Beruflich Dokumente

Kultur Dokumente

630-33 Refrigerant Piping by Rses

Hochgeladen von

miniongskyCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

630-33 Refrigerant Piping by Rses

Hochgeladen von

miniongskyCopyright:

Verfügbare Formate

BY: Cecil R.

Visger

Past International President, RSES

TABLE OF CONTENTS

INTRODUCTION

DISCHARGE OR HOT GAS LINES

EVAPORATIVE CONDENSER DISCHARGE LINES

LIQUID LINES

SUCTION LINES

SUCTION LINE DESIGN FOR MULTIPLE EVAPORATORS

SIZING REFRIGERANT PIPING

Copyright 1964, 2001, By Refrigeration Service Engineers Society.

Refrigeration Service Engineers Society

1666 Rand Road

Des Plaines, IL 60016

630-33

REFRIGERANT PIPING Home Back TOC Next

Home Back TOC Next

Page 1 of 1 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

INTRODUCTION

In recent years, manufacturers of condensing units have more and more gone

to motor-compressor units and direct-drive compressors, which means that the

compressors are turning at motor speeds. These relatively high-speed

compressors cannot operate without proper lubrication at all times. Even more

than formerly, adequate oil return must be maintained.

Proper piping is conducive to long life and minimum repairs to the equipment,

such as reduction of damage to compressors by broken valves, burned out

bearings and scored cylinders by the lack of proper oil return; and damage to

expansion valves due to wire drawing as a result of flash gases, to name only

a few of the possible damages. After all, it is to the best interest of all to make

the customer's equipment operate as efficiently and economically as possible.

The chief purpose of this discussion on refrigerant piping is to point out some

of the precautions to be taken which affect the life and efficiency of

refrigerating equipment, and to offer some helpful suggestions in piping design,

selection and erection.

The author knows of nothing the user appreciates more, and which causes him

to feel that he has received his money's worth, than NEATNESS. That is

something he can see and understand. The only way fittings will fit properly is

to install the piping runs plumb and level, except when otherwise necessary to

pitch for proper drainage. The supporting of pipes is part of the job of

neatness, and should be done as part of the permanent results as intended in

the original engineered layout. The intervals or spacing of the supports will be

governed by the type and size of pipe, but should be close enough to avoid

any sagging between the supports.

In order to be able to properly select the valves, fittings and pipe for an

installation, and the connection of the equipment for a given job, the location of

each piece of the equipment with relation to each other component must be

determined. These locations decide the design of the piping as well as the size

and length, and they also determine the necessary valves and fittings. The first

thing to do then is to make a layout. For small installations, the layout may

even be mental; but there should be a thought-out plan before erection is

started.

To simplify our discussion we shall divide it into four sub-topics, namely:

DISCHARGE OR HOT GAS LINES

Refrigeration Service Engineers Society

1666 Rand Road

Des Plaines, IL 60016

630-33

REFRIGERANT PIPING Home Back TOC Next

Page 1 of 2 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

LIQUID LINES

SUCTION LINES FOR R-12

SIZING REFRIGERANT PIPING

MISCELLANEOUS.

Copyright 1964, 2001, By Refrigeration Service Engineers Society.

Home Back TOC Next

Page 2 of 2 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

DISCHARGE OR HOT GAS LINES

The discharge or hot gas piping is as important as the other two lines. In many

installations remote condensers are used, such as remote air-cooled

condensers and evaporative condensers. Installations of these types present

their problems, and should be piped to avoid excessive vibration, provide

against the entrainment of oil, and for traps where necessary to protect the

equipment.

The usual recommended maximum pressure drop for calculations of R-12 hot

gas lines is 2 psig, and a minimum velocity of 1,500 fpm (feet per minute) in

vertical, and 750 fpm in horizontal piping to maintain oil movement. These

results can be obtained by referring to the manufacturers' charts on "pipe

sizing".

Care should be taken when connecting condensing units in parallel, and each

with its own receiver. The hot gas lines should be arranged so that the

equalizer pipe between them is as short and as near the receivers as possible.

(See Figure 66F01.) This equalizer should be at least the next size smaller

pipe than the discharge piping. When connecting two or more compressors to

one condenser, it is best to run a discharge line for each compressor directly

into the condenser. If this method is not practical, each compressor discharge

line should be connected to the main hot gas line in a "Y" or offset "T", as in

Figure 66F02A and Figure 66F02B, but never bull-headed, as in Figure

66F02C.

Figure 66F01

Paralleling Condensing Units

Refrigeration Service Engineers Society

1666 Rand Road

Des Plaines, IL 60016

630-33

REFRIGERANT PIPING Home Back TOC Next

Page 1 of 4 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

The opposing flow of refrigerant gases, as shown in the left diagram in Figure

66F02C, can set up a turbulence that may cause pulsation in the piping. If the

rise to the main hot gas line is over 4 or 5 ft, the branch lines should connect to

the main line above the center of the main line piping. Another suggested

method for hot gas lines, when paralleling two compressors, is shown in Figure

66F03A.

Figure 66F02A

Y connection for paralleling the hot gas lines from two compressors to a condenser at a

lower level (right).

Figure 66F02B

T or offset connection for paralleling the hot gas lines from two compressors to a

condenser at a lower level (right).

Figure 66F02C

Bullhead (Wrong) and two permissible connections for paralleling two hot gas lines.

Page 2 of 4 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

If the condenser is as much as 8 or 10 ft above the compressor, provisions

should be made to trap the oil and refrigerant that might otherwise condense in

the compressor heads when the compressors are stopped. (See Figure

66F03B and Figure 66F03C.) Using this method, oil and refrigerant will soon

return to the system when the machine starts again, without damage to valve

plates or heads. For each additional 30 ft rise, another trap should be provided,

dividing the amount of pipe proportionately to each trap. These traps should be

made as short as fittings will permit.

Another method of equalizing hot gas and receiver pressures and crankcase oil.

Figure 66F03B

Separate hot gas lines from compressors to one condenser at a higher level, showing

traps to prevent oil, and refrigerant from running back down into the compressor heads

when the compressors stop.

Page 3 of 4 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

If it is anticipated that the compressor temperature may be lower than the

receiver temperature, and that the receiver is located above the compressor, a

check valve should be installed in the discharge piping near the receiver

(Figure 66F03D). This will prevent refrigerant evaporated out of the receiver

from condensing in the compressor head, and causing serious damage when

the compressor starts.

EVAPORATIVE CONDENSER DISCHARGE LINES

Figure 66F03C

Similar connections to those in Figure 66F03B, except one hot gas line is used for both

compressors. Note use of Y connections and trap.

Figure 66F03D

Use of check valve in hot gas line with condenser above the compressor if compressor

is in cooler location than condenser.

Copyright 1964, 2001, By Refrigeration Service Engineers Society.

Home Back TOC Next

Page 4 of 4 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

EVAPORATIVE CONDENSER DISCHARGE LINES

Today we are becoming concerned with water-saving devices, and one of

these is the evaporative condenser. As has been previously pointed out, the

inlet and outlet piping of a multi-coil evaporative condenser should not be bull-

head connected. The liquid outlet of an evaporative condenser should be piped

downward from the condenser coil outlet and full size, before a reduction in

pipe size is made. This will avoid trapping any refrigerant in the coils of the

evaporative condenser (Figure 66F04A and Figure 66F04B).

Figure 66F04A

Bullhead tee connection (wrong) of hot gas line to two sections of evaporative

condenser. T connection (right) of liquid lines. Note check valve in main liquid line to

receiver.

Refrigeration Service Engineers Society

1666 Rand Road

Des Plaines, IL 60016

630-33

REFRIGERANT PIPING Home Back TOC Next

Page 1 of 3 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

Again, we have the temperature difference affecting the refrigerant in the

discharge circuit. To avoid any difficulty, it is recommended that a check valve

be installed at the inlet of the receiver, to prevent the refrigerant from

recondensing out of the receiver back into the condenser coils, should the

refrigerant temperature in the receiver exceed that in the evaporative

condenser coils.

In cases of two or more evaporative condensers connected in parallel, the

outlets should have a drop of at least 24" to provide a static head to insure the

condensed refrigerant draining into the receiver.

Under certain weather conditions when the evaporative condenser is installed

outside, and sometimes under what appears to be normal operating

conditions, liquid refrigerant will have a tendency to hang up in the condenser

coil, caused by gas binding in the receiver. This makes the system appear to

be short of refrigerant, but after adding refrigerant and making another

inspection, the system may be found to be over-charged. To help this

condition, a control can be used to operate the fan motor or spray pump to

maintain a pressure in the condenser sufficient to overcome the pressure to

the receiver.

Another condition may be due to difference in levels, and may be corrected by

repositioning the inlet and outlet of the condenser piping, as shown in Figure

66F05.

Figure 66F04B

Correct hot gas and liquid lines for two section evaporative condenser.

Page 2 of 3 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

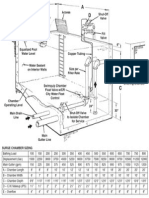

In some installations, it may be necessary to raise the evaporative condenser

to obtain a minimum of 18" drop between the outlet of the condenser and the

inlet to the receiver. Also, there must be a trap in this line at the lowest run to

prevent gas from rising to the condenser coil. The small equalizer line from the

receiver to the inlet piping of the condenser should have a valve for shutting off

the receiver. The size of this pipe can be 3/8" up to 25 tons capacity, and 1/2"

up to 60 tons.

Figure 66F05

Evaporative condenser should be at higher level than its receiver. Note trap in liquid

line and equalizer from top of receiver to hot gas line.

Copyright 1964, 2001, By Refrigeration Service Engineers Society.

Home Back TOC Next

Page 3 of 3 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

LIQUID LINES

When designing a system, the engineer needs to maintain a solid column of

liquid refrigerant to the flow control device, such as a thermostatic expansion

valve, low-side float valve or high-side float valve, and make sure that column

will stay at a reasonable working temperature. Any flashing of liquid refrigerant

in the liquid line affects the capacity of flow-control devices and of the

evaporator. Also, it may cause damage to these controls, or may be noisy in

operation.

If the evaporator is located above the receiver, there are three important

precautions that should apply:

a. The liquid refrigerant should be delivered to the evaporator without

flashing due to heating of liquid from surrounding air, or to drop in

pressure due to friction in the piping or to static head.

b. The expansion valve or other flow control devices should be selected

according to the manufacturers' rating for the capacity required after

pressure drop due to friction and static head have been considered.

c. The liquid refrigerant should reach the flow control device sub-cooled at

least 1F below the exit temperature at the receiver.

The limits in height to which liquid refrigerant can be piped without flash gas

differ among engineers, but a maximum rise of 15 ft for R-12 is usually

recommended. The controlling factor is the static head of the refrigerant at a

given temperature. For R-12 at 97F, this is .55 psi per ft of rise, and .57 psi

per ft of rise at 70F. For R-22 at 97F, it is .50 psi per foot of rise, and .52 psi

per foot of rise at 70F, so the maximum rise may be a foot or so more than for

R-12.

Several steps can be taken to reduce flash gas in lifts higher than that

mentioned above:

1. Increase liquid pipe size one size over the calculated size, to reduce

pressure drop due to pipe friction.

2. Increase shut-off valves, strainers, solenoid valves and dryers to match

above piping. These measures (1 and 2) will not reduce pressure drop

due to static head.

3. If, due to excessive static head, the above recommendations cannot be

Refrigeration Service Engineers Society

1666 Rand Road

Des Plaines, IL 60016

630-33

REFRIGERANT PIPING Home Back TOC Next

Page 1 of 3 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

used a heat exchanger installed between the suction and liquid line in

(Figure 66F06A) to sub-cool the liquid will accomplish satisfactory

results. It is important that the heat exchanger be installed in a position

that will not allow oil to be trapped in the suction side of it, which in turn

reduces the oil level in the compressor.

4. Another alternative is to locate the receiver on the same floor level and

near the evaporator. This method will be more applicable when a

receiver is used with a shell and tube condenser-receiver or other type

condenser.

The following are precautions to be followed in liquid line piping that will

improve the service of the equipment:

Never locate a stop valve directly below a"Y" type strainer in a vertical

pipe see left drawing (Figure 66F06B), as balls of solder, scale and

foreign particles will drop into the valve when the flow of refrigerant

ceases, causing damage to the valve disc and seat, as the valve is

turned to the closed position. Figure 66F06C and Figure 66F06D show

suggested installations of stop valves and strainers in the liquid line. The

use of an angle strainer usually eliminates one fitting.

Figure 66F06A

Use of heat exchanger in liquid and suction line to sub-cool the liquid in case of

excessive static head.

Figure 66F06B

Stop valve directly beow strainer in vertical liquid line (Wrong).

Page 2 of 3 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

Dryers should be installed in a vertical position and the liquid fed upward.

The large volume of the drier causes a reduced velocity of the liquid. If

the drier is placed in a horizontal position, oil may tend to separate out

and fill that portion below the outlet, thus reducing the capacity of the

drier. According to recent research, a good cleanable strainer should be

installed in the liquid line between the receiver and drier, to save the drier

from becoming contaminated with the foreign substances that may be in

the refrigerating system. This procedure will improve and increase the

effectiveness of the drier.

If the liquid line is run through an area with an ambient temperature

above the design refrigerant temperature, then the line should be

insulated the required thickness to protect it from outside heat gain.

Figure 66F06C

Stop valve ahead of angle strainer in horizontal liquid line (Right).

Figure 66F06D

Stop valve ahead of Y strainer in horizontal liquid line (Right).

Copyright 1964, 2001, By Refrigeration Service Engineers Society.

Home Back TOC Next

Page 3 of 3 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

SUCTION LINES

The design and sizing of suction piping requires very careful consideration for

the successful and efficient operation of each part of the equipment, since the

suction line plays a most important part in the rapid return of oil to the

compressor. If this one thing is accomplished without abnormal pressure drop

due to friction and without slugging, long compressor life will result.

The paralleling of compressors and evaporators present many difficult

problems. There are important designs to be practiced in paralleling either, and

they are NOT the same.

For installations of the evaporator or evaporators above the condensing unit,

the suction line should be trapped by running the piping upward from the coil

outlet trap, and as near the coil as possible, and to the height of the coil, to

prevent the condensed vapors remaining in the coil from draining directly into

the compressor.

Many times, the importance of proper piping design when inter-connecting

evaporators is overlooked, and consequently the expansion valve is

condemned. To further explain the principle involved, Figure 66F07 compares

a dribbling coffee cup to the suction line. As the coffee is slowly poured, it will

follow the outside of the cup to the lowest point. Now refer to the suction line

branches in this same picture. The shaded area represents small quantities of

semi-vapor and liquid refrigerant. As this mixture flows from the top coil toward

the lower coil, it tends to flow into the tee branch, following the wall of the

tubing and spreading out as shown in cross section A-A, thus causing an

effective temperature change of the TEV bulb, and in turn affecting the proper

functioning of the valve itself.

Refrigeration Service Engineers Society

1666 Rand Road

Des Plaines, IL 60016

630-33

REFRIGERANT PIPING Home Back TOC Next

Page 1 of 2 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

SUCTION LINE DESIGN FOR MULTIPLE EVAPORATORS

Comparison of coffee dribbling from cup, and liquid following inside tube of suction line

of lower evaporator. Locate T.E.V. bulbs on side, rather than top or bottom of suction

line.

Copyright 1964, 2001, By Refrigeration Service Engineers Society.

Home Back TOC Next

Page 2 of 2 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

SUCTION LINE DESIGN FOR MULTIPLE EVAPORATORS

The suction piping layout shown in Figure 66F08A and Figure 66F08B might

lead to three coils in adjoining walk-in or reach-in refrigerators. Suppose there

are three walk-ins in Figure 66F08A, each with identical blower coils, each

controlled by a thermostat and a liquid line solenoid valve. If the suction piping

were installed in the manner shown, it would interfere with the proper operation

of the TEV's. For instance, assume that the left end cooler were requiring

refrigeration, the condensing unit is running, and the solenoids were open on

either or both of the coolers. It would be possible for the cold suction vapors to

drain into the left and coil and suction line and effect the operation of the TEV

on this left end coil, since a trap has been installed in the main suction piping

preventing free drainage and return of the suction vapors and oil.

Figure 66F08A

Suction line from three adjacent refrigerators with trap in main line (Wrong).

Figure 66F08B

Same refrigerators as in Figure 66F08A, but with trap in each of the three branch

suction lines (Right).

Refrigeration Service Engineers Society

1666 Rand Road

Des Plaines, IL 60016

630-33

REFRIGERANT PIPING Home Back TOC Next

Page 1 of 8 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

The solution to this problem is shown in Figure 66F08B. Here the trap in the

main suction line has been removed, and the branch suction lines from each

blower coil have been connected into the top of the main suction line, thus

preventing the draining of refrigerant from one coil into another.

Notice how the piping from the unit in Figure 66F09A has been rearranged in

Figure 66F09B with the same number of fittings, to prevent suction vapors

from the upper coil draining into the lower one.

When evaporators are stacked in banks, one on top of the other, precautions

should be taken to pipe them so that the draining vapors from the upper coil do

not have a chance to affect the control of the coil or coils below. Figure

66F10A is a diagram of the wrong method, while Figure 66F10B shows the

right method of piping such an installation.

Figure 66F09A

Upper coil of two evaporators in parallel can drain into lower coil (Wrong).

Figure 66F09B

Suction piping of Figure 66F09A rearraged to provide trap (Right).

Page 2 of 8 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

Two air-conditioning coils stacked in a vertical bank. Upper coil can drain into lower

(Wrong).

Page 3 of 8 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

Following the recommendations of cold plate manufacturers, cold plates

should be piped so the refrigerant enters the bottom opening, and with a

maximum of 75 sq ft of surface in any one circuit. As in the case of other

suction piping, the return or suction pipe from each plate or bank of plates fed

by one TEV should be connected into the top or at a 45 angle downward to

the main suction line, as illustrated in Figure 66F10C and 66F10D. This is to

maintain proper refrigerant control, as previously explained.

Piping of Figure 66F10A rearranged to provide trap (Right).

Page 4 of 8 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

Figure 66F10C

Piping layout for two parallel banks of vertical overhead plate coils.

Page 5 of 8 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

Occasionally, it is necessary to install the condensing unit several feet above

the evaporator. If the suction riser in such an installation is over 30 ft, traps

should be installed at 30-foot intervals or less, to catch the oil and refrigerant

remaining in the suction line when the compressor stops. When the

compressor starts again, the oil and refrigerant will gradually return to the

compressor, pushed by the velocity of the vapors through the open portion of

the trap. Otherwise, this oil and refrigerant might come back to the compressor

as a "slug" and damage it.

Along with high-speed compressors has come suction capacity controls and

cylinder unloaders. These devises have brought about the problems of

maintaining riser velocity and suction lift, which will provide continuous oil

return to compressors. During the running cycle the reduction of capacity may

be as much as 25%, thus reducing the velocity of the suction gas which will be

below the required velocity to entrain and return sufficient oil to the

compressor.

Figure 66F10D

Piping layout for two parallel banks of horizontal plate coils in rack.

Page 6 of 8 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

Most high-speed compressors have some type of oil pump, or are designed to

provide forced lubrication to the bearings. At these motor speeds all bearings

must have full lubrication at all times. A matter of minutes without sufficient oil

and the bearings will become damaged.

To provide for oil return during the reduced capacity period, where the main

suction line or compressor are above the evaporator, a two-pipe or double riser

can be used (Figure 66F11). The two pipes should be sized with a combined

capacity for full compressor load to maintain a velocity of 1,500 fpm, and the

smaller pipe selected with a capacity to maintain the required velocity with the

compressor operating at it's minimum capacity.

This two-pipe riser is made by installing a tee in the suction line below the level

of the outlet of the coil or coils, with the branch opening pointing upward. DO

NOT reduce the run of the tee. This would make a trap in the wrong place. It

would be necessary to reduce or use a tee with branch size of the selected

small pipe size. On the down stream side of the tee make a trap as short as

fittings will permit. When using solder fittings, this can be done with two 45

street ells and one 90 street ell. (See Figure 66F11.) If a reduction is

necessary to accommodate the larger pipe, put the reducer immediately after

the trap. Both riser pipes are run high enough so that they enter the main

suction line in the top or on a 45 angle downward.

This design prevents any refrigerant from draining back, once it has reached

the main suction line. From the point where these two pipes enter the main

suction line, the suction piping should be pitched or sloped at least 1" for every

20 ft, toward the compressor. This latter recommendation is good practice in

piping all suction lines.

Now that we have installed a two-pipe riser in the suction line, how does it

function? As suction vapor volume is reduced, so is the velocity in a certain

size suction pipe. Since the compressor capacity reduction is controlled by

Figure 66F11

Two vertical parallel sections of a suction line from two evaporators in multiple

operated by condensing unit at higher level and provided with capacity reduction as

load decreases.

Page 7 of 8 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

suction pressure, oil in the suction gas, with its reduced velocity, will separate

out in the trap and seal it, causing the refrigerant vapors to pass up the small

pipe. Then, as the suction pressure builds up, creating sufficient pressure

difference on each side of the trap, the trap seal will be broken and the vapors

passing over the oil will gradually pick up all the oil in the trap and return it to

the compressor.

For systems with controlled suction capacity and a short suction line to just

above the evaporator, minimum velocity for proper oil return can be maintained

by reducing the riser to a size equal to the size pipe required for minimum

velocity at the lowest capacity of the compressor. In making the turn at the top

of this riser, use an elbow the same size as the riser; then increase the piping

to the full suction line size.

Copyright 1964, 2001, By Refrigeration Service Engineers Society.

Home Back TOC Next

Page 8 of 8 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

SIZING REFRIGERANT PIPING

Pressure drop in refrigerant piping has been mentioned previously, but needs

to be considered again in planning for the erection of the piping. Referring to

Table 66T12A, a 1-1/8" 90 wrought elbow equals 1.85 ft of the same size

pipe, and for a 45 wrought elbow, the equivalent is 1 ft. of pipe or nearly 50 %

less pressure-drop through a 45 elbow than for a 90 elbow. In making short

offsets, minimize pressure drop by using a 90 and a 45 elbow or two 45

elbows rather than two 90 elbows.

It is economical to use angle valves instead of straight-through globe valves.

The saving in this practice can be seen in a study of the pressure drop through

these valves in this same chart. It will be noted that angle valves have about

1/2 the pressure drop as that of globe valves. In many cases an angle valve

can be used to make a turn instead of an elbow, thus conserving one fitting

and reducing the leak potential at least by two.

The foregone information and a mental or drawn plan of installation are

necessary before any attempt can be made to select the pipe size. For

example, in Figure 66F16 you see a proposed air conditioning installation. The

condensing unit is 15 hp selected for R-12 at 40F suction temperature and

100F condensing temperature, hence the load will be about 15 tons or

180,000 Btu/per hr. To temporarily select the suction piping for 2 psig pressure

drop, 100F condensing and 40F suction temperatures, refer to the chart,

(Figure 66F17), pressure drops in refrigerant lines for R-12. It is found that it is

near 2-1/8" pipe.

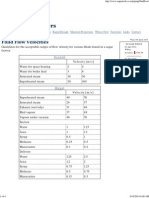

Table 66T12A Equivalent resistance of copper fittings and valves in feet of copper tubing of same size. Length in

Feet of Pipe to be Added to Actual Length of Run Owing to Fittings.

Copper pipe

size (O.D. in.)

90 elbow

45

elbow Tee Gate valve Globe valve Angle valve Wrought Cast

1/2 0.8 1.3 0.4 2.5 0.26 7.0 4.0

3/4 1.0 1.5 0.6 2.5 0.3 12.0 6.5

7/8 1.45 1.8 0.8 3.6 0.36 17.2 9.5

1-1/8 1.85 2.2 1.0 4.6 0.48 22.5 12.0

1-3/8 2.4 2.9 1.3 6.4 0.65 32.0 16.0

1-5/8 2.9 3.5 1.6 7.2 0.72 36.0 19.5

2-1/8 3.6 4.2 2.0 9.6 0.96 48.0 22.5

2-5/8 4.5 5.1 2.4 11.2 1.1 56.0 28.0

3-1/8 1.0 6.5 2.9 12.8 1.4 72.0 32.0

3-5/8 1.0 7.6 3.4 16.0 1.6 80.0 40.0

4-1/8 1.0 9.6 4.0 18.6 1.7 100.0 48.0

Refrigeration Service Engineers Society

1666 Rand Road

Des Plaines, IL 60016

630-33

REFRIGERANT PIPING Home Back TOC Next

Page 1 of 8 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

Figure 66F16

Typical 15 HP air-conditioning installation with dimensioned piping layout.

Figure 66F17

Page 2 of 8 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

In order to be within the limitations, make a calculation including the fittings

and valves, thus:

To use the chart in Figure 66F17, follow these instructions:

In the upper right-hand corner you will find no indication for 15 tons, but you

can select a spot half-way between 10 and 20 tons. Imagine a vertical line

there, and follow it down until it intersects with the slanting 40 Evaporator

Temperature line. From this intersection, run a horizontal line toward the left

edge of the chart.

Next, we have assumed a 100 condensing temperature and have allowed a

maximum pressure drop in the suction line of 2 psig; so, at the bottom of the

chart, find the point where the horizontal 100 condenser line intersects the

diagonal pressure-drop line marked "2." From this intersection, run a line

upward until it intersects the horizontal line you drew toward the left of the

chart from the 15 tons and 40 evaporator intersection.

Where these two lines meet is the size of suction tubing to use (indicated by

another set of slanting diagonals, with pipe sizes on them). However, the

intersection does not fall exactly on any size, but is just below the diagonal line

for 2-1/8" tube size, and much above the diagonal line for the 1-5/8" tube size.

Since the selected pipe is under the 100 ft in length, as noted in the chart, by

using 2-1/8" suction line for this installation, proper oil return with a minimum

pressure drop can be expected.

Liquid and hot gas piping can be selected in the same manner as the suction

piping, except with maximum allowable pressure-drop being in the 5 to 7 psig

range.

Table 66T12A, Table 66T12B, Table 66T13, Table 66T14A, Table 66T14B,

and Table 66T15 are for the selection of refrigerant liquid and suction piping for

open self-service refrigerated store fixtures, and for other refrigerated fixtures

having the same Btu/hr load and held at approximately the same

temperatures.

Pressure Drops in Refrigerant Lines Freon 12.

Figured for type L copper tubing. For iron pipe subtract 1/8 from copper tubing size to

find nominal iron pipe size. Multiply copper pressure by 16.

Page 3 of 8 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

Table 66T13 R-12 Piping Requirements for Open Self-Service Meat Cases (with bottom storage) and for other

refrigerated fixtures having the same BTU/hr load and held at approximately the same temperatures.

Condensing unit,

hp Refrigerant line sizes

Number

of

cases**

Air-

cooled

(or air

and

water)

Water-

cooled

First case* Second case Third case Fourth case

Liquid Suction Liquid Suction Liquid Suction Liquid Suction

1 (8 ft) 3/4 1/2 3/8 5/8

1 (11 ft) 1/1 3/4 3/8 5/8

2 (8 ft) 11/2 1/1 3/8 5/8 3/8 7/8

1 (8 ft)

1 (11 ft) 1-1/2 1-1/2 3/8 5/8 3/8 7/8

2 (11 ft) 1/2 1-1/2 3/8 5/8 3/8 7/8

3 (8 ft) 1/2 1-1/2 3/8 5/8 3/8 7/8 3/8 1 1/8

2 (8 ft)

1 (11 ft) 1/2 1/2 3/8 5/8 3/8 7/8 1/2 1 1/8

1 (8 ft)

2 (11 ft) 1/3 1/2 3/8 5/8 3/8 7/8 1/2 1 1/8

3 (11 ft) 1/3 1/3 3/8 5/8 3/8 7/8 1/2 1 1/8

1 (8 ft)

3 (11 ft) 1/3 3/8 5/8 3/8 7/8 1/2 1 1/8 1/2 1 3/8

4 (11 ft) 1/3 3/8 5/8 3/8 7/8 1/2 1 1/8 1/2 1 3/8

* Each case equipped with Heat-Exchanger.

** 1st case is farthest one from condensing unit.

Page 4 of 8 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

Recommendation based on designed 20F evaporator

and 28F. shelf temperature when operating in a 90F

store. NOTE:

Table 66T14A R-12 Piping Requirements for Self-Service Dairy & Delicatessen Cases and for other refrigerated

fixtures having the same BTU/hr load and held at approximatly the same temperatures.

Condensing unit, hp Refrigerant line sizes

Overall case

length**

Air-cooled (or

air and water)

Water-

cooled

First case* Second case Third case

Liquid Suction Liquid Suction Liquid Suction

6 ft 3 in. 3/4 3/4 3/8 5/8

12 ft 3 in. 1-1/2 1-1/2 3/8 5/8 3/8 7/8

18 ft 4 in. 3 2 3/8 5/8 3/8 7/8 3/8 7/8

24 ft 5 in. 3 3/8 5/8 3/8 7/8 3/8 7/8

30 ft 5 in. 5 3/8 5/8 3/8 7/8 3/8 7/8

36 ft 6 in. 5 3/8 5/8 3/8 7/8 3/8 7/8

Condensing unit, hp Refrigerant line sizes

Overall

case length

Air-cooled

(or air and

water)

Watercooled Fourth case Fifth case Sixth case

Liquid Suction Liquid Suction Liquid Suction

6 ft 3 in. 3/4 3/4

12 ft 3 in. 1-1/2 1-1/2

18 ft 4 in. 3 2

24 ft 5 in. 3 1/2 1 1/8

30 ft 5 in. 5 1/2 1 1/8 1/2 1 1/8

36 ft 6 in. 5 1/2 1 1/8 1/2 1 1/8 1/2 1 3/8

* 1st case is farthest one from condensing unit.

** Overall dimensions are the total length of case to the nearest inch.

Recommendation based on designed 20F. evaporator

and 40F. shelf temperature when operating in a 90F.

store temperature. NOTE:

Table 66T14B R-12 Piping Requirements for Refrigerated Vegetables Display Cases and for other refrigerated

fixtures having the same BTU/hr load and held at approximatly the same temperatures.

Condensing unit,

hp

Refrigerant line sizes

Number

of cases

Air-

cooled

(or air

and

water)

Water-

cooled

First case* Second case Third case Fourth case

Liquid Suction Liquid Suction Liquid Suction Liquid Suction

1 (8 ft) 3/4 3/4 1/4 5/8

1 (11 ft) 1 3/4 3/8 5/8

2 (8 ft) 1-1/2 1 3/8 5/8 3/8 7/8

1 (8 ft)

1 (11 ft) 2 1-1/2 3/8 5/8 3/8 7/8

Page 5 of 8 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

These recommendations are based on field experience of the manufacturer

and are practical data. These requirements are suitable under normal

conditions, and at 90F store temperature.

For the refrigerant lines in excess of 50 ft from the nearest refrigerator to the

condensing unit, follow the recommended pipe size for the first 50 ft from the

refrigerator, then increase to next larger size for the balance of the run to the

condensing unit.

These charts are offered as a help in diagnosing service problems on these

2 (11 ft) 2 1-1/2 3/8 5/8 3/8 7/8

1 (8 ft)

2 (11 ft) 3 2 3/8 5/8 3/8 7/8 1/2 1 1/8

3 (11 ft) 3 3 3/8 5/8 3/8 7/8 1/2 1 1/8

1 (8 ft)

3 (11 ft) 3 3/8 5/8 3/8 7/8 1/2 1 1/8 1/2 1 1/8

4 (11 ft) 3 3/8 5/8 3/8 7/8 1/2 1 1/8 1/2 1 1/8

* 1st case is farthest one from condensing unit.

Recommendation based on designed 20F evaporator

and 38F shelf temperature when operating in a 90F

store temperature. NOTE:

Table 66T15 R-22 Piping Requirements for Frozen Food Self-Service Display Cases and for other refrigerated

fixtures having the same BTU/hr load and held at approximatly the same temperatures.

Refrigerant line sizes

Number of cases Condensing

unit, hp Water-

cooled

First case* Second case Third case

Liquid Suction Liquid Suction Liquid Suction

1 (8 ft) 2 3/8 5/8

1 (11 ft) 2 3/8 5/8

1 (8 ft) 5

1 (11 ft) 3/8 5/8 1/2 7/8

2 (8 ft) 3 3/8 5/8 1/2 7/8

2 (11 ft) 5 3/8 5/8 1/2 7/8

3 (8 ft) 5 3/8 5/8 1/2 7/8 5/8 7/8

3 (11 ft) 7.5 3/8 5/8 1/2 7/8 5/8 1 1/8

* First case is farthest case from condensing unit. Liquid-line sizes shown do not have to be increased for runs

up to 250 ft. Important: If there is a rise in the suction line of 5 ft or more anywhere in the run, reduce the

suction piping to next smaller size for the rise only, then continue the run with recommended size. Exception:

Suction lines should never be reduced below 5/8 in.

Insulate liquid lines and suction lines together for 30 ft

toward the condensing unit after the nearest case. If

the run is less than 30 ft, insulate between the nearest

case and the condensing unit.

NOTE:

Page 6 of 8 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

types and sizes of equipment. For selection of proper pipe sizes on initial

installation refer to the data provided by the manufacturer whose equipment is

being installed.

Figure 66F19A shows the suggested piping of oil and crankcase gas pressure-

equalizing lines for parallel-connected compressors. It is important that the oil

equalizing line be connected to the compressor body at the minimum oil level

line, so that a slight difference in crankcase pressure will not force the oil below

a minimum operating level in the crankcase. The gas equalizing line should be

pitched from the center toward each compressor or supported rigidly enough to

prevent sags or traps which might fill with oil and restrict the passage of gas.

These lines should be of ample size to allow free equalizing of the oil level. If

the manufacturer has provided taps in the compressor for these lines, use the

same size pipe as the compressor openings provided by him. One valve in

each line, and a means of disconnecting at each compressor, should be

provided for the removal of either compressor without taking the other out of

service.

NEVER connect the oil return pipe from an oil separator into the compressor

below the oil level in the crankcase, because in case of failure of the oil

separator float or leak through of liquid refrigerant, it may agitate the oil in the

crankcase enough to cause foaming, and consequently reduce the oil pump's

ability to supply enough oil, resulting in insufficient lubrication and compressor

damage. Installers should refrain from connecting oil return piping from oil

separators to the suction service valve port. In cases of closed crankcases, the

oil may not get into the crankcases quick enough, and the bearings are again

subject to damage.

On the larger systems of 3 hp and over, it is quite convenient to the service

engineer to install a 1/4" flare angle valve in a tee in the liquid line between the

stop or receiver valve and the strainer. This valve provides an easy means of

adding or removing refrigerant.

It is often desirable to install a sight glass in the liquid line piped with the larger

sizes of copper tube or iron pipe. In the case of copper pipe, a 3/8" sight glass

can be installed by drilling two 3/8" holes about 12" apart and in line with the

length of the pipe. Next, silver braze two short lengths of 3/8" soft copper

tubing, with one end cut on 45 angle and the angle end extending about

1/2"into the two drilled holes. Then flare and bend to install a stock 3/8" flare-

Figure 66F19A

Oil and Gas equalizing lines between compressors in parallel.

Page 7 of 8 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

connection sight glass. For iron pipe, cut or drill two holes as above, that will

receive 1/4" long steel coupling. These should be cut at a 45 angle, as in the

case of the tubing, and inserted in the same manner, similar to the method

shown in Figure 66F19B.

As the installer, keep in mind that you may be called on the report service or

remove some part of the equipment you are installing, so for your own

protection, arrange the components in serviceable and work-man-like

locations.

MAKE EACH JOB A MASTERPIECEIT WILL PAY.

Figure 66F19B

Sight glass connections for large copper tube and steel pipe lines.

Copyright 1964, 2001, By Refrigeration Service Engineers Society.

Home Back TOC Next

Page 8 of 8 REFRIGERANT PIPING

7/5/2008 http://www.rses.org/main/sam/xml/630-33/630-33.xml

Das könnte Ihnen auch gefallen

- Nissan Maxima Air Conditioning Service ManualDokument132 SeitenNissan Maxima Air Conditioning Service Manualap00Noch keine Bewertungen

- Air Cooled CondenserDokument20 SeitenAir Cooled CondenserVivek SinghNoch keine Bewertungen

- Combining DOAS and VRF, Part 1 of 2Dokument8 SeitenCombining DOAS and VRF, Part 1 of 2miniongskyNoch keine Bewertungen

- "Solutions For The Plastics Industry": Co. IncDokument4 Seiten"Solutions For The Plastics Industry": Co. IncminiongskyNoch keine Bewertungen

- Air King Ventilation Ashrae 62Dokument5 SeitenAir King Ventilation Ashrae 62miniongskyNoch keine Bewertungen

- Design of Air IDokument5 SeitenDesign of Air IInvedeNoch keine Bewertungen

- Industrial/Power Plant Engineering: Prepared By: Engr. Jose R. FranciscoDokument7 SeitenIndustrial/Power Plant Engineering: Prepared By: Engr. Jose R. FranciscoJerick HernandezNoch keine Bewertungen

- High-Pressure Fluid Phase Equilibria: Phenomenology and ComputationVon EverandHigh-Pressure Fluid Phase Equilibria: Phenomenology and ComputationNoch keine Bewertungen

- 16 Ways To Reduce HVAC Energy in Supermarkets and RetailDokument4 Seiten16 Ways To Reduce HVAC Energy in Supermarkets and RetailminiongskyNoch keine Bewertungen

- Or YorkDokument32 SeitenOr YorkJavier BarbeytoNoch keine Bewertungen

- Process Air ChillersDokument24 SeitenProcess Air Chillersciccio100% (1)

- Combining DOAS and VRF, Part 2 of 2Dokument9 SeitenCombining DOAS and VRF, Part 2 of 2miniongskyNoch keine Bewertungen

- PERFORMANCE ANALYSIS OF INTERNAL HEAT EXCHANGERDokument39 SeitenPERFORMANCE ANALYSIS OF INTERNAL HEAT EXCHANGERNeal Christian ParatoNoch keine Bewertungen

- Distillation Notes 2011Dokument40 SeitenDistillation Notes 2011samuelgranthamNoch keine Bewertungen

- Doosan DL200 Electrical System Schematic Manual-1Dokument101 SeitenDoosan DL200 Electrical System Schematic Manual-1Ariel CarranzaNoch keine Bewertungen

- Khan 2000Dokument18 SeitenKhan 2000HIMANSHU YADAVNoch keine Bewertungen

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Von EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Noch keine Bewertungen

- Pur-15-02 - Air Purger Type PurDokument4 SeitenPur-15-02 - Air Purger Type PurAnderson Giovanny Herrera DelgadoNoch keine Bewertungen

- York Navy Systems PUBL6539Dokument6 SeitenYork Navy Systems PUBL6539Maria Gabriela BusteloNoch keine Bewertungen

- Ca0536 Bro Cascade GBR 10-04Dokument2 SeitenCa0536 Bro Cascade GBR 10-04geoteg2011Noch keine Bewertungen

- Refrigerants 2013 FebDokument33 SeitenRefrigerants 2013 Febdita ayuNoch keine Bewertungen

- NHsoft VPDokument5 SeitenNHsoft VPBASEM NOMAN ALI MOHAMMEDNoch keine Bewertungen

- Types of Evaporator in Air ConditioningDokument20 SeitenTypes of Evaporator in Air ConditioningEhsan DanishNoch keine Bewertungen

- Refrigeration (Kylteknik) : 2. Vapour-Compression Refrigeration ProcessesDokument36 SeitenRefrigeration (Kylteknik) : 2. Vapour-Compression Refrigeration ProcessesiJeng RalluNoch keine Bewertungen

- Distillation Experiment LehighDokument10 SeitenDistillation Experiment Lehighcgjp120391Noch keine Bewertungen

- Frcik Introducción A La RefrigeraciónDokument24 SeitenFrcik Introducción A La RefrigeraciónAldo Danilo Frias MuñozNoch keine Bewertungen

- Non Electric ChillerDokument52 SeitenNon Electric ChillerP Venkata SureshNoch keine Bewertungen

- Multicomponent Distillation OptimizationDokument9 SeitenMulticomponent Distillation OptimizationSriparthan SriramanNoch keine Bewertungen

- Ad Gt700e Brochure-EnDokument2 SeitenAd Gt700e Brochure-EnMohamed AlkharashyNoch keine Bewertungen

- Fractionation and Absorption ExplainedDokument26 SeitenFractionation and Absorption ExplainedmohamedNoch keine Bewertungen

- R&T 2007 - CO2 Issues - Halsey CascadeDokument18 SeitenR&T 2007 - CO2 Issues - Halsey CascadePRKrauseNoch keine Bewertungen

- Ammonia Absorption Chiller 09Dokument13 SeitenAmmonia Absorption Chiller 09AhmAd GhAziNoch keine Bewertungen

- Hot Gas Defrost - Final ReportDokument22 SeitenHot Gas Defrost - Final ReportHoàngViệtAnhNoch keine Bewertungen

- SHARKDokument4 SeitenSHARKUnilabNoch keine Bewertungen

- Cascade Refrigeration System "For Blood Storage"Dokument4 SeitenCascade Refrigeration System "For Blood Storage"International Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- GEA PHE Evaporation enDokument16 SeitenGEA PHE Evaporation enGuerrero OmarNoch keine Bewertungen

- The World: A Brief Introduction To CO Refrigeration PossibilitiesDokument21 SeitenThe World: A Brief Introduction To CO Refrigeration PossibilitiesCarlos YzaguirreNoch keine Bewertungen

- Non-Electrical Auto-Purger (NEAP) : Operator Installation & Instruction ManualDokument8 SeitenNon-Electrical Auto-Purger (NEAP) : Operator Installation & Instruction ManualfriguzNoch keine Bewertungen

- Design of Vertical KO Pot-V2Dokument45 SeitenDesign of Vertical KO Pot-V2myself_riteshNoch keine Bewertungen

- Basic Refinery Equipment - Heat Exchanger (E003/1)Dokument27 SeitenBasic Refinery Equipment - Heat Exchanger (E003/1)ebsmsart100% (1)

- Hansen Refrigerant Auto Purge R BrochureDokument12 SeitenHansen Refrigerant Auto Purge R BrochureamiguitoNoch keine Bewertungen

- Aspen Plate Fin Exchanger GuideDokument17 SeitenAspen Plate Fin Exchanger Guideingbarragan87Noch keine Bewertungen

- Refrigeration Liquid Recirculation SystemsDokument7 SeitenRefrigeration Liquid Recirculation Systemsgoodspeed_phNoch keine Bewertungen

- Troubleshooting A Plate Heat Exchanger - CPE Systems IncDokument7 SeitenTroubleshooting A Plate Heat Exchanger - CPE Systems Incrajmohan_kNoch keine Bewertungen

- EconomiozerDokument65 SeitenEconomiozerRaj PatelNoch keine Bewertungen

- All Models Are Wrong PreiewDokument12 SeitenAll Models Are Wrong PreiewJoão VictorNoch keine Bewertungen

- OM HandbookDokument163 SeitenOM HandbookAmanullahNoch keine Bewertungen

- Biruk Endale Design On Heat Exchanger-1Dokument32 SeitenBiruk Endale Design On Heat Exchanger-1nigus gereziherNoch keine Bewertungen

- Sabroe SMC & TSMC Units Control 2009Dokument40 SeitenSabroe SMC & TSMC Units Control 2009aveselov88Noch keine Bewertungen

- HVAC en CatalogueDokument64 SeitenHVAC en CataloguesafinditNoch keine Bewertungen

- 3D Solar TowersDokument4 Seiten3D Solar TowersRoxana GaborNoch keine Bewertungen

- Presentation AirDokument19 SeitenPresentation AirMohd JamalNoch keine Bewertungen

- OVUR-type Oil Separator: Installation, Operation and Maintenance ManualDokument8 SeitenOVUR-type Oil Separator: Installation, Operation and Maintenance Manualmiguel callata0% (1)

- Performance Analysis of Plate Heat Exchangers Used As Refrigerant EvaporatorsDokument295 SeitenPerformance Analysis of Plate Heat Exchangers Used As Refrigerant EvaporatorskarthikeyanNoch keine Bewertungen

- Alcohol DistillationDokument4 SeitenAlcohol DistillationprocesspipingdesignNoch keine Bewertungen

- E 805011 Com Control GEA Omni GBR 1-A4Dokument138 SeitenE 805011 Com Control GEA Omni GBR 1-A4Manuel MartinezNoch keine Bewertungen

- Xist PDFDokument2 SeitenXist PDFAgustin Gago LopezNoch keine Bewertungen

- Effect of Flash Gas Bypass On Performance of VCR SystemDokument4 SeitenEffect of Flash Gas Bypass On Performance of VCR SystemesatjournalsNoch keine Bewertungen

- Designing CO2 Evaporators for Refrigeration SystemsDokument29 SeitenDesigning CO2 Evaporators for Refrigeration SystemsgamunozdNoch keine Bewertungen

- METHER1 - Machine Problems 2 PDFDokument2 SeitenMETHER1 - Machine Problems 2 PDFJhon Lhoyd CorpuzNoch keine Bewertungen

- Condensers Control and Reclaim VOCsDokument3 SeitenCondensers Control and Reclaim VOCsgpcshfNoch keine Bewertungen

- SI Chiller Sub 11.24.08Dokument32 SeitenSI Chiller Sub 11.24.08Kokoh RayNoch keine Bewertungen

- 1079Dokument3 Seiten1079Mahmoud MohamedNoch keine Bewertungen

- Refrigeration Screw Compressors and Chilling Units PDFDokument8 SeitenRefrigeration Screw Compressors and Chilling Units PDFAmandeep singhNoch keine Bewertungen

- Positioning of Air Cooled CondensersDokument9 SeitenPositioning of Air Cooled CondensersAlexNoch keine Bewertungen

- Progress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963Von EverandProgress in Refrigeration Science and Technology: Proceedings of the XIth International Congress of Refrigeration, Munich, 1963Noch keine Bewertungen

- Refrigerant Piping: By: Cecil R. Visger, Past International PipingDokument18 SeitenRefrigerant Piping: By: Cecil R. Visger, Past International PipingBehnam AshouriNoch keine Bewertungen

- CIH Taco7aExpansionTankAirSepDokument16 SeitenCIH Taco7aExpansionTankAirSepminiongskyNoch keine Bewertungen

- Bolger Group Logistics Consultants To Management - Pdfwarehouse Fire ComplianceDokument6 SeitenBolger Group Logistics Consultants To Management - Pdfwarehouse Fire ComplianceminiongskyNoch keine Bewertungen

- Types and efficiencies of fuel-fired boilersDokument4 SeitenTypes and efficiencies of fuel-fired boilersminiongskyNoch keine Bewertungen

- Glossary - Education - CAGI - Compressed Air and Gas InstituteDokument6 SeitenGlossary - Education - CAGI - Compressed Air and Gas InstituteminiongskyNoch keine Bewertungen

- Selecting Chillers, Chilled Water Systems - Consulting-Specifying EngineerDokument5 SeitenSelecting Chillers, Chilled Water Systems - Consulting-Specifying EngineerminiongskyNoch keine Bewertungen

- Application & Design of Energy Recovery Wheels - Airxchange, Inc PDFDokument8 SeitenApplication & Design of Energy Recovery Wheels - Airxchange, Inc PDFminiongskyNoch keine Bewertungen

- Cooling-Tower Design Tips - Air Conditioning Content From HPAC EngineeringDokument3 SeitenCooling-Tower Design Tips - Air Conditioning Content From HPAC EngineeringminiongskyNoch keine Bewertungen

- Sugar - Fluid Flow VelocitiesDokument4 SeitenSugar - Fluid Flow VelocitiesminiongskyNoch keine Bewertungen

- Improving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringDokument7 SeitenImproving Efficiency With Variable-Primary Flow - Air Conditioning Content From HPAC EngineeringminiongskyNoch keine Bewertungen

- Expert Cooling Tower Repair, LLC - 303.790Dokument4 SeitenExpert Cooling Tower Repair, LLC - 303.790eimrehNoch keine Bewertungen

- ACH Recommended air changes per hourDokument2 SeitenACH Recommended air changes per hourminiongskyNoch keine Bewertungen

- FMDS 1-35 Green Roof SystemsDokument27 SeitenFMDS 1-35 Green Roof SystemsminiongskyNoch keine Bewertungen

- FM Global Property Loss Prevention Data Sheets: List of FiguresDokument13 SeitenFM Global Property Loss Prevention Data Sheets: List of FiguresminiongskyNoch keine Bewertungen

- Characteristics, Behavior, and Properties of LPG - Petronas Energy Philippines, IncDokument2 SeitenCharacteristics, Behavior, and Properties of LPG - Petronas Energy Philippines, IncminiongskyNoch keine Bewertungen

- Table - First Hour RatingDokument1 SeiteTable - First Hour RatingminiongskyNoch keine Bewertungen

- APEC Building Codes, Regulations and StandardsDokument227 SeitenAPEC Building Codes, Regulations and StandardsminiongskyNoch keine Bewertungen

- Table 1MDokument2 SeitenTable 1MminiongskyNoch keine Bewertungen

- Back To Basics - Water Pipe SizingDokument5 SeitenBack To Basics - Water Pipe Sizingminiongsky100% (1)

- Table 6 - Demographic2Dokument1 SeiteTable 6 - Demographic2miniongskyNoch keine Bewertungen

- Table - Hot Water Temperatures NHSDokument1 SeiteTable - Hot Water Temperatures NHSminiongskyNoch keine Bewertungen

- Surge ChamberDokument1 SeiteSurge ChamberminiongskyNoch keine Bewertungen

- Table - Hot Water Temperatures22Dokument2 SeitenTable - Hot Water Temperatures22miniongskyNoch keine Bewertungen

- Back To Basics - Water HeatersDokument5 SeitenBack To Basics - Water HeatersminiongskyNoch keine Bewertungen

- Design Considerations of Water FeaturesDokument102 SeitenDesign Considerations of Water Featuresminiongsky100% (1)

- Evaporative Pool DehumidificationDokument9 SeitenEvaporative Pool DehumidificationminiongskyNoch keine Bewertungen

- Hf61g00255e Jref-0-Um-Gb - R410a 1Dokument32 SeitenHf61g00255e Jref-0-Um-Gb - R410a 1Slobodan MilosavljevicNoch keine Bewertungen

- Technical Guide R-410A Affinity™ Series BHX, BHQ and BHZ Models 2 - 5 TON 60 HertzDokument83 SeitenTechnical Guide R-410A Affinity™ Series BHX, BHQ and BHZ Models 2 - 5 TON 60 HertzGina Itzel MartzNoch keine Bewertungen

- Latest Course On RACDokument24 SeitenLatest Course On RACvipin kumarNoch keine Bewertungen

- FXMQ-NVE6 Data BookDokument36 SeitenFXMQ-NVE6 Data BookmohamedroyaleyeuaeNoch keine Bewertungen

- Types of Air Conditioning SystemsDokument19 SeitenTypes of Air Conditioning Systemsa_mohid17Noch keine Bewertungen

- Catalogue VRVIII DAIKIN 2 ChieuDokument317 SeitenCatalogue VRVIII DAIKIN 2 ChieuMinhSon HaNoch keine Bewertungen

- Daikin RXYHQ12-36P (8) SpecificationsDokument78 SeitenDaikin RXYHQ12-36P (8) SpecificationsserbanicNoch keine Bewertungen

- Eme Ic Engine Module-3 22eme13Dokument68 SeitenEme Ic Engine Module-3 22eme13SHARATH RNoch keine Bewertungen

- Installation Module: Xarios RangeDokument20 SeitenInstallation Module: Xarios Rangefaza1111Noch keine Bewertungen

- 100-20 EEV-2LowDokument20 Seiten100-20 EEV-2LowRizky MuhammadNoch keine Bewertungen

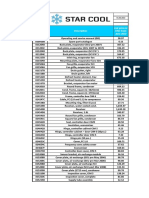

- 2022 06 01 Star Cool LIST PRICES USDDokument8 Seiten2022 06 01 Star Cool LIST PRICES USDbyu byuNoch keine Bewertungen

- 1334337428180-Electr - QUESTION - BANK - TL - AC - AND - EM - Final PDFDokument116 Seiten1334337428180-Electr - QUESTION - BANK - TL - AC - AND - EM - Final PDFPankaj KumarNoch keine Bewertungen

- RKNL-G (7.5-12.5 Ton)Dokument72 SeitenRKNL-G (7.5-12.5 Ton)Meghana BuchiNoch keine Bewertungen

- Composing Modeling and Simulation with Machine Learning in JuliaDokument11 SeitenComposing Modeling and Simulation with Machine Learning in Juliaachraf NagihiNoch keine Bewertungen

- February 2023Dokument2 SeitenFebruary 2023rohitchanakya76Noch keine Bewertungen

- Capacity Control For 3D CompressorsDokument11 SeitenCapacity Control For 3D CompressorsHumaid ShaikhNoch keine Bewertungen

- Spare Parts Catalogue: Combistar Beta.C-LineDokument211 SeitenSpare Parts Catalogue: Combistar Beta.C-LineFix SirNoch keine Bewertungen

- Installation and Commissioning: GPG347 Good Practice GuideDokument20 SeitenInstallation and Commissioning: GPG347 Good Practice GuideДанил ПорохницкийNoch keine Bewertungen

- A R290 Split Air ConditionerDokument10 SeitenA R290 Split Air ConditionerReddy JuliardiNoch keine Bewertungen

- CSR - 40 - mP3000 Parts CatalogueDokument47 SeitenCSR - 40 - mP3000 Parts CatalogueSARATH MENONNoch keine Bewertungen

- AFHX Series 60Hz Air Cooled Screw Flooded Chillers 77 to 191 TRDokument28 SeitenAFHX Series 60Hz Air Cooled Screw Flooded Chillers 77 to 191 TRTanjim FakirNoch keine Bewertungen

- Traulsen RHT-AHT Reach in Refrigerator WUTDokument2 SeitenTraulsen RHT-AHT Reach in Refrigerator WUTwsfc-ebayNoch keine Bewertungen

- HVAC1Dokument107 SeitenHVAC1deesing100% (1)

- RAC Lab Experiment No 1Dokument3 SeitenRAC Lab Experiment No 1HallucinatoryNoch keine Bewertungen

- Technical Manual - EASICOOL - EZRE (Air Edale)Dokument146 SeitenTechnical Manual - EASICOOL - EZRE (Air Edale)Tong Hong LapNoch keine Bewertungen

- Watermicronworld AWG-C 5,000liter Prer Day - Operation ManualDokument16 SeitenWatermicronworld AWG-C 5,000liter Prer Day - Operation ManualRobert RainmanNoch keine Bewertungen

- Chapter 21-50-00 Enviromental System - CoolingDokument48 SeitenChapter 21-50-00 Enviromental System - CoolingAnggarda Bagus SejatiNoch keine Bewertungen