Beruflich Dokumente

Kultur Dokumente

GE Mentor EM Weld Brochure

Hochgeladen von

dimachampion0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

120 Ansichten6 SeitenMentor EM for eddy current weld inspection makes inspections easier, more accurate, and faster. By allowing the workflows to be instantly accessible on the device, Mentor EM helps to ensure strict compliance with codes, guidelines, and standard practices.

Originalbeschreibung:

Originaltitel

GE Mentor EM Weld Brochure (1)

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenMentor EM for eddy current weld inspection makes inspections easier, more accurate, and faster. By allowing the workflows to be instantly accessible on the device, Mentor EM helps to ensure strict compliance with codes, guidelines, and standard practices.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

120 Ansichten6 SeitenGE Mentor EM Weld Brochure

Hochgeladen von

dimachampionMentor EM for eddy current weld inspection makes inspections easier, more accurate, and faster. By allowing the workflows to be instantly accessible on the device, Mentor EM helps to ensure strict compliance with codes, guidelines, and standard practices.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 6

Remotely collaborate with experts in real

time. Introducing Mentor EM for eddy

current weld inspection.

Mentor EM

More experience in every inspection.

This powerful new technology makes

eddy current weld inspections easier,

more accurate, and faster. By allowing

the workows to be instantly accessible

on the device, Mentor EM helps to

ensure strict compliance with codes,

guidelines, and standard practices.

Transforming Nondestructive Testing

Portable eddy current testing instrument with industry-dening signal-to-

noise ratio

Reduces need for paper and manuals

Large, bright, high-denition touchscreen that can be used while wearing gloves

No knobs, dials, or switches to mistakenly adjust during use

Superior IP rating and rugged cast magnesium housing to withstand harsh

work environments

Multiple alarm gates, which can be set to color or sound, to warn of possible defects

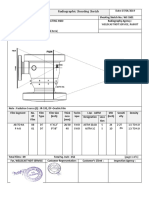

Specications

Battery Size 62 watt-hours/air transport compliant

Battery Life

4 hours for most conditions

90-minute charge time

Extended battery pack adds 6 hours

Generators

2 generators and 2 connectors

2 time slices max per generator

4 frequency simultaneous injection

Display

10.4" XVGA 1024 x 768

Projected capacitive touch

Frequency Range 10 Hz6 MHz

Sample Rate (max) 50 kHz

Receiver Gain 034 dB

Gain 0120 dB in 0.1 dB steps

Drive Voltage 0.5, 1, 2, 4, 8, and 16 VPP

Gates Output 2 per channel

Alarm Outputs

2 total, TTL levels, one per input

One LED on instrument face, audio through Bluetooth (headset protocol)

Operating Temperature -20 to 55C

Storage 8 GB SSD

Connectivity Wi-Fi; 6 Bluetooth channels

Dimensions

2.5 kg without modules; 295 mm x 230 mm x 60 mm

2.9 kg with 2-probe connector module and connectivity module

Image Formats BMP, JPG

Video Formats MPEG 4, Type 10

Workow Launcher

Calibrate for Paint Layer

Workow Description

Calibrate for Weld

Equipment Used

Picture/Video Instruction

Perform Inspection

Workow-On-Device

Instantly Collaborate

and Access Information

Connect to local network to

share data and collaborate

remotely with experts in

real time

Immediately download

the most up-to-date

procedures and workows

Bluetooth enabled

Mentor Create Software

Tailor on-device inspection workow

applications for technicians of all levels

Aid inspectors by placing photos,

procedures, and videos on device for

reference while setting up, acquiring

data, or analyzing data

Limit range of adjustments available

to the operator; and therefore limit the

opportunity to make errors

Use in Expert Mode as well as

Workow-on-Device mode

Weld Probes for All Use Conditions

Complete Line of Wide-Frequency Probes

Standard, high-wear, high-temperature, and cableized models for all job requirements

2013 General Electric Company. All rights reserved.

GEA31023 11/2013

Straight 90 Inline Tip 90 Right Angle Tip

Straight Probes Frequency Cable Length Disconnect

7/32" Straight 450 kHz2.5 MHz

6" 632-267-002

Probe

12" 632-267-012

3/8" Straight 60 kHz1.2 MHz

6" 632-266-002

632-266-008

12" 632-266-012

5/8" Straight 60 kHz700 kHz

6" 632-265-002

632-266-009

12" 632-265-012

90 Tipped Probes

7/32" inline, 1/4" drop 450 kHz2.5 MHz

6" 632-267-102

632-267-108

12" 632-267-112

3/8" inline, 1/4" drop 60 kHz1.2 MHz

6" 632-266-102

632-266-108

12" 632-266-112

5/8" inline, 1/4" drop 60 kHz700 kHz

6" 632-265-102

12" 632-265-112

5/8" 90, 1/4" drop 60 kHz700 kHz

6" 632-265-102

12" 632-265-112

High-Wear Straight Probes

3/8" High-wear (ceramic tip) 60 kHz1.2 MHz 632-266-011

5/8" High-wear (ceramic tip) 60 kHz700 kHz 6" 632-265-003 632-265-011

5/8" High-wear (SST) 60 kHz700 kHz 632-265-018

High-Temperature Probes

5/8" Straight Handle Length 6" 60 kHz700 kHz 632-265-008

Das könnte Ihnen auch gefallen

- PRACTICAL RESEARCH 2 - Q1 - W1 - Mod1Dokument13 SeitenPRACTICAL RESEARCH 2 - Q1 - W1 - Mod1Ma Fe Evangelista Galia77% (48)

- Phased Array Probes Application MatrixDokument1 SeitePhased Array Probes Application MatrixFethi BELOUISNoch keine Bewertungen

- E-Studio 205L, 255, 305, 355, 455 MFP Service HandbookDokument732 SeitenE-Studio 205L, 255, 305, 355, 455 MFP Service HandbookAnonymous gn8qxx66% (35)

- Diagbootx: // Public Release 1Dokument4 SeitenDiagbootx: // Public Release 1Tedy AdhinegoroNoch keine Bewertungen

- Question For Practice Oracle (11g) With AnswersDokument32 SeitenQuestion For Practice Oracle (11g) With AnswersAnonymous J8V2pZZ100% (4)

- High Temperature Ultrasonic ScanningDokument7 SeitenHigh Temperature Ultrasonic ScanningscribdmustaphaNoch keine Bewertungen

- RT Procedure 10.09.16Dokument9 SeitenRT Procedure 10.09.16mukeshsingh6Noch keine Bewertungen

- Jireh Circ It ScannerDokument2 SeitenJireh Circ It ScannerMarcos Kaian Moraes RodriguesNoch keine Bewertungen

- Itp AsntDokument33 SeitenItp AsntSYED FADZIL SYED MOHAMED100% (1)

- ASME Sección V - Artículo 6Dokument9 SeitenASME Sección V - Artículo 6Jhonathan ST100% (1)

- Asme NDT MethodDokument1 SeiteAsme NDT Methodkinglordofato100% (1)

- Visible Penetrant Examination Using The Water-Washable ProcessDokument6 SeitenVisible Penetrant Examination Using The Water-Washable ProcessERNESTO ENRIQUE FERNANDEZ BAPTISTANoch keine Bewertungen

- Lamtiation Ut ProcdureDokument12 SeitenLamtiation Ut ProcduremnmsingamNoch keine Bewertungen

- Api Ut Thickness Procedure PDFDokument7 SeitenApi Ut Thickness Procedure PDFShreekanthKannath100% (1)

- MPI Cal Cert-002 SampleDokument1 SeiteMPI Cal Cert-002 SampleJohn OLiverNoch keine Bewertungen

- Ut ReportDokument6 SeitenUt ReportVijay PandeyNoch keine Bewertungen

- LS - prt.TUB.073 Residual Magnetic Inspection MethodDokument6 SeitenLS - prt.TUB.073 Residual Magnetic Inspection MethodAlphonse YACKAMAMBO DIBACKANoch keine Bewertungen

- DMTA 20006 01EN - Rev - B COBRA - Scanner Users - Manual PDFDokument80 SeitenDMTA 20006 01EN - Rev - B COBRA - Scanner Users - Manual PDFDanny Milton Silva VasquezNoch keine Bewertungen

- P 11 CNDT JP41 Ut-Aws D1.1 Rev 07Dokument22 SeitenP 11 CNDT JP41 Ut-Aws D1.1 Rev 07Vimal MenonNoch keine Bewertungen

- Agpl QP RFT 03 PDFDokument8 SeitenAgpl QP RFT 03 PDFMaged Ali RaghebNoch keine Bewertungen

- Ultrasonic Testing of Tube To Tube SheetDokument6 SeitenUltrasonic Testing of Tube To Tube SheetDARSHIL RAJPURANoch keine Bewertungen

- Iso18563 1 2022Dokument54 SeitenIso18563 1 2022baurzhannNoch keine Bewertungen

- CMAP Reporting - Operating ManualDokument46 SeitenCMAP Reporting - Operating ManualJesus E ContrerasNoch keine Bewertungen

- Coded Marking Procedure - CM-01Dokument7 SeitenCoded Marking Procedure - CM-01carlosNoch keine Bewertungen

- Form PAUTDokument1 SeiteForm PAUTLuong Ho VuNoch keine Bewertungen

- Saferad ProcedureDokument19 SeitenSaferad ProcedureExsan OthmanNoch keine Bewertungen

- Larsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: LT/MSQ/P/UT/011Dokument11 SeitenLarsen & Toubro Limited MSQ Up Gradation (Epcc 1) Project: LT/MSQ/P/UT/011Saut Maruli Tua SamosirNoch keine Bewertungen

- Inspection Report Bifab Ut On Duplex Stainless Steel Piping PDFDokument11 SeitenInspection Report Bifab Ut On Duplex Stainless Steel Piping PDFquiron2014Noch keine Bewertungen

- Dye Penetrant ProcedureDokument8 SeitenDye Penetrant ProcedureTouil HoussemNoch keine Bewertungen

- UT Chapter 11Dokument70 SeitenUT Chapter 11knizam1971100% (1)

- Eddy Current Array TutorialDokument13 SeitenEddy Current Array TutorialsameerNoch keine Bewertungen

- E428Dokument6 SeitenE428valentinNoch keine Bewertungen

- PAUT Procedure EEISDokument13 SeitenPAUT Procedure EEISZakirUllahNoch keine Bewertungen

- Visual Examination Procedure: 1. PurposeDokument4 SeitenVisual Examination Procedure: 1. PurposeElvin MenlibaiNoch keine Bewertungen

- NDT Procedure BS EN 10160:1999 (Full Version Available From N-D-T.com)Dokument6 SeitenNDT Procedure BS EN 10160:1999 (Full Version Available From N-D-T.com)Mark BrailsfordNoch keine Bewertungen

- 4#600 Body RSSDokument1 Seite4#600 Body RSSRavi patelNoch keine Bewertungen

- Evaluation For Paut ASME 8 DIV 2Dokument3 SeitenEvaluation For Paut ASME 8 DIV 2Woodrow Fox100% (1)

- Lesson 3 - IsO 9712Dokument13 SeitenLesson 3 - IsO 9712Abdelaziz AbdoNoch keine Bewertungen

- Cp16 Issue Renewal and Recertification of PCN Levels 1 & 2 CertificatesDokument19 SeitenCp16 Issue Renewal and Recertification of PCN Levels 1 & 2 Certificatesndt_inspectorNoch keine Bewertungen

- Thickness Gauging Level 2 (Questions & Answers)Dokument3 SeitenThickness Gauging Level 2 (Questions & Answers)kingston100% (2)

- Computed Radiographic Testing (CRT) Qualification Report: Rev. ADokument12 SeitenComputed Radiographic Testing (CRT) Qualification Report: Rev. ATrung Tinh HoNoch keine Bewertungen

- Astm E1065 E1065m 20Dokument10 SeitenAstm E1065 E1065m 20Mohamed AboelkhierNoch keine Bewertungen

- PCN Training and Certification of PCN Level 2 and 3 Course Brochure - BIT - BINDT, 2020Dokument13 SeitenPCN Training and Certification of PCN Level 2 and 3 Course Brochure - BIT - BINDT, 2020AMITNoch keine Bewertungen

- Procedure of UT-TestDokument2 SeitenProcedure of UT-TestJohn ShermanNoch keine Bewertungen

- Asnt Level 2Dokument1 SeiteAsnt Level 2MohammedBujairNoch keine Bewertungen

- Se 797Dokument7 SeitenSe 797donaldoguerreroNoch keine Bewertungen

- D-p5-Bv-pd-005 - Paut, Issue 01, Rev 00 - Phased Array TestingDokument40 SeitenD-p5-Bv-pd-005 - Paut, Issue 01, Rev 00 - Phased Array TestingThinh NguyenNoch keine Bewertungen

- DN Wind Systems India Pvt. LTD.: Ultrasonic Procedure FOR Wind Mill TowerDokument23 SeitenDN Wind Systems India Pvt. LTD.: Ultrasonic Procedure FOR Wind Mill TowermaheshNoch keine Bewertungen

- MT Work InstructionDokument3 SeitenMT Work Instructionpandab bkNoch keine Bewertungen

- Demo SUMDokument27 SeitenDemo SUMRudolph RednoseNoch keine Bewertungen

- Silverwing RMS2 01Dokument4 SeitenSilverwing RMS2 01rubiodegoNoch keine Bewertungen

- Scan Plan (PAUT) For Taper Joints and K WeldsDokument4 SeitenScan Plan (PAUT) For Taper Joints and K WeldsRamakrishnan AmbiSubbiahNoch keine Bewertungen

- API 6A RadiographyDokument4 SeitenAPI 6A RadiographyminakshissawantNoch keine Bewertungen

- Ultrasonics Blank ReportDokument3 SeitenUltrasonics Blank ReportSteven GoughNoch keine Bewertungen

- Aws d1.1-UT Procedure For Back Strip T or Corner Joint PDFDokument6 SeitenAws d1.1-UT Procedure For Back Strip T or Corner Joint PDFnathgsurendraNoch keine Bewertungen

- Iso 5580-1985 Illuminators RT PDFDokument9 SeitenIso 5580-1985 Illuminators RT PDFMario Gaytan100% (1)

- Ultrasonic Examination Based Acceptance CriteriaDokument2 SeitenUltrasonic Examination Based Acceptance CriteriaAngelTinocoNoch keine Bewertungen

- LPT Spe QB 2Dokument6 SeitenLPT Spe QB 2Aruchamy SelvakumarNoch keine Bewertungen

- RTDokument14 SeitenRTaravindanNoch keine Bewertungen

- Industrial radiography A Complete Guide - 2019 EditionVon EverandIndustrial radiography A Complete Guide - 2019 EditionNoch keine Bewertungen

- PR-11146 - Brochure TM Optix MTS Brochure PR-11146Dokument8 SeitenPR-11146 - Brochure TM Optix MTS Brochure PR-11146lab RSUDPameungpeukNoch keine Bewertungen

- Foerster Defectomat BrochureDokument8 SeitenFoerster Defectomat BrochureDaniel OliveiraNoch keine Bewertungen

- Videojet 3340: Laser Marking SystemDokument2 SeitenVideojet 3340: Laser Marking Systemjoe dermawanNoch keine Bewertungen

- Evaluation and Selection of Sustainable Strategy For Green Supply Chain Management ImplementationDokument28 SeitenEvaluation and Selection of Sustainable Strategy For Green Supply Chain Management ImplementationMuhammad Dzaky Alfajr DirantonaNoch keine Bewertungen

- WDH-SL3 Iom M01M40N13-07 - 1542713324932Dokument72 SeitenWDH-SL3 Iom M01M40N13-07 - 1542713324932irwantino susilo100% (1)

- What Is A Stress Intensification FactorDokument7 SeitenWhat Is A Stress Intensification FactorMahendra RathoreNoch keine Bewertungen

- All Intervals From G For Guitar (Ear Training Exercise)Dokument1 SeiteAll Intervals From G For Guitar (Ear Training Exercise)dalcha100% (1)

- IC Project Report Dashboard 10673 0Dokument6 SeitenIC Project Report Dashboard 10673 0Anonymous Sls6WCF100% (2)

- MS Word 3Dokument2 SeitenMS Word 3Misha RaviNoch keine Bewertungen

- Caliper Xy MemoryDokument6 SeitenCaliper Xy MemoryA MuNoch keine Bewertungen

- ACPS CP S1 01 FDA SlidesDokument78 SeitenACPS CP S1 01 FDA SlidesBlueSagaNoch keine Bewertungen

- Direct Synthesis of Sodalite From Kaolin: The Influence of AlkalinityDokument7 SeitenDirect Synthesis of Sodalite From Kaolin: The Influence of AlkalinityIsye RahmaenaNoch keine Bewertungen

- SMO Senior 2017Dokument6 SeitenSMO Senior 2017Kanchit SaehoNoch keine Bewertungen

- Midterm rp - Nguyễn Phú Minh Nhật - 20202795Dokument1 SeiteMidterm rp - Nguyễn Phú Minh Nhật - 20202795Minh Nhật100% (1)

- Metron 05 CR DataDokument10 SeitenMetron 05 CR DatamkgohNoch keine Bewertungen

- GGGB6023 Tugasan Tutorial 3 - P69060 Mior SyazrilDokument5 SeitenGGGB6023 Tugasan Tutorial 3 - P69060 Mior SyazrilAmizan AbdullahNoch keine Bewertungen

- Vector AlgebraDokument7 SeitenVector AlgebraDeeeNoch keine Bewertungen

- Summative Test in Grade 10 Science PDF FreeDokument2 SeitenSummative Test in Grade 10 Science PDF FreeMalyn ReyesNoch keine Bewertungen

- X2IPI ManualDokument51 SeitenX2IPI ManualFadiliAhmedNoch keine Bewertungen

- Design and Implementation of Audio Transceiver Using Infrared Laser For Audio Signal DetectionDokument4 SeitenDesign and Implementation of Audio Transceiver Using Infrared Laser For Audio Signal DetectionGoitom HaileNoch keine Bewertungen

- ECA 2markDokument4 SeitenECA 2markthangarajelectresNoch keine Bewertungen

- Evaluation of Professional Bra Fitting Criteria For Bra Selection and Fitting in The UKDokument9 SeitenEvaluation of Professional Bra Fitting Criteria For Bra Selection and Fitting in The UKaqsa imranNoch keine Bewertungen

- Lecture 4: Expert Systems: What Is An Expert System?Dokument5 SeitenLecture 4: Expert Systems: What Is An Expert System?Zerihun BekeleNoch keine Bewertungen

- An Isogeometric Analysis Approach For The Study of Structural VibrationsDokument59 SeitenAn Isogeometric Analysis Approach For The Study of Structural VibrationsBharti SinghNoch keine Bewertungen

- Section 3 Quiz, Database Design ORACLEDokument8 SeitenSection 3 Quiz, Database Design ORACLEMostragNoch keine Bewertungen

- Midterm BUS510Dokument8 SeitenMidterm BUS510Ramesh KomarapuriNoch keine Bewertungen

- Earthquake EnginneringDokument11 SeitenEarthquake EnginneringkkkNoch keine Bewertungen

- EWAD-CF EEDEN15-435 Data Books EnglishDokument42 SeitenEWAD-CF EEDEN15-435 Data Books EnglishrpufitaNoch keine Bewertungen

- Adelio Lattuada TL10AV & TL10Dokument7 SeitenAdelio Lattuada TL10AV & TL10yaser radNoch keine Bewertungen