Beruflich Dokumente

Kultur Dokumente

Medifusion 1000

Hochgeladen von

patolin_123Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Medifusion 1000

Hochgeladen von

patolin_123Copyright:

Verfügbare Formate

MF-1000

CFEF/IlNG M/NU/L

0aiwha Corp., Ltd.

C

Copyrght owned by 0AlwhA Corporat on, Ltd. All rghts reserved. 1Oth hovember, 2OO8

|AhUAL hU|8EP: |PEO64

8efore usng the pump, please carefully read safety precautons.

Ths |anual descrbes the use of nfuson pump (model: |P1OOO) manufactured by

0AlwhA Corp., Ltd.

0nly the person who s authorzed by the company can repar ths equpment and

change a crcut. The equpment that s dsmantled or repared wthout pror

permsson cannot get any postmanagement servce.

Parts and crcuts used n ths equpment can be changed for better performance

and safety reasons.

After readng ths manual, put t n a place wth easy access so that everybody can

use t.

lf you have any questons or concerns regardng ths equpment and user manual,

feel free to contact at the below company.

Address:

0awha Corp., Ltd. 7JJ18 0awha 8ldg Yeoksamdong KangnamKu

Seoul, Korea

TEL: (822) 558 1711-6

FAX: (822) 554 - OJ17

E|al: dawha@dawha.com

Program 7erson - 7J.xx

Safety precautons are dvded nto the followng categores dependng on the level

of the expected hazard and damage caused by napproprate use of the product and

the level of urgency that requres actons.

I/8LE CF CCNIENIS

1. PPECAUTl0hS..................... 1

2. TEChhlCAL SPEClFlCATl0hS............. 4

J. ChAPACTEPlSTlCS................... 5

J.1 PP00UCT 07EP7lEw..................... 5

J.2 |E|0PY FUhCTl0h...................... 5

J.J ChAPACTEPlSTlCS 0F ThE 0CCLUSl0h 0ETECTl0h.... 5

J.4 FUhCTl0h 0F ThE 0P0P SEhS0P (0PTl0h)........ 5

J.5 FL0w PATE ACCUPACY.................... 7

4. hA|ES Ah0 FUhCTl0hS 0F EXTEPhAL PAPTS.... 9

4.1 KEY............................... 9

4.2 0lSPLAY............................. 1O

4.J lhSl0E 0F ThE 000P...................... 1J

4.4 |0UhTlhC PAPT 0h ThE 8ACK............... 14

4.5 SY|80L............................. 15

4.6 ACCESS0PlES.......................... 16

5. 0PEPATl0h....................... 17

5.1 ATTACh ThE PU|P T0 Ah lhFUSl0h STAh0........ 17

5.2 h0w T0 C0hhECT ThE P0wEP................ 17

5.J h0w T0 lhSTALL Ah0 SET UP Ah lhFUSl0h SET...... 17

5.4 h0w T0 lhSTALL ThE 0P0P SEhS0P (0PTl0h)....... 19

5.5 h0w T0 SET UP A FL0w PATE................ 19

5.6 h0w T0 SET UP T0TAL 70LU|E (70LU|E T0 8E lhFUSE0) 19

5.7 h0w T0 STAPT ThE 0PEPATl0h................ 2O

5.8 h0w T0 ST0P & PESTAPT ThE 0PEPATl0h......... 2O

5.9 h0w T0 7lEw lhFUSE0 70LU|E................ 21

5.1O lhFUSl0h C0|PLETl0h..................... 21

5.11 PUPCE FUhCTl0h ....................... 21

I/8LE CF CCNIENIS

6. ALAP|........................... 22

6.1 AlP (8U88LE) ALAP|...................... 22

6.2 0CCLUSl0h ALAP|....................... 22

6.J 000P 0PEh ALAP|....................... 2J

6.4 L0w 8ATTEPY ALAP|...................... 2J

6.5 FPEE FL0w & h0 0P0P ALAP|................ 2J

6.6 TU8lhC |lSL0A0lhC ALAP|.................. 2J

6.7 0ThEPS.............................. 24

7. USEP SETTlhC...................... 25

7.1 h0w T0 SET UP CALl8PATl0h (ACCUPACY)........ 26

7.2 h0w T0 SET UP 00wh STPEA| 0CCLUSl0h SEhSlTl7lTY 27

7.J h0w T0 SET UP ALAP| 70LU|E............... 27

7.4 h0w T0 SET UP PUPCE PATE................. 28

7.5 h0w T0 SET UP PUPCE 70LU|E............... 28

7.6 h0w T0 SET UP SA7E FUhCTl0h............... 29

7.7 h0w T0 SET UP K.7.0. PATE................. 29

7.8 h0w T0 SET UP lhFUSl0h SET 0rops/ml (0PTl0h)..... JO

7.9 h0w T0 SET UP hUPSE CALL (0PTl0h)............ JO

7.1O h0w T0 SET UP STAh08Y ALAP|............. J1

7.11 h0w T0 SET UP TU8lhC |lSL0A0lhC ALAP|...... J1

7.12 h0w T0 SET UP AlP SEhSlTl7lTY............. J2

7.1J 0ThEPS (TEST |00E).................... J2

8. |AlhTEhAhCE...................... JJ

8.1 ChECK0UT ThE PU|P .............. JJ

8.2 CLEAhlhC Ah0 STEPlLlZATl0h................ J4

8.J ST0PACE 0F ThE lhFUSl0h PU|P.............. J4

8.4 LlFE SPAh............................ J4

9. wAPPAhTY............................ J5

0anger Warning Caution

0efinition of Terms

PIease use the infusion Pump with extreme care 8 correctness after reading this

- 0anger : Possble hazards that could cause serous njury or even lhSTAhT 0EATh.

- Warning : Possble hazards that may cause serous njury or even death.

Caution : Possble hazards that may cause mld njury to user or patent or damage to product.

information and checking any improper thing, if any, in advance.

1. FFEC/UIlCNS

The followng nformaton s provded to help user operate the pump safely and

accurately and further prevent hazard, physcal njures or damages.

0anger

1. Keep the pump away from nflammable anesthetc.

Warning

1. |ake sure that an nlet that s connected to the external power stays dry all the

tme.

2. 0o not use a moble phone, rado set or defbrllator generatng hgh frequency

near the pump.

J. 0o not use ths pump n |Pl rooms, hghpressure rooms or places whle hgh

electromagnetc radaton s generated.

4. 8e sure to set the nfuson set rghtly. lf t s set by reversed manner to a normal

pump operaton, the patent's blood wll be drawn up nto the tubng.

Caution

1. 0perate the pump by the desgnated steps.

2. when the external power sources are used, keep n mnd the followng matters:

1) Use the power cord for the hosptal and plug t nto the grounded outlet.

2) Pror to use, check the rated voltage and frequency.

J) 8e sure to check whether an extenson cord s normal or not.

J. Use only the person educated about the pump or a sklled hand.

1. FFEC/UIlCNS

4. Attach the pump securely to an nfuson stand and ensure ts stablty. lf the pump

s dropped or gven any hard shocks, do not use t. Please call the local agences or

the company.

5. 0urng nfuson, frequently check the nfuson lne such as a rupture n the flter or

a leak n the lne. Check both pump and patent's condtons on a regular bass

whle drugs are nfused. To ensure a good connecton between the patents wth the

nfuson lne, a maletofemale luerlock type connecton s recommended.

6. Pay close attenton to the followng matters when the nfuson set s used.

1) Use a desgnated nfuson set for nfuson pump. lf any nfuson set other than

specfed s used, proper flow rate accuracy and alarm functon (ar and

occluson) are not guaranteed. lf the desgnated set s not avalable, contact to

the agent or company.

2) 0o not pull on the tubng wth excessve force. Then the ntended flow rate may

not be acheved.

J) Ft the tubng nsde of the door from the bottom to the top. Securely set the

tubng along the groove of the PU|PlhC UhlT J1. lf not, free flow or leak can be

occurred.

4) 0o not connect an nfuson set admnstrated from an nfuson pump to another

nfuson lne admnstrated only by the manual roller clamp (gravty nfuson)

because ths may nfluence the accuracy of nfuson and alarm functons.

5) when drugs are nfused for extended tme, change the tubng locaton every 12

hours to use the tubng wthn the margn of errors.

6) 0o not reuse the nfuson set.

7. when the pump s operated under the shown descrbed condtons, the flow rate

accuracy may be ncorrect.

1) Usng drugs of the hgher vscosty such as 0extrose 5O.

2) 0peratng under the ambent temperature between +5 ' and 4O ', a relatve

humdty between 2O and 9O.

8. Pay attenton to the followng matters when the pump s operated on battery.

1) Check the battery use tme. (The battery can be used for 2 hours at flow rate

25ml/h f t s fully charged.)

.

1. FFEC/UIlCNS

2) Connect the man power to charge the battery f the ndcator that dsplays

L0w 8ATTEPY ALAP| lh0lCAT0P 21 on the front s turned on or the alarm

sounds.

J) Charge the nternal battery to full capacty by connectng the pump to an AC

power supply for 15 hours at least.

4) when the external (AC/0C) power s suppled, J lamps of the 8attery capacty

ndcator 17 wll be turned on wthout regard to the battery capacty.

9. hever connect both AC and 0C power sources to the nfuson pump at the same

tme. To use the 0C power, be sure to check the polarty of the 0C jack.

1O. 0o not sterlze the pump wth autoclave or E.0. gas. 0o not wpe the pump wth

thnner, solvent, benzene, ammona, acetone, etc. Use a wet cloth to clean.

11. 0o not dsmantle the pump.

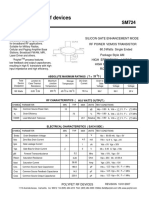

2. IECHNlC/L SFEClFlC/IlCNS

+ Product hame 7olumetrc lnfuson Pump

+ |odel hame |P1OOO

+ lnfuson Prncple Perstaltc SemTranst Fnger

+ Pange of Flow Pate

O.1-999 ml/h

O.1-99.9 ml/h: ncrease and decrease by O.1 ml/h

1OO-999ml/h: ncrease and decrease by 1 ml/h

+ Accuracy 5 (80 K0PEA: model PU|P A122)

+ Pange of 7olume

- Total 7olume

- lnfused 7olume

1-9999ml or no lmt: 1-9999ml: ncrease by 1 ml

O.1-9999 ml: O.O-99.9ml: ncrease by O.1ml

1OO-9999ml: ncrease by 1ml

+ Purge Pate 7OOml/h (subject to change)

+ Purge 7olume Jml (subject to change)

+ K.7.0. Pate

1ml/h: Flow rate 1.O-999 ml/h (subject to change)

O.1ml/h: Flow rate O.1-O.9ml/h

+ 0splay 7 segment (4 dgt * 2 lne)

+ 8attery

2 hours at flow rate 25ml/h

Chargng tme - approx. 15 hours

+ Alarm

7sble and Audble Alarm

0oor open

0ccluson (0etecton range: 1OO-95Ommhg)

: 0own stream 0ccluson J steps are adjustable

: |axmum nfuson pressure: 95O mmhg

Ar 8ubble detecton

Low battery

lnfuson complete

Alarm for malfuncton

+ Power supply

1OO-24O 7AC, 5O/6Ohz (Fuse: 25O7, TJ.15A)

1270C

+ Power consumpton Less than JO7A

+ Classfcaton Class l, Type 8F, lPX 1 (0rpproof)

+ 0menson (0 x w x h) 125 x 166 x 258 mm

+ weght Approx. J.2 Kg

* The specfcaton s subject to change wthout pror notce to mprove the

performance of equpment.

T

3. CH/F/CIEFlSIlCS

3.1 FkODbCI OVEkVIEW

The nfuson pump |odel |P1OOO s ntended for use n the l7 admnstraton of

parental nutrton and drug therapy, such as those used n chemotherapy, ant

tumor drugs, and oxytoccs and the lke, where precse, powered nfuson s

requred.

3.2 MEMOkY FbNCIION

The last used flow rate, total volume and optons of the settng mode are saved when

the pump s selected by pressng the STAPT key 1J.

3.3 CHAkACIEkISIICS OF IHE OCCIbSION DEIECIION

Ths test was performed accordng to the lEC 6O6O1224. The characterstcs about

the maxmum tme, pressure generated and bolus volume for actvaton of the

occluson alarm when the pump s operatng at the flow rate 1 ml/h and 25ml/h. For

each flow rate, the occluson pressure detecton level was set to each of the J

dfferent levels (Low, |ddle, hgh). And the used nfuson set s 0 KDREA MD0EL

PUMP A122.

Flow rate 0ccluson level 0ccluson Pressure Tme to alarm 8olus volume

1 ml/h

Low J71 mmhg 18mn 2Osec O.18 ml

|ddle 57O mmhg J9mn 15sec O.J8 ml

hgh 95O mmhg 1h JOmn O.51 ml

25 ml/h

Low 285 mmhg JOsec O.15 ml

|ddle 5J5 mmhg 1mn O.28 ml

hgh 921 mmhg 2mn 5Osec O.7J ml

Each pump can be a numercal dfference.

3.4 FbNCIION OF IHE DkOF SENSOk {OFIION}

1. The drop sensor alarm s actvated n case of accdental free flow, flow error or

empty contaner. lf t occurs, the pump s stopped.

2. lt s recommended that the drop sensor be used for addtonal safety.

3. CH/F/CIEFlSIlCS

3.4 FbNCIION OF IHE DkOF SENSOk {OFIION}

J. when usng the drop sensor, drop volume of the nfuson set should be selected

rghtly at 7.8 HDW TD SET UP INFUSIDN SET 0ropslmI.

4. when the drop sensor s attached, poston the drop chamber vertcally. lf

postoned nclned, correct drop sensor alarm s not ensured.

5. Ensure that the drop sensor s not exposed to drect sunlght.

6. Always mantan clean surface of the chamber of the nfuson set located the

drop sensor nsde.

See the 5.4. HDW TD INSTALL THE 0RDP SENSDR (Dption) secton

===============================================================

CAbIION

1. 0nly use the drop sensor for |edfuson |P1OOO.

2. 0urng nfusng, do not connect or dsconnect the drop sensor at the pump.

===============================================================

ST ART - U P C U RVE

T RUM P ET CURV E

15 30 45 60 75 90 105 120

F

lo

w

r

a

t

e

(

m

l/

h

)

3. CH/F/CIEFlSIlCS

3.5 FIOW kAIE ACCbkACY

Ths test was performed accordng to the IEC 60601-2-24.

The test are devsed to characterze the steadystate flow and to dentfy errors

both n the mean flow and n varatons about the mean flow. The graphs,

START-UP CURVE and TRUMPET CURVE, are shown to llustrate the whole and

nstant flow rate accuracy of the pump. The measured flow rate s flow rate

25ml/h. And a used nfuson set s 0 KDREA (modeI PUMP A122)

These graphs s related to the performance of the nfuson set. So, the graphs

can only serve as a representaton of the performance of the combnaton of

nfuson set and pump.

1. STAPTUP CUP7E

The graph of tme (horzontal axs) versus flow rate (vertcal axs) gve a clear

and smple pcture of the general stablty wth tme. Ths s generated durng

the stablzaton perod and produces the socalled START-UP CURVE. The start

up tme to reach the desred flow rate decreases as the desred flow rate s

ncreased.

5 0

1 0

[ % ]

8

4 0

6

4

3 0

2

0

2 0

- 2

- 4

1 0

- 6

- 8

0

T i m e [ m i n ]

- 1 0

2 5 1 1 1 9 3 1

O b s e r v a t i o n i nt e r v a l [ m i n ]

2. TPU|PET CUP7E

Flow rate : 25 ml/h

The graph of observaton nterval (horzontal axs) versus percentage error (vertcal

axs) s processed to ntegrate flow over a range of tme perods. The maxmum

postve and negatve errors occurrng wthn these tme perods are plotted. The end

of the trumpet curve shows the regularty of the flow rate as measured for the 2, 5,

11, 19 and J1mnute wndow. The end of the trumpet curve becomes smaller as the

flow rate s ncreased.

4. N/MES /ND FUNCIlCNS CF EXIEFN/L F/FIS

0ispIay Parts on the Front >

T

4. N/MES /ND FUNCIlCNS CF EXIEFN/L F/FIS

4.1 KEY

1. PUPCE KEY

8

Ths key s used for the PUPCE. when you press the purge, the settng up purge

volume wll be nfused automatcally. (hote: lt does not sense the ar and

occluson.)

2. T0TAL 70LU|E KEY

9

Ths key s used for settng up the total volume.

J. lhFUSE0 70LU|E KEY - 1O

Ths key s used for checkng the nfused volume.

4. FL0w PATE KEY 11

Ths key s used for settng up the flow rate.

5. ShlFT KEY 12

Ths key s used for settng up the total volume or the flow rate. when you press

ths key, the dgts wll be shfted to the left.

6. STAPT KEY -1J

Ths key s used for startng nfuson.

7. ST0P KEY -14

Ths key s used for stoppng nfuson. lf you press the button durng 1 or 2 seconds,

the selected nfused volume, flow rate and total volume wll be cleared off.

8. 0h/0FF KEY 15

.

Ths key s used for turnng the pump on/off. Press the key for 2 or J seconds to

turn the pump on/off. lf external power s suppled, the battery wll be charged

even f the correspondng ndcator s off.

4. N/MES /ND FUNCIlCNS CF EXIEFN/L F/FIS

4.1 KEY

9. UP KEY - J4

Ths key s used for settng up total volume or flow rate. The number wll be

ncreased by one each tme and wll rapdly ncrease whle the key s beng held

down.

1O. 00wh KEY J5

Ths key s used for settng up total volume or flow rate. The number wll be

decreased by one each tme and wll rapdly decrease whle the key s beng held

down.

4.2 DISFIAY

1. FL0w PATE 0lSPLAY wlh00w 1

Ths wndow dsplays nfuson flow rate to the patent. lt wll be blnked when flow

rate set up functon s selected (by pressng the Flow rate key 11).

2. 70LU|E 0lSPLAY wlh00w

4

Ths wndow dsplays total volume or nfused volume to the patent. lt wll be

turned on along wth Total volume ndcator

J

when Total volume set up functon s

selected (by pressng Total 7olume key

9

). however, only lnfused volume ndcator

2

wll be turned on when nfused volume s dsplayed (by pressng lnfused volume

key 1O).

J. T0TAL 70LU|E lh0lCAT0P

J

Ths ndcator wll be turned on when selectng Total volume selecton (by pressng

the Total volume key 9 ). At ths tme, the total volume data wll be dsplayed on

the 7olume dsplay wndow

4

.

4. N/MES /ND FUNCIlCNS CF EXIEFN/L F/FIS

4.2 DISFIAY

4. lhFUSE0 70LU|E lh0lCAT0P 2

Ths ndcator wll be turned on when nfused volume s selected (by pressng the

lnfused volume key 1O). At ths tme, lnfused volume data wll be dsplayed on the

7olume dsplay wndows

4

.

5. PUPCE lh0lCAT0P 5

Ths ndcator wll be turned on when purge starts (by pressng the PUPCE key

8

). lt

wll be turned off when purge stops.

6. ST0P lh0lCAT0P 6

Ths ndcator wll be turned on when nfuson s stopped. lt wll be turned off when

nfuson starts.

7. lhFUSl0h lh0lCAT0P 7

Ths ndcator dsplays the drug nfuson state n percentage ().

8. AC/0C lh0lCAT0P 16

Ths ndcator wll be turned on when external power (AC/0C) s suppled. lt wll be

turned off when operatng on batteres.

9. 8ATTEPY CAPAClTY lh0lCAT0P 17

Ths ndcator dsplays the battery capacty status n three levels (full, medum,

low). when external (AC/0C) power s suppled, J lamps of ths ndcator s turned

on, no concern wth battery capacty.

1O.AlP (8U88LE) ALAP| lh0lCAT0P 18

Ths ndcator wll be blnked wth the alarm soundng when an ar (bubble) sensor

detects bubbles durng the nfuson process.

4. N/MES /ND FUNCIlCNS CF EXIEFN/L F/FIS

4.2 DISFIAY

11. 0CCLUSl0h ALAP| lh0lCAT0P 19

Ths ndcator wll be blnked wth the alarm soundng when up or down occluson

sensor detects the blockng of the nfuson set durng nfuson process.

12. 000P 0PEh ALAP| lh0lCAT0P 2O

Ths ndcator wll be blnked wth the alarm soundng when the door s open or

somebody opens the door forcefully durng the nfuson process. however, the

ndcator wll be turned on wthout the alarm soundng when the door s open after

the nfuson s stopped.

1J. L0w 8ATTEPY ALAP| lh0lCAT0P 21

Ths ndcator wll be blnked wth the alarm soundng when the battery s

exhausted.

14. C0|PLETl0h ALAP| lh0lCAT0P 22

Ths ndcator wll be blnked wth the alarm soundng when nfuson s completed.

15. |lCP0 FUCTl0h lh0lCAT0P 2J

Ths ndcator wll be turned on only n mcro mode (Flow rate O.1 - 99.9ml/h).

T

4. N/MES /ND FUNCIlCNS CF EXIEFN/L F/FIS

4.3 INSIDE OF IHE DOOk

1. UP 0CCLUSl0h 0ETECT0P 29

Ths part senses whether or not the tubng s blocked on the upper part of the

pump.

< DOOk INSIDE >

2. Kh08 JO

Pull down the knob to open the Pumpng unt (J1) and push t back to close t.

when the door s closed wthout pushng the knob back, the knob wll be pushed

back automatcally.

J. PU|PlhC UhlT J1

Ths part s used to nfuse drugs by pressng the tubng on the nfuson set.

4. 00wh 0CCLUSl0h 0ETECT0P J2

Ths part senses whether or not the tubng s blocked on the lower part of the pump.

5. AlP 0ETECT0P JJ

Ths part s used to prevent ar from beng nfused by detectng ar n the nfuson

set.

4. N/MES /ND FUNCIlCNS CF EXIEFN/L F/FIS

4.4 MObNIING FAkI ON IHE 8ACK

1. hUPSE CALL P0PT - 24 (0PTl0h)

lf you connect the nurse call cable to the pump, the port wll transmt the warnng

to the nurse call n case of problem.

2. 0P0P SEhS0P P0PT 25 (0PTl0h)

Ths port s connected to a drop sensor.

J. P0wEP SwlTCh 26

Ths swtch s used for turnng power on/off.

4. 0C P0wEP P0PT 27

12-15 70C power can be suppled through ths port.

5. AC P0wEP P0PT 28

1OO-24O 7AC and 5O/6O hz can be suppled through ths port.

4. N/MES /ND FUNCIlCNS CF EXIEFN/L F/FIS

4.5 SYM8OIS

0escrpton of symbol used on front and rear panel.

SYM8OIS

Power off

(Power : 0sconnecton form the

mans)

Shift key

(0ne step a movement the lft)

Power on

(Power : 0sconnecton to the mans)

Purge

(The l/7 and F/P whch are set

automatc pourng)

0own key

(Fgure one 0ecrease)

Up key

(Fgure one addton )

Start key

(|edcne water pourng nto the

start)

Type F equpment accordng to

lEC6O6O11

StoplCIear

(|otor 8 Alarm stop, l/7 8 F/P 8 T/7

clear)

|anufacturer's seriaI number.

0ate of Manufacture

Address of manufacturer.

0evce comples wth the

requrements of the EC 0rectve

9J/42/EEC.

Fuse replacement on wth type

and ratng shown

EU Pepresentatve

Attention : See nstructons for use

REF Catalogue ho.

0o not dspose of ths product as unsorted muncpal waste.

Follow local muncpal waste ordnances for proper dsposal provsons to reduce the

envronmental mpact of waste electrcal and electronc equpment (wEEE).

.T

4. N/MES /ND FUNCIlCNS CF EXIEFN/L F/FIS

4. ACCESSOkIES

0hLY USE ThE SPEClFlE0 ACCESS0PlES 8Y ThE C0|PAhY.

1. PP07l0E0 ACCESS0PlES

= AC Power cord

= 0peratng |anual For User

= lnfuson set : 5 ea

2. SPEClAL ACCESS0PlES

= 0rop Sensor

= hurse Call

= 0C Cable

.

..

5. CFEF/IlCN

5.1 AIIACH IHE FbMF IO AN INFbSION SIAND

Secure the pump properly to the nfuson stand by turnng the handle of the clamp

at the backsde of the pump. 8e sure to check the stablty of the nfuson stand.

5.2 HOW IO CONNECI IHE FOWEk

1. Plug the power cord nto the AC power port

of the pump to connect the power.

28 on the back

2. Turn on the Power Switch 26 on the back and then

AC/0C ndcator 1

6

wll be turned on.

J. Press DNlDff key 1

5

on the front for 2 or J seconds.

4. The ndcator on the front wll be turned on and the pump wll

start examnng ts functons.

5. when the examnaton s completed, the FIow rate dispIay window

1

wll be

blnked and enter nto the flow rate setup state.

5.3 HOW IO INSIAII AND SEI bF AN INFbSION SEI

1. Locate the roller clamp of the nfuson set between the nfuson pump and the tp

connector of the nfuson set, and closes the roller clamp.

2. Connect the nfuson set wth the soluton contaner, then pnch the drop chamber

and fll t about one thrd to one half wth soluton.

J. 0pen the roller clamp and fll the nfuson set up to the tp wth soluton and then

close the roller clamp.

4. hang the soluton contaner on the nfuson stand and t should hot be placed above

1 m from the patent's heart because gravty may be relevant to the performance.

5. 0pen the door by pushng back the handle on the front door.

6. Pull down the knob JO to open the Pumping unit J1 as fgure 1.

Fgure 1 Fgure 2 Fgure J

.

5. CFEF/IlCN

5.3 HOW IO INSIAII AND SEI bF AN INFbSION SEI

NDTICE!

7. At ths tme, make sure to nstall the tubng on the nfuson set n the gven space

as fgure 2 and fgure J.

8. ln partcular, nstall the DccIusion Sensor

them wth fngers.

29, J2 and the Air sensor JJ by pressng

9. lf the nfuson set s not nstalled normally, ar alarm or occluson alarm wll sound.

1O. hold up the knob JO to close the pumping unit J1. At ths tme, make sure to

nstall the tubng on the nfuson set.

11. Close the door by pullng down the handle.

12. when the roller clamp on the nfuson set s opened, check f there s any leakage

and then nsert the needle nto the patent's ven.

=========================================================================

CAbIION

1. Check f the nfuson set s avalable.

2. |ake sure that the nfuson set s not bent or twsted. lf t s not straght,

occluson or ar alarm wll occur or the flow rate wll not be fully reached.

J. 8efore openng the door or removng the nfuson set, be sure to close the tubng

by usng a clamp on the nfuson set. lf not, t wll cause leakage.

4. when the soluton contaner or nfuson set s replaced or change, follow the

above statements.

5. when the same secton of the tubng s used for a long tme, deformaton of the

tubng may occur, resultng n a flow rate devaton. Ether move the tubng at

least 2O cm every 12 hours, or replace the nfuson set wth a new one.

=========================================================================

.

5. CFEF/IlCN

5.4 HOW IO INSIAII IHE DkOF SENSOk {OFIION}

1. lnsert the plug of the drop sensor nto the drop sensor connector at the back of

the pump.

2. Set optons of mode by the statements descrbed at the 7.8 HDW TD SET UP

INFUSIDN SET 0ropslmI.

J. Attach the drop sensor to the chamber of the nfuson set by squeezng the drop

sensor wth your fngers. The drop sensor should be located between the drop

nozzle of the chamber and the surface of the soluton. Ensure the drop sensor's

locaton to avod any ncorrect detecton.

=========================================================================

CAUTIDN

1. when the drop sensor s used, the drop sensor must be postoned vertcally at

the drop chamber. ln addton, drop sensor s not exposed to the drect sunlght.

lf not, sensor may work ncorrectly.

2. Please do not connect t to nurse call port.

=========================================================================

5.5 HOW IO SEI bF A FIOW kAIE

1. Press the FIow rate key , and FIow rate dispIay windows on the front s

blnked.

2. Set a desred flow rate by usng the Up key, 0own key and SHIFT key @.

* The number contnues to changes rapdly whle the key s beng held down.

J. ln addton, when the STDP key @ s pressed for one or two seconds, the data

wll become O.

5.. HOW IO SEI bF IOIAI VOIbME {VOIbME IO 8E INFbSED}

1. Press the TotaI voIume key , and VoIume dispIay window and the TotaI

voIume indicator on the front are turned on.

2. Set the desrable total volume by pressng Up, 0own and SHIFT key @.

* The number contnues to changes rapdly whle the key s beng held down.

J. ln addton, when the STDP key @ s pressed for one or two seconds, the data

wll become O.

.

5. CFEF/IlCN

5.. HOW IO SEI bF IOIAI VOIbME {VOIbME IO 8E INFbSED}

4. To set up unlmted data, press 0own key at total volume 1ml or Up key at total

volume 9999 ml. Then, " wll be dsplayed on VoIume dispIay window .

lnfuson wll contnue untl ar or occluson alarm occurs.

5.7. HOW IO SIAkI IHE OFEkAIION

1. Start the pump by pressng the START key @ on the front.

2. lf the total volume s O ml, or nfused volume s bgger than total volume, the

VoIume dispIay window wll be blnked. ln ths case, reset the total volume or

clear the nfused volume.

J. 0nce t s started, the STDP ndcator wll be turned off and the Infusion

indicator wll be blnked dsplayng the nfused volume n percentage () n

proporton to the total volume.

4. At ths tme, n case of mcro mode (Flow rate of O.1-99.9ml/h), the |cro functon

ndcator wll be turned on, notfyng that the pump s n the mcro mode.

5. As the pump starts ts operaton, the nfused volume ncreases by steps.

6. lf the memory functon s set up by "0h" n the program mode, the total volume

and flow rate wll be saved n case of sudden power off. That means the most

prevous data wll be dsplayed when the power s back on.

=========================================================================

CAbIION

1. 8efore you start the nfuson, check the flow rate and total volume whether you

set them exactly.

2. After push the start button, check the nfuson for several mnutes whether t s

well workng.

=========================================================================

5.8. HOW IO SIOF & kESIAkI IHE OFEkAIION

1. when the STDP key @ on the front s pressed to stop the nfuson by force durng

the normal operaton (.e., durng general nfuson or purge nfuson), the Infusion

indicator wll be turned off and the STDP indicator wll be turned on.

2. To contnue the nfuson, press the START key @ on the front.

.T

5. CFEF/IlCN

5.. HOW IO VIEW INFbSED VOIbME

1. ln order to vew the nfused volume, press the Infused voIume key durng

nfuson or whle settng up the total volume and flow rate setup. Then, the Infused

voIume indicator wll be turned on dsplayng the correspondng nformaton.

At ths pont, the VoIume dispIay window s not blnked.

2. ln addton, when the STDP key @ s pressed for one or two seconds, the lnfused

volume data wll become O.

5.10. INFbSION COMFIEIION

1. when nfuson s completed accordng to the settng data (Total volume and flow

rate), the completon alarm ndcator wll be blnked wth the alarm soundng.

2. The nfuson wll contnue at K.7.0 rate by usng the K.7.0 (keepvenopen)

functon.

J. The K.7.0 wll not stop unless the STDP key @ s pressed or alarm s occurred.

4. Press the STDP key @ to stop the nfuson. Then, the alarm and the Completon

alarm ndcator wll be turned off along wth the Infusion indicator . 0nly the

STDP indicator wll be turned on.

5.11. FbkGE FbNCIION

1. To start purge, press the PURCE key on the front n

condton the nfuson s stopped.

2. lt automatcally nfuses the purge volume set up at the

desgnated speed and then stops the nfuson.

J. At ths tme, the Purge indicator wll be turned on, but ar

or occluson wll not be detected.

4. Press the STDP key @ to stop purge durng the purge

operaton.

=========================================================================

CAbIION

ln case of purge nfuson, ar or occluson s not detected; therefore the user should

pay a close attenton to the pump.

.

=========================================================================

.

. /L/FM

=========================================================================

ALARM

Ths secton covers the alarm that occurs when the pump s not operated normally

and provdes effcent ways to deal wth t.

For the safety of the patents, several alarm devces are prepared. when they operate,

the alarm ndcator wll be blnked and the alarm wll sound. Press the STDP Key @

to stop the alarm. Snce each alarm has dfferent sound, the user can tell the knds of

problems just by lstenng to the alarm.

=========================================================================

hormal Ar Alarm 0ccluson 0oor 0pen Low 8att.

Alarm Alarm Alarm

.1 AIk {8b88IE} AIAkM

1. lf an ar sensor senses ar n the tubng, the pump wll stop nfuson, and the Ar

(8ubble) alarm ndcator wll be blnked wth the alarm soundng.

2. Press the STDP key @ to deactvate the alarm.

J. Pemove the ar from the nfuson set and restart the pump by pressng the START

key @.

.2 OCCIbSION AIAkM

1. Ths occurs when the pump s operated n the followng condtons: when an

nfuson set s bent or abnormally mounted, or the needle on the nfuson set s

clogged, preventng drugs from gettng n. ln ths case, the nfuson wll stop, the

0ccluson alarm ndcator wll be blnked, and alarm wll sound.

2. Press the STDP key @ to deactvate the alarm.

J. To restart the pump, remount the tubng or straghten the lnfuson set or unclog

the needle and then press the START key @.

.

. /L/FM

.3 DOOk OFEN AIAkM

1. Ths occurs when the pump's door s open or not shut completely. ln ths case, the

current nfuson wll stop, the 0oor open alarm ndcator wll be blnked, and the

alarm wll sound. however, the 0oor open alarm ndcator wll be turned on wthout

the alarm soundng when the door s open after the nfuson s stopped.

2. Press the STDP key @ to deactvate the alarm.

J. Close the door completely and press the START key @ to restart the pump.

.4 IOW 8AIIEkY AIAkM

1. Ths occurs when the pump can no longer operate on ts nternal battery or when

the battery chargng s low. ln ths case, the Low battery alarm ndcator wll be

blnked and then alarm wll sound.

2. Low battery alarm wll sound approxmately for JO mnutes and before the battery

goes out completely, the pump wll stop the nfuson automatcally and the dsplay

wll be off.

J. Connect to the external power to deactvate the alarm.

.5. FkEE FIOW & NO DkOF AIAkM {IN CASE IHE DkOF SENSOk IS bSED}

1. when the drop sensor s used, the drop sensor senses accdental free flow, lqud

leakage, flow error or empty contaner. And then the pump wll stop the nfuson

wth alarm.

2. when the alarm s actvated, "F.Err" s dsplayed at the FIow rate dispIay

Windows n addton to the alarm soundng.

J. Press the STDP key @ to deactvate the alarm.

See the 5.4. how to nstall the drop sensor (0pton) secton

. Ib8ING MISIOADING AIAkM

1. Ths occurs when the tubng s not loaded or mslead through

Pumpng unt.

2. when the alarm s actvated, SET Err s dsplayed at the FIow

rate dispIay windows and VoIume dispIay window wth

the alarm soundng and then the pump wll stop the nfuson.

J. Press the STDP key @ to deactvate the alarm.

T

4. To restart the pump, reload the tubng through the Pumpng unt and then press

the START key @.

. /L/FM

.7 OIHEkS

1. when the pump operates abnormally, nfuson wll stop, the error wll be dsplayed

n FIow rate dispIay windows , and alarm wll sound.

2. Check the alarm message

Err.

0splay

Causes Err.

0splay

Causes

Er.O1 Key lnput Error Er.O5 Error n the operaton of

the pumpng unt

Er.O2 lnternal lC Error Er.O6 Error n the operaton of

the pumpng unt

Er.OJ lnternal lC Error Er.O7 Error n the operaton of

the pumpng unt

Er.O4 Error n the operaton

of the pumpng unt

J. Contact local agences or the company for further assstance.

.

7. USEF SEIIlNG

bSEk SEIIING

Ths secton deals wth data settng by the user. Ths program s desgned to serve

the followng purposes: (1) help the user set up optons drectly accordng to the

envronment and (2) guarantee safety and convenence. User settng mode can be

performed when nfuson s stopped.

=======================================================================

1. when the lnfused volume key s pressed for two seconds, the program verson n

the pump wll be dsplayed for one or two seconds and the pump wll enter nto the

user settng mode. The User settng can be done when nfuson s stopped.

2. Select the opton of each functon by pressng Up and 0own key.

J. Press the ShlFT key @ to swtch to other functon settng modes.

4. Press the lnfused volume key to save the settng opton or ST0P key @ to

cancel the settng, and then go back to the ntal mode. (Total volume or flow rate

settng mode)

5. The functons that the user can set up are as follows:

Parameter 0pton 0escrpton Pemark

1. Accuracy 5 O (80 K0PEA |odel A122)

2. 0ccluson Alarm |ddle |ddle

J. Alarm sound |ddle |ddle

4. Purge Flow Pate 7OO 7OO ml/h

5. Purge 7olume J J ml

6. |emory Functon on |emory mode

7. K.7.0 Pate 1 1 ml/h

8. lnfuson set Type 15 15 0rops/ml

9. hurse call 0h/0FF off hurse call s not allowed

1O. Standby alarm on Standby alarm s allowed

11. Ar alarm |ddle 8elow 7 mm

12. Tubng msloadng alarm on |sloadng alarm s allowed

Table: Settng optons when Peleased from the Factory (Program 7erson 2.O8)

7. USEF SEIIlNG

7.1 HOW IO SEI bF IHE CAII8kAIION {ACCbkACY}

1. Enter nto the user settng mode by press the Infused

voIume key for two seconds when nfuson s stopped.

2. Change the mode by pressng the SHIFT key @ untl the

calbratonsettng state s dsplayed.

J. To cancel the settng and go back to the ntal mode, press

the STDP key @.

4. Change the opton to a desrable one by pressng Up and 0own key. Then, press the

Infused voIume key to save the changed opton and go back to the ntal mode.

5. lf ths functon s used for calbraton, contact local agences or the company.

6. The followng table shows how the pump operates at specfc optons:

0ispIayed options 1 3 5 7 11 13 15 ..

Correction () -20 -10 0 10 20 30 40 50 ..

7. lf errors occur whle usng the pump, correct optons that were prevously set up.

For example, f the opton s set to '5' and ts error s +8 (ndcatng that t s 8

hgher than the settng opton), set the opton to J or 4.

8. Please be nformed that the maxmum flow rate can be lmted accordng to the

each ACC value. Please refer to the below table.

0ispIayed options 1-13 14-15 16-18 1-21 22

Maximum F l R(mIlh) 00 800 700 600

=========================================================================

CAbIION

1. Use a desgnated nfuson set for nfuson pump. lf any nfuson set other than

specfed s used, proper flow rate accuracy and alarm functon (ar and occluson)

s not guaranteed. lf the desgnated set s not avalable, contact the local agency or

the company.

2. Pay close attenton to the dfference of the occluson senstvty, purge rate and

maxmum flow rate by the Accuracy optons.

J. lf serous errors occur due to the extended use of the pump, contact the company.

lt s recommended that the user make correcton by testng once a year.

========================================================================

7. USEF SEIIlNG

7.2 HOW IO SEI bF OCCIbSION FkESSbkE

1. Enter nto the settng mode by pressng the Infused voIume

key for two seconds when nfuson s stopped.

2. Change the mode by usng the SHIFT key @ untl occluson

pressure settng state s dsplayed.

J. Press the STDP key @ to cancel the settng and go back to

the ntal mode.

4. Change the opton to a desrable one by usng Up and 0own key. Then, press the

Infused voIume key to save the changed opton and go back to the ntal mode.

5. The followng table shows how the pump operates at the specfc optons:

0ispIayed

Dption

Pressure 100-450 mmHg 300-750 mmHg 600-50 mmHg

7.3 HOW IO SEI bF AIAkM VOIbME

1. Enter nto the user settng mode by pressng the Infused

voIume key for two seconds when nfuson s stopped.

2. Change the mode by usng SHIFT key @ untl alarm volume

settng state s dsplayed.

J. Press the STDP key @ to cancel the settng and return to

the ntal mode.

4. Change the opton to a desrable one by pressng Up and 0own key. Then, press

Infused voIume key to save the changed opton and go back to the ntal mode.

5. The followng table shows how the pump operates at specfc optons:

0ispIayed

Dption

VoIume Low Medium High

7. USEF SEIIlNG

7.4 HOW IO SEI bF FbkGE kAIE

1. Enter nto the user settng mode by pressng the Infused

voIume key

1O for two seconds when nfuson s stopped.

2. Change the mode by usng the SHIFT key

settng state s dsplayed.

1

2

untl purge rate

J. Press the STDP key

ntal mode.

1

4

to cancel the settng and return to the

4. Change the opton to a desrable one by pressng Up and

J4 0own keyJ5. Then,

press the Infused voIume key

ntal mode.

1

O

to save the changed opton and go back to the

5. The followng table shows how the pump operates at specfc optons:

0ispIayed option 300 500 700 00

Purge rate 300 mIlh 500 mIlh 700 mIlh 00 mIlh mIlh

6. The purge flow rate can be lmted by the calbraton data (ACC).

Acc. 1 - 13 14 - 15 16 - 21 22

SeIectabIe purge rate 300, 500, 700, 300, 500, 300, 500, 300, 500

(mIlh) 00, 700, 00 700

7.5 HOW IO SEI bF FbkGE VOIbME

1. Enter nto the user settng mode by pressng the Infused

voIume key for two seconds when nfuson s stopped.

2. Change the mode by usng the SHIFT key @ untl purge

volume settng state s dsplayed.

J.Press the STDP key @ to cancel the settng and return to the

ntal mode.

4. Change the opton to a desrable one by pressng Up and 0own key. Then, press the

Infused voIume key to save the changed opton and go back to the ntal mode.

5. The followng table shows how the pump operates at specfc optons:

T

0ispIayed option 1 2 3 4 5 6 7 8

Purge VoIume 1 mI 2 mI 3 mI 4 mI 5 mI 6 mI 7 mI 8 mI mI

7. USEF SEIIlNG

7. HOW IO SEI bF SAVE FbNCIION

1. Enter nto the user settng mode by pressng the Infused

voIume key for two seconds when nfuson s stopped.

2. Change the mode by usng the SHIFT key @ untl save

functon settng state s dsplayed.

J. Press the STDP key @ to cancel the settng and return to

the ntal mode.

4. Change the opton to a desrable one by pressng UP and 0own key. Then, press the

Infused voIume key to save the changed opton and go back to the ntal mode.

5. The followng table shows how the pump operates at specfc optons:

0ispIayed option

TotaI VoIume,

FIow Rate Save

Set up Not Set up

7.7 HOW IO SEI bF K.V.O. kAIE

1. Enter nto the user settng mode by pressng the Infused

voIume key for two seconds when nfuson s stopped.

2. Change the mode by usng the SHIFT key @ untl K.7.0 rate

settng state s dsplayed.

J. Press the STDP key @ to cancel the settng and return to

the ntal mode.

4. Change the opton to a desrable one by pressng Up and 0own key. Then, press the

Infused voIume key to save the changed opton and go back to the ntal mode.

5. The followng table shows how the pump operates at specfc optons:

0ispIayed option 1 2 3 4 5 6 7 8

K.V.D rate 1 mIlh 2 mIlh 3 mIlh 4 mIlh 5 mIlh 6 mIlh 7 mIlh 8 mIlh mIlh

7. USEF SEIIlNG

7.8 HOW IO SEI bF INFbSION SEI DropsJm| {WHEN bSING A

DkOF SENSOk}

1. Enter nto the user settng mode by pressng the Infused

voIume key for two seconds when nfuson s stopped.

2. Change the mode by usng the SHIFT key @ untl nfuson set

drops/ml settng state s dsplayed.

J. Press the STDP key @ to cancel the settng and return to

the ntal mode.

4. Change the opton to a desrable one by pressng Up and 0own key. Then, press the

Infused voIume key to save the changed opton and go back to the ntal mode.

5. The followng table shows how the pump operates at specfc optons:

0ispIayed option 15 20 60

Infusion Set Type 15 0ropslmI 20 0ropslmI 60 0ropslmI

7. HOW IO SEI bF NbkSE CAII {OFIION}

1. Enter nto the user settng mode by pressng the Infused

voIume key for two seconds when nfuson s stopped.

2. Change the mode by usng the SHIFT key @ untl nurse call

settng state s dsplayed.

J. Press the STDP key @ to cancel the settng and return to

the ntal mode.

4. Change the opton to a desrable one by pressng Up and 0own key . Then, press

the Infused voIume key to save the changed opton and go back to the ntal

mode.

5. The followng table shows how the pump operates at specfc optons:

0ispIayed option

Nurse caII Set up Not set up

7. USEF SEIIlNG

7.10 HOW IO SEI bF SIAND8Y AIAkM

1. Enter nto the user settng mode by pressng the Infused

voIume key

1O for two seconds when nfuson s stopped.

2. Change the mode by usng the SHIFT key

alarm settng state s dsplayed.

1

2

untl standby

J. Press the STDP key

ntal mode.

1

4

to cancel the settng and return to the

4. Change the opton to a desrable one by pressng Up and 0own key. Then, press the

Infused voIume key

1O to save the changed opton and go back to the ntal mode.

5. The followng table shows how the pump operates at specfc optons:

0ispIayed option

Standby aIarm Set up Not set up

7.11 HOW IO SEI bF Ib8ING MISIOADING AIAkM

1. Enter nto the user settng mode by pressng the Infused

voIume key for two seconds when nfuson s stopped.

2. Change the mode by usng the SHIFT key @ untl tubng

msloadng alarm state s dsplayed.

J. Press the STDP key @ to cancel the settng and return to

the ntal mode.

4. Change the opton to a desrable one by pressng the Up key , 0own key . Then,

press the Infused voIume key to save the changed opton and go back to the

ntal mode.

5. The followng table shows how the pump operates at specfc optons:

0ispIayed option

MisIoading aIarm Set up Not set up

7. USEF SEIIlNG

7.12 HOW IO SEI bF AIk SENSIIIVIIY

1. Enter nto the settng mode by pressng the Infused voIume

key for two seconds when nfuson s stopped.

2. Change the mode by usng the SHIFT key @ untl ar sensor

senstvty settng state s dsplayed.

J. Press the STDP key @ to cancel the settng and go back to

the ntal mode.

4. Change the opton to a desrable one by usng Up and 0own

key . Then, press the Infused voIume key to save the changed opton and go

back to the ntal mode.

5. The followng table shows how the pump operates at specfc optons:

0ispIayed

Dption

ubbIe size beIow 3 mm beIow 7 mm beIow 10 mm

7.13 OIHEkS {IESI MODE}

1. Press the FIow rate key for two seconds when nfuson s stopped. At ths tme,

enter nto the test mode whch s used to manufacture the pump and to provde

customer servce.

T

2. To get out of the test mode, go back to the user settng mode by pressng the STDP

key @.

=========================================================================

CAbIION

Ths test functon s desgned to check the presence of problems n each sensor. For

the best results, the user needs to refer to the servce manual or contact the

company drectly.

=========================================================================

8. M/lNIEN/NCE

8.1 CHECKObI OF IHE FbMF

* lt s recommended that the user make correcton by testng the pump once a year

for the more safe usage.

* lf any problem occurs, contact the local agences or company.

1. Accuracy

Perodcally check the nfused volume. lf the nfused volume s not accurate, contact

the Local agences or Company.

2. Checkout of the Air (ubbIe) aIarm

Poston the ar(bubble) below the Pumpng unt and above the ar sensor. The

ar(bubble) sze should be bgger than 1Omm. Start the nfuson. when the ar

reaches the ar sensor, check the Ar alarm s occurred.

J. Checkout of the DccIusion aIarm

1) Upstream occluson alarm

Pnch off the tubng located between the drop chamber and above the pump wth

roller clamp or fngers. And then check the 0ccluson alarm s occurred.

2) 0ownstream occluson alarm

Pnch off the tubng located between below the pump and the patent lne wth

roller clamp or fngers. And then check the 0ccluson alarm s occurred.

4. Checkout of the 0oor open aIarm

1) Set the nfuson set, and opens the door. Check the 0oor open alarm s occurred

when the START key @ s pressed.

2) 0urng nfuson, open the door. And then check the 0oor open alarm s occurred.

5. Checkout of the Low battery aIarm

1) Charge the nternal battery to full capacty by connectng the pump to an AC

power supply for at least 15 hours.

2) Set the flow rate 25ml/h, and unplug the pump for operatng the pump by the

nternal battery. Start the nfuson by pressng the START key @

J) Check the pump s operated about approxmately 2 hours and Low battery alarm

s occurred when J lamps of the 8attery capacty ndcator s turned off.

.

8. M/lNIEN/NCE

8.2. CIEANING AND SIEkIIIIAIION

8efore cleanng the pump, be sure to turn off the pump by Power swtch , and

dsconnect the AC power port or 0C power port from the pump.

0o not sterlze the pump wth autoclave or E.0 gas.

0o not use thnner, solvent, benzene, ammona or acetone.

Use a gauze mostened wth cold or warm water.

8efore usng t, be sure to dry the pump.

8.3 SIOkAGE OF IHE INFbSION FbMF

1. Ensure that ths pump s not exposed to drect sunlght or water.

2. Avod the place danger to fall.

J. Storage condtons

1) Temperature : 2O'45'

2) humdty : 1O95

8.4 IIFE SFAN

1. These lfe spans are marked to mantan the accuracy and operaton of the pump.

1) 8attery approxmately 1 year

2) lnfuson pump(|P1OOO) approxmately 5 years

2. 0scard the pump passng the tme lmt. ln case of dscard of ths pump, be sure

to remove the nternal battery. As to the battery, please dscard t accordng to

your local regulaton or contact the local agences.

. W/FF/NIY

The |anufacturer warrants that pump s free from defects n materal and

workmanshp under normal use and servce for a perod of 12 months after the

purchase date.

The |anufacturer or ts authorsed representatve takes oblgaton to carry out

the warranty repar of the pump or to replace the pump wth an operatonal

one n case the |anufacturer or ts authorsed representatve determnes that

the cause of the pump's falure was related to the manufacturng process.

lf the 8uyer fnds a defect n the pump durng the warranty perod, he must

report t and nform the |anufacturer or ts authorsed representatve wthn JO

days.

A pump sent for testng, repar or replacement shall be submtted to the

|anufacturer or ts authorsed representatve n ts orgnal or equvalent

packagng. The pump s sent for repar and back at 8uyer's expense.

lf no defect s found durng testng, the |anufacturer or ts authorsed

representatve reserves the rght to submt the nvoce to the 8uyer for the

work carred out.

Ths warranty s not applcable to pumps wth damaged seal or when falure

was caused by volatons of requrements of ths 0peraton |anual, by mans

voltage nonconformty to the requrements of lEC, by splls of lquds, by

mechancal damages caused by shocks or a pump beng dropped, by pump

damages caused durng transportaton, or when packagng s damaged.

Serial No:

Delivery date:

Quality inspector:

DCCUMENI HlSICFY

0rgnal ssue (MP-E-061): March 2006

Revision 1 (MP-E-062): May 2006

Revision 2 (MP-E-063): November 2006

Revision 3 (MP-E-064): November 2008

Das könnte Ihnen auch gefallen

- mp1000 g2Dokument93 Seitenmp1000 g2Ezequiel MelendresNoch keine Bewertungen

- TEEL BRONZE ROTARY PUMP Manual & Parts ListDokument8 SeitenTEEL BRONZE ROTARY PUMP Manual & Parts ListMoToBunnYNoch keine Bewertungen

- Accessory Manual - Operation Flow Meter FMBC2000 OIM (106761)Dokument10 SeitenAccessory Manual - Operation Flow Meter FMBC2000 OIM (106761)Pkk Siam Rayong co-saleNoch keine Bewertungen

- BEKO - WB 6106 XD, 6108 XE, 6110 XE - User GuideDokument20 SeitenBEKO - WB 6106 XD, 6108 XE, 6110 XE - User GuideVlad Florescu100% (6)

- Functioning and Maintenance Manual: Progressing Cavity PumpsDokument42 SeitenFunctioning and Maintenance Manual: Progressing Cavity PumpsJoão Rosa e Correia100% (1)

- Bomba Infusion MP 1000Dokument69 SeitenBomba Infusion MP 1000Betancur Alejandro100% (5)

- Centrifuge Eppendorf 5415C PDFDokument9 SeitenCentrifuge Eppendorf 5415C PDFTarekNoch keine Bewertungen

- CS Sample Extractor (24 VDC, 115 VAC) User Manual: Clif Mock™Dokument12 SeitenCS Sample Extractor (24 VDC, 115 VAC) User Manual: Clif Mock™Gibran TorresNoch keine Bewertungen

- Millipore Chemical Duty Vacuum PumpDokument12 SeitenMillipore Chemical Duty Vacuum PumpMartin Lizarbe Williams100% (1)

- ""1J186 8' 4NC1J186 P144, C$J4R 16c$e$ E$co1$ 41'$Dokument16 Seiten""1J186 8' 4NC1J186 P144, C$J4R 16c$e$ E$co1$ 41'$Marian DunareanuNoch keine Bewertungen

- Leaning The Eaction ELL: Figure 5-10. Photolytic Lamp Assembly ReplacementDokument105 SeitenLeaning The Eaction ELL: Figure 5-10. Photolytic Lamp Assembly ReplacementEdwar Vicente Moreno AsmatNoch keine Bewertungen

- P QUIP Swab and Pony RodDokument5 SeitenP QUIP Swab and Pony Rodkrishnsgk0% (1)

- Directions for Use of Samson Liquid Ring Pumps ME65-ME160Dokument12 SeitenDirections for Use of Samson Liquid Ring Pumps ME65-ME160Al0611981Noch keine Bewertungen

- Accessory Manual - Operation Flow Meter FM3000 OIM (106740)Dokument7 SeitenAccessory Manual - Operation Flow Meter FM3000 OIM (106740)Pkk Siam Rayong co-saleNoch keine Bewertungen

- Service instructions for SQFlex water supply systemsDokument66 SeitenService instructions for SQFlex water supply systemsPeter KariukiNoch keine Bewertungen

- TP-601D & TP-601LDokument149 SeitenTP-601D & TP-601LMyface BookNoch keine Bewertungen

- Intruction Manual FSADokument10 SeitenIntruction Manual FSAtrantuan74Noch keine Bewertungen

- Boyser FMP60 ManualDokument17 SeitenBoyser FMP60 ManualBoopyJoeNoch keine Bewertungen

- AHTOIrrigation Pump Service ManualDokument24 SeitenAHTOIrrigation Pump Service Manualchad100% (1)

- 152012.B OptiFloDokument36 Seiten152012.B OptiFloShaheen S. RatnaniNoch keine Bewertungen

- Barton 202 User ManualDokument44 SeitenBarton 202 User Manualkerons67% (3)

- Functioning and Maintenance Manual: Pompe Monovite - Progressing Cavity PumpsDokument44 SeitenFunctioning and Maintenance Manual: Pompe Monovite - Progressing Cavity PumpsCarla Ayelen Chorolque BorgesNoch keine Bewertungen

- Unico Power Spin Centrifuge Operators ManualDokument11 SeitenUnico Power Spin Centrifuge Operators ManualManuel Alejandro Iza GutierrezNoch keine Bewertungen

- Table Top Centrifuge: PLC-01, PLC-02, PLC-03, PLC-04, PLC-05Dokument18 SeitenTable Top Centrifuge: PLC-01, PLC-02, PLC-03, PLC-04, PLC-05sasyaNoch keine Bewertungen

- Woodpecker Endomatic EndomotorDokument42 SeitenWoodpecker Endomatic Endomotorpreethi.badamNoch keine Bewertungen

- Watson-Marlow Baseplate Mounted Pumps Installation and Operating Instructions 701FB/RDokument24 SeitenWatson-Marlow Baseplate Mounted Pumps Installation and Operating Instructions 701FB/RDeniMestiWidiantoNoch keine Bewertungen

- Suction Pump FAZZINI F-30 - Service ManualDokument10 SeitenSuction Pump FAZZINI F-30 - Service ManualAnonymous qmNwOUtUd100% (1)

- Goulds Pumps: G&L Series SSH-C and SSH-FDokument36 SeitenGoulds Pumps: G&L Series SSH-C and SSH-F1luckywolfNoch keine Bewertungen

- Programmable dispensers control chemicalsDokument8 SeitenProgrammable dispensers control chemicalsLuisNoch keine Bewertungen

- MC450 User ManualDokument32 SeitenMC450 User ManualCarlos Ubaldo100% (1)

- Modulus II PlusDokument10 SeitenModulus II PlusMiguelNoch keine Bewertungen

- Accessory Manual - Operation Flow Meter FM2000 OIM (106607)Dokument9 SeitenAccessory Manual - Operation Flow Meter FM2000 OIM (106607)Pkk Siam Rayong co-saleNoch keine Bewertungen

- Tourniquet User Manual 2012 PDFDokument10 SeitenTourniquet User Manual 2012 PDFphuongo2Noch keine Bewertungen

- Fluidrain: Installation & Maintenance InstructionsDokument12 SeitenFluidrain: Installation & Maintenance InstructionsAlejandro LamuedraNoch keine Bewertungen

- Installation, Operation and Maintenance Manual: 5-Stage Filtration Model S51-ICE4-2400-2Dokument4 SeitenInstallation, Operation and Maintenance Manual: 5-Stage Filtration Model S51-ICE4-2400-2WattsNoch keine Bewertungen

- Accessory Manual - Operation Flow Meter FMBC3000 OIM (106784)Dokument7 SeitenAccessory Manual - Operation Flow Meter FMBC3000 OIM (106784)Pkk Siam Rayong co-saleNoch keine Bewertungen

- 1 System Description LP3-RLU - 13.02.2006 New NHP5Dokument9 Seiten1 System Description LP3-RLU - 13.02.2006 New NHP5Andrei ZahaNoch keine Bewertungen

- Hypro D50 Service ManualDokument32 SeitenHypro D50 Service Manualjimi9488Noch keine Bewertungen

- Catalogue For TFM-FR-TZ-TX-B PDFDokument15 SeitenCatalogue For TFM-FR-TZ-TX-B PDFGuru Vaga50% (2)

- Volute Casing Pumps Installation Operation Servicing2Dokument49 SeitenVolute Casing Pumps Installation Operation Servicing2Mario StrašniNoch keine Bewertungen

- Fire Alarm SystemDokument12 SeitenFire Alarm SystemhapisstendeNoch keine Bewertungen

- SAVE THESE INSTRUCTIONSDokument23 SeitenSAVE THESE INSTRUCTIONSHosein HashemianNoch keine Bewertungen

- Gilian Operating ManualDokument37 SeitenGilian Operating ManualMatthew KingNoch keine Bewertungen

- Manual PLC-01-05 2014 0219Dokument26 SeitenManual PLC-01-05 2014 0219JanneDoee0% (1)

- Fill Rite PumpsDokument18 SeitenFill Rite PumpsCentral HydraulicsNoch keine Bewertungen

- SAT - Centrifugal Pump For TDUDokument4 SeitenSAT - Centrifugal Pump For TDUNIKHIL JOHRI100% (4)

- Accessory Manual - Operation Flow Meter FM1000 OIM (106606)Dokument6 SeitenAccessory Manual - Operation Flow Meter FM1000 OIM (106606)Pkk Siam Rayong co-saleNoch keine Bewertungen

- LX-VX-FX Service Manual-R2Dokument25 SeitenLX-VX-FX Service Manual-R2Jan100% (1)

- Ahto IfuDokument312 SeitenAhto IfuVanzari RBMNoch keine Bewertungen

- Eurostream-Installation Operation & Maintenance1Dokument20 SeitenEurostream-Installation Operation & Maintenance1M Kumar MarimuthuNoch keine Bewertungen

- Instruction Manual - Ultra Pompe V16.1Dokument31 SeitenInstruction Manual - Ultra Pompe V16.1AdvanDooremaalNoch keine Bewertungen

- Speedyblue Pool PumpDokument36 SeitenSpeedyblue Pool PumpLucian LeonteNoch keine Bewertungen

- Plunger Pump ManualDokument23 SeitenPlunger Pump Manualgovindharajalu75% (4)

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideVon EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideBewertung: 4 von 5 Sternen4/5 (8)

- Prevention of Actuator Emissions in the Oil and Gas IndustryVon EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNoch keine Bewertungen

- Sucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingVon EverandSucker-Rod Pumping Handbook: Production Engineering Fundamentals and Long-Stroke Rod PumpingBewertung: 5 von 5 Sternen5/5 (9)

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesVon EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesBewertung: 5 von 5 Sternen5/5 (1)

- Operator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowVon EverandOperator’S Guide to Centrifugal Pumps, Volume 2: What Every Reliability-Minded Operator Needs to KnowNoch keine Bewertungen

- Automotive Actuators and EVAP System TestingVon EverandAutomotive Actuators and EVAP System TestingBewertung: 4.5 von 5 Sternen4.5/5 (4)

- Service Manual President Jack PCDokument33 SeitenService Manual President Jack PCpatolin_123100% (1)

- Superstar ss-158Dokument48 SeitenSuperstar ss-158patolin_123Noch keine Bewertungen

- RD70HVF1: Mitsubishi RF Power Mos FetDokument8 SeitenRD70HVF1: Mitsubishi RF Power Mos Fetpatolin_123Noch keine Bewertungen

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Irf520 ModDokument1 SeiteIrf520 Modpatolin_123Noch keine Bewertungen

- 6th Central Pay Commission Salary CalculatorDokument15 Seiten6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- FT100D ServDokument123 SeitenFT100D Servpatolin_123Noch keine Bewertungen

- Polyfet RF Devices: Silicon Gate Enhancement Mode RF Power Transistor VdmosDokument2 SeitenPolyfet RF Devices: Silicon Gate Enhancement Mode RF Power Transistor Vdmospatolin_123Noch keine Bewertungen

- BK4802N - IC Radio PDFDokument19 SeitenBK4802N - IC Radio PDFpatolin_123Noch keine Bewertungen

- TFT ArduinoDokument42 SeitenTFT Arduinopatolin_123Noch keine Bewertungen

- Bionet BM3PatientMonitor - Service ManualDokument61 SeitenBionet BM3PatientMonitor - Service ManualIvan Berino0% (1)

- VCC3V3 circuit diagramDokument1 SeiteVCC3V3 circuit diagramNguyễn Hưng100% (1)

- FTK(X)N-N, FTK(X)-N Series Inverter Pair Service ManualDokument133 SeitenFTK(X)N-N, FTK(X)-N Series Inverter Pair Service ManualKevin AryaNoch keine Bewertungen

- Cos14310m5-V1 04hpc-En Manual H-P-Cosmos Running Machine STDokument176 SeitenCos14310m5-V1 04hpc-En Manual H-P-Cosmos Running Machine STpatolin_123Noch keine Bewertungen

- GEHC Service Manual CARESCAPE MV100 Vital Signs Monitor 2011Dokument178 SeitenGEHC Service Manual CARESCAPE MV100 Vital Signs Monitor 2011patolin_123Noch keine Bewertungen

- LM2586Dokument32 SeitenLM2586patolin_123Noch keine Bewertungen

- Voltage Dividers and Current DividersDokument24 SeitenVoltage Dividers and Current DividersRon RexNoch keine Bewertungen

- 1 s2.0 S0030402622009494 Main1Dokument20 Seiten1 s2.0 S0030402622009494 Main1K SiriusNoch keine Bewertungen

- 2016/01/13 Service Tools: The Following Service Tools Should Be Used To Aid in Troubleshooting The Electrical SystemDokument3 Seiten2016/01/13 Service Tools: The Following Service Tools Should Be Used To Aid in Troubleshooting The Electrical SystemLuis Lossio GuayamaNoch keine Bewertungen

- Chapter 1Dokument44 SeitenChapter 1John Jairo Ortiz Martinez91% (11)

- EECE 210 Circuit Analysis TechniquesDokument55 SeitenEECE 210 Circuit Analysis TechniquesstarboyNoch keine Bewertungen

- Getting Started With ATV312: Verify The Delivery of The DriveDokument4 SeitenGetting Started With ATV312: Verify The Delivery of The Driveteguh perkasaNoch keine Bewertungen

- Smart Security SystemDokument8 SeitenSmart Security SystemNeeraj Chowdary BinnuNoch keine Bewertungen

- R6 Hotel Project Electrical, Mechanical and Plumbing Works SpecificationDokument42 SeitenR6 Hotel Project Electrical, Mechanical and Plumbing Works SpecificationGabriella EllaNoch keine Bewertungen

- LCD Thermostat 2Dokument27 SeitenLCD Thermostat 2Mauro MarafonNoch keine Bewertungen

- SensoMAG MCP50 Manual Call Point EN54-11 SpecsDokument2 SeitenSensoMAG MCP50 Manual Call Point EN54-11 SpecsXavierNoch keine Bewertungen

- Shift Registers - 74HC595 & 74HC165 With ArduinoDokument26 SeitenShift Registers - 74HC595 & 74HC165 With Arduinochafic WEISSNoch keine Bewertungen

- FanTech FR BrochureDokument2 SeitenFanTech FR BrochureUBHappyNoch keine Bewertungen

- Electrical Engineer Resume - 3+ Years ExperienceDokument5 SeitenElectrical Engineer Resume - 3+ Years ExperienceAri MachaNoch keine Bewertungen

- Voltage Detector Ic With Counter Timer: Bd45Xxxg Bd46XxxgDokument5 SeitenVoltage Detector Ic With Counter Timer: Bd45Xxxg Bd46XxxgPham LongNoch keine Bewertungen

- 1. 3Φ TransformersDokument220 Seiten1. 3Φ TransformersKyambi MutiaNoch keine Bewertungen

- IC A110 BrochureDokument2 SeitenIC A110 BrochureChrome PicassoNoch keine Bewertungen

- TSPL - Generator - Protecction.Dokument8 SeitenTSPL - Generator - Protecction.Amaresh NayakNoch keine Bewertungen

- JBL Manual - Northridge E150PDokument8 SeitenJBL Manual - Northridge E150PionelflorinelNoch keine Bewertungen

- Design Considerations of The RF Front-End For High Dynamic Range Digital Radar ReceiversDokument4 SeitenDesign Considerations of The RF Front-End For High Dynamic Range Digital Radar ReceiversNuman KayaNoch keine Bewertungen

- 6ES72315PF320XB0 Datasheet en PDFDokument4 Seiten6ES72315PF320XB0 Datasheet en PDFahmad 58parsNoch keine Bewertungen

- Basic Electrical Circuits Tutorial (3 PhaseDokument2 SeitenBasic Electrical Circuits Tutorial (3 PhaseRahul KumarNoch keine Bewertungen

- Sw4548e PDFDokument152 SeitenSw4548e PDFGA16DET100% (1)

- Electrical System Design GuidelinesDokument125 SeitenElectrical System Design Guidelinescarlosmarciosfreitas100% (1)

- Philips fx70-55, x78 Ver.2.0 SMDokument48 SeitenPhilips fx70-55, x78 Ver.2.0 SMOrlando SilvaNoch keine Bewertungen

- Smart TV Mainboard ZLS47HIS-V1 With Cannot Startup Problem SolvedDokument6 SeitenSmart TV Mainboard ZLS47HIS-V1 With Cannot Startup Problem SolveduzenNoch keine Bewertungen

- Seminar, Workshop, ConferenceDokument30 SeitenSeminar, Workshop, ConferenceMutharasu SNoch keine Bewertungen

- Manual Gerador PWM XY-PWM1Dokument5 SeitenManual Gerador PWM XY-PWM1Elias Calçados100% (2)

- 1.8 ltr./110 KW Motronic, Engine Code AGU,: Current Flow DiagramDokument13 Seiten1.8 ltr./110 KW Motronic, Engine Code AGU,: Current Flow DiagramsergioNoch keine Bewertungen

- INfusia VP7 Operating ManualDokument59 SeitenINfusia VP7 Operating ManualDaniel Vargas100% (10)

- Infini 3-10KW Hybrid InvertersDokument2 SeitenInfini 3-10KW Hybrid InvertersZamran GillNoch keine Bewertungen