Beruflich Dokumente

Kultur Dokumente

Lyons (Wind Energy Systems)

Hochgeladen von

sagararlaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lyons (Wind Energy Systems)

Hochgeladen von

sagararlaCopyright:

Verfügbare Formate

Wind

Wind

Energy

Systems

Cornell

12 J une, 2009

J P Lyons - CTO

Novus Energy Partners

Wind Now Mainstream

Boomingglobal market $50B industrygrowingat 25%CAGR

GE1.5MWTurbines

Lamar,Colorado

Booming global market, $50B industry growing at 25% CAGR

GE $6.5B 2008 revenues, 10,000 1.5 machines installed

Good US sites (8+m/s) - lowest COE of any new generation

US 20+GWs, 8.3 GW 2008, 42% new electricity

20% Wind Energy by 2030 300+GW

GW scale projects in sight

2/

J une 2009

Land Based Technology

Todays Land Base Utility Class Turbines

Vestas V100-2.75

Today s Land Base Utility Class Turbines

1.5 3.0 MW Upwind Configuration

80 100 Meter Tower Height

Conventional 3 stage gearbox Conventional 3 stage gearbox

Distributed component drivetrain

Full Span Pitch Control

Tapered Cylinder Steel Towers

Clipper 2.5-93

p y

~65 kWhr/kg tower top mass

200 MW + Windfarms

Performance

98% Availability

40+% Capacity Factor at IEC-II 8.5 m/s

GE 2.5xl

3/

J une 2009

CF% +10 pts in last 5 yrs

GE Wind Turbines

Electrical Pitch

Drives

GE 1.5 MW

77 M Rotor Diameter

50-100 M Tower

Doubly-Fed

Generator

Main Shaft &

98% Availability

Speed 10-20 RPM

Variable Pitch

Gearbox

Epoxy-Glass

Composite Blades

Main Shaft &

Bearing

Transformer &

Electrical

Power Electronic

Converter

4/

J une 2009

Turbine Speed vs. Size

Southwest Windpower Storm

1 8 kW Wind Turbine 3 7 m diameter

Clipper 2.5 MW with 93 m

Rotor

1.8 kW Wind Turbine, 3.7 m diameter

Rotor

5/

J une 2009

Wind Energy Conversion

Rotor power: P = 1/2 c

p

Av

w

3

c

p

- rotor power coefficient

i d it - air density

A - rotor swept area

Ideal c

p

= 0.593 (Betz factor)

h V 1/3 V ( i d l it l b 2/3) where V

2

= 1/3 V

1

(wind velocity slows by 2/3)

Tip speed ratio: = v

t

/ v

w

6/

J une 2009

c

p

= f()

Windturbines: Fundamentals, Technologies, Application and Economics , Erich Hau, ISBN: 3540570640; (April 30, 2000)

Wind

Turbine

Dynamics

P i di F E i M h i l S PeriodicForcesExciteMechanicalSystem

bladepassingfrequency(BP)

3P windshear,yawerror,towershadow

1P rotor unbalance gravity 1P rotorunbalancegravity

P rotationalfrequency

TurbineNaturalFrequencies

T b di d Towerbendingmodes

Bladeflapbendingmode

Bladeflutter&torsional modes

Yaw system torsional mode

7/

J une 2009

Windturbines:Fundamentals,Technologies,ApplicationandEconomics,ErichHau,ISBN:3540570640;(April30,2000)

Yawsystemtorsional mode

Drivetraintorsional oscillation

IEC Design Envelope

IEC 61400 defines a standard design envelope for

different design classes. g

Assumes most extreme conditions for which a 20 year

design life can be maintained.

Air density 1.225 kg/m3, shear coefficient of 0.2 AND

IECIIIB IECIIIA IECIIB IECIIA IECIB IECIA

Mean WS 7.5 7.5 8.5 8.5 10 10

TI@15m/s 16% 18% 16% 18% 16% 18%

V50 - 3s 52.5 52.5 59.5 59.5 70 70

8/

J une 2009

Loads Analysis Aero Elastic Model

9/

J une 2009

Time Series

Blade

Root

B

Main Shaft

R

T

Tower Top

Load

Time Series

Wind speed

Parameter I

u

,,z

0

10/

J une 2009

Wind Turbine Performance

Power Curve - Electrical power as a function of wind speed Power Curve Electrical power as a function of wind speed

1,200

1,400

1,600

r

(

k

W

)

Rated

Cut-out

Rated Power

400

600

800

1,000

E

l

e

c

t

r

i

c

a

l

P

o

w

e

r

Cut-in

Windspeed

Rated

Wind speed

Wind speed

0

200

0 5 10 15 20 25

Wind Speed (m/s)

EWind speed

Capacity Factor Annual yield / max possible (nameplate) Capacity Factor Annual yield / max possible (nameplate)

Energy in the Wind

(1/2 V

3

S) (1/2 V

3

S)

Captured Energy

(1/2 V

3

S cp)

Wind Distribution

11/

J une 2009

( p)

Annual Energy

Production (AEP)

Power Curve

Energy

Specific Yield Comparisons

SpecificYield kWHrperkg

Key turbine design metric Keyturbinedesignmetric

Yielddrivenbyrotorsweptarea

&captureefficiency

Weight of similar technology Weightofsimilartechnology

WTGsproxyforcost

Weightscalesfasterthanpower

rating

Neednewtechnologyto

decreasepuweightandimprove

COE

12/

J une 2009

St ti ti l th d

Analysing the wind

Statistical methods

(1)

Once the roughness length and the according

height exponent a is estimated, the formula (1)

gives the wind speed (v

2

) in a projected height (h

2

):

=

1

2

1 2

h

h

v v

(2)

Because the estimation of a is subjective, the

following formular gives an objective way of

calculating the height exponent out of two different

heights of measurement:

( )

( )

2 1

2 1

ln

ln

h h

v v

=

Further formulas for calculation of wind

characteristics:

( f C )

V

ref

=5 x V

m

V

e1

=0.75 x V

e50

(3)

(4)

g

(Empiric formulas according IEC standards)

V

e50

=1.4 x V

ref

( )

(5)

13/

J une 2009

Tech Improvements

Scale

5MWmachinesontheGreatPlains

GWscalelandprojects

Logistics:insitublade&towermfg

PowerTrain

Compact1stageintegratedgearbox,

90kWhr/kgspecificyield

p g g g

bearings,generator

Directdrive

PMgenerators

WTCompositesSheathed

SpaceFrameTower

BendTwistCoupledBlades

Controls

FullMVpowerconversion

Multivariablemodelbasedcontrols

Loadmitigation&damping

Cyclic&independentbladepitchcontrol

Blades

Largerrotors,higheffairfoils+10%CF

Loadmitigatingsweepandflaptwistcoupledblades

A t t d b fib & bl d t

Medium Speed PM Monocoque Load

14/

J une 2009

Automatedcarbonfibersparcap&bladeroot

Onsitebladeinfusion

MediumSpeedPM

Drivetrain

MonocoqueLoad

BearingNacelle

2 blade machines have higher tip speed ratios

2-Blades: Back to the Future?

Nordic1000

2 blade machines have higher tip speed ratios

rotate 25-30% faster: power with less torque

more blade noise

3 blade turbines dominant in EU: less noise visual esthetics 3 blade turbines dominant in EU: less noise, visual esthetics

Eliminates weight/cost of 3

rd

blade - decrease in Cp

compensated by slightly longer blades

Teetered hub minimizes bending loads on the mainshaft /gears

Simplified installation logistics

Potential 25% weight/cost advantage: Technology for COE driven markets e.g.

Optimized3blade Optimized2blade

g g gy g

Great Plains, Northern China, Offshore?

15/

J une 2009

New Innovation

FloDesign Turbine

16/

J une 2009

Venturi + Mixer/Ejector

(Mass)

Coriolis Wind VAWT

(Israel)

Wind Turbine Electrical Conversion

Industry Evolution Industry Evolution

Type 1: Squirrel-cage induction generator -

Fixed speed stall regulated turbine

generator

Plant

Feeders

Fixed speed stall regulated turbine

Limited LVRT and pf capability

T 2 W d t i d ti t ith i bl t

PF control

capacitors

generator

Plant

Feeders

Type 2: Wound rotor induction generator with variable rotor

resistance

Fixed speed variable pitch turbine

Slip power

as heat loss

PF control

capacitors

ac

to

dc

Plant

F d

Type 3: Doubly-fed wound rotor induction generator -

Limited variable speed variable pitch turbine

generator

Feeders

ac

to

dc

ac

to

dc

Type 4: Full power converter interface

Full variable speed variable pitch turbine

partial power

generator

Plant

Feeders

ac

to

d

ac

to

d

17/

J une 2009

full power

dc dc

Rapidevolution of Grid Codes: e-on Vattenfall

Grid Codes

Power & Frequency Operating Range

Rapid evolution of Grid Codes: e on, Vattenfall,

FERC/WECC, HQ, UK, ESB, ...

Initiated by e-on 2001

LVRT/ZVRT fault ride-thru & transient volt support pp

Reactive power specs

Power vs, Frequency

Germany

1.1 pu

1.15 pu

For Britain, Reactive Power required

Alberta Alberta

Austr

alia,

Albert

a

Alberta Alberta

VARSupport

VoltageTransientRideThruRequirements

Alberta,

Phillipines

, LIPA,

NSP,

PSCO,

Italy

Britain,

Scotland,

Thailand,

Turkey,

ERCOT,

PG&E

and the

rest on

LHS

V

o

l

t

a

g

e

(

k

V

)

1 pu

1.05 pu

Rated Power, Continuous

For Britain, Reactive Power required

is the same as that for the reduced

output power (poorer pf)

Ontario,

LIPA, NSP,

PG&E and the

rest on RHS

Iris

h,

Gr

ee

ce

an

d

the

res

t

on

LH

S

Britain, Irish,

Scotland,

Alberta,

Greece,

Phillipines,

Thailand,

Turkey

Austr

alia,

ERC

OT,

PSC

O,

Italy

and

rest

on

RHS

Common,

Except

Australia,

Ontario

(upto upf)

Insert another image

Irish,

Greece and the rest on

LHS

Irish, Greece

0.95 pu

0.875 pu

0.9 pu

Irish, Alberta, Greece

Austr

alia

and

RHS

Alberta

For ERCOT, at lower powers, Reactive

according to capability (poorer pf)

For Germany, any power level, duration

not specified. (assumed continuous)

18/

J une 2009

Power Factor

0

.

8

5

0

.

9

0

.

9

51

0

.

9

5

0

.

9

0

.

8

5

Over Excited Under Excited

Mimic thermal plants freq droop, var support

Grid (Friendly) Integration

59.50

60.00

3 GW wind w/ new

active power

controls

59.50

60.00

3 GW wind w/ new

active power

controls

Mimicthermalplants freqdroop,varsupport

Powerelectronicshavechangedwindtechnology

fromadetrimenttoanattribute

ZVRTfaultridethrutoberequiredbyFERC

58.50

59.00 HQ Base case w/o

wind - UF Load

Shed at 58.5 Hz

1 GWwind w/o

58.50

59.00 HQ Base case w/o

wind - UF Load

Shed at 58.5 Hz

1 GWwind w/o

Reactivepowercontrol voltageregulation,VAR

supportw/opower

Activepowercontrol ramprates,powercurtailment,

power droop W/ frequency virtual inertia

HydroQuebec VirtualInertia

58.00

58.0 a fbul 90 Load 220.0 1 1 60.0

58.0 b fbul 90 Load 220.0 1 1 60.0

58.0 c fbul 90 Load 220.0 1 1 60.0

58.0 d fbul 90 Load 220.0 1 1 60.0

Time( sec )

0.0 30.0

1 GW wind w/o

new controls

58.00

58.0 a fbul 90 Load 220.0 1 1 60.0

58.0 b fbul 90 Load 220.0 1 1 60.0

58.0 c fbul 90 Load 220.0 1 1 60.0

58.0 d fbul 90 Load 220.0 1 1 60.0

Time( sec )

0.0 30.0

1 GW wind w/o

new controls

powerdroopW/frequency,virtualinertia

10%PowerIncrease

VoltageatPOI

WindPlantVoltage

F

r

e

q

u

e

n

c

y

(

H

z

)

P

o

w

e

r

(

k

W

)

4%FrequencyReduction

WindPlantPowerOutput

Average Wind Speed

19/

J une 2009

ColoradoGreen220kVBusVoltageRegulation

ActivePowerRampRateControl GE/ESBIreland

AverageWindSpeed

2001 NYISO Day Ahead Forecast Error (F-A) J anuary

Wind in New York

1500

2500

3500

W

E

r

r

o

r

Load Error (F-A)

Wind Error (A-F)

Total Error (F - A)

-1500

-500

500

1 49 97 145 193 241 289 337 385 433 481 529 577 625 673 721

Hour

M

W

NY RPS

25% renewables by 2013 (15% existing hydro)

10 % i d 3 3 GW hi bl / i h i ti

Summer Morning Load Rise - Hourly Variability

10+% wind 3.3 GW achievable w/ minor changes in operations

Day-ahead uncertainty w/ wind similar to load forecast

Wind improves post-fault response of interconnected grid

100

150

200

u

e

n

c

y

State Jun-Sep 7AM-9AM 1HR Delta Histogram

Largest Hourly Change

2575 MWwithout wind

With Day-Ahead

Wind Forecasting

Without Wind

Forecasting

Total variable cost reduction

(includes fuel cost, variable O&M, start-up

costs, and emission payments)

$ 430M $ 335M

Total variable cost reduction per MW-hour

of wind generation

$48 / MWh $38 / MWh

$

95M

0

50

100

-3000 -2000 -1000 0 1000 2000 3000

F

r

e

q

2575 MW without wind

2756 MW with wind

NYS Benefits

$48/MWhr of Wind Energy Production Cost

$50/MWhr Reductionin Wholesale Generation

Wind revenue $ 315M $ 305M

Non-wind generator revenue reductions $ 795M $ 960M

Load payment reductions

(calculated as product of hourly load and

the corresponding locational spot price)

$ 515M $ 720M

MW

Load Load-Wind

20/

J une 2009

$50/MWhr Reduction in Wholesale Generation

Costs

Annual Operating Cost Impacts

for 2001 Wind and Load Profiles

Wind Forecasting

Eltra, Denmark - 2000 Study

1.9GW onshore farms, 16% consumption

3.4TWh produced, 1.3TWh miscalculated (38%)

Climatology-based forecast, inaccuracies up to 800MW

$12M i b l t (0 3 /kWh) $12M imbalance payments (0.3c/kWh)

Advanced forecast using a

combination of local

Current State-of-the-Art

combination of local

statistical models, and 3D

meso-scale climatology

Local statistical model + 3D climatology model - 10-15% mean abs

error for day-ahead and 5-10% error for 6 hr ahead forecasts

2005 regulations in Spain provide:

- Penalties for >20% error on 24hr production forecast

Incentives for <10%error over rolling4hr forecast - Incentives for <10% error over rolling 4hr forecast

2003 Cal ISO regulations unbiased hourly, daily forecasts settlement

monthly for net deviations at average rate

Utilities need short (<6h), med (24-36h) and long term (>72h) forecasts

21/

J une 2009

Site Specific Power Forecasting System

Wind Speed

Forecast

Power

Curve

Power

Forecast

Availabilit

y Model

Yield

Forecast

Assume we are

Down for 5 min(to)

K

W

K

W

Wind Speed

Wind Speed

For all Downtimes (t) > (to)

Calculate t- to

Calculate

Average(log(t- to ))

Stddev (log(t- to ))

Increment (to)

By 1 hour

while (to)

<=48

Hours

Create Lookup Table

(to) vs

By 1 hour

Geostrophic

Wind: going

from metmast to

turbine

3DMeso scale

Turbine power

curves validated

Turbine

availability

characterized

Integration to farm

production

(MAE<8%)

Multi-scale transfer

of meteorology:

Real-time Web

delivery system

Wind and

production forecast

accuracymetrics

Wind Speed

Wind Speed

Incorporating

Turbine Availability

Same procedure for

the Uptime

3D Meso-scale

Climatology

Statistical

Models

characterized

Adaptation to

machine

condition

of meteorology:

Turbine

Metmast

Farm

accuracy metrics

SCADA/Commercia

l Wind Forecasting

Forecast Accuracy Improved (MAE) (24hr : 17%->12%)

$2M Customer Value for 100 MW Plant

Web Interface Developed

22/

J une 2009

Offshore Wind

23/

J une 2009

Offshore Wind

176 MW Siemens/Bonus

Nysted DK

90MW Vestas

Barrow, UK

Offshore Technology

19 Projects, 900 MW Installed, shallow water

Nysted, DK

3 4 MW upwind configuration

5-6 MW turbines in prototype

80 m towers

P f

Monopile & gravity foundations < 15m

Many challenges turbine only 1/3 project costs

Performance

Average 45+% Capacity Factor

11 c/kwhr UK Thames Estuary site

SOA 5 MWviable in UK market

40 MW Bonus Middlegrunden

Farm in Copenhagen Harbor

24/

J une 2009

SOA 5 MW viable in UK market

p g

Middlegrunden Copenhagen Harbor

25/

J une 2009

Gamechanger: US Offshore Wind

Wind Map off Long Island

Virginia to Boston,

densest US population

with 12-16c/kWhr

LIPA planning 140 MW pilot offshore

with 12-16 c/kWhr

electric prices

Huge renewable asset

within 50 km of coast

and less than 50 m

depth

pa g 0 p ot o s o e

farm

US Offshore

depth

US Offshore

RPS in NY, Mass, Conn RPS will drive need for large scale

renewables

Deeper water foundation technology & higher power more

economic turbines needed

Great Lakes close to large load centers in US & Canada

Toronto, Cleveland, Detroit, Chicago, Milwaukee,

Lake Erie shallowest at 15-30 m

26/

J une 2009

Foundation technology 50-70 m would enable large

deployment need to withstand ice conditions

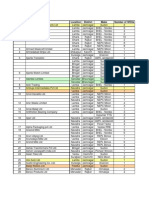

Offshore Machines

Nacel l e

Manufacturer Model

Power

(MW)

Rotor

(m)

Wei ght

+ Rotor

(kg)

Generator

Cf

(%)

# Uni ts

Enercon E112 4.5 112 440 WF Sync 44.0 5

Enercon E120 6 120 440 WF Sync 41.6 0*

Vestas V90 3 90 108 DFIG 43 5 9 Vestas V90 3 90 108 DFIG 43.5 9

Vestas NM110 4.2 110 214 DFIG 44.6 1

Vestas V120 4.5 120 214 DFIG 46.5 0*

GE 3.6s 3.6 104 280 DFIG 45.3 9

GE 3.6sl 3.6 111 265 DFIG 47.9 0*

Siemens/Bonus 3.6 3.6 107 200 Induction 46.4 1

Repower 5M 5 126 400 DFIG 46.3 1

Prokon Nord Multibrid 5 116 280 PM Sync 43.4 1

Vestas V90

3MW, 90m

Siemens Bonus 3.6

3.6MW, 107m

* planned upgrades

27/

J une 2009

Enercon E-112/120m,

4.5/6MW

Prokon Nord

5MW, 116m

Vestas NM110/V120m

4.2/4.5 MW

GE 3.6 MW 104/111m Repower 5M 5MW, 126m

Offshore Installation Techniques

Early Industry Approach

J i J k b i ll bi J umping J ack barge to install turbines not

designed for offshore wind industry

Separate cable-laying vessel additional

ship to charter

Turbine access using conventional boat

1m wave height limit.

Learning from Experience

Mayflower Resolution vessel purpose-designed to install offshore

wind turbines and infrastructure

Transports turbines, towers, blades to foundation and erects

Capable of laying cables

Specially-designed Windcat turbine access craft allows installation

and commissioning to continue in strong sea-states (2.5m wave

height)

Going Deeper

Floating platforms / turbines can be assembled at a port

Tugs to take assembly to wind farm location

Sec rel attachedto anchoringpoints

28/

J une 2009

Securely attached to anchoring points

Foundation Technologies

0 20m : Monopile & gravity foundations are most

J acket weight increases

with depth even at

constant MW rating

D th d d i ht

p g y

prevalent; Resonance constraints from rotor

operation leads to increasing tonnage &

manufacturing limits.

.

Depth dependence on weight

can be reduced substantially

with a floating foundation

system

Gravity Foundation

Near Shore

Monopile

20 m, 12 km

20 40m: Multi-legged jacket/tripod/braced pile

structures from O&G industry experience. J oint

Fatigue & O&M issues are main design drivers.

40m beyond : Floating Platforms: Mini-TLP / Spar

buoy based platforms under investigation; Primary

motivationis to de couple WTG weight

29/

J une 2009

motivation is to de-couple WTG weight

dependence from water depth.

Monopile Foundation System Design Drivers

Modal Analysis - 3.6s/sl Tower/Foundation

2

2

nd

Mode Desi gn Box:

1.2

1.6

y

(

H

z

)

6P +/-10%

(2X Blade

Pass Fr eq)

=

1

5

.

3

r

p

m

1

4

4

0

r

p

m

n

e

r

a

t

o

r

i

n

=

8

.

5

r

p

m

o

r

,

8

0

0

r

p

m

g

e

n

e

r

a

t

o

r

N

m

a

x

=

2

1

.

3

r

p

m

r

o

t

o

r

,

2

0

0

0

r

p

m

g

e

n

e

r

a

t

o

r

g

f

1

>1.607

0.8

F

r

e

q

u

e

n

c

y

3P +/-10%

(Blade Pass Fr eq

N

r

t

d

=

r

o

t

o

r

,

g

e

n

N

m

i

r

o

t

o

g

N

0

0.4

0 0 2 0 4 0 6 0 8 1 1 2 1 4

1P +/-10%

(Rot or Pass Fr eq

1

st

Mode Desi gn Box: 0.28< f

0

>0.383

n = rotor speed

nR = Rated

rotor speed

Note: Range for f1 depends on chosen rated rpm

0 0.2 0.4 0.6 0.8 1 1.2 1.4

Rel ati ve Rotor Speed (n/n R)

30/

J une 2009

Eigen Frequency Often Primary Driver for Monopile Designs

Nysted Rdsand

72 foundations: 1300 tons +500 tons ballast at depths of 7 12 m

31/

J une 2009

Source: http://www.aarsleff.com/internet/acms.nsf/Webpages/168241DB8B190997C1256D2B0029822E

72 foundations: 1300 tons + 500 tons ballast at depths of 7-12 m

Deep(er) Water Foundations

Quad Jacket - Beatrice Blue H

32/

J une 2009

Principle Power

Electrical BOP

Switchgear protection and control gear requires shelter for low

Radial 33 kV collector system

Switchgear, protection, and control gear requires shelter for low

maintenance and 20 year design life.

Need shelter in case someone gets stranded on the platform.

Emergencypower supplyreqd for stormconditions

Radial 33 kV collector system

Emergency power supply reqd for storm conditions

High capacitances of sea cables - reactive compensation and

regulation can play a substantial role in system design.

Transmission

Connection

x

x

x

x

x x x

CBs

33kV

Collector ESP

(500MW block)

Collector Circuits

1-7

8-14

15-21

22-28

70 76

x x

400kV

Shore Connection

(500MW block)

x x

132kV

x x

CB

132kV

System Layout for 500MW UK Farm

BOP Esti mate

Equi pment Cost Total

x Transformer

Disconnect/

Earthing Switch

70-76

77-84

Disconnect/

Earthing Switch

Transformer

Horns Rev 180 MW ESP

500 MW ESP (electrical equipment) $12,925,000

500 MW ESP (platform) $32,075,000 $45,000,000

33 kV Cable (84 miles) $25,000,000

33 kV Cable installation and burial (84 miles) $33,000,000

115 kV Cable (8 miles submarine, 6 miles land) $64,000,000

115 kV C bl I t ll b i $21 000 000 $143 000 000

33/

J une 2009

115 kV Cable - Install submarine $21,000,000 $143,000,000

Total $188,000,000

Transmission Options, UMass

UK Offshore 500MW Farm Thames Estuary

Assumptions

Next-gen turbines: 4, 5, 6, or 7 MW

Swept Area: 2.6 m

2

/kW (approx. same as 3.6sl)

Specific Weight: 55 kg/kW

Tip clearance to water: 25m

Soil Profile from GunFleet Sands

12 m water depth, 20 km to shore

90 m/s tip speed p p

4 MW 5 MW 6 MW 7 MW

# Turbines 125 100 83 71

Rotor (m) 116 130 142 153.5

Hub Height (m) 83 90 96 102

Model Inputs

UK economics structure w/ 10.25 c/kWhr

Tower Top Mass (tonnes) 220 275 330 385

Yield (MWhr) 15600 19500 23400 27650

Capacity Factors 44.5% at Gunfleet 9.3m/s at 78m

After Tax Unlevered IRR =9.5%

Foundation & Tower costs f(MW size)

Civil installation costs f(MW size)

Electrical BOP costs f(MW size)

ModelOutput

Wind Farm Price/MW f(MW

Size)

34/

J une 2009

CSA costs f(MW size)

Economics of 500 MW Offshore Wind Park

Assumptions Windfarm Price vs Turbine Size Assumptions

Nextgenturbines:4,5,6,or7MW

SweptArea:2.6m

2

/kW

SpecificWeight:55kg/kW

Windfarm Price vs. Turbine Size

1350

1400

1450

C

o

s

t

(

$

)

270

2.80

2.90

r

M

W

Tipclearancetowater:25m

ThamesEstuary 12mwaterdepth,20kmtoshore

90m/stipspeed

1200

1250

1300

1350

W

i

n

d

f

a

r

m

C

a

p

i

t

a

l

C

2.40

2.50

2.60

2.70

C

a

p

i

t

a

l

C

o

s

t

p

e

r

(

$

/

M

W

)

InstallationCostsvs

T bi R ti (MW)

ElectricalBOPCostsvsTurbineRating

$170M

$180M

$190M

P

C

o

s

t

1150

4 5 6 7

Turbine Rating (MW)

W

2.30

500MW Wind Farm Breakdown

$1.2B Total w/ 5MW Turbines

35%

16%

12%

Turbines

Foundations &Towers

Foundation Costs vs Turbine Rating

TurbineRating(MW)

$140

$160

$180

$200

$220

$

M

M

$150M

$160M

3 4 5 6 7 8

TurbineMW

B

O

12%

15%

16% Foundations & Towers

CSA

Construction & Installation

BOP Electrics

Project Other

Foundation Costs vs Turbine Rating

550

600

650

700

750

800

850

900

950

1000

C

o

s

t

(

K

$

)

60

80

100

120

140

160

180

200

F

a

b

C

o

s

t

(

K

$

/

M

W

)

$100

$120

$140

3 4 5 6 7 8

35/

J une 2009

%

10%

400

450

500

GE 4 MW uni t GE 5 MW uni t GE 6 MW uni t GE 7 MW uni t

0

20

40

GW Scale Wind

10 MW Turbines

180 m rotor diameter

D i d2 bl d hi Downwind 2 blade machine

Flexible compliant blades

Flow control blades

Hi h /ti l it 100 / High rpm/tip velocity > 100 m/s

Space frame structure

Multivariable damping controls

40 t d th f d ti 40 m water depth foundation

Hurricane ride-thru capability

EU Upwind R&D Program

Can the economics work?

36/

J une 2009

Wind Energy

Systems

Cornell

12 J 2008

Systems

12 J une 2008

J P Lyons - CTO Novus Energy Partners

20% US Wind Vision

2030 DOE, AWEA, 20% Energy Roadmap

Black & Veatch US Wind Supply Curve

300+ GW, 15% CAGR, 25 years

$60B investment in Transmission

Benefits (2030):

- 50% reduction NG electric gen

- 18% reduction in coal gen

- 7500 MMTCE cumulative carbon reduction

- 17% water use reduction for west generation

- 150,000 direct jobs created

Great Plains Wind

Lamar, CO Lamar, CO

38/

J une 2009

US Wind Resource

High Penetration Wind Beyond 10%

Fast - Generation Smoothing Slow - Generation Firming Fast Generation Smoothing Slow Generation Firming

+

Vref

(fromgrid operator)

Ihs [A B]

Line Drop Compensation

Vhs

Vhs max

Verror

-

High Side Voltage Limiter

QB up

(MVAr)

Vhs ref

Vhs min

Vhs

-

Qi

(to N WTGs)

Voltage Regulation Mode

-

Y

switch delay

(for sim.

model)

deadband

Regulation

Mode

Selection

Qtotal

Qshunt

Qwtgnet

fromSCADA:

N WTGs on-line

N

+

+

+

Qmax=Bma+N*Qimax

Qmin=Bmin+N*Qimin

anti-windup

on Qmax/min

PFAref

(fromgrid

operator)

Ihs

[A B]

PF Calculation with Line

Drop Compensation

Vhs

+

+

PFAc

-

PFAerr

anti-windup

on Vhs max/min

Power Factor Regulation Mode

Kppf +

Kipf/s

1

N

1

s

If Qerr1 >0

then

out =Qerr1

else

reset

integrator

Qerr1 out

reset

If X1 >

MSC/Rtol

then

disconnect

L or

connect C

Switched

L or C?

X1

reset

-

+

+

QB down

(MVAr)

If Qerr2 <0 If X2 <

-

+

Kpv

1 +sTv

KiV

s

1 - sTr/2

1 +sTr/2

s3 s1

s2

s4

Wind

Advanced Forecasting Advanced Power Controls

Y

1

s

Qerr2

then

out =Qerr1

else

reset

integrator

Qerr2 out

reset

2

-MSC/Rtol

then

disconnect

C or

connect L

Switched

L or C?

X2

reset

-

+ s5

Advanced Generation

Active Demand

Participation

Storage

Dispatchablepower generationoutput

Demand

Participation

Windor PV power generationoutput

39/

J une 2009

ISO

Time

r

s

)

Planni ng and

Operation Process

Technol ogy

Issues

Unit Dispatch

600

700

Capacity Valuation

1 Year

e

Lines

S

l

o

w

e

r

(

Y

e

a

r

Resource and

Capacity Planning

(Reliability)

0

100

200

300

400

500

0 2000 4000 6000 8000

Hour

M

W

Capacity Valuation

(UCAP, ICAP)

and

Long-Term Load

Growth Forecasting

Unit Commitment

and

Day-ahead and

Multi-Day

2001 Average Load vs Average Wi nd

20,000

25,000

30,000

o

a

d

(

M

W

)

1,000

1,200

1,400

1,600

p

u

t

(

M

W

)

1 Day

Day-Ahead

Scheduling

Multi Day

Forecasting

m

e

F

r

a

m

e

0

5,000

10,000

15,000

1 6 11 16 21

Hour

N

Y

I

S

O

L

o

0

200

400

600

800

W

i

n

d

O

u

t

p

July load Augus t load Sept ember load

July wind Augus t wind Sept ember wind

3000

Load Following

(5 Minute Dispatch)

T

i

m

Hour-Ahead

Forecasting

and

Plant Active Power

Maneuvering and

Management

500

1000

1500

2000

2500

3000

M

W

3 Hours

Frequency and

Tie-Line Regulation (

s

e

c

o

n

d

s

)

g

Real-Time and

Autonomous Protection

and Control Functions

0

500

1 61 121

Mi nu te s

September Morning August Morning May Evening October Evening April Af ternoon

10 Minutes

40/

J une 2009

(AGC)

F

a

s

t

e

r

(AGC, LVRT, PSS,

Governor, V-Reg, etc.)

Wind Energy Handbook

byTony Burton(Editor) David Sharpe Nick J enkins Ervin Bossanyi

References

by Tony Burton(Editor), David Sharpe, Nick J enkins, Ervin Bossanyi

Hardcover: 642 pages ; Dimensions (in inches): 1.58 x 9.82 x 6.70

Publisher: J ohn Wiley & Sons; ISBN: 0471489972; 1st edition (November 15, 2001)

Windturbines: Fundamentals, Technologies, Application and Economics

by Erich Hau

Hardcover: 650 pages

Publisher: Springer Verlag; ISBN: 3540570640; (April 30, 2000)

Large WindTurbines: Design andEconomics Large Wind Turbines: Design and Economics

by Robert Harrison, Eric Hau, Herman Snel

Paperback: 200 pages ; Dimensions (in inches): 0.57 x 10.86 x 8.66

Publisher: J ohn Wiley & Sons; ISBN: 0471494569; (J anuary 2001)

Wind Energy Explained

by J . F. Manwell, J on McGowan, Anthony Rogers

Hardcover: 512 pages ; Dimensions (in inches): 1.49 x 9.88 x 6.64

Publisher: J ohn Wiley & Sons; ISBN: 0471499722; 1st edition (J une 15, 2002)

Grid Integration of Wind Energy Conversion Systems

by Siegfried Heier, Rachel Waddington(Translator

Hardcover: 250 pages ; Dimensions (in inches): 1.01 x 9.92 x 6.80

Publisher: J ohn Wiley & Son Ltd; ISBN: 047197143X; (September 1998)

41/

J une 2009

y ( p )

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Shiyas 2021Dokument9 SeitenShiyas 2021Pakol PlNoch keine Bewertungen

- Tài Liệu Business Partner (MYENGLISHLAP)Dokument47 SeitenTài Liệu Business Partner (MYENGLISHLAP)jqmrtcs7xbNoch keine Bewertungen

- REVIEWER SUSTAINABLE (Midterm)Dokument8 SeitenREVIEWER SUSTAINABLE (Midterm)Khatelyn CodillaNoch keine Bewertungen

- Training Course WindDokument1 SeiteTraining Course WindDavid Enrique Alanis RojasNoch keine Bewertungen

- Wind Repowering in The NetherlandsDokument2 SeitenWind Repowering in The NetherlandswklunneNoch keine Bewertungen

- MB MarineSpace Concrete CenterDokument216 SeitenMB MarineSpace Concrete CenterMREFAATNoch keine Bewertungen

- Prony Monitoring Report 2Dokument22 SeitenProny Monitoring Report 2Amine LakouismiNoch keine Bewertungen

- Evidence Review of The Impact of Solar Farms On Birds, Bats and General EcologyDokument126 SeitenEvidence Review of The Impact of Solar Farms On Birds, Bats and General EcologyMário CarmoNoch keine Bewertungen

- Input To Roadmap For Offshore Wind Development in Vietnam PDFDokument56 SeitenInput To Roadmap For Offshore Wind Development in Vietnam PDFĐặng Thành LợiNoch keine Bewertungen

- WWEA Report Wind Energy 2050Dokument84 SeitenWWEA Report Wind Energy 2050Abhinav BhatnagarNoch keine Bewertungen

- Siemens Gamesa Onshore Product Portfolio enDokument49 SeitenSiemens Gamesa Onshore Product Portfolio enPhillippe FoixNoch keine Bewertungen

- PH-electric Power Plants 02 Visayas GRID Connected December 2021Dokument4 SeitenPH-electric Power Plants 02 Visayas GRID Connected December 2021Scriptlance 2012Noch keine Bewertungen

- Wind Energy in KuwaitDokument21 SeitenWind Energy in KuwaitHmaedNoch keine Bewertungen

- Amar Polymers - Manufacturing CapabilityDokument31 SeitenAmar Polymers - Manufacturing CapabilitybalaNoch keine Bewertungen

- World Hydrogen & Renewables Italy Green Hydrogen in Italy - Intelligence ReportDokument21 SeitenWorld Hydrogen & Renewables Italy Green Hydrogen in Italy - Intelligence ReportIsmael YahmiNoch keine Bewertungen

- Merged SEIADokument226 SeitenMerged SEIAOmarNoch keine Bewertungen

- TE Harsh Environment EBook - R2 - Single PagesDokument38 SeitenTE Harsh Environment EBook - R2 - Single Pagesjohn BronsonNoch keine Bewertungen

- The Wind Wake and Park Effect: Since A Wind Turbine Generates Electricity From The Energy inDokument9 SeitenThe Wind Wake and Park Effect: Since A Wind Turbine Generates Electricity From The Energy inKumar PranayNoch keine Bewertungen

- TedaDokument30 SeitenTedaPrabha KaruppuchamyNoch keine Bewertungen

- 10-Planning and Design of Wind FarmDokument42 Seiten10-Planning and Design of Wind FarmSein Win TunNoch keine Bewertungen

- ADVANCED 12 FINAL TEST ResueltoDokument8 SeitenADVANCED 12 FINAL TEST ResueltoLos locos de suyoNoch keine Bewertungen

- Amazon AssignmentDokument37 SeitenAmazon AssignmentJatin Goel100% (1)

- Organisational Study in ACC Private LTD: DeclarationDokument7 SeitenOrganisational Study in ACC Private LTD: DeclarationNaveen NaikNoch keine Bewertungen

- Reliability Assessment of Offshore Networks For Connection of Offshore WindfarmsDokument6 SeitenReliability Assessment of Offshore Networks For Connection of Offshore WindfarmsAmmar LateefNoch keine Bewertungen

- Deutsche Windguard: Company PresentationDokument34 SeitenDeutsche Windguard: Company PresentationyuliaNoch keine Bewertungen

- Flying Windmills (Or) Flying Electric Generator (Feg) TechnologyDokument17 SeitenFlying Windmills (Or) Flying Electric Generator (Feg) TechnologyAvinash moreNoch keine Bewertungen

- Guidelines For Assessing The Impact of Wind Farms On Birds and Bats PDFDokument118 SeitenGuidelines For Assessing The Impact of Wind Farms On Birds and Bats PDFSahida1980Noch keine Bewertungen

- Wind Energy CDM DataDokument40 SeitenWind Energy CDM DataSatyaveer Rhythem Pal100% (1)

- International Brotherhood of Electrical Workers, Local # 111'S Comments On 120-Day ReportDokument21 SeitenInternational Brotherhood of Electrical Workers, Local # 111'S Comments On 120-Day ReportAmy OliverNoch keine Bewertungen

- Power PlantsDokument17 SeitenPower PlantsGabriel SuguitanNoch keine Bewertungen