Beruflich Dokumente

Kultur Dokumente

Foundation Specifications: Installation Instructions

Hochgeladen von

César CastilloOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Foundation Specifications: Installation Instructions

Hochgeladen von

César CastilloCopyright:

Verfügbare Formate

Installation Instructions

Bulletin 237636

Foundation

Specifications

for 4.9-Meter Earth Station Antennas

1.0 INTRODUCTION

1.1 This document specifies typical foundation character-

istics, designs, requirements and dimensional specifica-

tions for the Andrew 4.9-Meter Earth Station Antennas.

2.0 FOUNDATION LOADING CHARACTERISTICS

2.1 Foundation loads are applied to the foundation pad

Figure 1

Foundation Orientation

Y

X

Z

Foundation Pad

Andrew Corporation

10500 West 153rd Street

Orland Park, IL U.S.A. 60462

Telephone: 708/349-3300

FAX (U.S.A.): 1-800/349-5444

Customer Service, 24 hours: U.S.A. Canada Mexico: 1-800/255-1479

U.K.: 0800 250055 Republic of Ireland: 1 800 535358

Other Europe: +44 1592 782612

Printed in U.S.A. 3/02

Copyright 2002 by Andrew Corporation

as shown in Figure 1. Positive applied forces are in the

direction of the X, Y, and Z coordinate axes.

2.2 Varying load conditions are dependent upon icing,

incident angle of the wind and elevation/azimuth angles

of the antenna. Foundation loading forces and moments

for various elevation versus wind conditions are listed in

Table 1.

Revision C

3.0 ANCHOR BOLT REQUIREMENTS

3.1 Typical anchor bolt installation configurations and

dimensions are shown in Figure 2.

3.2 Andrew Type 302689 Anchor Bolt Kit includes anchor

bolts, alignment plates and required mounting hardware as

shown.

4.0 FOUNDATION DESIGNS

4.1 The selected foundation for a particular site is depen-

dent upon local conditions. Soil borings and foundation

analysis should be performed by a qualified civil engineer.

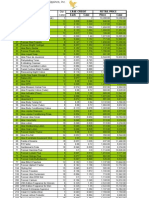

Table 1

2

4.9M ESA Foundation Loads, wind speed = 125mph

Forces Moments

F

X

F

Y

F

Z

M

X

M

Y

M

Z

Elevation Wind Side Lift Drag Pitch Yaw Roll

Angle (deg) Direction (deg) (lbs) (lbs) (lbs) (ft-lbs) (ft-lbs) (ft-lbs)

0 0 214 -171 -12630 -108826 801 -3529

0 30 495 -214 -13123 -113889 6568 -5073

0 60 -712 120 -11670 -104490 10114 5565

0 90 -2213 197 1008 7879 -18339 19457

0 120 -2771 85 3080 26763 -20987 23810

0 150 -1565 0 6556 57432 -16638 13902

0 180 -77 -111 7853 69704 529 1930

20 0 205 -4880 -11887 -84695 393 -3068

20 30 968 -4794 -12133 -88299 5600 -10338

20 60 -951 -3828 -10880 -80322 8932 2588

20 90 -2145 419 974 6519 -16812 22272

20 120 -2786 795 2951 25666 -19838 28387

20 150 -1805 1171 5826 53289 -15359 19671

20 180 0 1436 7460 68970 -846 1269

40 0 248 -8426 -9451 -49669 340 -2877

40 30 -416 -7785 -9233 -49253 4318 -2015

40 60 -1432 -5828 -7330 -44003 -2561 7442

40 90 -2153 795 820 3927 -14280 25027

40 120 -2761 1137 2344 20804 -16038 30245

40 150 -1960 1718 4710 45617 -12573 23130

40 180 -17 1957 5734 57253 409 976

60 0 94 -10656 -6777 -12155 113 -1390

60 30 -786 -8469 -6010 -18073 1026 185

60 60 -1930 -4956 -3630 -19358 -7968 19444

60 90 -2188 1008 521 469 -11804 27088

60 120 -2250 1769 2118 16741 -10329 25170

60 150 -1701 1316 3014 31565 -7974 19830

60 180 -51 1393 3572 39307 -203 1079

80 0 43 -3700 -2786 -19582 214 -1150

80 30 -1358 -2982 -2591 -20820 -4705 13640

80 60 -2201 -1384 -1212 -12467 -8959 26399

80 90 -2068 1051 222 -2040 -8591 28100

80 120 -2166 2435 1478 9899 -8336 26878

80 150 -1368 2897 2506 21245 -5145 15850

80 180 -34 2478 2606 22780 -58 525

4.2 A typical slab type foundation is shown in Figure 2. An

enlarged copy of this design is available from Andrew on

request. Refer to drawing number 240287.

5.0 FOUNDATION ORIENTATION

5.1 Proper foundation orientation is required to obtain the

desired orbital arc coverage from a particular site location.

The required azimuth and elevation angles of the antenna,

relative to the mount must be determined to establish the

appropriate foundation orientation. A specific foundation

orientation requirement may be requested with the antenna

as part of the installation package.

3

Figure 2

1. Remove all burrs and sharp edges.

2. Dimensions apply before plating.

3. Interpret drawing per ANSI Y14.5M-1982.

4. Dimensions are shown in feet and inches. Dimensions in

brackets [ ] are in millimeters.

5. A tolerance of 1/8" [3] applies to all anchor bolt layout

dimensions.

6. Foundation Notes:

A) This foundation is a typical design only. Certification

of it's suitability for a particular installation by a professional

engineer is required prior to it's use for actual fabrication.

B) Contractor shall field verify all dimensions locating exist-

ing construction before fabrication of new construction begins.

C) Concrete and related work shall be mixed, placed and

cured in accordance with "Building Code Requirements for

Reinforced Concrete" ACI 318-89 (Rev. 88) and

"Specifications for Structural Concrete" ACI 301-84 (Rev.

88) publication SP-15 (88).

D) Concrete for foundations shall develop a compressive

strength of at least 3000 psi [211 kgf/cm

2

] in 28 days with a

maximum slump of 3" [76] at time of placing.

E) Reinforcing bars shall conform to ASTM A 615 [S1]

grade 60 deformed type Fy = 60000 psi [4219 kgf/cm

2

].

F) Unless otherwise noted, concrete cover of reinforcing bars

shall conform to minimum requirements of ACI 318-89 (Rev. 88).

G) Fabrication of reinforcing steel shall be in accordance

with "Manual of Standard Practice for Detailing Reinforcing

ConcreteStructures" ACI 315-80 (Rev. 86).

H) Provide 3/4" x 45 [19 x 45] chamfer on all exposed

concrete edges.

J) Foundations have been designed to rest on undis-

turbed soil (per EIA-411-A and RS-222-D) with a minimum

allowable net vertical bearing capacity of 2000 psf [9770

kgf/m

2

]. If undesirable soil conditions are encountered, the

engineer shall be notified.

K) Backfills shall be suitable excavated material or other

suitable material compacted in 6" lifts to 90% of maximum

density as determined by ASTM D1557.

L) If this foundation is to be located in an area where

annual frost penetration depth exceeds 15" [381], the local

building code specifying a minimum required foundation

depth should be consulted.

7. Grounding Electrode System Notes:

The grounding system shown represents the minimum

requirements to achieve satisfactory grounding. Actual site

conditions and soil resistivity levels will determine final

grounding system design to comply with the following:

A) All ground ring, ground rod and antenna structure

connections to be EIRCO products, Inc. Calweld

exothermic type welded electrical connections or equiva-

lent.

B) Ground rods shall be driven to a depth below perma-

nent moisture level (minimum depth shown) as dictated by

geographical location.

C) The antenna structure shall be connected to a

grounding electrode system consisting of a number of

interconnected ground rods. The system shall meet the

requirements of the Underwriters' Laboratories Publication

No. ,UL96A for Lightning protection.

D) The grounding electrode system to earth resistance

shall not exceed 10 Ohms, measured with a Biddle 3 termi-

nal device or equivalent. The grounded conductor (neutral)

supplied to all ac equipment on the antenna structure

should be disconnected before taking measurement.

E) Actual site conditions may require longer ground rods,

additional ground rods and/or land fill additives to reduce

soil resistivity levels.

F) Avoid sharp bends when routing grounding wire.

Grounding wires to antenna structure to be run as short

and straight as possible.

G) Final grade directly above grounding electrode sys-

tem to be water permeable.

8. Power/IFL Conduit Notes:

A) Electrical power - Drawing depicts suggested location

for electrical power conduit to antenna. Size, type and

depth to bury conduit to be determined by customer in

compliance with local codes. Direction to route conduit to

be determined by the relative location of communcations

building/shelter. Power conduit to extend 6" (minimum)

above surface of foundation slab. Open ends of conduit to

be sealed to prevent moisture and foreign particle contami-

nation.

Customer to provide main load center assembly and

over-current protection devices for electrical equipment.

Mounting location of load center to be determined by cus-

tomer in accordance with local codes.

B) For routing IFL cables, 4 size conduit recommended.

Type and depth to bury conduit to be determined by cus-

tomer, in compliance with local codes. Location of conduit

on foundation and direction to route conduit to be deter-

mined by location of communications building/shelter.

Conduit to extend 36 (minimum) above surface of founda-

tion slab. All bends to be large radius, maximum of two

bends per run. Open ends of conduit to be sealed to pre-

vent moisture and/or foreign particle contamination.

General Notes

4

6.0 ANTENNA GEOMETRY

6.1 Figures 3 and 4 illustrate basic dimensional characteristics and azimuth adjustment range capabilities of the 4.9-

meter antenna.

Figure 3

5

Figure 4

6

Figure 5

6.75

Motorized Mount Dimensions

7

6.50

42.00

Das könnte Ihnen auch gefallen

- Triple Band Combiner Datasheet V1.1Dokument1 SeiteTriple Band Combiner Datasheet V1.1Сергей МирошниченкоNoch keine Bewertungen

- Autonics TimerDokument2 SeitenAutonics TimernooralhudNoch keine Bewertungen

- Calculate satellite carrier bandwidth using basic formulaDokument1 SeiteCalculate satellite carrier bandwidth using basic formulaAthan CalugayNoch keine Bewertungen

- Substation Lightning Protection and EarthingDokument8 SeitenSubstation Lightning Protection and Earthingamrit90320Noch keine Bewertungen

- Earthing of Telecom Installations Using Single Point EarthingDokument83 SeitenEarthing of Telecom Installations Using Single Point EarthingHari KumarNoch keine Bewertungen

- Option 1: Bandwidth To Multiplex Information Rate CalculationDokument4 SeitenOption 1: Bandwidth To Multiplex Information Rate CalculationYathish H GowdaNoch keine Bewertungen

- INSTALLATION, OPERATION, AND MAINTENANCE MANUAL - 500-0646A With 600-1046C GDSTDokument72 SeitenINSTALLATION, OPERATION, AND MAINTENANCE MANUAL - 500-0646A With 600-1046C GDSTMartinien N'tamonNoch keine Bewertungen

- 7H17-28 Clearances and Wear Limits PDFDokument3 Seiten7H17-28 Clearances and Wear Limits PDFDimitris K100% (1)

- Portage County Pump Station Design Manual SCADA GuideDokument66 SeitenPortage County Pump Station Design Manual SCADA GuidePablo Angel Olguin VivarNoch keine Bewertungen

- MW Checklist StabilityZJKT - 6046-ZJKT - 5692 ZTE (Up 4+0)Dokument40 SeitenMW Checklist StabilityZJKT - 6046-ZJKT - 5692 ZTE (Up 4+0)akhbar laysaNoch keine Bewertungen

- Airtel Nigeria L2600 - BTS ATP Checklist - FinalVDokument8 SeitenAirtel Nigeria L2600 - BTS ATP Checklist - FinalVValentine Ezekaka100% (1)

- Andrew 4.6m PDFDokument2 SeitenAndrew 4.6m PDFAntonio HerreraNoch keine Bewertungen

- Proposed Rule: Domestic Mail Manual: Domestic Mailing Services New StandardsDokument45 SeitenProposed Rule: Domestic Mail Manual: Domestic Mailing Services New StandardsJustia.comNoch keine Bewertungen

- OETC-74 - 400kV Tower Design Inputs To AL-BABTAINDokument146 SeitenOETC-74 - 400kV Tower Design Inputs To AL-BABTAINMohamed Gad67% (3)

- Installation - A - EarthmatDokument11 SeitenInstallation - A - Earthmatpdky yadavNoch keine Bewertungen

- PTN 950 Huawei Product DescriptionDokument244 SeitenPTN 950 Huawei Product DescriptionRaziel VelazquezNoch keine Bewertungen

- OSHA Standard For Fixed Ladders SummaryDokument12 SeitenOSHA Standard For Fixed Ladders SummarysesabcdNoch keine Bewertungen

- Huawei Ups Alarm TableDokument43 SeitenHuawei Ups Alarm TableAhmad Imad100% (1)

- Corrosion in Oil and Gas Industry A Perspective On Corrosion InhibitorsDokument1 SeiteCorrosion in Oil and Gas Industry A Perspective On Corrosion InhibitorsAsma Sed100% (1)

- Engineering Structures: SciencedirectDokument8 SeitenEngineering Structures: SciencedirectFeleki AttilaNoch keine Bewertungen

- Solve Process Problems Quickly with Simulation TrainingDokument6 SeitenSolve Process Problems Quickly with Simulation TrainingAnonymous qPt2MHzXTNoch keine Bewertungen

- NX Training Syllabus Module IDokument5 SeitenNX Training Syllabus Module IDharaiya HardikNoch keine Bewertungen

- FIBER OPTIC DEPLOYMENT CHALLENGES & SOLUTIONS Final PDFDokument63 SeitenFIBER OPTIC DEPLOYMENT CHALLENGES & SOLUTIONS Final PDFamrefat77100% (1)

- Preliminary IssueDokument3 SeitenPreliminary Issuepolio NanoNoch keine Bewertungen

- LTE Advanced Pro - Towards The 5G Mobile NetworkDokument321 SeitenLTE Advanced Pro - Towards The 5G Mobile NetworkElvis JoelNoch keine Bewertungen

- Wheel Loader L50E: 2 EngineDokument4 SeitenWheel Loader L50E: 2 EngineInjeletro Diesel100% (1)

- Safety ValvesDokument11 SeitenSafety Valvesravindra_jivaniNoch keine Bewertungen

- Prefab Canopies Technical SpecificationDokument10 SeitenPrefab Canopies Technical SpecificationTabish IzharNoch keine Bewertungen

- Specifications for 750kg passenger liftDokument19 SeitenSpecifications for 750kg passenger liftlahiruNoch keine Bewertungen

- Fundamentals of DB, Watt, DBM and DbiDokument6 SeitenFundamentals of DB, Watt, DBM and Dbibyarkhan100% (1)

- GSM Network KPI Guide for OptimizationDokument36 SeitenGSM Network KPI Guide for OptimizationJosue Jeremie100% (1)

- Electromechanical Work at 132kv SiteDokument14 SeitenElectromechanical Work at 132kv SitePius Odaba100% (1)

- Add Info B-82974EN 01Dokument3 SeitenAdd Info B-82974EN 01Charles JacobNoch keine Bewertungen

- KATHREIN AntennasDokument186 SeitenKATHREIN Antennashulio100% (2)

- NTC/2080/Zx SeriesDokument4 SeitenNTC/2080/Zx Seriesagj18Noch keine Bewertungen

- FZE Retail Price ListDokument2 SeitenFZE Retail Price ListLeo TesoroNoch keine Bewertungen

- FLP Philippines Retail PricesDokument1 SeiteFLP Philippines Retail PricesLeo Tesoro100% (1)

- Drive Test PDFDokument3 SeitenDrive Test PDFRaymond Katungi100% (1)

- Bandwidth CalculatorDokument7 SeitenBandwidth CalculatorSenan AlkaabyNoch keine Bewertungen

- 3 GSM Traffic ManagementDokument58 Seiten3 GSM Traffic ManagementEldineNoch keine Bewertungen

- Call Flow ComparisonDokument5 SeitenCall Flow ComparisonGürsoy PekşenNoch keine Bewertungen

- RF Drive Test Over ViewsDokument11 SeitenRF Drive Test Over ViewsMustafa Bin AmarNoch keine Bewertungen

- Wireless Power CalculatorDokument1 SeiteWireless Power Calculatordeepak4uNoch keine Bewertungen

- Antenna Electrical and Mechanical TiltDokument15 SeitenAntenna Electrical and Mechanical Tiltnaveedraza4213Noch keine Bewertungen

- TN-25 - RVR Frangibility PDFDokument1 SeiteTN-25 - RVR Frangibility PDFNguyễn Văn TrungNoch keine Bewertungen

- Channel Element Resources in 3G NetworksDokument13 SeitenChannel Element Resources in 3G Networksnunk72100% (1)

- GSM Key Performance Indicator KPI Guidebook V1.1Dokument45 SeitenGSM Key Performance Indicator KPI Guidebook V1.1Rafi AnsariNoch keine Bewertungen

- Atol CalculatorDokument10 SeitenAtol CalculatorangnavaNoch keine Bewertungen

- UNIT - 3 - GSM Logical Channels and Frame Structure PDFDokument17 SeitenUNIT - 3 - GSM Logical Channels and Frame Structure PDFsumanaacharNoch keine Bewertungen

- CE Dimensioning ZTEDokument10 SeitenCE Dimensioning ZTErichmapache100% (1)

- Formula RNC M 1 50Dokument6 SeitenFormula RNC M 1 50azure_etherealNoch keine Bewertungen

- Flatpack 2 Power System Installation GuideDokument30 SeitenFlatpack 2 Power System Installation GuideNdambuki Dickson100% (1)

- Tilt CalculatorDokument2 SeitenTilt CalculatorAmmar Saifan0% (1)

- OptiX OSN 550 Hardware Description (V100R006)Dokument321 SeitenOptiX OSN 550 Hardware Description (V100R006)Thunder-Link.com100% (4)

- GSM Dimensioning Tools ChapterDokument8 SeitenGSM Dimensioning Tools ChapterAhmed GamalNoch keine Bewertungen

- Dialog NewtecDokument20 SeitenDialog NewtecHillNoch keine Bewertungen

- TiltCalc V3 1Dokument10 SeitenTiltCalc V3 1Gagandeep Singh JassalNoch keine Bewertungen

- SDCCHDokument53 SeitenSDCCHGupta Manish100% (6)

- HTTPS://WWW Scribd com/doc/261924128/Emf-SurveyDokument209 SeitenHTTPS://WWW Scribd com/doc/261924128/Emf-SurveySajith KumarNoch keine Bewertungen

- Assignments and Project 2014aDokument32 SeitenAssignments and Project 2014aMin Khine KyawNoch keine Bewertungen

- RBS SpecificationsDokument1 SeiteRBS SpecificationssenjamirNoch keine Bewertungen

- Planet 7.0 GSM Planning GuideDokument67 SeitenPlanet 7.0 GSM Planning GuideHillary K BettNoch keine Bewertungen

- Click HereDokument9 SeitenClick HereronaljkNoch keine Bewertungen

- Engineering Data: Wireway SelectionDokument3 SeitenEngineering Data: Wireway SelectionFidel Castrzzo BaeNoch keine Bewertungen

- Work Order Number Site Name Print Date WO Due Date C0219-CI-2502-504-3-001-A Project Name: Revision Reason: Project DescriptionDokument41 SeitenWork Order Number Site Name Print Date WO Due Date C0219-CI-2502-504-3-001-A Project Name: Revision Reason: Project Descriptionjulio villaNoch keine Bewertungen

- Calculation Note: Armadillo 500RDokument27 SeitenCalculation Note: Armadillo 500RMacNoch keine Bewertungen

- Tuty Court Genset ESTIMATES NewDokument42 SeitenTuty Court Genset ESTIMATES NewRajaDurai RamakrishnanNoch keine Bewertungen

- CHIKO Installation Guide Flat RoofDokument17 SeitenCHIKO Installation Guide Flat RoofGuille ParejoNoch keine Bewertungen

- SpecsDokument309 SeitenSpecsNarendra GoudNoch keine Bewertungen

- Zoiper Communicator ManualDokument49 SeitenZoiper Communicator ManualMarco OrlandiNoch keine Bewertungen

- Fax Panasonic KXFHD332Dokument92 SeitenFax Panasonic KXFHD332César CastilloNoch keine Bewertungen

- Tenor Ax User GuideDokument78 SeitenTenor Ax User Guidecham2095Noch keine Bewertungen

- Return Material Authorization Form: Fault InformationDokument1 SeiteReturn Material Authorization Form: Fault Informationcesar_castillo23Noch keine Bewertungen

- I Direct 1200 NetworkDokument2 SeitenI Direct 1200 NetworkCésar CastilloNoch keine Bewertungen

- Eusso AP - Ugl2454-Apxr (v2) - User - ManualDokument29 SeitenEusso AP - Ugl2454-Apxr (v2) - User - ManualCésar CastilloNoch keine Bewertungen

- Vmware Install InstructionsDokument514 SeitenVmware Install InstructionsBrent EnglandNoch keine Bewertungen

- CHM096-Tutorial 1 (Alkanes & Alkenes)Dokument4 SeitenCHM096-Tutorial 1 (Alkanes & Alkenes)Anonymous RD1CrAINoch keine Bewertungen

- Chapter 4.1 Basic Call Procedure (ED01 - 53 - EN)Dokument53 SeitenChapter 4.1 Basic Call Procedure (ED01 - 53 - EN)quaderbtech06Noch keine Bewertungen

- Tu 1-5Dokument8 SeitenTu 1-5Made easy classes0% (2)

- Time Table Spring 2017 18Dokument10 SeitenTime Table Spring 2017 18SuvamNoch keine Bewertungen

- Installation Tools and Equipment - ACCC Pasadena.Dokument12 SeitenInstallation Tools and Equipment - ACCC Pasadena.EDGARDO DIAZGRANADOSNoch keine Bewertungen

- XXXXXXX XXXXXXX: Pour Exemple: Pour Exemple: ArteorDokument5 SeitenXXXXXXX XXXXXXX: Pour Exemple: Pour Exemple: ArteorGilbert MartinezNoch keine Bewertungen

- 460 (Part-2)Dokument16 Seiten460 (Part-2)rambinod0% (1)

- Acee 2018 039Dokument13 SeitenAcee 2018 039threedlabsNoch keine Bewertungen

- Vista 128BPT Program ManualDokument72 SeitenVista 128BPT Program ManualyalmanzaNoch keine Bewertungen

- DWTS, WDWTS: Improving MRI Image Reconstruction with Directional Wavelet ThresholdingDokument1 SeiteDWTS, WDWTS: Improving MRI Image Reconstruction with Directional Wavelet ThresholdingSumit ChakravartyNoch keine Bewertungen

- Adobe Photoshop: The EditingDokument10 SeitenAdobe Photoshop: The EditingMer Cjielo BalloonsNoch keine Bewertungen

- Multiple-Choice QuestionsDokument8 SeitenMultiple-Choice Questionsvijayganesh pinisettiNoch keine Bewertungen

- Messerschmitt Me 262 - Wikipedia, The Free Encyclopedia3Dokument5 SeitenMesserschmitt Me 262 - Wikipedia, The Free Encyclopedia3beta2009Noch keine Bewertungen

- HW03 5ad S19 PDFDokument2 SeitenHW03 5ad S19 PDFbobNoch keine Bewertungen

- Fisher Poistioner CatalogueDokument12 SeitenFisher Poistioner CatalogueUsama IqbalNoch keine Bewertungen

- LMS Adaptive FiltersDokument14 SeitenLMS Adaptive FiltersalialibabaNoch keine Bewertungen

- Study of Buffer Overflows and Keyloggers in The Linux Operating SystemDokument8 SeitenStudy of Buffer Overflows and Keyloggers in The Linux Operating Systemrobyrulz100% (1)

- User's Guide: BondekDokument8 SeitenUser's Guide: BondekMing ChongNoch keine Bewertungen

- BTSDokument75 SeitenBTSgyanesh198450% (2)

- T REC K.Sup16 201905 I!!PDF E PDFDokument24 SeitenT REC K.Sup16 201905 I!!PDF E PDFMark LionNoch keine Bewertungen

- 61 35 122 Removing and Installing - Replacing General ModuleDokument2 Seiten61 35 122 Removing and Installing - Replacing General ModuleTung NguyenNoch keine Bewertungen