Beruflich Dokumente

Kultur Dokumente

438d8b4c-9d3a-4e95-be60-0b3a7dd96f1e

Hochgeladen von

Cristian Jhair Perez0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

87 Ansichten4 SeitenCompabloc range provides the most efficient, cost-effective, compact and cleanable heat exchanger solution available today. Heart of The Compabloc is a stack of corrugated heat transfer plates in 316L stainless steel, or other high-grade material. Design can be configured in single or multi-pass arrangements in either co-current or counter-current operation.

Originalbeschreibung:

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCompabloc range provides the most efficient, cost-effective, compact and cleanable heat exchanger solution available today. Heart of The Compabloc is a stack of corrugated heat transfer plates in 316L stainless steel, or other high-grade material. Design can be configured in single or multi-pass arrangements in either co-current or counter-current operation.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

87 Ansichten4 Seiten438d8b4c-9d3a-4e95-be60-0b3a7dd96f1e

Hochgeladen von

Cristian Jhair PerezCompabloc range provides the most efficient, cost-effective, compact and cleanable heat exchanger solution available today. Heart of The Compabloc is a stack of corrugated heat transfer plates in 316L stainless steel, or other high-grade material. Design can be configured in single or multi-pass arrangements in either co-current or counter-current operation.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

Application

The Alfa Laval Compabloc is a fully welded compact heat

exchanger designed for the complete range of process and

utility duties. The Compabloc range provides the most

efficient, cost-effective, compact and cleanable heat exchanger

solution available today. After 20 years on the market, the

Compabloc has shown itself to be the market leader in terms

of life-cycle costs and energy savings.

Design

Alfa Laval designed the Compabloc range of welded heat

exchangers with a focus on performance, compactness, and

serviceability.

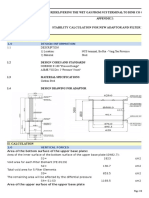

The heart of the Compabloc is a stack of corrugated heat

transfer plates in 316L stainless steel, or other high-grade

material. The plates are laser welded (models CP30 and

above) and form a compact core. This core is then enclosed

and supported by four corner girders, top and bottom heads

and four side panels (see Sectional view of Compabloc).

These components are bolted together and can be quickly

taken apart for inspection, service and cleaning.

The design can be configured in single or multi-pass arrange-

ments in either co-current or counter-current operation, for

liquid-to-liquid or two-phase duties.

Operating Principles

The two media in the Compabloc heat exchanger flow in

alternately welded channels between the corrugated plates.

These corrugated plates promote high turbulence which pro-

vides high heat transfer efficiency and help minimize fouling.

The media flows in a cross-flow arrangement within each

pass (see figure below) while the overall flow arrangement is

counter-current for a multi-pass unit (if required the unit can

also be designed with overall co-current operation). Each

pass is separated from the adjacent passes by a pressed

baffle which forces the fluid to turn between the plate pack

and the panel.

Compablocs flexible pass arrangements make it suitable for

liquid-to-liquid duties with dissimilar flow rates, or two phase

condensation or reboiler applications.

COMPABLOC compact heat exchanger range

High-performance fully welded heat exchanger for process industries

Options

The Compabloc is available in virtually any material that can

be pressed and welded, including:

316L SST

254 SMO

Titanium

Alloy C-276

904L SST (UB6)

Alloy B-2

Alloy C-22

Incoloy 825

Inconel 600

Tantalum

The panels and nozzles can be un-lined or lined using the

same materials as the plate pack. The nozzle size is variable

and can be selected independently for each side.

Process Optimization

Because of the Compablocs unique design concept the

possibilities for process optimization and flexibility are limitless.

The Compabloc can be designed with both single-pass or

multi-pass configurations. For condensation, reboiling and

liquid-to-liquid duties without temperature cross, the single-

pass configuration is suitable with its total cross-flow. The

large cross flow area and short flow path fit low-pressure

conden-sing duties and allow very low pressure drops. A

multi-pass configuration is suitable for duties with temperature

cross and close temperature approaches.

The two media flow in cross-flow in alternately welded channels.

The design concept allows a different number of passes on

the two circuits thereby enabling large differences in flow

rates between the hot side and the cold side. The baffling can

easily be re-arranged to suit a new duty should the flow rates

or temperatures change. Close temperature approaches

down to 3C (5.4F) can be achieved.

The Compabloc can be mounted vertically, for normal liquid-

to-liquid duties, condensation with sub-cooling and gas

cooling duties, or horizontally, for most condensation duties,

reboiling or liquid-to-liquid duties where height is restricted.

There are currently seven plate family models with heat trans-

fer areas ranging from 0.7 to 840 m

2

per unit and each model

is modularized with different numbers of plates to allow the

best fits for any duty.

Special applications

Panel

Upper

head

Girder

Support

Gasket

Baffle

Heat transfer

plate pack

Lower

head

Sectional view of Compabloc

Compabloc two cooling media

For special applications, the Compabloc 2 cooling medium

range is available which offers a two-section condenser with

two different cooling medias.

Standard Press. Standard Max. Dimensions (mm) *** Max. Weight

Model Range (bar) * Temp. Range (C) *Code A x A x B (kg) ****

CP 15 FV - 32 -40 - 300 PED 280 x 280 x 540 250

CP 20 FV - 32 -40 - 300 PED 430 x 430 x 730 550

CP 30 FV - 32 -40 - 300 PED 500 x 500 x 1070 1160

CP 40 FV - 32 -40 - 300 PED 600 x 600 x 1400 2330

CP 50 FV - 32 -40 - 300 PED 840 x 840 x 2050 5940

CP 75 FV - 32 -40 - 300 PED 1240 x 1240 x 3600 17780

CP 120 FV - 42 -50 - 400 PED 2190 x 2190 x 3500 50000

* other pressures and temperatures may be available on request.

** ASME is also available

*** does not include nozzle length.

**** weight is determined by maximum number of plates and highest pressure rating.

Note: both vertical and horizontal configurations are available..

Technical Data

Dimensions

A

A

B

Pressure vessel codes

The Compabloc is available as standard in accordance with

international pressure vessel codes such as ASME (with or

without U stamp) or ADM (code for PED and CE marking).

How to contact Alfa Laval

Up-to-date Alfa Laval contact details for

all countries are always available on our

website at www.alfalaval.com

PCT00096EN 0903 All rights reserved for changes in specifications without prior notification

Das könnte Ihnen auch gefallen

- ShopNotes No. 121 FullDokument52 SeitenShopNotes No. 121 FullKen Lock100% (13)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsVon Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsBewertung: 4 von 5 Sternen4/5 (1)

- Air Handling Units Air Handling Units: Technical Catalogue Technical CatalogueDokument34 SeitenAir Handling Units Air Handling Units: Technical Catalogue Technical CatalogueSMBEAUTYNoch keine Bewertungen

- Asme B31e (2008) PDFDokument18 SeitenAsme B31e (2008) PDFCristian Jhair Perez100% (3)

- Clasificacion Universal de Los MaterialesDokument24 SeitenClasificacion Universal de Los MaterialesMateo100% (1)

- Astm B267 07Dokument5 SeitenAstm B267 07Srinivasan Krishnamoorthy100% (1)

- COMPABLOC Compact Heat Exchanger RangeDokument4 SeitenCOMPABLOC Compact Heat Exchanger RangeCarlos Bermejo AlvarezNoch keine Bewertungen

- CP LeftletDokument4 SeitenCP LeftletSiang LingNoch keine Bewertungen

- Funke Shell Tube He eDokument24 SeitenFunke Shell Tube He eSubrata DasNoch keine Bewertungen

- eBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeDokument18 SeiteneBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeMoly69xNoch keine Bewertungen

- Dryplus EvaporatorDokument24 SeitenDryplus EvaporatorsreekanthchemiNoch keine Bewertungen

- Shell-And-Tube Heat Exchangers: Standard Series and Customer Oriented SolutionsDokument24 SeitenShell-And-Tube Heat Exchangers: Standard Series and Customer Oriented SolutionsZewdu TsegayeNoch keine Bewertungen

- Alfa Laval PHE For REFDokument4 SeitenAlfa Laval PHE For REFNiraj ReginaldNoch keine Bewertungen

- The Compabloc Compact Heat ExchangerDokument2 SeitenThe Compabloc Compact Heat ExchangerlaythNoch keine Bewertungen

- Basco - Type - Es-Heat Exchangers BrochureDokument8 SeitenBasco - Type - Es-Heat Exchangers BrochureMarco Andrés Guevara LunaNoch keine Bewertungen

- Brochure Alfa Laval Compabloc Ppm00033enDokument8 SeitenBrochure Alfa Laval Compabloc Ppm00033enAnie EkpenyongNoch keine Bewertungen

- Compabloc Product Brochure Compact PerformanceDokument4 SeitenCompabloc Product Brochure Compact PerformancebogdanNoch keine Bewertungen

- Alfawatercoolcondenser PDFDokument24 SeitenAlfawatercoolcondenser PDFyeshig2000Noch keine Bewertungen

- Prime Surface Plate CoilDokument12 SeitenPrime Surface Plate CoilGrimmo1979Noch keine Bewertungen

- MLine KatalogDokument36 SeitenMLine KatalogSrdjan BudisinNoch keine Bewertungen

- APV Heat Transfer Handbook PDFDokument64 SeitenAPV Heat Transfer Handbook PDFAndronic Cosmin100% (2)

- Three Way ValvesDokument8 SeitenThree Way ValvesWalter JosephNoch keine Bewertungen

- AH AV CatalogDokument16 SeitenAH AV CatalognomurapreNoch keine Bewertungen

- Chromalox Tank Heating System BrochureDokument16 SeitenChromalox Tank Heating System BrochuregbgbhagavanNoch keine Bewertungen

- BASF Germany Condensing and Subcooling PDFDokument2 SeitenBASF Germany Condensing and Subcooling PDFSook Thiam LeeNoch keine Bewertungen

- Heat ExchangerDokument17 SeitenHeat ExchangerADIPESHNoch keine Bewertungen

- Basco Type ESDokument8 SeitenBasco Type ESkawag51241Noch keine Bewertungen

- Heat Exchanger Handbook - Heat Exchangers PDFDokument66 SeitenHeat Exchanger Handbook - Heat Exchangers PDFhonghai_dl100% (3)

- Heat Pipe Heat ExchangerDokument20 SeitenHeat Pipe Heat ExchangerrolwinNoch keine Bewertungen

- h11-515 - Rev - 6 Ruud Wiring PicDokument12 Seitenh11-515 - Rev - 6 Ruud Wiring PicElvis FariasNoch keine Bewertungen

- Heat Ex Changer Model Selection TypeDokument10 SeitenHeat Ex Changer Model Selection TypenoxleekNoch keine Bewertungen

- Cbe enDokument14 SeitenCbe enStefanNoch keine Bewertungen

- Air Cooled Screw Chillers ALSDokument60 SeitenAir Cooled Screw Chillers ALSsantiago cuadradoNoch keine Bewertungen

- Cbx26uh 060Dokument12 SeitenCbx26uh 060Alberto Nava RodriguezNoch keine Bewertungen

- Alfa Laval PHEDokument16 SeitenAlfa Laval PHESergio SmithNoch keine Bewertungen

- Cb14 77 2Dokument2 SeitenCb14 77 2LudimillaFreitasNoch keine Bewertungen

- Special Applications: Compact Heat Exchangers Product InformationDokument12 SeitenSpecial Applications: Compact Heat Exchangers Product InformationEsteban Lopez ArboledaNoch keine Bewertungen

- 608 750GDokument2 Seiten608 750GbioarquitecturaNoch keine Bewertungen

- Gem Chiller Catalogue Proof - 27 4 13Dokument4 SeitenGem Chiller Catalogue Proof - 27 4 13abianshbaralNoch keine Bewertungen

- 50841160201Dokument52 Seiten50841160201Erick RodriguezNoch keine Bewertungen

- 1 - Jacketed PipingDokument6 Seiten1 - Jacketed PipingJorge Hugo CorreaNoch keine Bewertungen

- Large-Tank Heating SystemsDokument4 SeitenLarge-Tank Heating Systemsmayukhguha88Noch keine Bewertungen

- Dynaforce Hot Water 300 5000Dokument3 SeitenDynaforce Hot Water 300 5000Oscar Dario Villada LopezNoch keine Bewertungen

- Als F Mcquay ChillerDokument60 SeitenAls F Mcquay Chillermk saravananNoch keine Bewertungen

- Spirax Sarco PDFDokument4 SeitenSpirax Sarco PDFandresaroNoch keine Bewertungen

- MCW Cooling Tower: Engineering Data & SpecificationsDokument36 SeitenMCW Cooling Tower: Engineering Data & SpecificationsRajendran SrnNoch keine Bewertungen

- PACSDokument33 SeitenPACSphilipnart100% (1)

- Da R Gewak Ks 10Dokument12 SeitenDa R Gewak Ks 10rtrajan_mech5408Noch keine Bewertungen

- 1.0 Chiller UnitDokument12 Seiten1.0 Chiller UnitfebousNoch keine Bewertungen

- Horizontal Condensate Collection Manifold - FabricatedDokument2 SeitenHorizontal Condensate Collection Manifold - Fabricatedkresimir.mikoc9765Noch keine Bewertungen

- Brazed Plate Heat ExchangersDokument6 SeitenBrazed Plate Heat ExchangersDhanielNoch keine Bewertungen

- Alfa Laval CB60 CoolerDokument2 SeitenAlfa Laval CB60 Coolerkman548Noch keine Bewertungen

- Specifications - FX 1502 - 7223Dokument4 SeitenSpecifications - FX 1502 - 7223ridNoch keine Bewertungen

- Inune Exchangers: M I N E Exchanger (After Brown Fintube Koch International)Dokument30 SeitenInune Exchangers: M I N E Exchanger (After Brown Fintube Koch International)Process EngineerNoch keine Bewertungen

- Steam TrapsDokument24 SeitenSteam Trapsiran1362Noch keine Bewertungen

- FCU McQUAYDokument12 SeitenFCU McQUAYben_splNoch keine Bewertungen

- Technical YLCSDokument34 SeitenTechnical YLCSnairam2003Noch keine Bewertungen

- CEB - E PumpDokument4 SeitenCEB - E PumpJan AlsicannNoch keine Bewertungen

- 6 Polley Compabloc FDokument5 Seiten6 Polley Compabloc FarianaseriNoch keine Bewertungen

- Sahara Substation BrochureDokument12 SeitenSahara Substation BrochureHOFFERNoch keine Bewertungen

- Vertical Steam Distribution Manifold - FabricatedDokument2 SeitenVertical Steam Distribution Manifold - Fabricatedkresimir.mikoc9765Noch keine Bewertungen

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- Effect of Biscuits Fortified With Haem Iron On The Intellectual State of Pre-School ChildrenDokument6 SeitenEffect of Biscuits Fortified With Haem Iron On The Intellectual State of Pre-School ChildrenCristian Jhair PerezNoch keine Bewertungen

- Process Industry Practices Insulation: PIP INTG1000 Insulation Inspection ChecklistDokument7 SeitenProcess Industry Practices Insulation: PIP INTG1000 Insulation Inspection ChecklistCristian Jhair PerezNoch keine Bewertungen

- Process Industry Practices Electrical: Pip Elsap01D Data Sheet For Battery Chargers For Station BatteriesDokument3 SeitenProcess Industry Practices Electrical: Pip Elsap01D Data Sheet For Battery Chargers For Station BatteriesCristian Jhair PerezNoch keine Bewertungen

- Ctce1013 EedsDokument2 SeitenCtce1013 EedsCristian Jhair PerezNoch keine Bewertungen

- Glass Manufacture BrochureDokument4 SeitenGlass Manufacture BrochureCristian Jhair PerezNoch keine Bewertungen

- Intense Heat. Extreme Cold. Aggressive Chemicals. InnovativeDokument2 SeitenIntense Heat. Extreme Cold. Aggressive Chemicals. InnovativeCristian Jhair PerezNoch keine Bewertungen

- Mill Design and Toolpaths: Course DescriptionDokument2 SeitenMill Design and Toolpaths: Course DescriptionCristian Jhair PerezNoch keine Bewertungen

- Recording Media Batteries 2009 BrochureDokument13 SeitenRecording Media Batteries 2009 BrochureCristian Jhair PerezNoch keine Bewertungen

- Ebooks Chemical Engineering PDFDokument1 SeiteEbooks Chemical Engineering PDFCristian Jhair PerezNoch keine Bewertungen

- Ccrule BrochureDokument2 SeitenCcrule BrochureCristian Jhair PerezNoch keine Bewertungen

- Greenbrier River TrailDokument7 SeitenGreenbrier River TrailCristian Jhair PerezNoch keine Bewertungen

- Digital Innovation: Experience The Power ofDokument6 SeitenDigital Innovation: Experience The Power ofCristian Jhair PerezNoch keine Bewertungen

- BrochureDokument8 SeitenBrochureCristian Jhair PerezNoch keine Bewertungen

- Offshore Wind Turbine 6mw Robust Simple EfficientDokument4 SeitenOffshore Wind Turbine 6mw Robust Simple EfficientCristian Jhair PerezNoch keine Bewertungen

- API RP 2A 21st 2000 Vs 2007-FatigueDokument16 SeitenAPI RP 2A 21st 2000 Vs 2007-Fatiguesm8575Noch keine Bewertungen

- State-Of-The-Art Review: Concrete Made of Recycled Waste Pet As Fine AggregateDokument18 SeitenState-Of-The-Art Review: Concrete Made of Recycled Waste Pet As Fine AggregateShaker QaidiNoch keine Bewertungen

- Home Assignment - 3: Chapter-3Dokument3 SeitenHome Assignment - 3: Chapter-3AkhilNoch keine Bewertungen

- Natural VentilationDokument6 SeitenNatural VentilationSumit Raina100% (1)

- Boys Hostel's Construction Site Report: Submitted By-: Utkarsh Kumar 3 Sem/B.ArchDokument37 SeitenBoys Hostel's Construction Site Report: Submitted By-: Utkarsh Kumar 3 Sem/B.ArchIXWarXINoch keine Bewertungen

- Crystallisation NotesDokument5 SeitenCrystallisation NotesClarence AG YueNoch keine Bewertungen

- Trolleys 1Dokument40 SeitenTrolleys 1Márcio AlvesNoch keine Bewertungen

- Heat InputDokument2 SeitenHeat InputjovanradovanoviNoch keine Bewertungen

- LEVA Parts Catalog V1.4 COLORDokument84 SeitenLEVA Parts Catalog V1.4 COLORMionnix KM-Service-premiumNoch keine Bewertungen

- Service Manual 38cvur13!16!42cvur13 16Dokument104 SeitenService Manual 38cvur13!16!42cvur13 16Leo De ocampoNoch keine Bewertungen

- LCA Methodology ReportDokument95 SeitenLCA Methodology ReportMOHAMEDABBASNoch keine Bewertungen

- B1ADokument7 SeitenB1ASumantrra Chattopadhyay0% (1)

- EDAPLAN ® 490 - MunzingDokument4 SeitenEDAPLAN ® 490 - MunzingLong An Đỗ0% (1)

- Kodak X-Omat M35-A - User ManualDokument22 SeitenKodak X-Omat M35-A - User ManualMilton CameraNoch keine Bewertungen

- Calculation SpreadSheetDokument8 SeitenCalculation SpreadSheetSally LuciaNoch keine Bewertungen

- MaterialData 7754Dokument2 SeitenMaterialData 7754Joko TriwardonoNoch keine Bewertungen

- Marbled Slipware1 PDFDokument5 SeitenMarbled Slipware1 PDFPilar Vezzani VaillantNoch keine Bewertungen

- Quiz PTT Answers HacDokument2 SeitenQuiz PTT Answers HacKanupriyaNoch keine Bewertungen

- Chapter 4Dokument23 SeitenChapter 4syedmuhammadtariqueNoch keine Bewertungen

- Loss Coeff KL On Valves & FittingsDokument5 SeitenLoss Coeff KL On Valves & FittingsJoren HuernoNoch keine Bewertungen

- Technical Data Sheet LG11 ENG 2021Dokument2 SeitenTechnical Data Sheet LG11 ENG 2021KEMPCHEN COMDIFLEXNoch keine Bewertungen

- Ezydek 44 Profile - DimensionsDokument2 SeitenEzydek 44 Profile - DimensionsAnirban BhattacharjeeNoch keine Bewertungen

- 2 TFB 4Dokument16 Seiten2 TFB 4blasspascalNoch keine Bewertungen

- Pond Accessories Price Catalog 2015Dokument8 SeitenPond Accessories Price Catalog 2015Relu MititeluNoch keine Bewertungen

- Generic PID DefinitionsDokument4 SeitenGeneric PID DefinitionsNicoara Stoica Paul FlorinNoch keine Bewertungen

- Medium Voltage Switching Devices: Assembly Operation MaintenanceDokument52 SeitenMedium Voltage Switching Devices: Assembly Operation MaintenanceGrid LockNoch keine Bewertungen

- Tdmis 1510Dokument3 SeitenTdmis 1510suman mollickNoch keine Bewertungen