Beruflich Dokumente

Kultur Dokumente

Conceptual Estimating: Steel Fabricator's Key to Early Project Involvement

Hochgeladen von

Ένκινουαν Κόγκ Αδάμου0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

72 Ansichten4 Seitenconceptual estimate in steel

Originaltitel

Conceptual Estimates in Steel

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenconceptual estimate in steel

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

72 Ansichten4 SeitenConceptual Estimating: Steel Fabricator's Key to Early Project Involvement

Hochgeladen von

Ένκινουαν Κόγκ Αδάμουconceptual estimate in steel

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

Y

ou are at lunch with a local devel-

oper and several members of her

staff. She spends 10 minutes excit-

edly talking about a new four-story office

building that she wants to build on a parcel

of land she owns. She turns to her director

of development and he madly sketches his

vision of the project on the back of a napkin.

Members of her staff chime in with ideas.

And then she asks the big question, How

much will it cost? The table falls silent. All

eyes turn to you, the steel fabricator. And

you say

What would you say? Would you tell her

that mill cost of a ton of steel is only $430?

That fabricated steel for an office building

today is around $1600 a ton? Or that a four-

story office building usually has about nine

pounds of steel per square foot of floor

space? Guess whatshe wouldnt care!

Would you tell her you only work with

steel, and that shed have to talk to an archi-

tect and a general contractor to get a price?

Youd miss getting in on the ground floor

and influencing the project!

Do you let it end there? Hopefully not!

This is your chance to look her in the eye

and let her know that youve worked as a

team with local architects, general contrac-

tors and structural engineers, and youd like

to bring them in to meet her and discuss the

project. Youll help her define the scope of

the project; the team will give her an esti-

mate that is representative of its actual cost.

You know that this is an opportunity to

get your foot in the door. You can influence

the project design to match the efficiencies

of your shop. Youll be able to avoid change

orders and negotiate your price. Youll be

part of a design-build team, and together

youll construct an office building that will

accelerate the construction schedule, save

the developer money, and put a smile on her

face.

But you need to put together a number

for the steel now. Before detailed structural

plans are completed. And youll need to live

with it as a maximum guaranteed price.

Welcome to the world of conceptual esti-

mating!

What is IT?

Jeff Beard, President of the Design-Build

Institute of America, defines conceptual es-

timating as the skill of forecasting accurate

costs without significant graphic design in-

formation (sometime no graphic design in-

formation) about a project. For the steel

fabricator, conceptual estimating is the skill

to look at the performance specifications

and footprint of a structure and develop a

budget for all of the activities relating to

steel in the structure: detailing, fabricating,

painting, transporting and erecting.

Conceptual estimating is not just making

a good guess at the cost of the steel in a proj-

ect. It is listening to the owner and under-

standing the projects goals. It is

understanding structural systems, assem-

blies and their costs. It is comprehending the

price of steel, not when it leaves the fabri-

cating shop, but when it is in place on the

structure. It is the search for a more efficient

and productive way to manage the steel

process. And it means clearly defining the

scope of your work for the amount you are

proposing to charge.

Conceptual estimating is the skill of cost-

ing a project from the view of the whole

project looking down, rather than from the

details looking up.

IS A CONCEPTUAL ESTIMATE

ETCHED IN STONE?

There are many stages of the conceptual

estimating process: feasibility estimates,

performance criteria estimates, conceptual

design estimates, detailed estimates and life

cycle-cost estimates. At each progressive

stage the estimate should be better refined

and contain fewer contingencies. That does

not mean that every successive estimate will

go down in cost. The scope of the project

may change or be better defined, resulting

in an increased estimate for the fabricated

steel. In such cases it is critical that a change

in scope be highlighted as the reason for the

increase in cost. It is an old rule of thumb

that no estimate is ever forgotten! and that

Reprinted from Modern Steel Construction / October 2002

William Liddy and John Cross, P.E.

Conceptual Estimating,

Design-Build

Steel Fabricator

and

the

By mastering the concept of conceptual estimating,

steel fabricators can form relationships with owners

and developers in the earliest stages of a project.

Everything takes time

Each progressive level of conceptual

estimation requires more time and ef-

fort to complete. The structural steel

fabricator can easily over-invest staff

hours in preparing conceptual esti-

mates. The basic rule of thumb should

be that the amount of effort to prepare

the estimate should be proportional to

the level of information and perform-

ance specifications available to the fab-

ricator. Typically the amount of time

proportionally invested for each type of

conceptual estimate is:

I feasibility estimate 1 hour

I performance estimate 4 hours

I conceptual design est. 10 hours

I detailed estimate 40 hours

is particularly true if subsequent estimates

increase in cost. Each estimate needs to be

fully documented and retained. The chal-

lenge for the fabricator is to track past proj-

ect costs and organize them in a way that

allows the creation of an accurate concep-

tual estimate in a minimal amount of time.

STAGE 1FEASIBILITY

ESTIMATES

The first stage of a conceptual estimate

is a feasibility estimate. It is developed from

very preliminary information, often the

proverbial back of a napkin. The goal is to

determine if a projects cost is justified by

the benefit received from the completed

structure. No design effort has yet begun,

and if costs come back too high, there will

be no project.

Afeasibility estimate gives the fabricator

a chance to address potential project solu-

tions, such as the savings possible with steel

as compared to concrete framing systems. A

project might not be feasible using a partic-

ular building type, but could become feasi-

ble as alternative materials and design

approaches are evaluated. A single project

might have multiple feasibility estimates as

the scope and performance requirements of

the project change. At this level of estimat-

ing there are no contingencies and no al-

lowances because the entire project is still

unknown. Often it is best to provide a feasi-

bility estimate as a range of probable values

although the client will typically only re-

member the low end of the range.

STAGE 2PERFORMANCE

CRITERIA ESTIMATE

The second stage is developing a per-

formance criteria estimate. The client has

moved from sketching the project on the

back of a napkin to a formal statement of the

performance requirements of the project.

This includes a site plan and suggested

structural footprint. The conceptual estima-

tor will begin to visualize the structure in

order to generate the performace criteria es-

timate. The estimator needs to evaluate the

effect of certain occupancies on the loads

imposed on the structure; the impact of

HVAC equipment on structural compo-

nents; the impact of architectural concepts

on connection design; and the impact of use

classification on fire protection regulations.

The estimator might base estimates on the

square footage of the structure, comparative

parameters to other recent projects, indus-

try costing tools or price indices. Multiple

approaches are applied to create a range of

costs from which the estimate is generated.

It is also important to discuss potential

contingencies with the entire project team.

Contingencies for unknown conditions and

scope changes should be carried in the over-

all project estimate, not in the estimates of

individual specialty contractors. Fabrica-

tors should define the scope of the concep-

tual estimate. They also should indicate

allowances for work performed by others or

undefined work that will be required on the

project.

STAGE 3CONCEPTUAL

DESIGN ESTIMATES

The third stage is the conceptual design

estimate. 10% design drawings, general

arrangement drawings, and layout and ar-

chitectural drawings provide a base from

which a representative structural design can

be developed. Design loads, special struc-

tural considerations and architectural re-

quirements must also be taken into account.

These loads and considerations might not

be assigned to their actual location in the

structure, but will be considered in the gen-

eral sizing of structural members and con-

nections. From this preliminary structural

model, take-offs can be generated to pro-

duce a typical material list, which can in

turn be priced.

This estimate often is the basis of the fab-

ricators negotiated fee and design-

builders fee for the project. The

assumptions and scope of the intended

work must be well defined in writing. It is

critical that the design-builder who submits

the final proposal to the client is aware of al-

lowances included in the fabricators esti-

mate, or possible miscommunication errors

could result. For example, a fabricator

might price all structural steel but not the

miscellaneous metal, while the design-

builder assumes that the fabricator will pro-

vide all steel.

As the owner modifies the project re-

quirements and the design-build team

changes the approach to the project, multi-

ple conceptual design estimates might be

necessary. The design-build team should

log these changes and track the incremental

cost of modifications to the overall project

cost. The fabricator should maintain a sim-

ilar log of the cost impact that performance

requirement and design changes have on

the structure.

STAGE 4DETAILED

ESTIMATE

Estimation does not end once the project

fee is negotiated. When design work reaches

the 50 percent level, a traditional detailed

estimate should be performed. The purpose

of this estimate, which is performed in the

same way as a hard-bid estimate, is to au-

thorize full funding for the project, to iden-

tify problems with the conceptual estimate,

and to provide a cost-control budget for the

fabricating and construction process. If

there is a disparity between the detailed es-

timate and the negotiated fee, a fabricator

can either propose alternative cost-saving

suggestions to the design-build team or uti-

lize the contingencies that the team built

into the negotiated fee.

STAGE 5LIFE-CYCLE COST

ESTIMATE

The final estimate is used on design-

build projects is the life-cycle cost estimate.

Unlike the other estimates, the life-cycle cost

estimate does not focus only on the cost to

design and construct the project. It includes

the original design and construction costs,

financing costs (taking into account acceler-

ated cash flows from early occupancy, and

maintenance and upkeep costs over the life

of the structure), renovation costs (particu-

larly if different loadings might be antici-

pated), and the residual value or demolition

costs at the end of the structures useful life.

These costs are discounted over time to de-

termine the true value in current dollars of

the project.

Life-cycle estimating involves predictive

assumptions about the performance of the

selected structural system that might gener-

ate uncertainty in the final cost estimate.

However, this procedure is beneficial to

weigh the relative benefits of comparative

systems. When comparing competing sys-

tems, the use of consistent assumptions can

minimize uncertainty. It provides a valuable

comparison between a low cost, high main-

tenance structure and a high cost, low main-

tenance structure.

Feeling overwhelmed?

Developing your methodology, collect-

ing historical data and producing con-

ceptual estimates takes time and hard

work. But conceptual estimating opens

the door to design-build.

Involvement in design-build projects as

a steel fabricator will:

I Allow you to negotiate your fees

I Increase your profitability

I Lower your risk

I Utilize the efficiencies of your shop

I Integrate your expertise into the final

project design

I Create an effective working relation-

ship between you and the structural

engineer

I Encourage the use of new time sav-

ing tools like EDI

I Develop a long-term relationship

with the project owner

I Accelerate the project and your shop

time

Each estimate should contain allowances

to address 1)areas of risk to the fabricator

and 2)items required by code or practice

that are not yet defined.

HOW DO I DEVELOP ONE?

The quality of a fabricators conceptual

estimate depends on the quality of informa-

tion provided to the fabricator. The more

uncertain the provided information, the

greater the variability in the estimate and

the more allowances will be added to the

cost of the projects steel. As project infor-

mation is revealed, a fabricator should de-

fine key parameters. These parameters can

then be referenced against a data-

base of similar parameters that

the fabricator has maintained on

previous projects. This process is

referred to as parametric estimat-

ing.

TYPE 1PARAMETRIC

ESTIMATES

The three most common pa-

rameters for a first estimate are

1)the type of structure, 2)the num-

ber of floors in the structure, and

3)the total square footage. These

data points help the fabricator ref-

erence similar projects to deter-

mine an approximate tonnage of

steel and associated cost. While

many experienced fabricators can

do this by memory, it is still ad-

vantageous to maintain a data-

base of these parameters. The

database can be a list of projects;

their size, location, and number of

stories; the number of tons of steel

shown on the plans; the fabrica-

tors bid; the winning bid for the

project; and the final cost of the

project. The list does not need to

be computerized, butcreating it

on a computerized spreadsheet al-

lows for easy sorting and catego-

rizing of data.

Additional parameters to better define

the project can be added to a database.

These parameters might include gross floor

area, footprint, roof area, exterior wall area,

floor-to-floor height, HVAC systems, in-

tended structure usage, special structure re-

quirements, structural engineer, and

governing building code. If the project has

been previously bid or negotiated, and a

hard take-off has been performed from the

plans, it is valuable to enter as many details

about the take-off as possible. This includes

the number of pieces, connections, shear

studs, bay sizes, and any additional infor-

mation thatof value.

The larger the number of items that can

be deduced from the client or design

builders information, the more accurate the

projects initial parametric estimate will be.

As projects age, an escalating cost factor can

be applied to earlier estimates to make them

relevant for current projects. Data in a

spreadsheet can be sorted and viewed in

different orders. Different ways of looking

at the project produces different cost ranges,

which can then be compared to determine a

target value for a new project. Aconceptual

estimator recognizes the difference between

the value of a bid and the true cost of a pro-

jects steel and adjusts the bid amounts ac-

cordingly.

When a conceptual estimate for steel is

provided to the developer or design-builder,

it should only include the value of the work

for which the fabricator is taking responsi-

bility. Fabricators should not provide a con-

ceptual estimate for the whole structure

unless they are responsible for it. Instead

they should indicate that steel typically rep-

resents about 10% of the project cost and in-

vite a design-builder to address the overall

cost.

Another way to obtain a feasibility or

early conceptual estimate is to use an esti-

mating program, such as CONEDIA or

D4COST. Both provide conceptual estimat-

ing values based on a database of costs ad-

justed for time and location factors.

CONEDIAworks from a design-component

methodology and builds a virtual project.

CONEDIA presents a series of what-if

scenarios so the estimator can test various

design alternatives. Once the model is cre-

ated, the estimator can override average

unit costs with values that are more repre-

sentative of local conditions. D4COST ap-

proaches the project differently. It looks at

projects similar to the proposed project in

the database and interpolates between

them. The estimator can create a library of

proprietary projects in addition to the proj-

ects already included and specify certain

unit-cost modules for use in the analysis. Al-

though no commercial program will ever re-

place the need for a companys cost

experience, these programs are a good start-

ing point. They provide a reminder of what

items should be included in the esti-

mate, a schedule overview in the case

of CONEDIA, and a way to check a

fabricators conceptual estimate.

TYPE 2SCHEMATIC

ESTIMATES

As the project is refined, the fab-

ricator can create a schematic or ele-

mental estimate. This estimate is

based on a fabricators trial model of

the structure. Once a model is cre-

ated, a process equivalent to the take-

off process of hard-bid estimating

follows. The more the prototype con-

forms to performance specifications,

the closer the quantities taken from it

will correspond to the actual project.

Models can be created easily with in

structural design packages. These

packages also generate a summary

take-off of the components of the

structure that can then be priced.

If the fabricator wants to perform

a more detailed take-off and if the

software supports a CIS/2 file trans-

fer capability (such as RAM Struc-

tural System or ETABS, the design

file can be read by a detailing pro-

gram with CIS/2 capability (SDS2 or

Xsteel) and displayed in 3-D. Con-

nections can be designed and de-

tailed take-offs performed. Shop

control packages (such as FABTROL) can

also importing the CIS/2 file and provide

quantity and cost estimates.

It is important to note that the fabricator

does not design the structure! The fabricator

only creates a model to address structural is-

sues and determine an approximate list of

materials from which an estimate can be

generated. The fabricators prototype will

have little correspondence to the structural

engineers design. But it is a good estimate

of the materials required. Involving the

structural engineer of record at this proto-

type level will integrate preliminary ideas

about the actual structure and reduce the

uncertainty in the estimate.

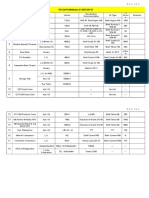

Project name

Customer

Project location

Project Architect

Engineer of Record

Construction Start

Construction Finish

Structure Type

Intended Structure Usage

Controlling Code

Fire Rating

Type of Fire Protection

Special Requirements

Footprint

Number of Stories

Total Square Footage

Roof Area

Roof Slope

Roof Deck

Interior Drains

Stairs?

Penthouse Area

Exterior Wall Type

Exterior Wall Area

Floor-to-floor Height

Typical Bay Size

Diaphragm

Expansion Joint?

Bracing Type

Tons of Steel

Steel/square foot

Tons of Joists

Joists/square foot

Number of Pieces

Type of Connections

Connection: Shop

Connection: Field

Lateral System

Number of Shear Studs

Delivery Method

If bidour bid

Winning bidder

Winning bid

Value of Steel Packag

Site Access

Erect Deck?

Erect Steel & Joists?

Value of Erection Package

Typical items to be included in

parametric spreadsheet

TYPE 3DETAILED ESTIMATE

Finally a detailed estimate is performed

once the design documents are developed at

least to a 50-percent level. The purpose of

this estimate is not to re-negotiate the proj-

ect, but to provide budgetary control to the

fabricating process and to identify areas

where contingency funds might need to be

applied. If a significant difference exists be-

tween the negotiated fee and the detailed es-

timate, the plans can be reviewed, and

cost-saving measures can be applied to the

structural system, detailing or erection.

DEFINING THE SCOPE

The definition of the scope of the serv-

ices provided by the fabricator is a critical

element of the conceptual estimate. The fol-

lowing items should be considered in defin-

ing the scope of the project:

I Identification of the documents (title and

date) that the conceptual estimate is

based upon

I Items included in the conceptual esti-

mate (for example: columns, beams,

joist, deck, bracing, pour stops, painting,

erecting )

I Items excluded in this conceptual esti-

mate (for example, the structural design.

Typically the design-builder will be ex-

pecting all items in section 5 of Master-

Spec to be included.)

I Design criterialoads and applicable

codes

I Allowable vibration and drift assump-

tions

I Framing assumptions

I Market conditions and timing that im-

pacts market costs

DEVELOPING CONFIDENCE

The feeling of risk associated with pro-

viding a fee for steel on a project without

completed drawings is intimidating - but a

lack of confidence in the estimate could

raise project contingencies. So how does a

steel fabricator develop the ability and con-

fidence to provide conceptual estimates?

1.

Hire or assign an individual in your

firm with the responsibility of concep-

tual estimating. For many design-builders

and specialty contractors this might not be

the same staff member that is experienced at

hard-bid estimating. The mentality of the

hard-bid estimator is one of looking at the

details and working up, rather than looking

at the scope of the project and working

down.

2.

Allow your conceptual estimator ac-

cess to historic project files and to the

firms senior management. The conceptual

estimator needs to know historic costs and

rules of thumbs that have served the firm

well. The firms management must have

confidence in the estimates produced,

which only results from confidence in the

estimator. Communication and trust is es-

sential between a firms estimator and its

management.

3.

Develop a spreadsheet with historic bid

costs and project parameters. Find old

drawings, take-offs and bid sheets. Concep-

tual estimating is best done with a usable his-

tory to draw from.

4.

Allow the conceptual estimator time

to experiment on past projects. Take a

job that was bid two years ago, identify two

or three parameters and then work through

a conceptual estimate for the project using

historic data from previous projects. Mea-

sure the conceptual estimate against the ac-

tual as-built cost for the project, not the bid

price, and refine the process on multiple

projects.

5.

Invest in technology that enhances the

conceptual estimating activity. Ac-

quire a commercially available estimating

package or consider utilizing one on a per-

project basis on the web. Invest in a design

package that can export design files using

CIS/2 to a detailing or shop management

package. Use it on historical projects to de-

velop confidence in the information that it

provides and the amount of contingencies

that need to be in place for varying design

conditions.

6.

Develop relationships with local struc-

tural engineers that may join your

firms design-build teams. Understand

their design approaches, work with them in

developing prototype models and discuss

the efficiencies of your particular fabricating

operation.

7.

Pursue design-build work in a famil-

iar market niche with other firms you

have trust. You will have more confidence in

providing a conceptual estimate in a market

you understand. Trustworthy team mem-

bers provide honest feedback on estimates.

8.

Give yourself time to prepare your

first few conceptual estimatesif you

have to rush your first opportunity, pass it

by.

9.

Always include a statement of scope

with any conceptual estimate.

10.

Confirm any conceptual estimate

with the most powerful tools you

haveyour common sense and experience.

Ask does this estimate make sense?

11.

Look at every design-build project

as an opportunity to provide the

owner with a better project at a lower cost,

on a more rapid schedule. Use your experi-

ence and your shops efficiencies to their ad-

vantage.

Conceptual estimating is a skill that

every design-build team member must

have. It is a skill that every fabricator can

and must developso next time youre at

lunch, your clients can benefit by an esti-

mate that brings their ideas off of the back of

a napkin and into the realm of possible proj-

ects.

William (Bill) Liddy is Senior EngineerSteel

Solutions Center in Chicago. John Cross, P.E., is

National Project Director, Design-Build, with

AISC Marketing, LLC, in Chicago.

How good are they?

Conceptual estimates typically have

the following accuracy ranges:

I feasibility estimate +/- 20%

I performance estimate +/- 7%

I conceptual design est. +/- 6%

I detailed estimate +/- 4%

Das könnte Ihnen auch gefallen

- Steel Estimating TodayDokument9 SeitenSteel Estimating Todayntah84100% (2)

- Basic Hydraulic SystemsDokument128 SeitenBasic Hydraulic Systemsbeau04297% (35)

- Estimate The Reinforcement in Shallow FoundationDokument12 SeitenEstimate The Reinforcement in Shallow FoundationEmdad Yusuf100% (2)

- Approximate Cost Estimating Model For PSC Beam Bridge Based On Quantity of Standard WorkDokument13 SeitenApproximate Cost Estimating Model For PSC Beam Bridge Based On Quantity of Standard WorkTejas SadvelkarNoch keine Bewertungen

- Pre-Engineered Metal Buildings SpecificationDokument30 SeitenPre-Engineered Metal Buildings SpecificationHaroon Ahmed0% (1)

- Fillet Welded Joints - A Review of The Practicalities - Job Knowledge 66Dokument4 SeitenFillet Welded Joints - A Review of The Practicalities - Job Knowledge 66Anuj ShahiNoch keine Bewertungen

- Guide Specification: Guide Specification Must Be Edited To Fit The Conditions of Use. Particular Attention Should BeDokument45 SeitenGuide Specification: Guide Specification Must Be Edited To Fit The Conditions of Use. Particular Attention Should BeAWNoch keine Bewertungen

- Structural Steel Specification for Offshore PlatformsDokument38 SeitenStructural Steel Specification for Offshore Platforms'Izzad AfifNoch keine Bewertungen

- Estimating Labor Unit Data For Concrete ConstructionDokument13 SeitenEstimating Labor Unit Data For Concrete ConstructionsoparlNoch keine Bewertungen

- Glossary of Construction Cost EstimatingDokument8 SeitenGlossary of Construction Cost EstimatingFaty BercasioNoch keine Bewertungen

- Pricing The Job-Mark-Up, Overhead & ProfitDokument6 SeitenPricing The Job-Mark-Up, Overhead & Profitbeq97009Noch keine Bewertungen

- Understanding Engineering DocumentsDokument20 SeitenUnderstanding Engineering DocumentsJose Arthur AbellaNoch keine Bewertungen

- Weld Symbols PDFDokument2 SeitenWeld Symbols PDFSwagat MohapatraNoch keine Bewertungen

- Commercial Steel Estimating: A Comprehensive Guide to Mastering the BasicsVon EverandCommercial Steel Estimating: A Comprehensive Guide to Mastering the BasicsNoch keine Bewertungen

- Constructing The Gold Standard FinalDokument135 SeitenConstructing The Gold Standard FinalGMA16Noch keine Bewertungen

- Construction Master ManualDokument108 SeitenConstruction Master ManualBrian leerNoch keine Bewertungen

- 2012 National Construction EstimatorDokument765 Seiten2012 National Construction EstimatorMiguel DeLa Cruz SilveraNoch keine Bewertungen

- Estimating Steel Building Installation PDFDokument2 SeitenEstimating Steel Building Installation PDFJurie_sk3608Noch keine Bewertungen

- Samaila Consultant Limited design calculations for single box culvertDokument8 SeitenSamaila Consultant Limited design calculations for single box culvertebed_meleck100% (2)

- Power Point 1 - Detailing Structural Steel Part1Dokument41 SeitenPower Point 1 - Detailing Structural Steel Part1Reynan Maurício0% (1)

- Edge Distance PDFDokument2 SeitenEdge Distance PDFJimmy SanDiegoNoch keine Bewertungen

- AP Calculus BC Study GuideDokument4 SeitenAP Calculus BC Study GuideHarshil SahaiNoch keine Bewertungen

- Economics of Structural Steel WorkDokument40 SeitenEconomics of Structural Steel Workthomas kilian100% (2)

- I Example Rev It KeynotesDokument88 SeitenI Example Rev It KeynotesjigarercivilNoch keine Bewertungen

- How To Estimate The Cost of Structural Steel - TechPaper - January2009Dokument9 SeitenHow To Estimate The Cost of Structural Steel - TechPaper - January2009Rezky MuliaNoch keine Bewertungen

- 7 Essential Construction Contract Clauses - 1Dokument2 Seiten7 Essential Construction Contract Clauses - 1sfreigaNoch keine Bewertungen

- Quantity Estimating: Indiana Department of Transportation-2013 Design ManualDokument137 SeitenQuantity Estimating: Indiana Department of Transportation-2013 Design ManualjaveedNoch keine Bewertungen

- CASE 962-D With AppendicesDokument65 SeitenCASE 962-D With AppendicesJhon Smit Gonzales Uscata100% (1)

- Design & Construction of the Contract Package ConceptVon EverandDesign & Construction of the Contract Package ConceptNoch keine Bewertungen

- South Africa’s Renewable Energy IPP Procurement ProgramVon EverandSouth Africa’s Renewable Energy IPP Procurement ProgramNoch keine Bewertungen

- Annexure-5-Technical Specification For Structural Steel WorksDokument20 SeitenAnnexure-5-Technical Specification For Structural Steel WorksGarapati Bala KrishnaNoch keine Bewertungen

- Duffer Inc a Construction Business Start Up AdventureVon EverandDuffer Inc a Construction Business Start Up AdventureBewertung: 5 von 5 Sternen5/5 (1)

- Some Helpful Construction TechniquesDokument10 SeitenSome Helpful Construction TechniquesNikulast KidsNoch keine Bewertungen

- Productivity Analysis of Steel Works For Cost Esti PDFDokument8 SeitenProductivity Analysis of Steel Works For Cost Esti PDFAkilanNoch keine Bewertungen

- Detailing GuidelinesDokument23 SeitenDetailing GuidelinesWayne Garner100% (2)

- Cost EstimatingDokument27 SeitenCost EstimatingAndrew Ugoh100% (1)

- Costing of Steel StructureDokument3 SeitenCosting of Steel StructureNithin100% (1)

- What Every Steel Erector Should Know About Welding RequirementsDokument6 SeitenWhat Every Steel Erector Should Know About Welding RequirementsrinuakNoch keine Bewertungen

- Metal Buildings: ChangersDokument24 SeitenMetal Buildings: ChangersBwabt sathishNoch keine Bewertungen

- Constructability of Embedded Steel Plates in CIP ConcreteDokument7 SeitenConstructability of Embedded Steel Plates in CIP ConcreteimranNoch keine Bewertungen

- Business Plan For Steel StructureDokument13 SeitenBusiness Plan For Steel StructureTariqul RabbiNoch keine Bewertungen

- Construction Cost Estimating: Section NineteenDokument16 SeitenConstruction Cost Estimating: Section NineteenStephen Megs Booh MantizaNoch keine Bewertungen

- Building Material Estimates and Rates Build Up: Second EditionVon EverandBuilding Material Estimates and Rates Build Up: Second EditionNoch keine Bewertungen

- Custom Home RenovationDokument9 SeitenCustom Home RenovationJessy MarshNoch keine Bewertungen

- Contractor Subcontractor RelationshipDokument11 SeitenContractor Subcontractor RelationshipClaire LimNoch keine Bewertungen

- VeEX OTN Quick Reference GuideDokument12 SeitenVeEX OTN Quick Reference GuideDewan H S SalehinNoch keine Bewertungen

- New-construction building commissioning The Ultimate Step-By-Step GuideVon EverandNew-construction building commissioning The Ultimate Step-By-Step GuideNoch keine Bewertungen

- Mathematics Class 10 CBSE (NCERT)Dokument369 SeitenMathematics Class 10 CBSE (NCERT)LinoNoch keine Bewertungen

- STS05120Dokument20 SeitenSTS05120JunaidAhmedNoch keine Bewertungen

- Rules of Thumb For Steel StructuresDokument5 SeitenRules of Thumb For Steel StructuresLincs lincoln100% (1)

- Steel Estimators GuideDokument13 SeitenSteel Estimators GuideBernhard von MuehlenenNoch keine Bewertungen

- Chapter 1: Introduction: 1.1 Background TheoryDokument36 SeitenChapter 1: Introduction: 1.1 Background TheoryBe-fit Be-strongNoch keine Bewertungen

- QR Code Attendance Monitoring SystemDokument6 SeitenQR Code Attendance Monitoring Systemjenny adlaoNoch keine Bewertungen

- Construction estimating software Standard RequirementsVon EverandConstruction estimating software Standard RequirementsNoch keine Bewertungen

- Cost Estimation and Prediction Using andDokument17 SeitenCost Estimation and Prediction Using andMayhendra ESNoch keine Bewertungen

- Back by Customer Demand!: Did You Know?Dokument5 SeitenBack by Customer Demand!: Did You Know?markigldmm918Noch keine Bewertungen

- Orwell Steel (Erection and Fabrication) LTDDokument5 SeitenOrwell Steel (Erection and Fabrication) LTDRenuka JeyabalanNoch keine Bewertungen

- Marketing Strategies for Promoting Steel Construction in Hong KongDokument15 SeitenMarketing Strategies for Promoting Steel Construction in Hong KongMk2Noch keine Bewertungen

- Behaviour of Steel To Concrete JointsDokument5 SeitenBehaviour of Steel To Concrete JointsTomNoch keine Bewertungen

- 2011 National Construction EstimatorDokument773 Seiten2011 National Construction EstimatorIsrael Allette70% (10)

- M2 U7 Plasma Arc CuttingDokument29 SeitenM2 U7 Plasma Arc CuttingKenan MuhamedagicNoch keine Bewertungen

- Introduction To The Economics of Structural SteelworkDokument156 SeitenIntroduction To The Economics of Structural SteelworkCharles AjayiNoch keine Bewertungen

- How To Make A PERT-CPM Chart and SWOT AnalysisDokument8 SeitenHow To Make A PERT-CPM Chart and SWOT Analysis'Ronnel Cris ⎝⏠⏝⏠⎠ Consul'0% (1)

- Count Formula in Excel 1Dokument3 SeitenCount Formula in Excel 1Ένκινουαν Κόγκ ΑδάμουNoch keine Bewertungen

- Part5 - Owners of NigeriaDokument4 SeitenPart5 - Owners of NigeriaΈνκινουαν Κόγκ ΑδάμουNoch keine Bewertungen

- Part4 - Owners of NigeriaDokument3 SeitenPart4 - Owners of NigeriaΈνκινουαν Κόγκ ΑδάμουNoch keine Bewertungen

- Definitions of FIDICDokument23 SeitenDefinitions of FIDICΈνκινουαν Κόγκ ΑδάμουNoch keine Bewertungen

- Part3 - Owners of NigeriaDokument3 SeitenPart3 - Owners of NigeriaΈνκινουαν Κόγκ ΑδάμουNoch keine Bewertungen

- Counta Formula in Excel.Dokument2 SeitenCounta Formula in Excel.Ένκινουαν Κόγκ ΑδάμουNoch keine Bewertungen

- Transpose in ExcelDokument2 SeitenTranspose in ExcelΈνκινουαν Κόγκ ΑδάμουNoch keine Bewertungen

- Part2 - Owners of NigeriaDokument3 SeitenPart2 - Owners of NigeriaΈνκινουαν Κόγκ ΑδάμουNoch keine Bewertungen

- Part1 - Owners of NigeriaDokument4 SeitenPart1 - Owners of NigeriaΈνκινουαν Κόγκ ΑδάμουNoch keine Bewertungen

- Oil List Preliminary of JASCON 55Dokument2 SeitenOil List Preliminary of JASCON 55Ένκινουαν Κόγκ ΑδάμουNoch keine Bewertungen

- Concatenate Names in Excel - How to Combine First & Last NamesDokument1 SeiteConcatenate Names in Excel - How to Combine First & Last NamesΈνκινουαν Κόγκ ΑδάμουNoch keine Bewertungen

- Excelculvert: TTTTTTTTT TTTTTTTT TTTTT TTTTTTTTDokument34 SeitenExcelculvert: TTTTTTTTT TTTTTTTT TTTTT TTTTTTTTmurthy pNoch keine Bewertungen

- Nigeria Wind Speed DataDokument13 SeitenNigeria Wind Speed DataΈνκινουαν Κόγκ ΑδάμουNoch keine Bewertungen

- Public Course Registration Form - Specialised Management Group FZ-LLCDokument3 SeitenPublic Course Registration Form - Specialised Management Group FZ-LLCΈνκινουαν Κόγκ ΑδάμουNoch keine Bewertungen

- How To Pass Your PMP Exam in 30 DaysDokument3 SeitenHow To Pass Your PMP Exam in 30 DaysΈνκινουαν Κόγκ ΑδάμουNoch keine Bewertungen

- Test Questions - Com Test QuestionsDokument3 SeitenTest Questions - Com Test QuestionsΈνκινουαν Κόγκ ΑδάμουNoch keine Bewertungen

- 2.3 Proposed Limits For Title III ApplicabilityDokument2 Seiten2.3 Proposed Limits For Title III ApplicabilityΈνκινουαν Κόγκ ΑδάμουNoch keine Bewertungen

- CPT SoundingsDokument32 SeitenCPT Soundingspieterjpeeters9924Noch keine Bewertungen

- Report On The Collapse of The Building by Dept. of Building, Hong KongDokument6 SeitenReport On The Collapse of The Building by Dept. of Building, Hong KongArzath SajeerNoch keine Bewertungen

- Nice Literature On Pile Driving and MonitoringDokument2 SeitenNice Literature On Pile Driving and MonitoringΈνκινουαν Κόγκ ΑδάμουNoch keine Bewertungen

- Vaida AkinfeDokument7 SeitenVaida AkinfeΈνκινουαν Κόγκ ΑδάμουNoch keine Bewertungen

- English MakalahDokument20 SeitenEnglish MakalahMintone Sajayah BekabekaNoch keine Bewertungen

- GlossaryDokument78 SeitenGlossaryraghu_chandra_3Noch keine Bewertungen

- Critical Lift ChecklistDokument2 SeitenCritical Lift ChecklistΈνκινουαν Κόγκ ΑδάμουNoch keine Bewertungen

- XSXSXSXSXDokument40 SeitenXSXSXSXSXAfiq JuwaidiNoch keine Bewertungen

- Abaqus 2016: Modeling and Visualization Analysis ReferenceDokument1 SeiteAbaqus 2016: Modeling and Visualization Analysis Referenceraghu_chandra_3Noch keine Bewertungen

- Soil StiffnessDokument24 SeitenSoil StiffnessMiguel Angel Romero FalconNoch keine Bewertungen

- DimaggioDokument77 SeitenDimaggioAmanda LucasNoch keine Bewertungen

- Caliendo09 Static AnalysisDokument62 SeitenCaliendo09 Static AnalysisMd AzaharyNoch keine Bewertungen

- Effect of Bond Administration On Construction Project DeliveryDokument7 SeitenEffect of Bond Administration On Construction Project DeliveryOlefile Mark MolokoNoch keine Bewertungen

- List of Practical Cs With SolutionDokument57 SeitenList of Practical Cs With SolutionArjun KalaNoch keine Bewertungen

- Social Media and Loneliness - Why An Instagram Picture May Be Worth More Than A Thousand Twitter WordsDokument13 SeitenSocial Media and Loneliness - Why An Instagram Picture May Be Worth More Than A Thousand Twitter WordsCarlos Leite Filho100% (1)

- Fault Report - Inventory Cpf1 Vs Caño LimomDokument37 SeitenFault Report - Inventory Cpf1 Vs Caño LimomJessica RiveraNoch keine Bewertungen

- A Framework For Transforming Artifacts From Data Flow Diagrams ToDokument7 SeitenA Framework For Transforming Artifacts From Data Flow Diagrams Tow_mahmudNoch keine Bewertungen

- Chapter 13: The Electronic Spectra of ComplexesDokument42 SeitenChapter 13: The Electronic Spectra of ComplexesAmalia AnggreiniNoch keine Bewertungen

- Lesson 17: Lightning Accidents: Grade 9-Science-Sussex College - WennappuwaDokument5 SeitenLesson 17: Lightning Accidents: Grade 9-Science-Sussex College - WennappuwaSwarnapaliliyanageNoch keine Bewertungen

- Job 1 SksoDokument5 SeitenJob 1 SksoFajAr OkTaNoch keine Bewertungen

- 1-Newton Second Law-ForMATDokument5 Seiten1-Newton Second Law-ForMATVAIBHAV KUMARNoch keine Bewertungen

- Amber & Company: A Reliable Company of WaterproofingDokument20 SeitenAmber & Company: A Reliable Company of WaterproofingRaj PatilNoch keine Bewertungen

- Brake SystemDokument19 SeitenBrake SystemSudarshan NepalNoch keine Bewertungen

- JACOB ThirdDokument16 SeitenJACOB ThirdWendell ReyesNoch keine Bewertungen

- Using Topcon GR-3 GPS for Topographic SurveysDokument4 SeitenUsing Topcon GR-3 GPS for Topographic SurveysFranco BaldiNoch keine Bewertungen

- MC0081Dokument385 SeitenMC0081Purushottam KumarNoch keine Bewertungen

- PEA ClocksDokument50 SeitenPEA ClocksSuresh Reddy PolinatiNoch keine Bewertungen

- Phase Transition of RNA Protein Complexes Into Ordered Hollow CondensatesDokument9 SeitenPhase Transition of RNA Protein Complexes Into Ordered Hollow CondensatesMilan StepanovNoch keine Bewertungen

- Hospital Managemen T System: Oose LAB FileDokument62 SeitenHospital Managemen T System: Oose LAB FileAASHNoch keine Bewertungen

- 006 PVC & CPVC Schedule 80 Fittings, Unions Tank Adapters, Expansion Joints & Saddles PDFDokument92 Seiten006 PVC & CPVC Schedule 80 Fittings, Unions Tank Adapters, Expansion Joints & Saddles PDFnicacio_89507470Noch keine Bewertungen

- NEO PGM 'AND'/'OR' FunctionalityDokument5 SeitenNEO PGM 'AND'/'OR' FunctionalityAndre EinsteinNoch keine Bewertungen

- OMC 140 Operator Manual v1.08Dokument38 SeitenOMC 140 Operator Manual v1.08Anderson DuarteNoch keine Bewertungen

- Oracle Database JDBC Developer Guide and ReferenceDokument432 SeitenOracle Database JDBC Developer Guide and Referenceapi-25919427100% (1)

- Correct AnswerDokument120 SeitenCorrect Answerdebaprasad ghosh100% (1)

- Digital Image Processing TechniquesDokument34 SeitenDigital Image Processing Techniquesaishuvc1822Noch keine Bewertungen

- Math Tutoring Announcement for 4th Year Literary StudentsDokument5 SeitenMath Tutoring Announcement for 4th Year Literary Studentsabed azzamNoch keine Bewertungen