Beruflich Dokumente

Kultur Dokumente

DVP06SN11R Datasheet

Hochgeladen von

Bustamante PerroneOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

DVP06SN11R Datasheet

Hochgeladen von

Bustamante PerroneCopyright:

Verfügbare Formate

o

n

l

i

n

e

c

o

m

p

o

n

e

n

t

s

.

c

o

m

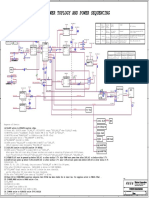

5011634601-SDE1

2006-12-13

DVP Slim

Digital I/O Extension Unit

Instruction Sheet

WARNING

This Instruction Sheet provides descriptions for electrical specifications, installation & wiring.

This is an OPEN TYPE Controller. The PLC should be kept in an enclosure away from airborne dust,

humidity, electric shock risk and vibration. Also, it is equipped with protective methods such as some

special tools or keys to open the enclosure, so as to avoid the hazard to users and the damage to the PLC.

DC type PLC never connect the AC main circuit power supply to any of the input/output terminals, as it will

damage the PLC. Check all the wiring prior to power up.

1 INTRODUCTION

1.1. Model Explanation & Peripherals

Thank you for choosing DVP-SS/SA/SX/SC series PLC. The 6 ~ 16 points extension offered by SS/SA/SX/SC

series make the maximum digital I/O extension including the MPU reach 128 points. In addition, maximum 8 special

modules (AD/DA/PT/TC/XA/RT) are extendable to DVP Slim series.

Nameplate Explanation

24Vdc 2W

MADE I N XXXXXX

CE

Delta PLC model name

Power input specification

Output module specification

Barcode, series No., Version

Model/Serial No. Explanation

S TYPE

DVP series

Points (input + output)

Model type

Version

M: Input point extension unit

N: Output point extension unit

P: I/O point extension unit

R: Relay

T: Transistor

N: No output module

11: DC power supply

12: AC power supply

Production No.

Production week

Production year (2005)

Production plant (Taoyuan)

Version No.

Model name

1.2. Product Profile and Outline

EXTENSION

PORT

60

8

8

9

10

44

7

5 6

25.20 3

.

0

0

9

0

.

0

0

3

.

0

0

3

1

2

3

POWER

D

V

P

-

L. V

3

.

0

0

9

0

.

0

0

6 5 8

60

3

.

0

0

25.20

2

7

3

3

1

4 4

POWER

L. V

EXTENSION

PORT

9

10

8

D

V

P

-

1. Status indicator (Power and low voltage) 6. Mounting hole of the extension unit

2. Model Name 7. Nameplate

3. Extension unit clip 8. Extension unit clip

4. Input/output terminal 9. DIN rail (35mm)

5. DIN rail clip 10. Extension port

1.3. Model Numbers

Input Unit Output Unit

Model

Point Type Point Type

Dimensions

(mm)

Weight (g)

DVP08SP11R 4 4 141

DVP16SP11R 8 8

Relay

162

DVP08SP11T 4 4 136

DVP16SP11T 8

DC Type

Sink/Source

8

Transistor

154

DVP08SM10N 8 100~120VAC 0 None 141

DVP08SM11N 8 0 None 162

DVP08SN11R 0 8 Relay 136

DVP08SN11T 0 8 Transistor 154

DVP06SN11R 0

DC Type

Sink/Source

6 Relay

25.2 x 90 x 60

200

2 ELECTRICAL SPECIFICATIONS

2.1 Electrical Specification

Model

Item

DVP08SM11N

DVP08SM10N

DVP08SN11R/T DVP08SP11R/T DVP16SP11R/T DVP06SN11R

Power Supply Voltage

24VDC (-15%~+20%) (the counter-connection protection towards the DC input power

polarity is included)

Motion Specifications Within 5ms of the momentary power loss, the device will keep on operating

Maximum Power

Consumption

1W 1.5W 1.5W 2W 1.5W

Insulation Resistance Above 5 M (500VDC between the ground and all the I/O points)

Noise Immunity

ESD(IEC 61131-2, IEC 61000-4-2): 8KV Air Discharge

EFT(IEC 61131-2, IEC 61000-4-4): Power Line: 2KV, Digital I/O: 1KV, Analog &

Communication I/O: 1KV

Damped-Oscillatory Wave: Power Line: 1KV, Digital I/O: 1KV

RS(IEC 61131-2, IEC 61000-4-3): 26MHz~1GHz, 10V/m

Grounding

The diameter of the grounding wire cannot be smaller than that of terminals L and N (if

numerous PLCs are used at the same time, make sure that each PLC is grounded

respectively to the ground poles)

Vibration/Shock

Immunity

International Standard Regulations: IEC1131-2, IEC 68-2-6 (TEST Fc)/ IEC1131-2 &

IEC 68-2-27 (TEST Ea)

Operation/Storage

Environment

Operation: 0~55(temperature), 50~95% (humidity), pollution degree: 2; Storage:

-40~70(temperature), 5~95% (humidity)

2.2 Input/Output Specification

Electrical Specification DC Input Point

Input type

Item

DC Type AC Type

Input Type DC (SINK or SOURCE) -

Input Impedance - 14.5Kohm/50Hz 12Kohm/60Hz

Input Voltage/Current 24VDC 5mA

85~132VAC 50~60Hz

9.2mA 110VAC/60Hz

OffOn, greater than 16VDC greater than 80VAC

Motion Level

OnOff, less than 14.4VDC less than 30VAC

Response Time

Default 10ms (Adjustable range of

0~15ms could be selected through

D1020 and D1021)

OffOn 15us

OnOff 20us

Circuit Isolation/

Operation Indication

Photocoupler/LED On

Maximum Off Current 1.8mA 2mA

Electrical Specification of Output Point

Output Type

Item

Relay-R Relay-R (*1) Transistor-T

Current Spec.

1.5A/1 point

(5A/COM)

6A/1 point

55 0.1A/1 point, 50 0.15A/1 point

45 0.2A/1 point, 40 0.3A/1 point

Voltage Spec.

250VAC, less than

30VDC

250VAC, less than

30VDC

30VDC

75VA (Inductive) 240VA (Inductive)

Max. Loading

90 W (Resistive) 150 W (Resistive)

9W

Response Time About 10 ms About 10 ms OffOn, 15us; OnOff, 25us

*1: Only for model DVP06SN11R

3 INSTALLATION & WIRING

3.1 Terminal Layout

DVP08SM11N DVP08SM10N

DVP08SN11R

DVP08SN11T

DVP08SP11R

DVP08SP11T

DVP16SP11R

DVP16SP11T

DVP06SN11R

S/S

X0

X2

X5

X6

X7

X3

X1

X4

COM

X0

X2

X5

X6

X7

X3

X1

X4

C0

Y0

Y2

Y5

Y6

Y7

Y3

Y1

Y4

S/S

X0

X2

X3

X1

C0

Y0

Y1

C2

C1

Y2

C3

C3

S/S

X0

X2

X3

X1

C0

Y0

Y2

Y3

Y1

Y4

Y5

Y6

X4

X6

X7

X5

Y7

C0

Y0

C1

C2

Y2

Y1

C3

Y3

C4

C5

Y5

Y4

3.2 System Assembly

Procedures:

1. Open the extension cover on the side of the

unit with a screwdriver so that the external

connector is exposed.

2. Raise the extension clips on the top and

bottom sides of the unit with a screwdriver.

3. Align the pins and holes in the four corners of

the control unit and extension unit, and insert

the pins into the holes so that there is no gap

between the units.

4. Press down the extension clip raised in step 2

to secure the unit.

o

n

l

i

n

e

c

o

m

p

o

n

e

n

t

s

.

c

o

m

3.3 Installation of the DIN rail

The PLC can be secured to a cabinet by using the DIN rail that is 35mm high with a depth of 7.5mm. When

mounting the PLC on the DIN rail, be sure to use the end bracket to stop any side-to-side motion of the PLC, thus

to reduce the chance of the wires being pulled loose. At the bottom of the PLC is a small retaining clip.

To remove it, pull down the retaining clip and gently pull the PLC

away from the DIN rail. As shown on the right:

When installing the PLC, make sure that it is installed in an

enclosure with sufficient space (as shown on the right) to its

surroundings so as to allow heat dissipation.

DVP

MPU

D

D

D D

D > 50mm

3.4 Input/Output points numbering order

No matter how many points of MPU, the input of the first I/O extension unit will start from X20 and output will start

from Y20.

PLC Models

Input

Points

Output

Points

Input

Numbering

Output

Numbering

MPU SS/SA/SX/SC 8 4/6 X0~X7 Y0~Y5

EXT1 DVP16SP11T 8 8 X20~X27 Y20~Y27

EXT2 DVP08SM11N 8 0 X30~X37 -

EXT3 DVP06SM11R 0 6 - Y30~Y35

System combined Example:

MPU EXT1 EXT2 EXT3 EXT4

EXT4 DVP08SP11R 4 4 X40~X43 Y40~Y43

Extension unit 3 DVP06SM11R will be used as 8 outputs, the higher 2 numbers of output points have no

corresponding output points.

Extension unit 4 DVP08SP11R will be used as 8 input points/8 output points, the higher part numbers of inputs

points and output points have no corresponding input/output points. It is recommended to place them at the end of

serial wiring, so that I/O points numbering will be continuous.

3.5 Wiring

22-16AWG

<1.5mm

Notes:

1. Please use 22-16AWG (1.5mm) wiring (either single or multiple core) for I/O

wiring terminals. The specification for the terminals is as shown on the left.

PLC terminal screws should be tightened to 1.95 kg-cm (1.7 in-lbs). Use

Copper Conductor Only, 60/75 C.

2. I/O signal wires or power supply should not run through the same multi-wire

cable or conduit.

3.6 Input Point Wiring

There are two types of DC type wiring: SINK and SOURCE, defined as follows:

SINK Mode SOURCE Mode

+24V 0V

DC Power Supply

S/S X0 X1 X2

Sink mode

+24V 0V

DC Power Supply

S/S X0 X1 X2

Source mode

3.7 AC Type Wiring

Input Circuit Connection 110V AC Input Specifications

Input voltage 85~132VAC 50~60Hz

Input impedance 14.5Kohm/50Hz 12Kohm/60Hz

Input current 9.2mA 110VAC/60Hz

greater than 80VAC

On/Off voltage level

less than 30VAC

OffOn 15us

Response time

OnOff 20us

85~132VAC

50/60Hz

Prox.

Sensor

COM X0 X1 X2

DVP08SM10N

Circuit isolation/Operation

indication

Photocoupler/LED On

3.8 Output Point Wiring

The Relay Output Circuit Wiring

1 Do not use this terminal

2 Fuse

3 Reverse-current protection diode *1

4 External mechanical interlock *2

5 Emergency stop

6 Surge absorber(0.1uf capacitor+100~120ohm

resistor) *3

7 Inductive load

8 Incandescent lamp

9 DC power supply

MC2 MC1

9

10

C0 C1 Y0 Y4 C2 Y2 Y3 Y5 Y1

5 2

3 7

8

1

6

7

2

5 4

MC2 MC1

10 AC power supply

*1: This PLC does not have any internal protection circuitry on the relay outputs. For switching direct current on

inductive loads, a reverse-current protection diode should be installed in parallel with the load. The relay contact

life decreases significantly if this is not done.

The reverse-current protection diode needs to satisfy the following specifications.

- The diode is rated for maximum reverse voltage of 5~10+ times the load voltage.

- The forward current is more that the load current

*2: Ensure all loads are applied to the same side of each PLC output, see above figure. Loads which should

NEVER simultaneously operate(e.g. direction control of a motor), because of a critical safety situation, should

not rely on the PLCs sequencing alone. Mechanical interlocks MUST be fitted to all critical safety circuits.

*3: This PLC does not have any internal protection circuitry on the relay output. For switching AC on inductive loads,

a surge absorber (0.1uF + 100ohm to 120ohm) should be installed in parallel with the load. The relay contat life

decreases significantly if this is not done. Besides protecting the internal circuity of the PLC, a surge absorber

decreases the noise emissions to the load.

The Transistor Output Circuit Wiring

1 Do not use this terminal

2 Emergency stop

3 Fuse

4 External mechanical interlock

5 DC power supply

6 Incandescent lamp

7 Reverse-current protection diode, *1

8 Inductive load

MC2 MC1

C0 C1 Y0 Y4 C2 Y2 Y3 Y5 Y1

5 7 8

1

6

6

4

MC2 MC1

2

3

3

9

9 Resistive load

*1: Ensure all loads are applied to the same side of each PLC output, see above figure. Loads which should

NEVER simutaneously operate (e.g. direction control of a motor), because of a critical safety situation, should

not rely on the PLCs sequencing alone. Mechanical interlocks MUST be fitted to all critical safety circuits.

*2: Transistor outputs use internal zener diode(39V) as protection circuitry. When driving the inductive load with

transistor output, a reverse-current protection diode can be installed in parallel with the load if necessary.

The reverse-current protection diode needs to satisfy the following specifications.

- The diode is rated for maximum reverse voltage of 5 to 10+ times the load voltage.

- The forward current is more than the load current.

4 TRIAL RUN

4.1. Before Turning ON the Power

After wiring, be sure to check the items below before turning ON the power supply to the PLC.

Item Description

Unit mounting status

- Does the unit type match the device list during the design stage?

- Are all of the units firmly attached?

Power supply

- Is operating voltage supplied correctly?

- Is the power supply cable properly connected?

- Are both voltage and polarity connected correctly for each connection?

- Protection against excess current: when overloaded, output voltage lowers.

Although the output voltage will return to normal when the load returns to normal, be

careful as long overloads or short-circuits will cause deterioration or destruction of

internal elements.

- Attaching additional power supply units in parallel is not allowed! It may destroy

internal elements and the load of the power supply.

Check input/output

terminals

- Does the wiring of connector and terminal match?

- Is the operating voltage of I/O correct?

- Are the connectors of I/O properly connected?

- Is the wire size correct?

Note: These precautions concern the DVP-PS01/PS02 power supply unit specifically.

4.2. Turning the Power ON

After checking the items given on the section 5, perform the trial operation by adhering to the following procedure.

1. Check POWER LED at the front of the PLC extension unit.

2. Check LV LED at the front of the PLC extension unit.

4.3. Check Communication with PLC control unit

After Power on and PLC is completing initial setup. The total number of extensive input/output points will be stored in

special data registers of D1142 and D1143. Please check D1142 and D1143 to confirm the adding extension unit is

connecting with control unit normally.

5 TROUBLESHOOTING

5.1 All LEDs are OFF

1. Check the power supply wiring.

2. Check if the power supplied to the PLC control units is in the range of the rating. Be sure to check the

fluctuation in the power supply.

3. Disconnect the power supply wiring to the other devices if the power supplied to the PLC control unit is

shared with them.

a) If the LEDs on the PLC control unit turn ON at this moment, the capacity of the power supply is not

enough to control other devices as well. Prepare another power supply for other devices or

increase the capacity of the power supply.

5.2 Diagnosing Input Malfunction

1. Check the wiring of the input devices (input indicator LEDs are OFF)

a) Check that the power is properly supplied to the input terminals.

If the power is properly supplied to the input terminal, there is probably an abnormality in the PLCs

input circuit. Please contact your dealer.

If the power is not properly supplied to the input terminal, there is probably an abnormality in the

input device or input power supply. Check the input device and input power supply.

2. Check the input condition (input indicator LEDs are ON)

a) Monitor the input condition using a programming tool.

If the input monitored is OFF, there is probably an abnormality in the PLCs input circuit. Please

contact your dealer.

If the input monitored is ON, check the program again. Also, check the leakage current at the input

devices (e.g. two-wire sensor) and check for the duplicated use of output or the program flow when

a control instruction such as MC or CJ is used.

3. Check the settings of the I/O allocation.

5.3 Diagnosing Output Malfunction

1. Check the wiring of the loads. (output indicator LEDs are ON)

a) Check if the power is properly supplied to the loads.

If the power is properly supplied to the load, there is probably an abnormality in the load. Check

the load again.

If the power is not supplied to the load, there is probably an abnormality in the PLCs output circuit.

Pleas contact your dealer.

2. Check of output condition (output indicator LEDs are OFF)

a) Monitor the output condition using a programming tool.

If the output monitored is turned ON, there is probably a duplicated output error.

b) Forcing ON the output using a programming tool.

If the output indicator LED is turned ON, go to input condition check.

If the output LED remains OFF, there is probably an abnormality in the PLCs output circuit. Please

contact your dealer.

Das könnte Ihnen auch gefallen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Bewertung: 2.5 von 5 Sternen2.5/5 (3)

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsVon EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsNoch keine Bewertungen

- Phy Interface Pci Express Sata Usb30 Architectures 3.1 PDFDokument161 SeitenPhy Interface Pci Express Sata Usb30 Architectures 3.1 PDFakssreenathNoch keine Bewertungen

- EMC Fundamentals Sept 2006Dokument63 SeitenEMC Fundamentals Sept 2006goodgoliers01Noch keine Bewertungen

- DVP SS2 ManualDokument19 SeitenDVP SS2 ManualMUIFTIKHARNoch keine Bewertungen

- Access Control SystemDokument5 SeitenAccess Control Systemnjwaghmare7392Noch keine Bewertungen

- DVP-10SX PLC DeltaDokument2 SeitenDVP-10SX PLC Deltawilfredomolina100% (1)

- DVP-Slim Digitai IO Module Instruction SheetDokument2 SeitenDVP-Slim Digitai IO Module Instruction SheetAgnimuthuNoch keine Bewertungen

- Dvpes2 ManualDokument10 SeitenDvpes2 Manualmarie1320Noch keine Bewertungen

- SS Instruction Sheet-English-20060505 PDFDokument2 SeitenSS Instruction Sheet-English-20060505 PDFstgpereiraNoch keine Bewertungen

- Delta Dvp-Se I Mul 20130208Dokument20 SeitenDelta Dvp-Se I Mul 20130208daocongdablNoch keine Bewertungen

- Manual - Dvp48eh00r PDFDokument2 SeitenManual - Dvp48eh00r PDFMauro KowalczukNoch keine Bewertungen

- Delta PLC DVP SS ModelDokument4 SeitenDelta PLC DVP SS ModelTarun SonwaneNoch keine Bewertungen

- Delta DVP-ES2 I MUL 20121031Dokument20 SeitenDelta DVP-ES2 I MUL 20121031Rafael BispoNoch keine Bewertungen

- TD 62107Dokument10 SeitenTD 62107wtn2013Noch keine Bewertungen

- DVP20SX211RDokument8 SeitenDVP20SX211RcurielvicNoch keine Bewertungen

- TLP5214 Datasheet en 20151226Dokument20 SeitenTLP5214 Datasheet en 20151226andrewNoch keine Bewertungen

- LV47002PDokument9 SeitenLV47002PchichedemorenoNoch keine Bewertungen

- PLC DVP28SV11TDokument20 SeitenPLC DVP28SV11TSarah DoyleNoch keine Bewertungen

- Instruction Manual: Models 7EF and 7HF ControllersDokument48 SeitenInstruction Manual: Models 7EF and 7HF ControllerskmpoulosNoch keine Bewertungen

- TA8248KDokument12 SeitenTA8248Ksontuyet82100% (1)

- VFDL Frekvenciavalto ENGDokument16 SeitenVFDL Frekvenciavalto ENGreghieNoch keine Bewertungen

- Barber Colman 7ESDokument48 SeitenBarber Colman 7ESkmpoulosNoch keine Bewertungen

- PT-76 Series Temperature Controller Operation Manual - B0Dokument2 SeitenPT-76 Series Temperature Controller Operation Manual - B0jowegNoch keine Bewertungen

- DK PC3000 ModulesDokument11 SeitenDK PC3000 ModulessickosatNoch keine Bewertungen

- Tda 7379 Data SheetDokument7 SeitenTda 7379 Data SheetJCMNoch keine Bewertungen

- ES - EX Instruction Sheet English 20060704Dokument2 SeitenES - EX Instruction Sheet English 20060704Luu Manh SonNoch keine Bewertungen

- LF 351Dokument14 SeitenLF 351Ivan PetrovicNoch keine Bewertungen

- La 42102Dokument8 SeitenLa 42102buyadiNoch keine Bewertungen

- La4628 PDFDokument8 SeitenLa4628 PDFRICHIHOTS2Noch keine Bewertungen

- IC200MDD840 and 843 VersaMax Ten 24VDC Inputs Six Relay Outputs gfk2540 PDFDokument2 SeitenIC200MDD840 and 843 VersaMax Ten 24VDC Inputs Six Relay Outputs gfk2540 PDFJosé Alexis Valero VillanuevaNoch keine Bewertungen

- A314JDokument16 SeitenA314JHeriberto FloresNoch keine Bewertungen

- Man Xle Hexe104Dokument2 SeitenMan Xle Hexe104Joao RobertoNoch keine Bewertungen

- Tda 7293Dokument16 SeitenTda 7293Gerson FelipeNoch keine Bewertungen

- Solare DatasheetDokument25 SeitenSolare Datasheetfb1145Noch keine Bewertungen

- Dsine MCCBDokument27 SeitenDsine MCCBKarthikeyanNoch keine Bewertungen

- 25 ManualDokument1 Seite25 ManualDian SafariNoch keine Bewertungen

- Description Power Range: Analog Servo DriveDokument9 SeitenDescription Power Range: Analog Servo DriveElectromateNoch keine Bewertungen

- Man Xle Hexe105Dokument2 SeitenMan Xle Hexe105Joao RobertoNoch keine Bewertungen

- Instalation ManualDokument9 SeitenInstalation Manualjoseluisrosglz1678Noch keine Bewertungen

- Description Power Range: Analog Servo DriveDokument7 SeitenDescription Power Range: Analog Servo DriveElectromateNoch keine Bewertungen

- Small Outline, 5 Lead, High CMR, High Speed, Logic Gate OptocouplersDokument10 SeitenSmall Outline, 5 Lead, High CMR, High Speed, Logic Gate OptocouplersHeriberto Flores AmpieNoch keine Bewertungen

- Instruction Manual: Model 7SL High/Low LimitrolDokument48 SeitenInstruction Manual: Model 7SL High/Low LimitrolkmpoulosNoch keine Bewertungen

- Description: Eagle Quantum Premier Agent Release Module EQ2500ARMDokument2 SeitenDescription: Eagle Quantum Premier Agent Release Module EQ2500ARMFernando Zambrano San Martín0% (1)

- Description Power Range: Analog Servo DriveDokument7 SeitenDescription Power Range: Analog Servo DriveElectromateNoch keine Bewertungen

- 8 Pin Dip High Speed 1Mbit/S Transistor Photocoupler 6N135 6N136 EL450x SeriesDokument13 Seiten8 Pin Dip High Speed 1Mbit/S Transistor Photocoupler 6N135 6N136 EL450x SeriesLuis Angel CastreNoch keine Bewertungen

- Delta DVP-SV Sv2 I Mul 20130722Dokument19 SeitenDelta DVP-SV Sv2 I Mul 20130722nilyenmaNoch keine Bewertungen

- 20 W 2-Channel BTL AF Power Amplifier For Car Stereos: SANYO Electric Co.,Ltd. Semiconductor Bussiness HeadquartersDokument9 Seiten20 W 2-Channel BTL AF Power Amplifier For Car Stereos: SANYO Electric Co.,Ltd. Semiconductor Bussiness Headquartersfernandes66Noch keine Bewertungen

- 25 A 20Dokument9 Seiten25 A 20s_barriosNoch keine Bewertungen

- A5800 and A5801: Discontinued ProductDokument13 SeitenA5800 and A5801: Discontinued Productitamar_123Noch keine Bewertungen

- Ta 8050 PDokument9 SeitenTa 8050 PJuan Alamada Reynoso100% (1)

- Description Power Range: Analog Servo DriveDokument7 SeitenDescription Power Range: Analog Servo DriveElectromateNoch keine Bewertungen

- Description Power Range: Analog Servo DriveDokument7 SeitenDescription Power Range: Analog Servo DriveElectromateNoch keine Bewertungen

- La 42205Dokument7 SeitenLa 42205ban4444Noch keine Bewertungen

- STK433-890-E: 4-Channel Class AB Audio Power IC, 80WDokument10 SeitenSTK433-890-E: 4-Channel Class AB Audio Power IC, 80WSelvacellsNoch keine Bewertungen

- Viper 100Dokument8 SeitenViper 100SeanNoch keine Bewertungen

- I Sol TesterDokument29 SeitenI Sol TesterDrayton Mizael de SouzaNoch keine Bewertungen

- RCB1200 :: ROAL Living EnergyDokument10 SeitenRCB1200 :: ROAL Living EnergyroalscribdNoch keine Bewertungen

- AE Previous Papers EEEDokument9 SeitenAE Previous Papers EEESathiya RajNoch keine Bewertungen

- GoalZero YETI 400 SOLAR GENERATOR User GuideDokument2 SeitenGoalZero YETI 400 SOLAR GENERATOR User GuideSteven AlmerothNoch keine Bewertungen

- 936X002b 78510908V01 K-BOW Outdoor PSU 150W DatasheetDokument3 Seiten936X002b 78510908V01 K-BOW Outdoor PSU 150W DatasheetNataša Mihić BoskovićNoch keine Bewertungen

- 8.buck Boost ConverterDokument5 Seiten8.buck Boost Convertermohanrajgupta19Noch keine Bewertungen

- APB ManualDokument104 SeitenAPB ManualPatricio LlumiquingaNoch keine Bewertungen

- 136CT052019Dokument2 Seiten136CT052019Murali BuchammagariNoch keine Bewertungen

- EDC Unit 6 FETDokument30 SeitenEDC Unit 6 FETmuralitmpsNoch keine Bewertungen

- PIC16F872 - Data Sheet 28-Pin, 8-Bit CMOS Flash Microcontroller With 10-Bit A/D - 30221cDokument168 SeitenPIC16F872 - Data Sheet 28-Pin, 8-Bit CMOS Flash Microcontroller With 10-Bit A/D - 30221cGuillermo HernandezNoch keine Bewertungen

- Chapter 1-Introduction To Power SuppliesDokument7 SeitenChapter 1-Introduction To Power SuppliesBricksoe NgwenyaNoch keine Bewertungen

- HMI Industrial PC and Display 2015ENDokument88 SeitenHMI Industrial PC and Display 2015ENEric Castillo PonceNoch keine Bewertungen

- Acer Extensa 4220 4620 - WISTRON BIWA - POWER SEQUENCE PDFDokument1 SeiteAcer Extensa 4220 4620 - WISTRON BIWA - POWER SEQUENCE PDFLas DusNoch keine Bewertungen

- KiwiSDR Design ReviewDokument65 SeitenKiwiSDR Design ReviewA Daniel LazarescuNoch keine Bewertungen

- Cis Handout 2Dokument24 SeitenCis Handout 2Trung1980ttNoch keine Bewertungen

- Operating Instruction ZETADYN 3BFDokument194 SeitenOperating Instruction ZETADYN 3BFReaper68Noch keine Bewertungen

- Overview of Microcomputer Structure and Operation: Input Devic eDokument4 SeitenOverview of Microcomputer Structure and Operation: Input Devic efuad_randomNoch keine Bewertungen

- Instruction Manual For AT7328/7340 Dual Channel OscilloscopeDokument12 SeitenInstruction Manual For AT7328/7340 Dual Channel OscilloscopeanswetNoch keine Bewertungen

- 16Dokument6 Seiten16Isnaldi NasrulNoch keine Bewertungen

- Bry 56 ADokument9 SeitenBry 56 AJulianoLuterekNoch keine Bewertungen

- CABANTOG, Gerard John T. ECE20L-2 / A1 2019151106 Activity 1.1Dokument5 SeitenCABANTOG, Gerard John T. ECE20L-2 / A1 2019151106 Activity 1.1MALAKIPWETKONoch keine Bewertungen

- Chap10 13 tmr2 PWMDokument38 SeitenChap10 13 tmr2 PWMThanh LeNoch keine Bewertungen

- Bluetooth Keyboard Mouse Adapter - 12 Steps (With Pictures)Dokument12 SeitenBluetooth Keyboard Mouse Adapter - 12 Steps (With Pictures)husa flaviuNoch keine Bewertungen

- Lecture25 130418Dokument28 SeitenLecture25 130418Peter BalikNoch keine Bewertungen

- Shure fp42Dokument20 SeitenShure fp42Denis ZhuravelNoch keine Bewertungen

- Project Title: Wireless Power Transmission Using Tesla Coil AbstractDokument5 SeitenProject Title: Wireless Power Transmission Using Tesla Coil AbstractKalyan Reddy AnuguNoch keine Bewertungen

- Hitachi Plasma 32pd3000eDokument93 SeitenHitachi Plasma 32pd3000eVictor EricNoch keine Bewertungen

- Mercury Battery ReplacementDokument3 SeitenMercury Battery ReplacementAntonio CompanyNoch keine Bewertungen

- Nokia Lumia 925 - Service ManualDokument68 SeitenNokia Lumia 925 - Service Manualwds555Noch keine Bewertungen