Click Display (see Figure 13).

(d) Close the Contours dialog box.

11. Plot contours of the distribution of the Sauter diameter.

Graphics and Animations Contours Set Up...

(a) Select Properties... from the Contours of drop-down list.

(b) Select air from the Phase drop-down list.

(c) Select Diameter from the Contours of drop-down list as the uid property for

plotting.

The Diameter option is available only after selecting air.

(d) Click Display (see Figure 14).

22 c ANSYS, Inc. January 24, 2011

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

Figure 13: Contours of Custom Field Function discrete-size-3-fraction

Figure 14: Contours of Sauter Diameter

c ANSYS, Inc. January 24, 2011 23

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

12. Similarly, plot the histogram of the Sauter diameter distribution in the uid volume.

Plots Histogram Set Up...

(a) Select Properties... from the Histogram of drop-down list.

(b) Select air from the Phase drop-down list.

(c) Select Diameter from the Histogram of drop-down list as the uid property.

(d) Click Plot (see Figure 15).

The plot shows the distribution of the length number density of bubbles with Sauter

diameter. You can also click Print to print the distribution in the ANSYS FLUENT

console.

24 c ANSYS, Inc. January 24, 2011

Modeling Bubble Breakup and Coalescence in a Bubble Column Reactor

Figure 15: Histogram of Sauter Diameter Distribution

Suggested Exercises

1. Calculate the gas hold-up in the column using the volume integration tools in ANSYS

FLUENT and knowing the initial dimensions of the water column.

2. Rerun the case for a ner bubble size distribution using a geometric volume ratio of

2 around the inlet bubble diameter of 3 mm.

Summary

This tutorial used the population balance approach to solve the bubble size and ow dis-

tribution in an axisymmetric bubble column and illustrated the setup, solution process and

postprocessing of gas-liquid multiphase ows with a size distribution. It used the discrete

method to calculate the bubble size distribution for the population of six dierent bubble

sizes.

References

[1] Luo, Hean; Svendsen, Hallvard F., Theoretical model for drop and bubble breakup in

turbulent dispersions, AIChE Journal v. 42, no. 5, May 1996, pp. 1225-1233.

[2] Sanyal, J.; Vasquez, S.; Roy, S.; Dudukovic, M.P., Numerical simulation of gas-liquid

dynamics in cylindrical bubble column reactors, Chemical Engineering Science, v. 54, no.

21, 1999, p. 5071-5083.

c ANSYS, Inc. January 24, 2011 25

Das könnte Ihnen auch gefallen

- ANSYS Mechanical APDL Material ReferenceDokument220 SeitenANSYS Mechanical APDL Material ReferenceWeb Logueando100% (4)

- Official SAT 2004-2005 Practice Test Answer KeyDokument4 SeitenOfficial SAT 2004-2005 Practice Test Answer KeyWeb LogueandoNoch keine Bewertungen

- 12 DM Ship WaveDokument27 Seiten12 DM Ship WaveWeb LogueandoNoch keine Bewertungen

- ANSYS - Tips and TricksDokument84 SeitenANSYS - Tips and Tricksmanel_drNoch keine Bewertungen

- SpaceClaim2011 SP0 UsersGuideDokument505 SeitenSpaceClaim2011 SP0 UsersGuideAnonymous P8Bt46mk5INoch keine Bewertungen

- Design and CFD Analysis of Different Pipe Joints Used in Water Supply IndutriesDokument7 SeitenDesign and CFD Analysis of Different Pipe Joints Used in Water Supply IndutriesPankaj AgarwalNoch keine Bewertungen

- Etab RSM Eccc Basics SCMDokument2 SeitenEtab RSM Eccc Basics SCMsathiyaseelann.sNoch keine Bewertungen

- Caesar II User Manual PDF - Google XXXDokument2 SeitenCaesar II User Manual PDF - Google XXXjasonwu1115Noch keine Bewertungen

- Good Student Sand-Salt Lab ReportDokument4 SeitenGood Student Sand-Salt Lab ReportKrystalLovejoy67% (3)

- 01 - Chemetics Anotrol 2000 InfoSheetDokument2 Seiten01 - Chemetics Anotrol 2000 InfoSheetWeb Logueando100% (1)

- Pipe Rack DesignDokument3 SeitenPipe Rack DesignDarshan NakawalaNoch keine Bewertungen

- ANSI Device NumbersDokument7 SeitenANSI Device Numbersrajpre1213100% (1)

- Convert Your PV Elite Output Report To WordDokument3 SeitenConvert Your PV Elite Output Report To WordGilang IndraputraNoch keine Bewertungen

- Workshop: Mixing Tank: ANSYS Fluent Watertight Geometry WorkflowDokument15 SeitenWorkshop: Mixing Tank: ANSYS Fluent Watertight Geometry WorkflowSahil JawaNoch keine Bewertungen

- Aqwa Theory ManualDokument168 SeitenAqwa Theory ManualWeb Logueando100% (3)

- Pbadupws - Nrc.gov Docs ML0731 ML073190432Dokument57 SeitenPbadupws - Nrc.gov Docs ML0731 ML073190432Ashish MahtoNoch keine Bewertungen

- Fluid Mechanics - Part 1Dokument83 SeitenFluid Mechanics - Part 1Ahmed BajoNoch keine Bewertungen

- Calculo de SilletasDokument5 SeitenCalculo de SilletasOmar muñozNoch keine Bewertungen

- Mixing TimeDokument7 SeitenMixing TimeakoNoch keine Bewertungen

- Design, Construction and Testing of A Low-Speed Wind Tunnel: Kumaresan Cunden & Professor Freddie L. InambaoDokument20 SeitenDesign, Construction and Testing of A Low-Speed Wind Tunnel: Kumaresan Cunden & Professor Freddie L. InambaoTJPRC PublicationsNoch keine Bewertungen

- Water Hammer Analysis Using An Implicit Finite-Difference Method PDFDokument12 SeitenWater Hammer Analysis Using An Implicit Finite-Difference Method PDFOmarNoch keine Bewertungen

- Eulerian Model Fluent TutorialDokument32 SeitenEulerian Model Fluent Tutorialbjhamnani100% (1)

- G-P-Pi 270 enDokument10 SeitenG-P-Pi 270 endeicaNoch keine Bewertungen

- Mechanical Unit AnchorageDokument1 SeiteMechanical Unit Anchoragentah84Noch keine Bewertungen

- Flexibility Analysis of A Bare Pipe Line Used For Cryo ApplicationDokument12 SeitenFlexibility Analysis of A Bare Pipe Line Used For Cryo ApplicationksvvijNoch keine Bewertungen

- Design of A Small Boat TrailerDokument9 SeitenDesign of A Small Boat TrailerM Hamza NadeemNoch keine Bewertungen

- Anexo 4 IDO-L.18.001-1212-EBD-3000 Rev.0 - Mechanical-Piping Design CriteriaDokument64 SeitenAnexo 4 IDO-L.18.001-1212-EBD-3000 Rev.0 - Mechanical-Piping Design CriteriaRusNoch keine Bewertungen

- Trailer Overall Dimensions:: Page 1 of 11Dokument11 SeitenTrailer Overall Dimensions:: Page 1 of 11Prem KumarNoch keine Bewertungen

- Cooling System Surge Analysis With AFT ImpulseDokument2 SeitenCooling System Surge Analysis With AFT ImpulsektejankarNoch keine Bewertungen

- FulltextDokument150 SeitenFulltextYusuf Luqman HakimNoch keine Bewertungen

- Voltage Sag and Harmonics Mitigation Using Distributed Power Flow ControllerDokument7 SeitenVoltage Sag and Harmonics Mitigation Using Distributed Power Flow ControllerAnonymous kw8Yrp0R5rNoch keine Bewertungen

- Paper Steel Geodesic Dome PDFDokument6 SeitenPaper Steel Geodesic Dome PDFAngga WijayaNoch keine Bewertungen

- Pvp1998-Vol368 1Dokument5 SeitenPvp1998-Vol368 1Nisarg PatelNoch keine Bewertungen

- Pages From Centrifugal Pumps HandbookDokument4 SeitenPages From Centrifugal Pumps HandbooksalamrefighNoch keine Bewertungen

- 1 Transients Unprotected PipelineDokument54 Seiten1 Transients Unprotected Pipelinegabriel147258369Noch keine Bewertungen

- 103 PipenetDokument23 Seiten103 PipenetLucious LightNoch keine Bewertungen

- Easy Guide 14Dokument37 SeitenEasy Guide 14Trilobite3000Noch keine Bewertungen

- CVE 372 Exercise Problems - Pipe FlowDokument10 SeitenCVE 372 Exercise Problems - Pipe FlowMahmoud I. MahmoudNoch keine Bewertungen

- Work Bench VerificationDokument220 SeitenWork Bench Verificationchkarthiksai0% (1)

- Modelling FRP and Plastic Piping in AutopipeDokument1 SeiteModelling FRP and Plastic Piping in AutopipehgscanavinoNoch keine Bewertungen

- Locating Field WeldDokument8 SeitenLocating Field WeldRafeek ShaikhNoch keine Bewertungen

- CAESAR II Input Echo and OutputDokument264 SeitenCAESAR II Input Echo and OutputSanjayNoch keine Bewertungen

- The Various Types of EnclosuresDokument4 SeitenThe Various Types of Enclosuresshan1009Noch keine Bewertungen

- Applicability of Caesar II For Stress Analysis of Lines Having DT Ratio More Than 100 PDFDokument2 SeitenApplicability of Caesar II For Stress Analysis of Lines Having DT Ratio More Than 100 PDFBogdan Chivulescu100% (1)

- API 650 10th Edition ErrataDokument6 SeitenAPI 650 10th Edition ErrataJosé Ramón GutierrezNoch keine Bewertungen

- Finite Element AnalysisDokument3 SeitenFinite Element AnalysisAshley_RulzzzzzzzNoch keine Bewertungen

- Manual InstalacionDokument18 SeitenManual Instalacionmguardia892Noch keine Bewertungen

- In Elastic Buckling of Geometrically Imperfect TubesDokument16 SeitenIn Elastic Buckling of Geometrically Imperfect TubesSiva RajNoch keine Bewertungen

- Stressman Engineering - Study - Stresses in Branch Connections at Different AnglesDokument7 SeitenStressman Engineering - Study - Stresses in Branch Connections at Different AnglesDesmond ChangNoch keine Bewertungen

- 5103 Syl Lab Us 2009Dokument3 Seiten5103 Syl Lab Us 2009ahmadskhanNoch keine Bewertungen

- Formula KircshmerDokument4 SeitenFormula Kircshmerhabibi_fiestaNoch keine Bewertungen

- Caepipe: Tutorial For Modeling and Results Review Problem 2Dokument93 SeitenCaepipe: Tutorial For Modeling and Results Review Problem 2FRANCISCONoch keine Bewertungen

- Norma Astm A1007Dokument9 SeitenNorma Astm A1007Alfredo RangelNoch keine Bewertungen

- SimMan Tut 01 BackstepDokument20 SeitenSimMan Tut 01 BackstepVenkata VasanthaNoch keine Bewertungen

- NTN DES 019 Pipe Support SpacingDokument1 SeiteNTN DES 019 Pipe Support Spacingjdsa123Noch keine Bewertungen

- Consideraciones Sismicas para Contenedores de LiquidoDokument21 SeitenConsideraciones Sismicas para Contenedores de Liquidodavid gonzalezNoch keine Bewertungen

- PB 52 File Slug CatcherDokument2 SeitenPB 52 File Slug CatcherGonzalo Arabey SañezNoch keine Bewertungen

- Coupling UW16.2 KL Ver 1.1Dokument4 SeitenCoupling UW16.2 KL Ver 1.1gopaltryNoch keine Bewertungen

- Equipment Anchorage To Wood Roof Based On NDS 05 / IBC 09 / CBC 10 Input Data & Design SummaryDokument1 SeiteEquipment Anchorage To Wood Roof Based On NDS 05 / IBC 09 / CBC 10 Input Data & Design SummaryMarianne Aravilla Dela CruzNoch keine Bewertungen

- Ace Tut 02 Turbulent BackstepDokument22 SeitenAce Tut 02 Turbulent BackstepHilario de JesusNoch keine Bewertungen

- ANSYS 2D TutorialDokument28 SeitenANSYS 2D TutorialYudha SimbolonNoch keine Bewertungen

- Models - Cfd.water Purification ReactorDokument10 SeitenModels - Cfd.water Purification ReactorHaniif PrasetiawanNoch keine Bewertungen

- Numerical CFD Simulations For Understanding and Optimizing A Biomass Gasifier Reactor Set-UpDokument10 SeitenNumerical CFD Simulations For Understanding and Optimizing A Biomass Gasifier Reactor Set-UparypurnomoNoch keine Bewertungen

- Bubble Column PDFDokument14 SeitenBubble Column PDFAjaykIndauriaNoch keine Bewertungen

- Models - Cfd.water Purification ReactorDokument11 SeitenModels - Cfd.water Purification ReactorzaidNoch keine Bewertungen

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportVon EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNoch keine Bewertungen

- Sa 285Dokument3 SeitenSa 285Web LogueandoNoch keine Bewertungen

- Sa 307Dokument8 SeitenSa 307Web LogueandoNoch keine Bewertungen

- To Section Iii, Division 2: (A) To Establish Rules in The Form of A Code For TheDokument2 SeitenTo Section Iii, Division 2: (A) To Establish Rules in The Form of A Code For TheWeb LogueandoNoch keine Bewertungen

- Sa 299Dokument3 SeitenSa 299Web LogueandoNoch keine Bewertungen

- Sysreq LinxDokument2 SeitenSysreq LinxWeb LogueandoNoch keine Bewertungen

- 11 DDPMDokument13 Seiten11 DDPMWeb LogueandoNoch keine Bewertungen

- Yale Hoist CatalogoDokument16 SeitenYale Hoist CatalogoWeb LogueandoNoch keine Bewertungen

- System Requirements For Windows: PrerequisitesDokument2 SeitenSystem Requirements For Windows: PrerequisitesWeb LogueandoNoch keine Bewertungen

- Magnatrol Solenoid ValveDokument34 SeitenMagnatrol Solenoid ValveWeb LogueandoNoch keine Bewertungen

- 09 SpargerDokument17 Seiten09 SpargerWeb LogueandoNoch keine Bewertungen

- 10 Pbed ReactorDokument16 Seiten10 Pbed ReactorWeb LogueandoNoch keine Bewertungen

- Carrier 35e DamperDokument1 SeiteCarrier 35e DamperWeb LogueandoNoch keine Bewertungen

- Nran-5te6he R3 enDokument7 SeitenNran-5te6he R3 entuwinnerNoch keine Bewertungen

- 08 InkjetDokument15 Seiten08 InkjetWeb LogueandoNoch keine Bewertungen

- 02 BoilDokument18 Seiten02 BoilWeb LogueandoNoch keine Bewertungen

- 01 - Chemetics Converter InfoSheetDokument2 Seiten01 - Chemetics Converter InfoSheetWeb LogueandoNoch keine Bewertungen

- 01 - Chemetics Gas-Gas Heat Exchanger InfoSheetDokument2 Seiten01 - Chemetics Gas-Gas Heat Exchanger InfoSheetWeb LogueandoNoch keine Bewertungen

- Magnetic Forces On WiresDokument4 SeitenMagnetic Forces On WiresasiyahNoch keine Bewertungen

- D-ControlsDokument75 SeitenD-ControlsyohayjoNoch keine Bewertungen

- Reducerea FrecariiDokument82 SeitenReducerea FrecariiDragomir IsabellaNoch keine Bewertungen

- Biochem - Lec 05Dokument3 SeitenBiochem - Lec 05Louis FortunatoNoch keine Bewertungen

- Sample 7580Dokument11 SeitenSample 7580SagarKasarla0% (1)

- Studi Optimasi Offshore Pipeline Indonesie, Balikpapan: Replacement Di Area Bekapai Total E&PDokument40 SeitenStudi Optimasi Offshore Pipeline Indonesie, Balikpapan: Replacement Di Area Bekapai Total E&PAbdul AziesNoch keine Bewertungen

- Transport Anurag Kanpur: TripathiDokument9 SeitenTransport Anurag Kanpur: TripathiPankaj Kumar SainiNoch keine Bewertungen

- Example 18: Pile and Hammer Gravity Changes: GRLWEAP Standard ExamplesDokument3 SeitenExample 18: Pile and Hammer Gravity Changes: GRLWEAP Standard ExamplesbozarromegustaNoch keine Bewertungen

- Conceptual Physics SampleDokument6 SeitenConceptual Physics SampleAhmed ElshinawyNoch keine Bewertungen

- 1978 Fairchild Optoelectronics Data Book PDFDokument300 Seiten1978 Fairchild Optoelectronics Data Book PDFItseed Corca0% (1)

- Jovian Atmosphere Case Study WriteupDokument7 SeitenJovian Atmosphere Case Study Writeupapi-480372762Noch keine Bewertungen

- State Space Model Nptel ModDokument30 SeitenState Space Model Nptel ModBarathNoch keine Bewertungen

- Practical Task Edm Djj40142 Sesi 1 2021-2022Dokument12 SeitenPractical Task Edm Djj40142 Sesi 1 2021-2022Rovinda AnnNoch keine Bewertungen

- MHD Flow of A Non-Newtonian Fluid Through A Circular TubeDokument10 SeitenMHD Flow of A Non-Newtonian Fluid Through A Circular TubeIJMERNoch keine Bewertungen

- Influence of Silica Fume On High Strength Lightweight ConcreteDokument8 SeitenInfluence of Silica Fume On High Strength Lightweight ConcretePhanHathamNoch keine Bewertungen

- Dsme h5375s Ane FDDokument29 SeitenDsme h5375s Ane FDtosveNoch keine Bewertungen

- Advanced Simulation Code For Alpha Spectrometry: Article in PressDokument10 SeitenAdvanced Simulation Code For Alpha Spectrometry: Article in PressAldo MartínezNoch keine Bewertungen

- MSE160 Custom Textbook SolutionsDokument541 SeitenMSE160 Custom Textbook Solutionstal4444Noch keine Bewertungen

- Complex Numbers in TrigonometryDokument13 SeitenComplex Numbers in TrigonometryHimanshu TiwariNoch keine Bewertungen

- A Case Study On Application of Fuzzy Logic in Electrical Discharge Machining (Edm)Dokument37 SeitenA Case Study On Application of Fuzzy Logic in Electrical Discharge Machining (Edm)TanviNoch keine Bewertungen

- The Riemann-Stieltjes Integral and Some PDFDokument49 SeitenThe Riemann-Stieltjes Integral and Some PDFAlexis Garcia DuranNoch keine Bewertungen

- Geologos 15 1soft SeddeformationsDokument54 SeitenGeologos 15 1soft SeddeformationsM HakimNoch keine Bewertungen

- Ideal FolowDokument31 SeitenIdeal FolowADIL BAHNoch keine Bewertungen

- Pressure Transducer DesignDokument112 SeitenPressure Transducer DesignSumeet GhodkeNoch keine Bewertungen

- Group1 Lab1b ReportDokument13 SeitenGroup1 Lab1b ReportMark Allen FacunNoch keine Bewertungen

- The Maurer-Cartan EquationDokument2 SeitenThe Maurer-Cartan EquationJohn BirdNoch keine Bewertungen

- Module 2 - Derivation of The Diffusivity EquationDokument4 SeitenModule 2 - Derivation of The Diffusivity EquationMuhammad Umair AliNoch keine Bewertungen

- Random Process PDFDokument91 SeitenRandom Process PDFramakant.savranNoch keine Bewertungen