Beruflich Dokumente

Kultur Dokumente

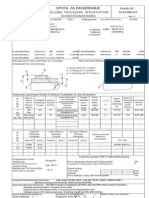

27 4264 Weld Preparation

Hochgeladen von

Lauren GarciaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

27 4264 Weld Preparation

Hochgeladen von

Lauren GarciaCopyright:

Verfügbare Formate

G

e

@

f-

a

z

o

O

<\

o

O

6

d6

oo

50

t:N

o-

o

can

or

=6

o

q

q

C)

o-

G

U)

{

!!

G

q)

(/)

t

0)

'tr

c)

I

0)

c

o

a

o

E

a

!

c

G

a

o

a

(!

=f

o

p

0)

!

O

a

o

i

q)

E

E

a

(t

G)

g,

c

'6

L

o

6

o

U'-

d).*

p

!S

qr!

rp

gtn

o.E

.sg

qq)

s

U'):

cl

!.q

ro .lc

(,A

L>

o-e

N

u,

e, u)

i;\

ot

EE

oo

OO

!O

ga

cr

oQa.s

sP

3 BF

o*Fa;*

:i>

:i:b

ac

S E3

Is z ,S

; F !E $ C

-J

r{

n

'tt

F

ls

E$

n;

i E nt

=

3

X t bs

*s

F

Q ie B s

s 3 ;= s

E=

P:

rtr

h so

b d E0) E.:R

.^ ?i a)-J \ o.E

!. ni tr{ *u

(D f,

g

b- is b 6S

$s

tE

cr i*

: t Es it

s

p

HH

sl

nE

Ri E : !l SS

5l E

3.m

Hl 8!

5l Sg ts El *t*

=FQq)

^c=--LH".EPo'

#

s

E E=* * ;

E

xF

a t l f;;c

i 5 $ HF}

;-'s=*u3tEF$:P

:.

'E

: Fg * ; E *;+

e e

E

qEe

E R

t

iel

E

E

;

'-n:

P X 8. 8c,s

-e

H ! ilF

; ; F

:FC

*

mi p

a:.s t S ; *"2

v

g' 5q$

s d

a

q5d

P Fc

-^

aaj

8

E-,^ E

tiI

i;EeX'EES

b!>-.o? qFE

EgeFEEESFEfFE=gtF

Egf:cB:Ei$iEtEI$iE

;iEEE!EEEEggifi$ig$f

3e Ea E: E;,i

; B ?E Eg

E:{is

F s ei i5 $ba

;

g;

gE

$t;E F E s; s +Sr

o)

trq

69

es

<3

ri

.v-

L:

o.v

}E

oi

EDO

oQ)

trt

co

o

oo"^a

\\p

O)o\

c-u)

.e3m

R

(D\ox

!*P0)

s s'd o

UIH'I:a

sie H

;r,a-

*'sl<;X

9RS F

::FF:

z z z Jl

Lrt t! U.t

O 6

<

= =

;:

o o o

()6

co

o_

o

O)

o

G

(U

tx

Pcu

(-lo

d6

c!

<F

zz

t! l.U

==

aa

co

!

a

c

f,

E

c)

3

(!)

c0

(

* c.r

*'

(o

a)o

d6N

zz

ul ul

zz.

clo

o)

-.<

o:

JS

ox

r?

lie

!>

o.!

=t o:

oro

oo

trc(

c0

U)

U)

(B

o

q

,oc

r

.:v

.-.-() : co

vNcD !

ro

Y(o\I .\ IO

\T\IF

E

N

zzz s z

tll t! tlJ

6

u.r

===

r Z

ddd ,i d

:P

u qrc

r E:H 6 e

!;$Fs*

:

qutsts

S T T F! F d

; ;

IsE se"

E E.iEgS F

f

N

c

(D

;.i

()

-o

-i -- 0)

N/or-i

O.\^

6.:-

--aru

ill *LaE

z id^ O

ILJU

: > b5 6i

zzZ*o.=o

LU LU.f+-C L N

=^-o=c

zztYo:c

a azaEzA

E3

-c :*

6:

o:

>Y

'J a)

o->

F

5

V)

q)

o

QE

P>.

*#

o1

TX

s

J

U)

o

o

c

o

U)

ss

F

l

o)

C

f

::J

o-

(o

-c

O

@

(o

=

l

q;l

8l El

(!l

bl

cl ol

<t

<ol

N

O

O

N

@

o)

O

O

cO

O

O

f--

c)

O

I

N

O

N

z

(o

o

@

N

ci

z

cj

o

O

.:

0)

t

o

=a

a

bi

o,

(u

0_

E

t!

5)

o

o

o

o

E

tr

o

I

o

o

o

o.

o

.=

E

E

t!

L

cD

o

o.

o-

I

o

o

.)<

o

o.

o

c.)

o

O

N

C\l

LL

E

c

:l

LL

L

o)

'a)

= .a

0)

=

=

v

c)

-o

E

=c

O

.o

o

0_

q)

!

o

o

c)

L

o_

F

&

*

k

m

J

e

o

o

o

0)

f

(g

co

ffi

trit!l.,

&\tgl

w

*}J48 w&Y&ul3t

INSTRACTION FOR OUTLET IIEADERS

MANAFACTURING/

POSTUPAKZA IZRADU IZLAZNIH KOMORA

27 .4264

-

Weisweiler F1&F2

60FK-0453/12

TERtvlOENERGETSKA

P0STR0,IFN,lA d o n

ease4i or

l\

nakon zavarivanja svakog

NAPOMENA: nakon

the base material.

Welcls shall be controlled after welding of each

row ofthe nozzles.

VERY IMPORTAN NOTE: a.fter weldirtg,

subassernbly lrurtillirtg, Itansport etc. huve lo be

very curefulllt, willtor.tl ony stress to the tinte

ufter PI4/HT.

osnovni matenjal.

Zavare kontrolirati

reda prikljucaka.

VRLO VAZNA

zavarivanja sa podsklopom se mora

paZljivo rukovati, transportirati itd., bez

ikakvih udaraca do trenutka nakon

odZarivanja.

11 Cleaning of the headers internals ancl control o/ Ci5cenje unutra5nlosti komora i vizualna

the cleanless by the encloscope. kontrola cistode putem endoskopa

12 Inductive preheating of the headers encls arrl lnduktivno predgrijavanje kraja komora, te

preheating of Flat heacls ltent 7 crncl nozzle ltem

predgrijavanje ravnih danaca poz 7 i

1, GTAW tackwelding according to WPSs.

prikljucaka poz 4, pripalanle TIG postupkom

prema WPS-ovima.

Visual and dimensional control of the i,uelc1s Kontrola pripreme za zavare, vizuelna i

preparation. dimenzionalna.

lVelding of the butt weld Flat head Itent 7 v,ith Zavarivanje suceonih zavata Ravno dance

Itent 4, and ltent 7 and headers ltent 2&26, pozT sapoz 4, te poz 7 sa komoramapozZ

according to WPS 001-6-814/02-01-H or WpS i26, premaWPS 004-6-8W02-01-H iliWPS

01 1-6-8W02-01-H. Control of the interpass

011-6-8W02-0'1-H. Kontrola meduprolazne

temperature with the contact therntonteter.

temperature sa kontaktnim termometrom.

Visual

qnd

dintensional control of the v,elds Vizuelna i dimenzionalna kontrola zavara

PWHT of the headers with nozzles in Electro

-

Toplinska obrada komora sa prikljuccima u

resistance Ftu'nace, acc. to Instruction

for

heat elektro

-

otpornoj peci, prema uputi za TO

treatn.tent No. 6-043, Holding temperatltre and br. 6-043, temperatura i vrijeme drlan)a

time 760-10"C / lS0mintttes. Sketch shall shov

760110"C / 180 minuta. Skica ce prikazivati

therntocotrples placement.

poloZaj termoparova.

Conn'ol of the PWHT record and the chart, Kontrola dijagrama i izvje5taja o TO

Grinding of the butt v,elds Flat heads ltems Z i 8 BruSenje nadvi5enja suceonih zavara Ravna

-headersltents2,26tothelevel

withbasemetal dancapozTi 8-komorepoz2,26 donivoa

and cleaning of the

fillet

welds

for

exantinations, osnovnog materijala, te ciScenje kutnih

IJ

14

1E

t.J

16

II

18

19

by grinding.

Exantination of thewelds after PWHT.

.

MTI00% and HTI0% of the

fillet

welds

.

MT, HT, RT&UT 100% of the butt welds

o

Flat heads

-

headers.

UT scanining shall not be done

front

area of

uT skeniranje

,nece

biti provedeno sa

nozzles, because of that RT 100%o sttalt be clone.'

strane prema prikljuccima, pa se zbog toga

radi RT'100%..

Assemblv ond weldins of the, transition

pieces,

Sastav i zavarivanie,

priielaznih

komada.

connectirts tubes, suspensions and PWHT spoinih ciievi, zavie5enia i toplinska

obrada

Preheating of the Transition piece Itent 3a & 4a Predgrijavanje prijelaznog komada poz3a,4a

and the nozzles ltem 3 & 4 with Electro

-

i prikljucaka poz 3,4 Elektro

-

otpornim

resistance heater and/or Gas

flante

torch,

gtijacem i/ili plinskim plamenikom, ugradnja i

assentbly and tack welding of the Itent 3a&|a,

pripajanje poz3a,4a prema WPS

according to wPS

remperaturu predgrijavanja kontrolirati sa

zavara bruSenjem za ispitivanja.

lspitivanje zavara nakon TO:

nozzles o MT100% i HT10% kutnih zavara

prikljudaka

MT, HT i UT 100% sudeonih zavara

ravna danca

-

komore.

3.1 .13

Rev. 3

1

Prepared bv: /t

-' /--

. ---l-

Ftrgnjo Kolar---

t\

Date.

14.01.2013

Revision:

3

Checked by:

M:/tehnoloiki postupal</ 27 4264 lzlazne komore P91

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- 20100526100623668Dokument1 Seite20100526100623668Lauren GarciaNoch keine Bewertungen

- Drawing1 Layout1Dokument1 SeiteDrawing1 Layout1Lauren GarciaNoch keine Bewertungen

- Pages From HRN en 12952-5Dokument14 SeitenPages From HRN en 12952-5Lauren GarciaNoch keine Bewertungen

- 20100526125044214Dokument1 Seite20100526125044214Lauren GarciaNoch keine Bewertungen

- 20100525083136149Dokument1 Seite20100525083136149Lauren GarciaNoch keine Bewertungen

- 20100330123609293Dokument29 Seiten20100330123609293Lauren GarciaNoch keine Bewertungen

- 20100525083319116Dokument1 Seite20100525083319116Lauren GarciaNoch keine Bewertungen

- 20100326085743579Dokument2 Seiten20100326085743579Lauren GarciaNoch keine Bewertungen

- Eagar 006Dokument15 SeitenEagar 006Lauren GarciaNoch keine Bewertungen

- 20100329112643710Dokument2 Seiten20100329112643710Lauren GarciaNoch keine Bewertungen

- Sandvik Pipe - Tube - Bar - Hollow Bar: Stock Program in StainlessDokument26 SeitenSandvik Pipe - Tube - Bar - Hollow Bar: Stock Program in Stainlessalbejo_r9Noch keine Bewertungen

- 2 2009 03 1563509Dokument1 Seite2 2009 03 1563509Lauren GarciaNoch keine Bewertungen

- 20100330101400145Dokument35 Seiten20100330101400145Lauren GarciaNoch keine Bewertungen

- 20100326074831446Dokument1 Seite20100326074831446Lauren GarciaNoch keine Bewertungen

- 20100326085743579Dokument2 Seiten20100326085743579Lauren GarciaNoch keine Bewertungen

- CTODDokument4 SeitenCTODthan79Noch keine Bewertungen

- Effect of Heat Input To Weld Residual StressDokument4 SeitenEffect of Heat Input To Weld Residual StressSurya DharmaNoch keine Bewertungen

- Etd1649 PDFDokument61 SeitenEtd1649 PDFLauren GarciaNoch keine Bewertungen

- BWE Brik Welding EvaluationDokument4 SeitenBWE Brik Welding EvaluationLauren GarciaNoch keine Bewertungen

- 20100617082758841Dokument1 Seite20100617082758841Lauren GarciaNoch keine Bewertungen

- N 9003Dokument4 SeitenN 9003Lauren GarciaNoch keine Bewertungen

- Dwg1 2825 RemarksDokument1 SeiteDwg1 2825 RemarksLauren GarciaNoch keine Bewertungen

- 20100618071206827Dokument2 Seiten20100618071206827Lauren GarciaNoch keine Bewertungen

- 20100716101107497Dokument1 Seite20100716101107497Lauren GarciaNoch keine Bewertungen

- 20100716121120727Dokument1 Seite20100716121120727Lauren GarciaNoch keine Bewertungen

- 20100709123225199Dokument5 Seiten20100709123225199Lauren GarciaNoch keine Bewertungen

- Influence of Heat Input On Corrosion Resistance of SAW Welded Duplex JointsDokument4 SeitenInfluence of Heat Input On Corrosion Resistance of SAW Welded Duplex JointsLauren GarciaNoch keine Bewertungen

- 20100713131211561Dokument2 Seiten20100713131211561Lauren GarciaNoch keine Bewertungen

- 20100716075629769Dokument3 Seiten20100716075629769Lauren GarciaNoch keine Bewertungen

- 51 4 341 346Dokument6 Seiten51 4 341 346Lauren GarciaNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Material Technology IInd SemDokument262 SeitenMaterial Technology IInd SemvinayakNoch keine Bewertungen

- 1 Introduction To Steel Structures PDFDokument70 Seiten1 Introduction To Steel Structures PDFCristan RetuermaNoch keine Bewertungen

- HARDFACING ALLOYS in Sugar IndustryDokument28 SeitenHARDFACING ALLOYS in Sugar IndustryfendynovapamelaNoch keine Bewertungen

- 6th Sem Group Diploma Front Pkiet BargarhDokument10 Seiten6th Sem Group Diploma Front Pkiet BargarhPrabir Kumar PatiNoch keine Bewertungen

- Diagrama TTT e Jominy Teórico: PL22, PL30, PL33, PL41, 4140 e 5135Dokument18 SeitenDiagrama TTT e Jominy Teórico: PL22, PL30, PL33, PL41, 4140 e 5135DanielNoch keine Bewertungen

- No 9Dokument156 SeitenNo 9Muhammad Fahmi MahmudNoch keine Bewertungen

- Soal CswipDokument1 SeiteSoal Cswipakun jeparaNoch keine Bewertungen

- Manual InoxDokument32 SeitenManual InoxCristianNoch keine Bewertungen

- Astm A20Dokument1 SeiteAstm A20jojo_32367% (3)

- Shielded Metal WeldingDokument74 SeitenShielded Metal WeldingwernhowNoch keine Bewertungen

- Calcul Des Structures AcierDokument7 SeitenCalcul Des Structures Aciertechno samirNoch keine Bewertungen

- Metals Building Tech NotesDokument11 SeitenMetals Building Tech Notescorazon philNoch keine Bewertungen

- Schedule of Beams & Girders Schedule of Beams & GirdersDokument1 SeiteSchedule of Beams & Girders Schedule of Beams & Girdersmr. oneNoch keine Bewertungen

- RM01 - Arc Weld ProcessesDokument53 SeitenRM01 - Arc Weld ProcessesAnonymous cgcKzFtXNoch keine Bewertungen

- Esfuerzos Maximo Permisibles Tablas Ucs Ii Asme Viii Div 1 PDFDokument643 SeitenEsfuerzos Maximo Permisibles Tablas Ucs Ii Asme Viii Div 1 PDFChuy Ramos0% (1)

- Nip Material ComparsionDokument1 SeiteNip Material ComparsionRob WillestoneNoch keine Bewertungen

- Metal Solid IronDokument46 SeitenMetal Solid IronImelda SitumorangNoch keine Bewertungen

- Filler Metals Chemical Industry enDokument16 SeitenFiller Metals Chemical Industry enrakeshbablooNoch keine Bewertungen

- S275NLDokument1 SeiteS275NLMukesh ShettyNoch keine Bewertungen

- Welding Consumables For Cast Iron MaterialsDokument4 SeitenWelding Consumables For Cast Iron MaterialsskidanjeNoch keine Bewertungen

- MIG and TIG WeldingDokument2 SeitenMIG and TIG WeldingshahzafNoch keine Bewertungen

- API 581 - Corrosion Rate TablesDokument10 SeitenAPI 581 - Corrosion Rate Tablesrocap76046Noch keine Bewertungen

- East SinghbhumDokument12 SeitenEast SinghbhumadhunikmicaNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldDokument3 SeitenSaudi Aramco Inspection Checklist: In-Process Welding Inspection SAIC-W-2006 30-Apr-13 WeldManoj KumarNoch keine Bewertungen

- MATERIAL GRADE COMPARISON TABLE For Web PDFDokument9 SeitenMATERIAL GRADE COMPARISON TABLE For Web PDFsucihaNoch keine Bewertungen

- BSEN 10025 2000 New EditionDokument68 SeitenBSEN 10025 2000 New Editionpbp2956Noch keine Bewertungen

- Chapter-17 Weldability ....Dokument6 SeitenChapter-17 Weldability ....shahid khanNoch keine Bewertungen

- PQR WPSDokument2 SeitenPQR WPSMiguel Alejandro SierraNoch keine Bewertungen

- Austenitic Stainless SteelsDokument5 SeitenAustenitic Stainless SteelsNickesh ShahNoch keine Bewertungen

- Wires & Fluxes: W.E.F. 6 APRIL 2022Dokument16 SeitenWires & Fluxes: W.E.F. 6 APRIL 2022Shivi ChaturvediNoch keine Bewertungen