Beruflich Dokumente

Kultur Dokumente

Introduction To Packaging

Hochgeladen von

Punyabrata GhatakOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Introduction To Packaging

Hochgeladen von

Punyabrata GhatakCopyright:

Verfügbare Formate

Introduction to packaging

Manjunath.M.S

MEMS Packaging

General Packaging process

Die Attach

Wafer saw

Vacuum Mount

Curing

Wafer Mount

Curing & die shear

Pick and Place

Epoxy dispensing

Wirebond Process

Sealing/ Encapsulation

Testing/Calibration/Shipping

Curing & die shear

Wirebond

Ball Shear test

Wire Pull test

Mold Compound dispensing

Curing

Laser welding

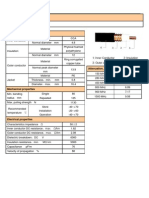

Semi Automatic Wafer Dicing Machine

Make M/s. MTI Cut

Model EC-400

Mode Semi Automatic

SPECIFICATIONS

Motor : DC motor (110V) with variable speed up to 3,000 rpm.

Accuracy : 0.0025 mm moving resolution and 0.01 mm position accuracy.

Cutting Blades : 4" dia x 0.35 mm thick fully sintered diamond blade

Control mode : Manual control / PC control

Range 3 dimensions : X-axis: 8" Y-axis:4" Z-axis:4"

The MTI Cut Wafer Dicer is semiautomatic machine, suitable to dice wafer.

Maximum size of wafer 4.

Wafer material Silicon, Glass etc

Blade width 0.35mm,

Device pitch min 2.5mm.

Semi Automatic Die attach & wirebonding

Machine

Bond head

Microscope

Motorized Wire-Spool

Fiber Optic Illuminator

Wedge bond 17-75

Ribbon max. 25x250

Ball & bump bond 17-50

Axis control Motorized Z & Y, Manual X

Ultrasonic system PLL control 62kHz transducer

Ultrasonic power 0 2 Watt output

Specifications:

Heater Stage

Control - Puck

6,5 TFT Touch Panel

Ultrasonic power 0 2 Watt output

Bond time 15 2,000 msec.

Bond force 15 150 cN

Heater stage

controller

Built-in, 250C max

Semi Automatic Die attach Machine

Epoxy vacuum pump

1. pick-up tool

1.

Semi Automatic Wirebonding Machine

Bond head

Control - Puck

Microscope

Motorized Wire-Spool

Fiber Optic Illuminator

Wedge bond 17-75

Ribbon max. 25x250

Ball & bump bond 17-50

Axis control Motorized Z & Y, Manual X

Ultrasonic system PLL control 62kHz transducer

Ultrasonic power 0 2 Watt output

Bond time 15 2,000 msec.

Specifications:

Heater Stage

6,5 TFT Touch Panel

Bond force 15 150 cN

Heater stage

controller

Built-in, 250C max

TPT Wirebonder is semiautomatic machine to establish connectivity between die and

substrate

Wire material Au (25) & Cu, Al (33)

Bonding type Ball bonding, Wedge bonding & Ball Bump

Minimum bond pad size 80x80, pad pitch of 90,

Distance btw 1

st

& 2

nd

Bond btw 1-5mm length

Metallization thickness of min 100nm of material Au/Al with a bond pad

appropriate seed layer.

Laser Dicing Machine

Make M/s. Miyachi Unitek

Model LW70AE

Mode Semi Automatic

Type Nd-YAG Laser

Laser Welding machine has capability of Spot and Seam welding MEMS packages made

of metals and alloys such as SS304/304L/316/321, Kovar, Invar etc

Tool Specifications:

Type Delta BDMS four (4) axis

Enclosure 40"W x 26"D x 40"H

XY Table 6" x 6"

Power Supply 220VAC, 50 Hz

Work Holding 5" rotary stage with 3-

jaw chuck & Collets

Work Holding

Capacity

50mm diameter parts

Laser Specifications:

Type Nd-YAG

Coolant Water Cooled

Power Supply 400 VAC, 3 - phase

Max Avg Power 70W

Max Pulse Energy 70J

Pulse Duration 0.25-30ms

Wavelength 1064nm

Pulse repetition 1-200Hz

Thermocompression Bonding:

A process which involves the use of force, time, and heat to join the two materials.

The wire (heated in some cases) is pressed against the hot surface (at 300

0

C or more)

at high force for a limited period of time to achieve the bond.

Wire Bonding Types

Thermosonic Bonding:

A process which involves the use of force, time, ultrasonics and heat to join two materials.

The wire (heated in some cases) is pressed against the hot surface (at 150 deg. C or less)

at low force and vibrated for a limited period of time to achieve the bond.

Wirebonding Temperature Ultrasonic energy Wire Pad

Thermocompression 300-500

o

C No Au Al, Au

Thermosonic /Ultrasonic 100-150

o

C Yes Au Al Au

Pressure calibrators

Make DH-Budenberg Make DH-Budenberg

Pressure Calibrator (Hydraulic and Pneumatic):

Hydraulic Pressure Calibrator(0-1200bar) and Pneumatic Calibrator (-1 to

100bar) with data acquisition system are available for pressure transducer

calibration and characterization.

Make DH-Budenberg

Type Hydraulic

Model DHB 42/501

Range 0 to 1200 bar

Make DH-Budenberg

Type Pneumatic

Model DHB 42/041

Range -1 to 100 bar

Hot and Cold Chamber

Make M/s. Vtsch

Model VCL7003

Mode Automatic

Tool Specifications:

Test space volume 34 Lts

Temperature Range for

temperature tests

-70

0

C to +180

0

C

Temperature Range for

climatic tests

+10

0

C to +95

0

C

Humidity range 10% r.h to 98% r.h

Data capture Simpati, Software Package

This Hot and Cold Enclosure / Test Chamber is used for evaluating

device quality, reliability and identify manufacturing flaws on MEMS

devices.

Das könnte Ihnen auch gefallen

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionVon EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Boq of Lab EquipmentsDokument5 SeitenBoq of Lab EquipmentsMuhammad TausifNoch keine Bewertungen

- Rogowski System Brochure 2016Dokument3 SeitenRogowski System Brochure 2016Anonymous xTGQYFrNoch keine Bewertungen

- Welded Mesh SpecificationDokument4 SeitenWelded Mesh Specificationsunil050776Noch keine Bewertungen

- 4 Lot3-MeDokument13 Seiten4 Lot3-MekosoeNoch keine Bewertungen

- SBM 1250 Double Twist Bunching LineDokument12 SeitenSBM 1250 Double Twist Bunching LineEMRE KAAN USTANoch keine Bewertungen

- RM 35 TF 30Dokument2 SeitenRM 35 TF 30Marco GrijalbaNoch keine Bewertungen

- Datasheet - NZMN3-AE630: Part No. Article No. Catalog NoDokument12 SeitenDatasheet - NZMN3-AE630: Part No. Article No. Catalog NoConstantin UdreaNoch keine Bewertungen

- Hypertherm Power Max 105Dokument2 SeitenHypertherm Power Max 105RetroPlasmaNoch keine Bewertungen

- PVDDokument5 SeitenPVDDani MarconiNoch keine Bewertungen

- 65 Parallel PVC Pipe Line 50-250mmDokument6 Seiten65 Parallel PVC Pipe Line 50-250mmzakariaNoch keine Bewertungen

- A2006 126 Type 68 Datasheet Issue A Draft 2Dokument3 SeitenA2006 126 Type 68 Datasheet Issue A Draft 2Micah KipropNoch keine Bewertungen

- Four Cavities PVC Wall Edges Extrusion LineDokument7 SeitenFour Cavities PVC Wall Edges Extrusion LineguldavistNoch keine Bewertungen

- Datasheet - NZMN3-AE630: Part No. Article No. Catalog NoDokument12 SeitenDatasheet - NZMN3-AE630: Part No. Article No. Catalog Nosampath sarangaNoch keine Bewertungen

- Final Automated Welding PresentationDokument26 SeitenFinal Automated Welding PresentationAbie RexoMenNoch keine Bewertungen

- Ultrasonic Fabric Embossing Machine PDFDokument7 SeitenUltrasonic Fabric Embossing Machine PDFmohsintNoch keine Bewertungen

- N.1 Flexographic Printing Press "Stack Type" Mod Sirio S-Plus 8 Colours - 1200 WidthDokument9 SeitenN.1 Flexographic Printing Press "Stack Type" Mod Sirio S-Plus 8 Colours - 1200 WidthMahmoud FathiNoch keine Bewertungen

- MTI PECVD SpecificationsDokument2 SeitenMTI PECVD SpecificationspvegaNoch keine Bewertungen

- Aggregates New-Products Upgrades 2014 2015Dokument10 SeitenAggregates New-Products Upgrades 2014 2015Kaizer BoNoch keine Bewertungen

- Kamla Karr A Jurk ArDokument56 SeitenKamla Karr A Jurk ArdhariyapankajNoch keine Bewertungen

- EdmDokument16 SeitenEdmaj87_goswamiNoch keine Bewertungen

- Cilindros e Servo CilindrosDokument16 SeitenCilindros e Servo CilindrosluisbottonNoch keine Bewertungen

- SJSZ80-156 For PVC Pipe Making Machine 50-250mmDokument8 SeitenSJSZ80-156 For PVC Pipe Making Machine 50-250mmzakariaNoch keine Bewertungen

- SXK-D01 Barriergate Installation ManualDokument27 SeitenSXK-D01 Barriergate Installation ManualHimaoneDwiAhmadANoch keine Bewertungen

- Parameter MachineDokument10 SeitenParameter MachinePhuong Thuc Duong LeNoch keine Bewertungen

- Upc-838 Plasma CutterDokument5 SeitenUpc-838 Plasma Cutteramirouche15Noch keine Bewertungen

- Analog Sensors AssignmentDokument7 SeitenAnalog Sensors AssignmentPathum SudasingheNoch keine Bewertungen

- Surgical Gown EquipmentDokument5 SeitenSurgical Gown EquipmentahmedNoch keine Bewertungen

- Mecontrol CoalPSA 2012 NL 5 2Dokument2 SeitenMecontrol CoalPSA 2012 NL 5 2skorpion64Noch keine Bewertungen

- Republic of The Philippines Western Mindanao State University Zamboanga City Telefax.: 062-992-4238 WWW - Wmsu.edu - PHDokument6 SeitenRepublic of The Philippines Western Mindanao State University Zamboanga City Telefax.: 062-992-4238 WWW - Wmsu.edu - PHWestern Mindanao State UniversityNoch keine Bewertungen

- Signal Conditioners Impulse Hammers Accelerometers Cables Custom Designs Pressure Sensors Accessories Force SensorsDokument6 SeitenSignal Conditioners Impulse Hammers Accelerometers Cables Custom Designs Pressure Sensors Accessories Force SensorsSyed HasanNoch keine Bewertungen

- Leuze Cubic 3 Series SensorsDokument48 SeitenLeuze Cubic 3 Series SensorsNurcholisNoch keine Bewertungen

- Accessories Final v.1Dokument11 SeitenAccessories Final v.1Peter TanNoch keine Bewertungen

- Eaton 290376 NZMH4 VE800 S1 en - GBDokument10 SeitenEaton 290376 NZMH4 VE800 S1 en - GBkarthik01heroNoch keine Bewertungen

- Eaton 290376 NZMH4 VE800 S1 en - GBDokument10 SeitenEaton 290376 NZMH4 VE800 S1 en - GBkarthik01heroNoch keine Bewertungen

- Datasheet - NZMH4-VE800-S1: Part No. Article No. Catalog NoDokument10 SeitenDatasheet - NZMH4-VE800-S1: Part No. Article No. Catalog Nogogo2021Noch keine Bewertungen

- Product Brochure VFK KoreaDokument12 SeitenProduct Brochure VFK KoreaRishi Malhotra100% (1)

- Data SheetDokument2 SeitenData SheetcciproductsNoch keine Bewertungen

- One Wave Soldering Machine-Interbras PDFDokument4 SeitenOne Wave Soldering Machine-Interbras PDFUserSMTNoch keine Bewertungen

- CLEAVER 45 V7A Datasheet 1300Dokument2 SeitenCLEAVER 45 V7A Datasheet 1300suneeljaganNoch keine Bewertungen

- 511 Pressure TransmitterDokument5 Seiten511 Pressure TransmitterDhp CiaNoch keine Bewertungen

- Micro Plasma Arc WeldingDokument5 SeitenMicro Plasma Arc WeldingJigar ChaudharyNoch keine Bewertungen

- AnnelingDokument31 SeitenAnnelingSatyam Singh100% (1)

- 6969-350 FlextensionalDokument8 Seiten6969-350 FlextensionalAdnan QaseemNoch keine Bewertungen

- Selina Product CatalogDokument19 SeitenSelina Product Catalogdondon correNoch keine Bewertungen

- Hioki 3197-01/5000 Pro Power Quality AnalyzerDokument3 SeitenHioki 3197-01/5000 Pro Power Quality AnalyzerVictor WidiputraNoch keine Bewertungen

- Types of Ferrite Materials: Material 33Dokument4 SeitenTypes of Ferrite Materials: Material 33lux302006Noch keine Bewertungen

- R of in Fine Welding With LaserDokument52 SeitenR of in Fine Welding With LaserMaher ShehabNoch keine Bewertungen

- CONTRINEX Capacitive Proximity SwitchesDokument15 SeitenCONTRINEX Capacitive Proximity SwitchesMemik TylnNoch keine Bewertungen

- Submerged Arc WeldingDokument4 SeitenSubmerged Arc WeldingAnkit BansalNoch keine Bewertungen

- Model 1 DS1703Dokument2 SeitenModel 1 DS1703dreyko77Noch keine Bewertungen

- Datasheet PDFDokument2 SeitenDatasheet PDFAnonymous jKNubumNoch keine Bewertungen

- Vitronics PresentDokument54 SeitenVitronics PresentCrina100% (1)

- Handheld Fiber Laser Welding Machine - DetailsDokument18 SeitenHandheld Fiber Laser Welding Machine - DetailsRasool SabeghiNoch keine Bewertungen

- Welding AutomationDokument42 SeitenWelding Automationharoub_nasNoch keine Bewertungen

- Prospekt Ersa Hammerpreise Productronica 2013 en WebDokument12 SeitenProspekt Ersa Hammerpreise Productronica 2013 en WebbehzadNoch keine Bewertungen

- Sensors For Wind Turbines PDFDokument6 SeitenSensors For Wind Turbines PDF13121977Noch keine Bewertungen

- It MaDokument23 SeitenIt MarosegoncaNoch keine Bewertungen

- TCW 605Dokument3 SeitenTCW 605Henry Manuel GomezNoch keine Bewertungen

- Industry 4.0 - Towards Future Industrial Opportunities and ChallengesDokument6 SeitenIndustry 4.0 - Towards Future Industrial Opportunities and ChallengesPunyabrata GhatakNoch keine Bewertungen

- Harnessing Technology Creating A Less Cash Society: Connect With UsDokument32 SeitenHarnessing Technology Creating A Less Cash Society: Connect With UsPunyabrata Ghatak100% (1)

- Understanding Sei Zures & EpilepsyDokument15 SeitenUnderstanding Sei Zures & EpilepsyPunyabrata GhatakNoch keine Bewertungen

- Epilepsy en inDokument2 SeitenEpilepsy en inPunyabrata GhatakNoch keine Bewertungen

- Lecture 10 Wet EtchingDokument12 SeitenLecture 10 Wet EtchingPunyabrata GhatakNoch keine Bewertungen

- Open Source Hardware Gets DefinedDokument2 SeitenOpen Source Hardware Gets DefinedPunyabrata GhatakNoch keine Bewertungen

- SY1 s17 s18 v12.01 DFDokument50 SeitenSY1 s17 s18 v12.01 DFKhalid Khalifa AtyaNoch keine Bewertungen

- Workbook SmartStruxure Lite - Ver 1.2.0Dokument70 SeitenWorkbook SmartStruxure Lite - Ver 1.2.0Oscar Javier Martinez Martinez0% (1)

- KUKA AppendixDokument43 SeitenKUKA AppendixAlexandru Ionut Toma100% (1)

- Reguladora de Voltaje MarathonDokument4 SeitenReguladora de Voltaje MarathonFercho SanchezNoch keine Bewertungen

- Wilfred Van Rooijen 200104Dokument100 SeitenWilfred Van Rooijen 200104vmsaNoch keine Bewertungen

- DC GeneratorDokument24 SeitenDC GeneratorRahmat Bagus ArdhiansyahNoch keine Bewertungen

- GV2ME32 TelemecaniqueDokument2 SeitenGV2ME32 TelemecaniqueRasek ResolfNoch keine Bewertungen

- Using The UPLOAD Program To Update CADSTAR DOS Files To CADSTAR Windows FilesDokument15 SeitenUsing The UPLOAD Program To Update CADSTAR DOS Files To CADSTAR Windows FilesJames Head50% (2)

- Umar Farooq CVDokument2 SeitenUmar Farooq CVhussaintariqueNoch keine Bewertungen

- ZW37 Heag 33 KV DrawingDokument8 SeitenZW37 Heag 33 KV Drawingabu sayedNoch keine Bewertungen

- World's Smallest: Up To 48 ZonesDokument16 SeitenWorld's Smallest: Up To 48 ZonesPedroGomes2Noch keine Bewertungen

- Manual Caterpillar Track Type Tractors Engine Control 3508 Components Operations TestingDokument23 SeitenManual Caterpillar Track Type Tractors Engine Control 3508 Components Operations TestingTansu Mavunacı100% (3)

- Starting Guide Frenic MegaDokument41 SeitenStarting Guide Frenic MegaMuhammad Jazztyan Indra PradanaNoch keine Bewertungen

- Speedtweaks Tips and Tricks Dodge RamDokument0 SeitenSpeedtweaks Tips and Tricks Dodge RamDarik OreskovichNoch keine Bewertungen

- SWR sm-400s Owners ManualDokument5 SeitenSWR sm-400s Owners Manualsquidman100% (1)

- Product Specifications: DBXLH-6565S-T0MDokument4 SeitenProduct Specifications: DBXLH-6565S-T0MRaluca Roxana SzaszNoch keine Bewertungen

- Switchyard Earthing Report - AkkareipattuDokument12 SeitenSwitchyard Earthing Report - AkkareipattuManjithaGeethadharaGunarathneNoch keine Bewertungen

- EC-Lab - Application Note #42 08/2012 The Modified Inductance Element La I - IntroductionDokument5 SeitenEC-Lab - Application Note #42 08/2012 The Modified Inductance Element La I - IntroductionR.SubramanianNoch keine Bewertungen

- Chapter 5pptDokument46 SeitenChapter 5pptkalehiwotkoneNoch keine Bewertungen

- G - SDokument8 SeitenG - SveenusNoch keine Bewertungen

- AIS-098 - Offset Front CrashDokument94 SeitenAIS-098 - Offset Front CrashDevavrat AnikhindiNoch keine Bewertungen

- Sicam Sat 1703 Acp - RtuDokument12 SeitenSicam Sat 1703 Acp - RtutduskoNoch keine Bewertungen

- Ansiasme B1.2-1983 (Revision of Ansi B1.2-1974) PDFDokument190 SeitenAnsiasme B1.2-1983 (Revision of Ansi B1.2-1974) PDFrzurabaezaNoch keine Bewertungen

- GATE 2016 EC (Set-1)Dokument42 SeitenGATE 2016 EC (Set-1)Mahesh SinghNoch keine Bewertungen

- Silicon Bridge Rectifiers KBP2005 - KBP210Dokument3 SeitenSilicon Bridge Rectifiers KBP2005 - KBP210Emad Ali Abu HassnaienNoch keine Bewertungen

- Manual Teensy 3.2 PDFDokument1.377 SeitenManual Teensy 3.2 PDFRoissmer LanzaNoch keine Bewertungen

- ColorimetryDokument6 SeitenColorimetryRaazia MirNoch keine Bewertungen

- D10T Track-Type Tractor Power Train System: Rjg1-UpDokument2 SeitenD10T Track-Type Tractor Power Train System: Rjg1-UpJHOSMAR_22Noch keine Bewertungen

- Fly XPR 5582Dokument2 SeitenFly XPR 5582Miguel Angel Rodriguez FloresNoch keine Bewertungen

- Interconnect I - Class 21: Prerequisite Reading - Chapter 4Dokument32 SeitenInterconnect I - Class 21: Prerequisite Reading - Chapter 4spyeagleNoch keine Bewertungen