Beruflich Dokumente

Kultur Dokumente

NESST Technical Rules 2014 Final

Hochgeladen von

wetharena0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

52 Ansichten13 Seiten1. The document outlines the technical rules for the NESST racing series. It specifies rules for vehicles, including that they must be American made rear wheel drive cars between 101-110 inches in wheelbase.

2. Extensive details are provided around bodywork, bumpers, spoilers, nerf bars, interior and exterior sheet metal requirements.

3. Chassis and suspension components must remain stock, including the frame rails, control arms, spindles, bearings, brakes and steering components.

4. Minimum weight requirements are specified depending on engine type. Ballast weight rules are also outlined.

Originalbeschreibung:

Originaltitel

235321878 NESST Technical Rules 2014 Final

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument melden1. The document outlines the technical rules for the NESST racing series. It specifies rules for vehicles, including that they must be American made rear wheel drive cars between 101-110 inches in wheelbase.

2. Extensive details are provided around bodywork, bumpers, spoilers, nerf bars, interior and exterior sheet metal requirements.

3. Chassis and suspension components must remain stock, including the frame rails, control arms, spindles, bearings, brakes and steering components.

4. Minimum weight requirements are specified depending on engine type. Ballast weight rules are also outlined.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

52 Ansichten13 SeitenNESST Technical Rules 2014 Final

Hochgeladen von

wetharena1. The document outlines the technical rules for the NESST racing series. It specifies rules for vehicles, including that they must be American made rear wheel drive cars between 101-110 inches in wheelbase.

2. Extensive details are provided around bodywork, bumpers, spoilers, nerf bars, interior and exterior sheet metal requirements.

3. Chassis and suspension components must remain stock, including the frame rails, control arms, spindles, bearings, brakes and steering components.

4. Minimum weight requirements are specified depending on engine type. Ballast weight rules are also outlined.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 13

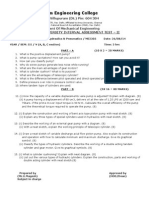

NESST Technical Rules 2014

***ALL CARS ARE SUBJECT TO RANDOM INSPECTION AT

AN TIME***

1! A""#$%e& '$&els an& ($&ies

a! All NESST racecars must be a rear wheel drive, American made 4

passanger car,maximum of 10! wheelbase with a minimum of

101!wheelbase" No convertibles or station wagons will be permitted"

(! #ord and $hr%sler from production %ears 1&'()000 with 10! wheelbase

or longer are permitted* +owever, the wheelbase must be shortened to 10!

b% cutting the center section of the frame rails e,uall% on both sides"

c! -nl% 1&. or newer /0 cars with a /(bod% frames and $amaros are

allowed"

&! The bod% must be stoc1 for the frame being used" All bod% parts must

remain stoc1 appearing" Steel or aluminum side panels onl%"

2! R$$) *+(e#,lass #$$)s will be -nl% stoc1 or stoc1 replacement

accepted-

.! /$$& +oods ma% be 2berglass, but must la% 3at at the stoc1 angle with no

rear opening" +ood must be secured with a minimum of 4 hood pins at all times- .

ac#$ss 0he )#$n0-

4! Bu'"e#s an& (u'"e# c$%e#s

a! All bumpers must be standard for the ma1e and model being used" 0odel

%rs from 1&.0()000" #ront and rear covers manditor%"

1! Ma2i'u' %en0 3in&$3 The vent window must measure maximum .!

from the base of the A pillar" 5ent window ma% not be tapered bac1* 0ust go

straight up the pillar"

4!5lass A full windshield is re,uired" 6uarter windows are allowed, but must be

made of clear pol%carbonate material onl%" 7ear windows allowed"

6! B$&7 s"$ile#s 8od% Spoilers Side s1irts are allowed between wheel

openings" The% must follow the contour of the bod% and ma% not be stepped or

angled" Side s1irts must ma1e ride height

8! Rea# s"$ile#s A rear,solid mounted spoiler ma% be used" 0ust not exceed

4! tall and ma% not extend be%ond the bod% panels of the car" An& (e clea#

le2an9 n$ si&es $n #ea# s"$ile#-

:! Ne#) Ba#s Nerf 8ars ma% be used between wheel openings at hub height"

The bars must be round or s,uare tubing, maximum one inch b% 0"1)4!, and s1in

tight to the bod% with no sharp edges, angles or points" Nerf bar ends must be

tapered or capped" $arriage t%pe bolts must mount inward" 9ol%carbonate rub rails

are allowed-

10! In0e#i$# Shee0 Me0al

a! All interior sheet metal must be a minimum 0"0))! steel" :rivers must be

separated from the engine and the trun1 area" #irewalls must be welded"

(! The front 2rewall must be in stoc1 location" No foot boxes"

c! The rear 2rewall must full% separate driver from trun1, and ma% go to rear

crossbar of rollcage, behind driver"

&! A full, stoc1 appearing 3oor pan must be used"

e! A 2ller panel must be used between the 2rewall ;roll cage upright< and the

right door" This panel must be straight to the frame rail = no bends or curves

11! ;#a'e < Chassis

a! All frames>chassis must be Stoc1 -E0" No repositioning, elongating, or

oversi?ing of an% mounting holes in the frame"

(! Two ;)< inch b% three ;@< inch b% 0"0@! magnetic steel tubing ma% be

used to replace the frame rails from the rear spring poc1et to the rear

bumper" The tubing must follow stoc1 dimensions of the frame being used"

Tubing must maintain a minimum ground clearance of 11!"

c! Anibod% cars must connect sub(frames with two ;)< inch b% three ;@< inch

b% 0"1)0! magnetic steel tubing"

&! The center section of the frame ma% insert tubing to form an BC"!

e! The Dohnson and +ammEs C(F(/ 0etric chassis and front clip are allowed"

The chassis and front clip must remain as manufactured and must retain all

factor% -E0 speci2cations including, but not limited to, mounting locations

for the following componentsG -E0 upper and lower A(frames, shoc1s, rear

trailing arms, steering components and engine mounts"

12! No oHset cages allowed"

1.! ;uel Cell C#ash Ba# A reinforcement bar, made of minimum one and

one half ;1 1>)< b% 0"0@!, must extend below the rear frame section behind the

fuel cell" This bar must be as wide as the rear frame rails and extend as low as the

bottom of the fuel cell with two ;)< vertical uprights evenl% spaced between the

frame rails and attached to the rear cross member" Two ;)< support bars, one ;1<

located on each corner, must angle upwards and be welded to the rear frame rails"

14! ;uel Cell an& /ei,h0 The fuel cell must be a minimum of 10! oH the

ground, and must be centered between rear frame rails"

11! Ballas0 =ei,h0

a< Added weight ma% be mounted under the car, providing that it is securel%

bolted to the 3oor pan and up as high as possible" The weight ma% not bloc1

the area behind the left front tire and the area in front of the left rear tire in

order to allow for chassis height to be chec1ed"

b< Added weight must be magnetic steel or lead onl%, in bloc1 form, and

weighing no less than 2ve ;4< lbs" per bloc1 ;no pellets<" Added weight must

be securel% bolted to the frame rail and painted white with the car number

stenciled in blac1" No added weight will be permitted inside the driverEs

compartment" Ieight must be welded in a box or attached with two ;)< or

more .>1'! minimum diameter, grade bolts and loc1ing nuts"

c< An% car loosing ballast weight or found with unmar1ed weight is subJect to

a 2ne" d< The mounting of ballast weight is subJect to the

approval of NESST -Kcials"

14! 5#$un& Clea#ance 1> 'ini'u' ($&79 chassis an& all

(a#s an& (#ac?e0s-

16! Ca# =ei,h0

a< All speci2ed weight re,uirements will be with the driver in drivers seat with

helmet in lap"

b< The minimum total weight at all times will be @000 lbs"

c< 0aximum left side weight is 44"0L of total weight"

d< $ars found under the minimum total weight rule after ,ualif%ing will be

placed to last in that event" $ars found under the minimum total weight rule

after the feature event will be penali?ed one ;1< position per pound under"

18! 5M 402 C#a0e En,ine@ Ca# =ei,h0

a< All speci2ed weight re,uirements will be with the driver in the drivers seat,

helmet in lap"

b< The minimum total weight at all times will be )&.4 lbs"

c< 0aximum left side weight of crate engine cars is 44"0L of total weight"

1:! AA;#a'es

a< Apper and lower A(frames must remain stoc1 ;as manufactured< and

unaltered" b< A(frames ma% not be changed from side(

to(side"

c< Screw(in ball Joints are allowed"

d< No oHset upper control arm shafts allowed"

e< Apper A(frame bolts ma% be replaced for added camber" Apper and lower

A(frame bushings ma% be replaced with pol%urethane bushings, but hole

location ma% not be altered"

20!Tu(ula# U""e# an& L$3e# c$n0#$l a#'s@

a< aftermar1et tubular control arms allowed, no adJustable control arms

b< The onl% chassis allowed to use tubular lower control arms are the +ammMs x(%(g

chassis>snout" 9art B

21! S3a7 Ba#

a< The front end swa% bar must be stoc1 1 pc -E0 or a stoc1 -E0

replacement" No rear swa% bars" N-NE"

b< Nin1 pins ma% be replaced with threaded rod

c< Of e,uiped with a stoc1 panhard bar, it 0AST be in stoc1 location and N-N(

A:DASTA8NE" No modi2cations"

22! S"in&le*/u(

a< Spindle ma% be changed to heav% dut% -E0 units" The% must be bolt on

units and not be altered in an% wa% except for the lower ball Joint hole ma%

be reamed or tapered to 2t the lower ball Joint pin" No aluminum spindles"

b< Tread width must remain stoc1"

c< Trac1 supplied spindles must 2t the car"

d< +ub>7otor must be stoc1 -E0" $oleman safet% hub will be allowed on both

sides

2.! Bea#in,s

a< All bearings= wheel ;front and rear<, diHerential, and transmission =must be

of stoc1 -E0 design" 8earings ma% be either angle(t%pe cone, straight barrel(

t%pe or ball bearing" All bearings, including the rollers, must be magnetic

steel onl%"

24! B#a?es

a< 8ra1e s%stems must be stoc1 -E0 h%draulic s%stems" No aluminum

calipers, All four ;4< bra1es must be in wor1ing order"

b< 7ear disc allowed, if rear disc is used No aluminum rear calipers allowed,

onl% stoc1 st%le -E0 calipers allowed"

c< No drilling or lightening of an% bra1e parts including bac1ing plates, shoes

and pads" d< Aftermar1et master c%linders>pedals are

allowed" e< AdJustable

proportioning valves are allowed = front to rear adJustment onl%-

f< /0 ma% use an aftermar1et caliper produced b% +owe ;part P+-I@@. or

+-I@@'4<" That part must have the +owe logo" -n front onl%"

21! B#a?e Lines

Steel bra1e lines manditor%""

24! S0ee#in,

a< The steering lin1age and steering box ;including turning ratio< must be

stoc1 -E0 for the chassis being used" The steering shaft ma% be removed

from the column and securel% reinstalled with +eim Joints"

b<Stoc1 tie rode EN:S must be used" AdJusters ma% be aftermar1et"

c<No rac1 and pinion unless the model used is ST-$Q on the chassis from

manufacturer" d< no steering ,uic1eners

26! C$il S"#in,s

a< #ront and rear steel racing springs are allowed" The% must measure

minimum 2ve ;4< inches in diameter" Springs ma% use spring spacers and

adJusting cups" 7ear Jac1ing bolts are allowed"

b< The onl% modi2cation permitted to the spring poc1et is the installation of a

Jac1ing bolt" On all other wa%s, the spring poc1et must remain stoc1 -E0" No

front Dac1ing bolts"

28! Lea) S"#in,s

-nl% steel leaf springs are permitted" Neafs ma% be added on both sides" All

leafs must be the same width" Stoc1(appearing, adJustable shac1les and

lowering bloc1s are allowed" No other modi2cations allowed" 7acing leaf

springs are allowed"

2:! Sh$c?s

An% stoc1 mounted shoc1 not exceeding the value of R.4"00 per shoc1" N-

+EO0 Doint shoc1s"

.0! T#ailin, A#'s

a< 0ust be stoc1 for the %ear, ma1e and model being used" Nower trailing

arms must be stoc1 -E0 and unaltered" Apper trailing arms ma% be slotted

or cut and welded and must be within one ;1< inch of stoc1 length, and must

be centered" 0ounting holes and locations must remain Stoc1 -E0" /0

metric cars ma% use Dohnson $hassis upper and lower trailing arms ;part

PD$O(0&(0@(04 S D$O(0&(0@(0@8<"

.1! Sus"ensi$n Tie D$3ns

No tie downs or travel limiting devices permitted on the front suspension"

7ear suspension devices must allow the frame rail to be raised a minimum

four ;4< inches before the rear tires come oH the ground"

.2! =heels

An% 14x. inch steel racing wheels allowed" 0inimum T inch studs with 1

inch lug nuts are re,uired"

..! =heel s"ace#s

0aximum wheel spacer approved for use is T inch and must be one solid

piece" A maximum of U .)! tread width will be allowed, outer bulge to outer bulge

at hub height"

.4! Cal%e s0e's

No Bbleed oHG t%pe valve stems permitted"

.1! Ti#es

An% .(inch American 7acing tire with .04 compound rubber will be

permitted" Absolutel% no treating or soa1ing of the tires will be permitted"

NESST oKcials reserve the right to con2scate an% tire at an% time for

inspection

.4! ! C#a0e En,ine@ 5ene#al En,ine ReDui#e'en0s

a< The onl% approved engines for $rate use are the /0 9erformance #actor%

Sealed $ircle Trac1 '0) ;9art P&4'0)<" Engines must be purchased

directl% through /eneral 0otors or an authori?ed service center" All crate

engines must be serviced through an authori?ed NESST service center"

b< #-7: crate engine option, the @4.Jr #ord crate engine ma% be used"

N-TEG All engines must be sealed and documented to compete in the NESST"

A completed crate engine registration form must be completed and

submitted to NESST -Kcials" Engine seals are onl% good for two ;)< %ears"

.6! 5ene#al En,ine ReDui#e'en0s

a< Stoc1 -E0 engines for %ear, ma1e and model of the car must be used"

Engine must be -E0 cast iron 5 production bloc1 with cast iron heads" The

onl% approved engine bloc1s are the followingG

$hevroletG @40

#ordG @0);4"0< @41I

$hr%slerG @40 and @'0

b< The engine bloc1 must retain all -E0 speci2cations with the exception of

the c%linder overbore and the surfacing of the bloc1 dec1" $%linders ma% be

bored a maximum of 0"040! from the standard si?e"

c< Stoc1 appearing, aftermar1et -E0(t%pe magnetic steel main bearing caps

are allowed" d< No splade caps are allowed"

e< -nl% stoc1 -E0(t%pe engine bearings will be permitted* no roller cam t%pe

bearings" f< The following head modi2cations are not permitted,

including, but not limited toG angle cutting of the bloc1s, port matching, 3ow

wor1, grinding, polishing, beading or chemical ;acid< milling" No welding or

sectioning" No internal modi2cations of an% 1ind, including painting or Te3on

coating"

g< -nl% normal -E0(t%pe engine balancing is permitted"

.8! C$'"#essi$n

a< 0aximum compression is &"4 to 1 for non(#ord engines"

b< 0aximum compression for the #ord engine is 10"0 to 1"

c< $ompression will be chec1ed with the BIhistler"! 14

d< The two(most forward bolts on both sides of the inta1e must be drilled to

accept a seal

.:! En,ine L$ca0i$n

a< The engine must be in the stoc1 location, centered in the chassis"

b< Steel replacement motor mounts are permitted"

c< The minimum cran1shaft height is 1@ T!, measured from the centerline of

the cran1shaft to the ground"

40! ! C#an?sha)0

a< -nl% stoc1 -E0 production cran1shafts are allowed" The maximum stro1e

on a $hevrolet will be @"4&4!" The maximum allowable stro1e tolerance will

be V>( "014W" 7egrinding of the rod and main Journals to a maximum of 0"0@0!

under standard si?e is permitted" b< The

following are exceptions for the $hevroletG

i< $hevrolet must use the large Journal cran1"

ii< $hevrolet ma% use the following S$AT $ran1shaftsG

;1< -ne(9ieceG 9art P&(104)' or 9art P4@4010N

;)< Two(pieceG 9art P&(1044) or P4@4010

c< The rod Journals ma% be drilled to obtain the minimum cran1shaft weight"

d< No machining or polishing of the cran1shaft allowed" Standard engine

balancing is the onl% acceptable modi2cation that can be performed on this

component" No painting or Te3on coating"

e< 0inimum cran1shaft weights areG /0 engines 40 lbs", #ord and $hr%sler 44

lbs"

41! /a#'$nic Balance# -nl% a stoc1 -E0 or exact replacement will be

allowed" No #luid dampers"

42! Pis0$ns < R$&s

a< An% 3at(top three ;@< ring aluminum piston is permitted" All three rings

must be magnetic steel" No portion of the piston ma% protrude above the top

of the bloc1" The minimum ring thic1ness is as followsG

compression 7ingsG 0"4@ inches

-il 7ing Assembl%G @"0 mm

b< -nl% stoc1 t%pe steel rods will be permitted" All aftermar1et connecting

rods must be steel sportsman rods with a steel pin" 7od length must be stoc1"

All rods must be the same length" No + beam rods"

c< 0inimum weight for piston, pin, rings, bearing and rod assembl% is 10.4

grams" d< $hevrolet must use 4". inch rod"

4.! Oil Pan

a< Stoc1(appearing, steel, aftermar1et oil pans are permitted" -NNF stoc1

appearing pans"

b< 8aXes ma% be installed in the -E0 oil pan onl%"

44! C7lin&e# /ea&s

a< -nl% -E0(t%pe cast iron c%linder heads will be permitted"

b< $%linder +eads must have stoc1 casting numbers visible

i< All factor% $hevrolet heads must be factor% listed for .0$$Es or greater"

$hevrolet ma% use the following -E0(replacement aftermar1et headsG

Iorld 9roduct Stoc1 7eplacement Series

8are $asting ;9art P04@'008 and 04@'108<

:A7T ;9art P100)4@'1(1'4$$ 7unner '.$$ $hamber S 9art P 100)4@'0(

1'4$$ 7unner .'$$ $hamber<

c< 0aximum 5alve Si?e permitted is as followsG0aximum Onta1e )"0) Exhaust

1"'0 d< +ead studs are not allowed on an%

c%linder heads" E<

All cast lines and insignias must be clearl% visible and complete Angle milling,

changing the angle of the head gas1et surface in relationship to the rest of

the head, f<

Angle milling, changing the angle of the head gas1et surface in relationship

to the rest of the head, not permitted" Additionall% altering the position or

angle of the valve guide is not permitted" The addition of screw(in studs,

guide(plates, valve spring seats, option valve seals" 9ol%(loc1s, or Jam nut

devices are permitted" The machining of valve guide bosses allowed is for

seals onl%" $oolant return lines are allowed to be placed on the ends of the

heads" The following head modi2cations are not permitted" Oncluding but not

limited toG port machining, 3ow wor1, grinding, polishing, beading or chemical

;acid< milling," No welding of sectioning" No internal modi2cations of an%

1ind, including painting or Te3on coating" No more than than two inta1e

mounting holes ma% have helicoils" Onta1e or exhaust manifold mounting

holes ma% not be added or relocated" +oles must ta1e standard inta1e

manifold bolts" No stud girdles or oil de3ectors

41!Cal%es

All valves must be identical in appearance and construction as an -E0 t%pe

valve" No air directional devices ;9ro#lo, Tulip, Altra Nite, or Titanium, etc"< will

be permitted on an% of the valve surfaces" An% valve stem with an undercut

of 0"014! or more will not be permitted"

44! Cal%e S"#in,s < Re0aine#s

a< The valve springsE maximum outside diameter must measure no larger

than 1"44! b< :ouble springs are permitted"

c< -nl% steel valve spring retainers are allowed"

d< onl% 1"4 ratio roc1er arms will be allowed, %ou ma% use stoc1, aluminum

roller, or roller tip"

46! Cal%e J$(

a< 0ulti(angle valve Jobs are permitted"

48! Ca'sha)0

-nl% h%draulic or solid camshafts will be permitted" No roller camshafts or

lifters are allowed" 0ust 1eep stoc1 2ring order"

4:! Ti'in, Chain

U a< An% timing chain and gears will be allowed" /ear drive or belt drive(t%pe

timing chains are not permitted"

b< :egree buttons and oHset cran1 1e%s will be allowed"

10! Li)0e#s

-nl% stoc1 diameter lifters allowed" No roller lifters"

11! In0a?e Mani)$l&

-nl% the latest Edelbroc1 9erformer inta1e, with the Edelbroc1(applied

American #lag, allowed" A stoc1, trac1(supplied inta1e, including gas1ets,

must 2t the engine" The inta1e must remain as manufactured" No alterations,

adding bolt holes, painting, or coating of the inta1e will be permitted" The

approved part numbers are as followsG

$hevrolet )101

#ord )11, )''4, ).40 1.

$hr%sler .1.'

NoteG NESST, at an% time, reserves the right to con2scate a competitorEs

inta1e manifold and re,uire them to compete with a stoc1 manifold provided

b% the NESST" A failure to compl% will result in :6, and %ou will not be

allowed to compete"

12! C#a0e En,ine an& 5ene#al En,ine Ca#(u#e0$#

a< +olle% two(barrel model P441) carburetor must be used" The bod%, base

plate, metering bloc1, and bowl must be a standard +olle% 441) part" +9

parts are not permitted" $arburetors and>or carburetor components machined

from billet materials are not permitted" b< -E0 t%pe

gas1ets, Jets and power valve must be used"

c< The diameter of ever% hole in the carburetor must pass the standard

NESST pin and tooling gauges as part of our routine inspection process"

d< The onl% changes that will be allowed are as followsG

i< The cho1e plate and shaft ma% be removed, but must be permanentl%

sealed" ii< Throttle plate screws ma% be trimmed

3ush with shaft e< 8od% of

carburetor and metering bloc1G No polishing, grinding or reshaping of an%

part" :rilling of additional holes or plugging holes is not permitted"

f< $ho1e horn ma% not be removed"

g< 8oosters ma% not be changed" Si?e or shape must not be altered" +eight

must remain standard"

h< 5enturi area must not be altered in an% manner" $asting ring must not be

removed" i< Alterations to allow additional air to be pic1ed up below

the opening of the venturi such as altered gas1ets, base plates, and drilling

holes into the carburetor will not be permitted" J< 8ase plate must

not be altered in shape or si?e"

1< The stoc1 +olle% 441) or Stainless Steel +oll% part P@4' butter3ies must

be used" The% ma% not be thinned or tapered" The 8utter3ies must remain as

manufactured, and must maintain the +olle% production tolerance thic1ness

of "04@! to "0@&!" Odle holes ma% be drilled in butter3ies" Screw ends ma%

be cut even with the shaft but screw heads must remain standard" l< Throttle

shaft must remain standard and must not be thinned or cut in an% manner"

m< See B$rate EngineG $arburetor! section for speci2c rules for cars with a

crate engine"

result in penalties"

1.! Ca#(u#e0$# S"ace#

a< -ne space>adapter, made of solid material, is allowed" 0aximum height of

one ;1< inch will be permitted"

b< No wedge shape spacers>adapters will be allowed" 8oth the top and

bottom surfaces must be parallel"

c< 9ortholes must be vertical to the top and bottom" 8eveling, tapering,

3aring, opening, or radiusing of porthole;s< is not permitted" -nl% one 0"0.4!

gas1et per side of the spacer will be allowed" The spacer ma% not be stepped

or undercut"

d< No additional openings for air induction will be allowed"

14! Ai# Cleane#*;il0e#

a<-nl% a round, paper, maximum four ;4< inch high air 2lter element is

allowed" The air cleaner top and bottom must be solid metal, measuring 1)(

14 b< Air 2lter ma%

not be spra%ed or soa1ed with chemicals"

c< No ducts, baXes or an%thing that ma% control air3ow is allowed on, or in,

the air cleaner assembl%" All air entering the carburetor must pass through

the air 2lter d< No air boxes are

permitted"

e< A shield ma% be used on the front outer half of the element if it is on the

element" Air cleaners must remain under the hood"

f< All air cleaners are subJect to NESST approval

11! E2haus0

a< An% stoc1 2tting manifold permitted"

b< +eaders will be permitted, 1 4> tubes max, no 10Y or over the top

headers"

c< 0aximum exhaust and collector diameter, @! id

d< Exhaust must have &' db muXers ;)< muXers 0AST be used" 0in 1)! long

14! I,ni0i$n

a< -nl% Stoc1 -E0(t%pe +EO distributors, using factor% production 2ring order,

are permitted, unless noted in letter b below" The 2ring order is as followsG

/0 S $hr%sler 1((4(@('(4(.()

#ord 1(@(.()('(4(4(

b< -nl% exact stoc1 replacement distributors allowed, no 0S: boxes no rev(

limiters"

c< -nl% stoc1 coils are permitted" /0 must have the coil in the cap" No 0S:

or super coil(t%pe, gm coil 0AST be in the cap"

d< The onl% aftermar1et part allowed in, or on, the complete distributor will be

advance springs"

NoteG The NESST, at an% time, reserves the right to con2scate a competitorEs

distributor and re,uire them to compete with a stoc1 component provided b%

the tour" A failure to compl% will result in penalties"

16! Ba00e#7

a< -nl% a single 1)(volt -E0 automotive t%pe or an automotive t%pe gel(

batter% is permitted" b< The batter% must be located inside of the frame

rails, forward of the rear end" The batter% ma% not be inside the driverEs

compartment" The batter% and>or box ma% not extend below the frame rails

where it is mounted"

c< The positive cable of the batter% must be inside of the frame rails"

18! En,ine C$$lin, S7s0e'

7adiators must remain in the stoc1 -E0 location" All cars must be e,uipped

with a minimum one ;1< gallon over3ow container" -nl% water or Iater

Ietter(t%pe additives ma% be used in the cooling s%stems" No antifree?e

allowed"

1:! =a0e# Pu'"

a< -nl% stoc1 -E0 water pumps are allowed"

b< The $hevrolet must use the stoc1 steel or aluminum water pump

40! Ra&ia0$# ;an

An electric radiator fan is permitted"

41! ;uel Shu0 OE S3i0ch

a< A Z(turn fuel shut oH valve is re,uired in the fuel line"

b< The fuel shut oH valveEs -N and -## positions must be clearl% labeled"

c< The valve must be open when the handle is aiming front to bac1, and the

valve must be closed when the handle is aiming left to right"

d< No fuel shut oHs permitted on the driverEs side" The switch must be easil%

accessible to emergenc% wor1ers"

42! ;uel

-nl% automotive fuel, pump gas or racing fuel allowed, no nitro, alcohol or

octane additives"

4.! Clu0ch < ;l73heelG No Mini clutches !!

a< The clutch and pressure plate must be stoc1 -E0 steel" No modi2cations

of an% 1ind are permitted" The minimum diameter for the clutch and the

pressure plate is 10"4!" b< An% steel 3%wheel for the ma1e

and model of the car ma% be used" Ot must have come with a 10"4! or larger

clutch and pressure plate"

c< 0inimum weights are as followsG

i< #l%wheelG )0 lbs"

ii< 9ressure 9lateG 1@ lbs"

iii< $lutch :iscG @"0 lbs"

d< #ords must compl% with the following regulationsG

i< The 3%wheel must be steel, have a Stoc1 -E0 part number, and weigh )0

lbs" ii< The clutch and pressure plate must be

-E0 steel" The minimum diameter is 10"0!" " The minimum total weight for

the clutch and pressure plate is 1."0 lbs"

U YY See B$rate EngineG $lutch S #l%wheel! section for additional, more speci2c

rules for cars with a crate engine"

44! C#a0e En,ine@ Clu0ch < ;l73heel

The crate engine must use the /0 3%wheel ;9art P 140'4'<, and weigh at

least 14"40 lbs" #ord crate must conform to ford clutch rules

41! T#ans'issi$n

a< -nl% -E0 production stoc1 @ S 4 speed transmissions will be permitted" All

internal parts must be stoc1" /ear ratio must be of stoc1 -E0 production"

b< 0achining or lightening of an% internal rotating or non(rotating parts

including gears, shafts and case is not permitted" /un drilled transmission

shafts are not be permitted" Ielding on an% internal not permitted"

c< Auxiliar%, over or under drive transmissions are not permitted" +igh gear

must have a ratio of 1 to 1 "

d< Aluminum transmissions are permitted"

e< Thermal coatings are not allowed"

f< Aftermar1et stoc1(t%pe shifters are allowed"

AAT- T7ANS -9TO-NG A ST-$Q th@40 AAT- T7ANS 0AF 8E ASE:, no mini

converters, if an auto trans is used, NESST will allow a )4lb, weight brea1"

44! Rea# En&s

Stoc1 rears for chassis being used, rears ma% be loc1ed" #ord &! option no

3oater or wide 4 rears" No ,uic1 change rears" 0AST 0EET .)! IO:T+ 7ANE"

46! A2le Sha)0s

a< Solid steel, aftermar1et axles are allowed" Axles must retain all stoc1

dimensions" b< A c(clip eliminator is strongl%

recommended

c< A heav% dut% axle must be used in the right rear" -n /0 rears"

Das könnte Ihnen auch gefallen

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- NESST 2015 RulesDokument13 SeitenNESST 2015 RulesNickRayNoch keine Bewertungen

- Thrust Bearing End PlayDokument3 SeitenThrust Bearing End PlayKrishnan SanthanarajNoch keine Bewertungen

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesVon EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesBewertung: 5 von 5 Sternen5/5 (1)

- E) Slitting: SLITTING: The Busbars Should Be Slit According To The Picture For Better Joint and AlignmentDokument61 SeitenE) Slitting: SLITTING: The Busbars Should Be Slit According To The Picture For Better Joint and AlignmentSanjeewa HemaratneNoch keine Bewertungen

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentVon EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentNoch keine Bewertungen

- Proclimb Procross Torsional Conversion KitDokument8 SeitenProclimb Procross Torsional Conversion KitcpcracingNoch keine Bewertungen

- AMCA Tech Rules 2008 09Dokument6 SeitenAMCA Tech Rules 2008 09Edwards RayNoch keine Bewertungen

- C208 Technical LecturesDokument73 SeitenC208 Technical Lecturesschabur412389% (9)

- Welder Series Mustang IIDokument14 SeitenWelder Series Mustang IIiforeman100% (1)

- Specifications Is 950-1980Dokument13 SeitenSpecifications Is 950-1980anuavi93Noch keine Bewertungen

- Technical Specifications For LPG Tank TruckDokument11 SeitenTechnical Specifications For LPG Tank TruckDayo Idowu100% (2)

- Steering Systems Exam P-22 2022MYDokument3 SeitenSteering Systems Exam P-22 2022MYNeo ZaoNoch keine Bewertungen

- Section Low Voltage Motor Control Centers Part 1 - GeneralDokument8 SeitenSection Low Voltage Motor Control Centers Part 1 - GeneralNardi VallejoNoch keine Bewertungen

- Ski Bee 1969 1970Dokument3 SeitenSki Bee 1969 1970Paul MartinNoch keine Bewertungen

- BC BRONCO Rear Disk Brakes: B.C. BRONCOS Tech LibraryDokument11 SeitenBC BRONCO Rear Disk Brakes: B.C. BRONCOS Tech LibrarycarlvpNoch keine Bewertungen

- Design of Rope Drum HoistDokument5 SeitenDesign of Rope Drum HoistDheeraj Verma100% (5)

- Chassis Superlight 4ft WeldedDokument9 SeitenChassis Superlight 4ft WeldedFelipe Maciel Del VecchioNoch keine Bewertungen

- Manual PDFDokument70 SeitenManual PDFUsama PopatiaNoch keine Bewertungen

- Sidewalk Play Car: by Elmer V. ClarkDokument5 SeitenSidewalk Play Car: by Elmer V. ClarkJimNoch keine Bewertungen

- A Project Report On Disc Brake PDFDokument36 SeitenA Project Report On Disc Brake PDFVIKASH KUMARNoch keine Bewertungen

- Volvo Repair Manual TP30000-1 Front Wheel SuspensionDokument56 SeitenVolvo Repair Manual TP30000-1 Front Wheel SuspensionDarrin SmithNoch keine Bewertungen

- Lesson Removal and Care of Crosshead and Connecting RodDokument7 SeitenLesson Removal and Care of Crosshead and Connecting Rodmister pogiNoch keine Bewertungen

- Schaku Coupler Rdso Spec No. 61-B-36-R - 1 - 68-1Dokument7 SeitenSchaku Coupler Rdso Spec No. 61-B-36-R - 1 - 68-1Sumit Shyamal100% (1)

- Section 14520 - Baggage Handling SystemsDokument7 SeitenSection 14520 - Baggage Handling SystemsHaryo WidodoNoch keine Bewertungen

- Steam Turbine Overhaul1Dokument44 SeitenSteam Turbine Overhaul1mister pogi100% (2)

- Lingaya's University: Roll No. .Dokument4 SeitenLingaya's University: Roll No. .ArifRachmanNoch keine Bewertungen

- Motor Kia SportageDokument36 SeitenMotor Kia Sportagecarbutz100% (3)

- Conveyor Belt TroubleshootingDokument4 SeitenConveyor Belt TroubleshootingchandankrdumkaNoch keine Bewertungen

- Bogie SKRDokument24 SeitenBogie SKRhayatmdazharNoch keine Bewertungen

- Crank Shaft PresentationgnsDokument42 SeitenCrank Shaft Presentationgnskr_abhijeet72356587100% (1)

- Any Changes/updates/revisions For 2021 Are Noted in RED.: Port Royal Speedway 2021 Limited Late Model RulesDokument18 SeitenAny Changes/updates/revisions For 2021 Are Noted in RED.: Port Royal Speedway 2021 Limited Late Model RulesWylieNoch keine Bewertungen

- 2011 Hobby Stock RulesDokument4 Seiten2011 Hobby Stock RulesjhoenigNoch keine Bewertungen

- Krupp KMK 8400 Specifications - 400 T Telescopic Crane Telescopic Crane 400 T at 3 MDokument2 SeitenKrupp KMK 8400 Specifications - 400 T Telescopic Crane Telescopic Crane 400 T at 3 MdimkirkNoch keine Bewertungen

- Krupp KMK 8400 Specifications - 400 T Telescopic Crane Telescopic Crane 400 T at 3 MDokument3 SeitenKrupp KMK 8400 Specifications - 400 T Telescopic Crane Telescopic Crane 400 T at 3 MdimkirkNoch keine Bewertungen

- Cat05 PDF 80-99Dokument20 SeitenCat05 PDF 80-99Rafael ReisNoch keine Bewertungen

- It-Ii AhpDokument1 SeiteIt-Ii AhpVignesh KumarNoch keine Bewertungen

- Volkswagen Workshop ManualsDokument126 SeitenVolkswagen Workshop Manualssssf-dobojNoch keine Bewertungen

- Ariens Models 1969 1973Dokument3 SeitenAriens Models 1969 1973Paul MartinNoch keine Bewertungen

- Pages From Festo - HydraulicsDokument19 SeitenPages From Festo - HydraulicsDiego PerezNoch keine Bewertungen

- Motor Volkswagen GolfDokument22 SeitenMotor Volkswagen GolfcarbutzNoch keine Bewertungen

- Constant Speed Vertical Turbine Irrigation Pumping StationDokument11 SeitenConstant Speed Vertical Turbine Irrigation Pumping StationGie Mak0% (1)

- Conveyor Belt InstallationsDokument95 SeitenConveyor Belt InstallationsCarlos Andrés Aguilar OrozcoNoch keine Bewertungen

- YTE Suspension Installation MaintenanceDokument16 SeitenYTE Suspension Installation MaintenanceRam OscNoch keine Bewertungen

- Scanned by CamscannerDokument10 SeitenScanned by CamscannerChandrashekhar KalyankarNoch keine Bewertungen

- Maintenance and Repair of Centrifugal PumpsDokument4 SeitenMaintenance and Repair of Centrifugal Pumpsaserf251Noch keine Bewertungen

- 47re Overhaul Instructions A1Dokument7 Seiten47re Overhaul Instructions A1JrsproulsNoch keine Bewertungen

- MT Bulleid Coach ManualDokument22 SeitenMT Bulleid Coach ManualMatrixTrainsNoch keine Bewertungen

- Honda Help TipsDokument7 SeitenHonda Help Tipsdannyralix17Noch keine Bewertungen

- BHEL Feed BackDokument58 SeitenBHEL Feed BackelrajilNoch keine Bewertungen

- G-33 (Rev. 1) : Indian Rail WaysDokument29 SeitenG-33 (Rev. 1) : Indian Rail Wayssenthil031277Noch keine Bewertungen

- Sae Baja India 2011 (FDR)Dokument22 SeitenSae Baja India 2011 (FDR)Rahul ReddyNoch keine Bewertungen

- Removal and Installation of The 1600 I EngineDokument10 SeitenRemoval and Installation of The 1600 I EngineCarlos CoxcaNoch keine Bewertungen

- E-Tec 170 and E-Tec 200 Aluminum Cylinder Heads For Small Block Chevrolet Using Vortec Style Manifolds Catalog #60959, #60969 (Bare) Catalog #60979, #60989 (Complete) Installation InstructionsDokument4 SeitenE-Tec 170 and E-Tec 200 Aluminum Cylinder Heads For Small Block Chevrolet Using Vortec Style Manifolds Catalog #60959, #60969 (Bare) Catalog #60979, #60989 (Complete) Installation InstructionsAdrian MacayaNoch keine Bewertungen

- 12thpak InstrutionsDokument5 Seiten12thpak InstrutionsJavier Rodriguez PaezNoch keine Bewertungen

- Technical ManualDokument0 SeitenTechnical ManualSerban DraganNoch keine Bewertungen

- Fabrication Tolerances: Api-Rp-2A (December 2000)Dokument2 SeitenFabrication Tolerances: Api-Rp-2A (December 2000)dareman_021Noch keine Bewertungen

- SpecificationsDokument3 SeitenSpecificationsajeesh_petrocilNoch keine Bewertungen

- Deed of Sale of Motor VehicleDokument2 SeitenDeed of Sale of Motor VehicleChester Pryze Ibardolaza Tabuena100% (1)

- Especificaciones MT-2010Dokument4 SeitenEspecificaciones MT-2010HEMER LUIS RIVERANoch keine Bewertungen

- Relatorio Final Avianca52Dokument295 SeitenRelatorio Final Avianca52Tatiana PedrosaNoch keine Bewertungen

- Traffic Signs, Road Signs PDF List For Computer Driving Learners TestDokument4 SeitenTraffic Signs, Road Signs PDF List For Computer Driving Learners TestAbhishek Sharma100% (2)

- 08 Federal Express Corporation vs. American Home Assurance Company and Phil Am Insurance Company Inc. G.R. No. 150094 18 August 2004 ScraDokument9 Seiten08 Federal Express Corporation vs. American Home Assurance Company and Phil Am Insurance Company Inc. G.R. No. 150094 18 August 2004 ScraJNoch keine Bewertungen

- (1878) The World On Wheels: Or, Carriages With Their Historical Associations From The Earliest To The Present TimeDokument514 Seiten(1878) The World On Wheels: Or, Carriages With Their Historical Associations From The Earliest To The Present TimeHerbert Hillary Booker 2nd100% (2)

- Lord of The Mysteries - 8 A New EraDokument18 SeitenLord of The Mysteries - 8 A New EraAchmad Kamal BadriNoch keine Bewertungen

- WEG40107 - Star Wars D6 - Platt's Starport GuideDokument162 SeitenWEG40107 - Star Wars D6 - Platt's Starport GuideMuujin100% (2)

- HAR1902Dokument152 SeitenHAR1902Ximena AranedaNoch keine Bewertungen

- The Best of SingaporeDokument264 SeitenThe Best of Singaporesven100% (7)

- CS 23 Amdt 6 MoCDokument129 SeitenCS 23 Amdt 6 MoCanirban pahariNoch keine Bewertungen

- Statement: Registered Name Account No. Khairul Sabastian 119686328Dokument2 SeitenStatement: Registered Name Account No. Khairul Sabastian 119686328Hizuafi KhairulNoch keine Bewertungen

- LVHMDokument44 SeitenLVHMNguyen Tuan VinhNoch keine Bewertungen

- Quick 3Dokument3 SeitenQuick 3dfggh hggjhvjjNoch keine Bewertungen

- Clean Air TestDokument56 SeitenClean Air TestPrathamesh Gangal100% (5)

- Gulfstream G280 - Flying MagazineDokument5 SeitenGulfstream G280 - Flying Magazinetom190465100% (2)

- Electromagnetic ClutchDokument5 SeitenElectromagnetic Clutchjd4u50% (2)

- MH370 (MAS370) Malaysia Airlines Flight Tracking and History 07-Mar-2014 (KUL - WMKK-PEK - ZBAA) - FlightAwareDokument2 SeitenMH370 (MAS370) Malaysia Airlines Flight Tracking and History 07-Mar-2014 (KUL - WMKK-PEK - ZBAA) - FlightAware陳佩Noch keine Bewertungen

- Bridge To Bridge - Urban Design Workshop PDFDokument34 SeitenBridge To Bridge - Urban Design Workshop PDFanamaria cristina lesiucNoch keine Bewertungen

- May 9, 2022 List of Pre-Owned Vehicles For Sale: Cut-Off Is Every SundayDokument2 SeitenMay 9, 2022 List of Pre-Owned Vehicles For Sale: Cut-Off Is Every SundayMashud AhmadNoch keine Bewertungen

- Alan Taggart: Current Approach To Managing The UK Road AssetDokument27 SeitenAlan Taggart: Current Approach To Managing The UK Road AssetGary Lopez0% (1)

- ABS Part4 - Vessel Systems & Machinery - 2001Dokument710 SeitenABS Part4 - Vessel Systems & Machinery - 2001AndréMenezesNoch keine Bewertungen

- Kaptan.1.Zabit 7denizcilik İngilizcesiDokument3 SeitenKaptan.1.Zabit 7denizcilik İngilizcesiAliNoch keine Bewertungen

- Ideas Fund Finances Key Cross-Border Infrastructure Deal With Kingdom MugadzaDokument2 SeitenIdeas Fund Finances Key Cross-Border Infrastructure Deal With Kingdom MugadzaKingdomNoch keine Bewertungen

- Cryogenic Power Conversion Systems: The Next Step in The Evolution of Power Electronics TechnologyDokument10 SeitenCryogenic Power Conversion Systems: The Next Step in The Evolution of Power Electronics TechnologyaliflailasurumiNoch keine Bewertungen

- Causes of GlobalizationDokument1 SeiteCauses of GlobalizationSergioSanabriaNoch keine Bewertungen

- 4T Owner Manual ENGDokument104 Seiten4T Owner Manual ENGruiznelsonNoch keine Bewertungen

- Ibc Code New 2 PDFDokument8 SeitenIbc Code New 2 PDFrajishrrrNoch keine Bewertungen

- Doctrine Uk Air Manoeuver JDN 1 16Dokument120 SeitenDoctrine Uk Air Manoeuver JDN 1 16arash100% (2)

- Process Plant Equipment: Operation, Control, and ReliabilityVon EverandProcess Plant Equipment: Operation, Control, and ReliabilityBewertung: 5 von 5 Sternen5/5 (1)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesVon EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNoch keine Bewertungen

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksVon EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksBewertung: 5 von 5 Sternen5/5 (1)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyVon EverandSodium Bicarbonate: Nature's Unique First Aid RemedyBewertung: 5 von 5 Sternen5/5 (21)

- Piping Engineering Leadership for Process Plant ProjectsVon EverandPiping Engineering Leadership for Process Plant ProjectsBewertung: 5 von 5 Sternen5/5 (1)

- Troubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesVon EverandTroubleshooting Process Plant Control: A Practical Guide to Avoiding and Correcting MistakesBewertung: 1 von 5 Sternen1/5 (2)

- The Perfumed Pages of History: A Textbook on Fragrance CreationVon EverandThe Perfumed Pages of History: A Textbook on Fragrance CreationBewertung: 4 von 5 Sternen4/5 (1)

- An Applied Guide to Water and Effluent Treatment Plant DesignVon EverandAn Applied Guide to Water and Effluent Treatment Plant DesignBewertung: 5 von 5 Sternen5/5 (4)

- Well Control for Completions and InterventionsVon EverandWell Control for Completions and InterventionsBewertung: 4 von 5 Sternen4/5 (10)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersVon EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNoch keine Bewertungen

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlVon EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlBewertung: 4 von 5 Sternen4/5 (4)

- A New Approach to HAZOP of Complex Chemical ProcessesVon EverandA New Approach to HAZOP of Complex Chemical ProcessesNoch keine Bewertungen

- Troubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersVon EverandTroubleshooting Vacuum Systems: Steam Turbine Surface Condensers and Refinery Vacuum TowersBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Guidelines for Chemical Process Quantitative Risk AnalysisVon EverandGuidelines for Chemical Process Quantitative Risk AnalysisBewertung: 5 von 5 Sternen5/5 (1)

- Pulp and Paper Industry: Emerging Waste Water Treatment TechnologiesVon EverandPulp and Paper Industry: Emerging Waste Water Treatment TechnologiesBewertung: 5 von 5 Sternen5/5 (1)

- Biochemical and Photosynthetic Aspects of Energy ProductionVon EverandBiochemical and Photosynthetic Aspects of Energy ProductionAnthony San PietroNoch keine Bewertungen

- Cathodic Protection: Industrial Solutions for Protecting Against CorrosionVon EverandCathodic Protection: Industrial Solutions for Protecting Against CorrosionNoch keine Bewertungen

- Guidelines for the Management of Change for Process SafetyVon EverandGuidelines for the Management of Change for Process SafetyNoch keine Bewertungen

- Fun Facts about Carbon : Chemistry for Kids The Element Series | Children's Chemistry BooksVon EverandFun Facts about Carbon : Chemistry for Kids The Element Series | Children's Chemistry BooksNoch keine Bewertungen