Beruflich Dokumente

Kultur Dokumente

Et WHP02 0000 Mec TPB 1003 - Ar 0001

Hochgeladen von

orea1Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Et WHP02 0000 Mec TPB 1003 - Ar 0001

Hochgeladen von

orea1Copyright:

Verfügbare Formate

N TECHNIP REV.

PAGE

F70072-000-SP-2300-001 0 1 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

OSX WELLHEAD PLATFORM WHP 2

0 07/26/2012 IFI LFFURTADO AKUHNE RSARAUJO

REV. DATE STATUS WRITTEN BY CHECKED BY APPROVED BY

DOCUMENT REVISION

PURPOSE OF ISSUE

PRE PRELIMINARY IFA FOR APPROVAL/COMMENTS IFI FOR ACKNOWLEDGE IFQ FOR QUOTATION

IFP FOR PURCHASE ASP AS PURCHASED ASB AS BUILT IFD FOR DETAIL

IFC FOR CONSTRUCTION CAN CANCELLED

TECHNICAL SPECIFICATION

PAINTING

Alexsandro Kuhne

2012.07.27 13:24:

01 -02'00'

Reginaldo Silva

Araujo

2012.07.27 13:24:

57 -02'00'

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 2 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

SUMMARY

1. INTRODUCTION .......................................................................................................................................... 3

2. OBJECTIVE.................................................................................................................................................. 3

3. STANDARDS................................................................................................................................................ 3

4. GENERAL CONDITIONS............................................................................................................................. 5

5. CLASSIFICATION OF ENVIRONMENT...................................................................................................... 9

6. PAINTING PROCEDURE........................................................................................................................... 10

7. COLOR PRINCIPLES ................................................................................................................................ 10

8. APPLICATION PROCESS......................................................................................................................... 22

9. PAINTING SURFACES.............................................................................................................................. 24

10. PAINTING SYSTEM REQUIREMENTS..................................................................................................... 25

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 3 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

1. INTRODUCTION

The purpose of this specification is to provide a summary of basic data available for the design of the Well

Head Platform WHP 2.

The WHP 2 will be located in Campos Basin, Rio de Janeiro states coast, at a distance of 90km Southeast

of Maca city.

The production from WHP 2 will be transferred to FPSO OSX 3 throughout a system of flowlines for

production and well tests, water injection, gas lift, gas injection, power and control cables.

2. OBJECTIVE

This specification establishes the minimum requirements to be followed by the VENDOR in preparation of

surfaces and painting of jacket, general structures, piping, valves, piping components, pressure vessels,

heat exchangers, tanks, pumps, compressors, electrical equipment, instrumentation, etc., to be installed in

Jacket and Topside of the Wellhead Platforms.

A complete and detailed Painting Specification, including a Painting Procedure and a Painting Plan, shall be

prepared by VENDOR to ensure compliance with requirements described in this specification. The Painting

Procedure shall include details of equipment, materials, surface preparation, painting scheme, application

process, application control, repairs and testing. The Painting Plan shall be detailed for each painting

procedure and each piping/equipment/compartment/tank/void space/deck, and, painting procedure to be

applied and colors.

3. STANDARDS

3.1. ISO STANDARDS

3.1.1. ISO 8501 Parts 1 to 3: Preparation of steel substrates before application of paints and related

products. - Visual assessment of surface cleanliness;

3.1.2. ISO 8502 Parts 1 to 10: Preparation of steel substrates before application of paints and related

products. - Test for the assessment of surface cleanliness;

3.1.3. ISO 9712: Non-destructive testing - Qualification and certification of personnel

3.1.4. ISO 17024: General requirements for bodies operating certification of persons.

3.1.5. ISO 17025 - General requirements for the competence of testing and calibration laboratories.

3.2. ASTM STANDARDS

3.2.1. ASTM A 123 Specification for zinc (hot-dip galvanized) coatings on iron and steel products

3.2.2. ASTM A 153 Specification for zinc coating (hot-dip) on iron and steel hardware

3.2.3. ASTM D 521 Test methods for chemical analysis of zinc dust (metallic zinc powder)

3.2.4. ASTM D 1141 Standard Practice for the Preparation of Substitute Ocean Water

3.2.5. ASTM D 2369 Test method for volatile content of coatings.

3.2.6. ASTM D 2371 Test method for pigment content of solvent-reducible paints

3.2.7. ASTM D 4060 Standard Test Method for Abrasion Resistance of Organic Coatings by the Taber

Abraser.

3.2.8. ASTM D 4285 Test method for indicating oil or water in compressor air.

3.2.9. ASTM D 4541 Standard Test Method for Pull-Off Strength of Coatings Using Portable Adhesion

Testers

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 4 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

3.2.10. ASTM D 4940 Test method for conduct metric analysis of water-soluble ionic contamination of

blasting abrasives.

3.2.11. ASTM D 6386 Preparation of Zinc (Hot-Dip Galvanized) Coated Iron and Steel Product and

Hardware Surfaces for Painting

3.2.12. ASTM F 22 Standard Test Method for Hydrophobic Surface Films by the Water-Break Test

3.2.13. ASTM F 1940 Standard Test Method for Process Control Verification to Prevent Hydrogen

Embrittlement in Plated or Coated Fasteners

3.2.14. ASTM G 39 Standard Practice for Preparation and Use of Bent-Beam Stress-Corrosion Test

Specimens

3.2.15. ASTM G 62 Standard Test Methods for Holiday Detection in Pipeline Coatings

3.3. NACE STANDARDS

3.3.1. NACE RP0188 Discontinuity (holiday) testing of protective coatings.

3.3.2. NACE RP0287 Field measurement of surface profile of abrasive blast cleaned steel surfaces

using replica tape.

3.3.3. NACE TM 0104 Offshore Platform Ballast Water Tank Coating System Evaluation.

3.3.4. NACE TM 0404 Offshore Platform Atmospheric and Splash Zone New Construction Coating

System Evaluation

3.4. SSPC STANDARDS

3.4.1. SSPC-Paint 20 Zinc-Rich Primers (Type I, "Inorganic," and Type II, "Organic)

3.4.2. SSPC-Paint 36 Two-component weatherabble Aliphatic Polyurethane Topcoat,

Performance-Based

3.4.3. SSPC-SP 1 Solvent cleaning

3.4.4. SSPC-SP 2 Hand Tool Cleaning

3.4.5. SSPC-SP 3 Power Tool Cleaning

3.4.6. SSPC-SP 7 Brush-off Blast Cleaning

3.4.7. SSPC-SP 8 Pickling

3.4.8. SSPC-SP 10 Near-White Blast Cleaning

3.4.9. SSPC-SP 11 Power Tool Cleaning to Bare Metal

3.4.10. SSPC-SP 12 Surface Preparation and Cleaning of Steel and Other Hard Materials by High-

and Ultrahigh-Pressure Water Jetting Prior to Recoating

3.4.11. SSPC-VIS 1 Visual Standard for Abrasive Blast Cleaned Steel

3.4.12. SSPC-VIS 3 Visual Standard for Power- and Hand-Tool Cleaned Steel

3.4.13. SSPC-VIS 4 Visual Reference Photographs for Steel Cleaned by Water Jetting

3.4.14. SSPC-TR 3/NACE 6A192 Dehumidification and temperature control during surface

preparation, application, and curing for coatings/lining of steel tanks, vessels, and other

enclosed spaces.

3.5. NSF STANDARDS

3.5.1. NSF 61: Drinking water system components Health effects.

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 5 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

3.6. IMO RESOLUTION

3.6.1. RESOLUTION MSC.215(82) Performance standard for protective coatings for dedicated

seawater ballast tanks in all types of ships and double side skin spaces of bulk carries.

3.7. NR STANDARD

3.7.1. NR 26 Brazilian Ministry of labor Rule (Sinalizao de Segurana);

3.7.2. NBR 12103 Tintas - Determinao do descaimento;

3.7.3. NBR 12104 Tintas - Separao do veculo;

3.7.4. NBR 12105 Tintas - Determinao da consistncia pelo viscosmetro Stormer;

3.7.5. NBR NM 787 Execuo de ensaios de resistncia nevoa salina de superfcie;

3.7.6. NBR 11003 Tintas - Determinao da aderncia.

3.8. SIS STANDARD

3.8.1. SIS 05 59 00 Pictorial Surface Preparation Standards for Painting Steel Surfaces.

4. GENERAL CONDITIONS

4.1. All promotional paint work or shop primer coats to be applied must be compatible with the

subsequent painting scheme.

4.2. Temporary painting (by manufacture) - for all new parts (plates, scantlings etc), the surface

preparation shall be done by Dry Blasting or Slurry Blasting to grade ISO 8501-1 Sa 2 , followed

by low pressure water cleaning (2000 to 3000 psi), application of a Surface Tolerant Solvent Free

Epoxy Paint Cured with Polyamine, in minimum dry film thickness of 150 micra per coat. After

assembly and mounting works, welds, sharp edges and damaged coatings shall be treated with

mechanical tools to grade St-3 ISO 8501-1.

4.3. Temporary painting (by manufacture) - using automatic shop priming plants, the following

procedures shall be adopted:

New plates shall be washed with detergent to remove oil and grease, followed by water rinsing;

Air-drying;

Dry blasting at blasting unit to grade ISO 8501-1 Sa 2 , surface profile 50 to 70 m and apply

one coat of 25 m of Primer Epoxy Polyamine at the painting cabinet;

After assembly and mounting works, welds, sharp edges and damaged coatings shall be treated

with mechanical tools grade St-3 ISO 8501-1.

4.4. In case of retouching on damaged paintwork, the original scheme must be repeated. Whenever is

not possible to perform abrasive or hydro blasting, mechanical cleaning (St-3) shall be used, after

OSX approval. In this situation the repaired area must be painted with two coats of a Surface

Tolerant Solvent Free Epoxy Paint Cured with Polyamine, in minimum dry film thickness of 150

micra per coat.

Minimum thickness recommended to industrial painting in harsh environment salt must be 200

micra and subsea environment 300 micra.

Regions welded after assembly shall follow the same as above whenever abrasive or hydro

blasting is not technically and economically advisable.

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 6 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

4.5. The time interval to apply any paint on a coat previously applied must be that required for the

preceding coat for repainting. For painting schemes in which provision is made for epoxy primer

coats, if the maximum time period has elapsed, the entire surface must be hand-sanded and then

cleaned off with a non-oil solvent before the next coat is applied.

4.6. Before preparing the surface to be painted, a visual inspection of the entire surface shall be done to

note points displaying vestiges of oil, grease or fat and the degree of corrosion affecting the surface

(A, B, C or D, in accordance with Standard ISO 8501-1).

4.7. For any of the painting schemes stipulated in this specification, it is required that the surface to be

painted is solvent cleaned only in those areas in which, during inspection, vestiges of oil, grease or

fat are observed to be present.

4.8. Temporary warehouses where paints, varnishes, solvents and diluents are stored must be

sheltered, well aired, not exposed to excessive heat, and protected against spark, atmospheric

discharges and the direct rays of the sun.

4.9. The above supplies must be stored in dedicated facilities having a fire fighting system.

4.10. Maximum stacking height of paint and solvent recipients must comply with the following criteria:

Twenty (20) one-gallon cans.

Five (5) bucket-type cans.

Three (3) 200-liter drums.

4.11. Paints must be stored in such a manner as to permit withdrawal first of all of the oldest material in

stock, (FIFO = first-in/first-out) with stocks being handled so as to avoid damage.

4.12. Flanges and connections surfaces shall be protected from abrasive blasting by means of wood or

plastic sailcloth covering.

4.13. Abrasive or hydro blasting in the vicinity of a recently painted surface must be performed only

when the paint is dry to the touch.

4.14. The whole of the respective paint or component must be homogenized in its recipients before and

during mixing and, in the course of application, must be stirred at frequent intervals so as to keep

the pigment in suspension.

4.15. Homogenization must be effected in the original recipient and paint must not be drawn from it until

the entire settled pigment has been incorporated into the vehicle. If there is any difficulty in

dispersing the pigment that has settled, the paint must not be used.

4.16. The mixing and homogenization must be performed according to following procedure:

Recipients with capacity up to 18 liters - mixing and homogenization shall be done manually.

Recipients with capacity greater than 18 liters - mixing and homogenization shall be done by

mechanical mixers.

4.17. Mixing operations on open recipients must be effected in a well-ventilated place, far away from

sparks or flames.

4.18. Use of a stream of air applied to the surface of the paint so as to mix or homogenize it is not

allowable in any circumstances. If a coating or thickened layer has formed in a newly opened can,

the paint must be rejected.

4.19. When homogenization is done manually, most of the vehicle must be poured off into a clean

recipient and the material must then be loosened up from the bottom of the recipient by means of a

broad spatula, after which the pigment is to be homogenized with the vehicle.

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 7 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

4.20. The portion of vehicle that was withdrawn must then be reincorporated into the paint while stirring

or while repeatedly pouring from one recipient to the other until the composition becomes uniform.

4.21. The bottom of the recipient must be examined to check whether or not the whole of the pigment

adhering to the bottom was homogenized with the paint.

4.22. Paints with two or more components must have the latter homogenized separately and then re-

mixed in precise agreement with the methods and in the exact proportions recommended by the

manufactures.

4.23. The homogenization and mixing must be complete, and there must be no veins or stripes of

different colors, so that the final appearance is uniform.

4.24. Mixing, homogenization and dilution must be effected only at time of application.

4.25. No paint must be left from one day to the next in the tanks of the spray guns and the painters cans.

Only single component paints may be re-used. In that case the leftover, paint must be transferred

to a recipient that is closed up, and must be mixed and/or homogenized again before it is re-used.

4.26. Paints that need to be sprayed on, if not specifically formulated for that form of application, may

require thinning in those cases in which it is not possible to achieve satisfactory application by

adjusting or regulating the spraying equipment and the air pressure.

4.27. When dilution is required to facilitate application painters must cut the paint with the thinner

specified by the paint manufacturers, and the maximum quantity recommended by the

manufactures for each method of application must not be exceeded.

4.28. The thinner must be incorporated into the paint during the process of mixing and homogenization.

Painters may not add thinner to the paint after it has been diluted to the proper consistency.

4.29. Paints that pot life has been exceeded must not be used.

4.30. For chemically cured dual component paints the induction time and pot life must be duly observed

in accordance with paint manufacturer instructions.

4.31. Drying compounds must not be added to paints.

4.32. Surface preparation and application of primer must always be performed in the field, before

assembly of the equipment or piping.

4.33. On equipment or piping to be connected by welding, the region between 5cm before and 5cm after

from welded connection must be left unpainted, in order to receive surface preparation and primer

paint after welding and testing, including hydrostatic testing.

4.34. Crevices, corners and low portions hard to paint must be evened up by welding or with epoxy paste

(composite).

4.35. Evening up by welding must in all cases to be done before painting proceeds. Evening up by epoxy

paste (composite) may be done after abrasive blasting or right after applying primer.

4.36. Before application of each coat of paint, all surfaces must be cleaned off by a hair brush or broom,

by air blast or by a damp rag, so as to remove dust, salts and/or other contaminants.

4.37. No paint must be applied when the ambient temperature is below 5C.

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 8 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

4.38. No paint must be applied if there are expectations that the ambient temperature is going to fall to 0

C before the paint has had time to dry.

4.39. Paint must not be applied to metallic surfaces when:

a) Surface temperature is lower than 5 C or

b) Surface temperature is higher than 52 C.

4.40. Painting shall not be performed when the temperature is below 5C. Painting shall not be

performed if the temperature is expected to drop to 0C before coating is dry. Painting shall not be

applied on metallic surfaces whose temperature is below dew point +3 C, below 5C, or above

52C. In the case of inorganic silicate based paints rich in zinc, the temperature of the metallic

surface shall not be above 40C. Painting shall neither be performed in rainy, foggy or hazy

weather, nor when relative humidity is over 85%, nor when the forecast is to reach this level.

4.41. On edges, corners, lowered areas, crevices, bolt holes and welds primer must always be applied

by paintbrush.

4.42. Each coat of paint must be of uniform thickness, free from flaws such as porosity, runs, wrinkling,

swelling up, cracking, blistering, pocking and impregnation of abrasive matter.

4.43. All areas with insufficient thickness of paint or other application defects must be repainted. The

next coat must be applied just after a complete drying of paints in the repaired areas.

4.44. The recommended thicknesses are those indicated under the specific conditions for each

equipment, piping or structure.

4.45. Time intervals (maximum and minimum) between coats must be specific for each painting set-up

for the respective equipment, piping or structure.

4.46. Equipment or piping painted before assembly must not be handled until all paints have dried.

Handling of this equipment or piping shall be performed in order to minimize damage to the

paint job. This procedure shall include the use of steel cables suitably protected or fabric belting in

the case of small parts.

4.47. When intervals for repainting have been exceeded, previous coat must be lightly sanded (to break

the gloss), so as to improve anchorage of subsequent coat.

4.48. Care must be taken to avoid contamination of the surface by ashes, salt, dust or other foreign

matter, during paints application and drying periods.

4.49. Surfaces that have been machined and other surfaces that are not to be painted must be covered

with a coat of removable varnish.

4.50. Equipment, piping or structural parts that have been painted but not yet assembled must comply

with following storage requirements:

To be kept apart from one another;

Not to be in contact with the ground;

4.51. To be positioned so as to keep down, as much as possible, the number of points exposed to build-

up of rainwater or earth, or to contamination or deterioration of the paint. Such parts must be

cleaned off, retouched with the required paint(s) whenever this is necessary to keep the film of

paint in proper condition.

4.52. Every paint used by the VENDOR for plate and stiffener marking will be compatible with the

subsequent painting scheme. It is not allowed to use chalk and oil pencil.

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 9 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

4.53. All materials and required facilities such as: paint maker surveyor, paints, solvents, staging,

temporary lights, ventilation fans etc. must be supplied by VENDOR and must be included in the

quotation.

4.54. VENDOR must fully comply with Paint Manufacturers Supervisor instructions regarding to blasting

and painting works.

4.55. All drains/scuppers must be plugged during blasting and painting works.

4.56. Any work concerned to blasting and painting shall only be carried out after completion of all

structural repairs at the region.

4.57. The high-pressure washing must be performed at a minimum pressure of 3,000 psi.

4.58. For tanks internal surfaces blasting/painting jobs, ventilation, heating and dehumidification

equipment must be arranged and used by VENDOR, in order to maintain a maximum relative

humidity according to paint makers specification and to guarantee the painting system for 25

years.

4.59. By the end of the blasting works in each tank, the tank shall be cleaned. Grit shall be removed and

sent ashore. This job must be performed to OSX Representative satisfaction.

4.60. All grit shall be removed by vacuum removal equipment through existing deck opening. Any holes

in bulkheads, decks and bottom shall be submitted for OSX inspector and Classification Society

(CS) Surveyor approval.

4.61. Hydro blasting shall be made with water pressure from 25000 to 45000psi (1700 to 3000bar).

4.62. All miscellaneous steel items such as piping supports, angle bars, ladders, gratings, platforms,

equipment foundations, electric boxes, wire ways, stations, handrails, bulwarks

(internal and external surfaces), chocks, etc, after replacement shall be rounded all edges and

corners before surface preparation and painting.

4.63. All vessel nozzles, adjacent pipes until block valve, internal shell welded components and

accessories shall be coated inside and shall allow mounting and dismounting without damages.

4.64. All sharp edges, fillets, corners and welds shall be rounded or smoothed by grinding prior to

blasting/painting.

5. CLASSIFICATION OF ENVIRONMENT

5.1. For offshore units the environment classification is according ISO 12944- Part 2.

5.1.1. Three regions are considered in offshore units:

Atmospheric zone: For offshore units it means those structures situated above the water,

Splash zone: For offshore units it means the structures that is alternately above and below

the water line. For fixed offshore units this means the region alternatively wet and dry due to

tide and waves. For mobile offshore units this means the bottom region.

5.1.2. Immersed zone: For offshore units this means the regions that are underwater and not

subjected to wet and dry alternation. For guidance only Table 1 specifies the environment

classification according to ISO 12944-Part 2.

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 10 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

Table 1 - Environmental Classification

Region Environmental classification

Atmospheric zone C5-M

Splash zone Im-2

Immersed zone Im-2

6. PAINTING PROCEDURE

The procedure for applying the schemes below shall contain at least the following pieces of information:

Painting scheme(s) to be used;

Delivery and storage of paints and solvents;

Preparing the surface;

Sequence of execution of painting scheme(s);

Process of applying paints;

Paints to be used, including suppliers and respective commercial references;

Retouching in the painting scheme;

Inspecting paint work, including items to be inspected, methods of inspection, frequency of

inspection visits and criteria for acceptance and rejection of paint work;

Printed forms of recording results of inspections;

Vendor Agreement according to all Specifications of this Document.

The painting scheme for non-specified items shall be the same of the area where they are installed.

7. COLOR PRINCIPLES

7.1. General

As a general rule, the top color defined in this document is Mandatory and shall be valid for all

items which require painting.

All painting shall follow the painting scheme specified in the Project documents.

Carbon Steel elements shall be coated according to the specific Project approved coating

scheme and shall receive a top coating of painting according to the MUNSELL color system

Metallized carbon steel,aluminum and stainless steel shall be painted only when specified in

the Project documents.

Color bands and/or signs shall be used complimentary for equipments identification.

Piping and ducting (except where insulated) which require painting shall generally be the

same color as the wall panel (when painted), ceiling, or underside of deck which it is located

adjacent to the basic color is the top coating that cover the full length of piping.

All equipment, vessels, non-structural tanks shall be identified by corresponding Name

Function and .TAG, painted visibly in Black (Munsell N 1) letters besides its nameplate.

7.2. Unless otherwise noted in the items below, the color used for the last coating of general

equipment shall be Light Green (MUNSELL 5 G 8/4) and omitted cases shall be White

(MUNSELL N 9.5). Deviations and Exceptions:

For equipment marked as [RC] the corresponding colour is the Recommended Colour,

however, any equipment manufactured with vendor standard colour which deviates from this

rule may be acceptable but require OSX written approval.

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 11 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

For general equipment, electric control panels, electric motors, small pumps, etc., assembled

in Package

Units, the manufacturer standard may be acceptable, except where otherwise indicated.

Omitted cases or of conflict between referred documents shall be directed to OSX for written

approval.

TABLE 1

DENOMINATION MUNSELL NOTATION

Black N1

White N 9.5

Aluminum ---------

Safety Red 5 R 4/14

Brown 2.5 YR 2/4

Safety Orange 2.5 YR 6/14

Safety Yellow 5 Y 8/12

Light Gray N 6.5

Ice Gray N 8

Green 2.5 G 5/10

Safety Blue 2.5 PB 4/10

Light Blue 2.5 PB 8/4

Light Cream 2.5 Y 9/4

Light Green 5 G 8/4

Note: The colors may be distorted depending upon the color settings of screen and/or printers.

7.3. Color Definition

7.3.1. Structural

7.3.1.1. External

All Steel Structures, Bulkheads shall be painted in Ice Gray (MUNSELL N 8)

including:

o Primary structure, including vertical columns and diagonal bracings.

o Secondary structure including penetration sleeves, and top of webs and

flanges.

o Decks including all faces of secondary steel, stiffeners, penetrations, etc.

o Bulkheads including all stiffeners.

Deck floors/Outfittings: shall be painted in Ice Gray (MUNSELL N 8).

o Deck and stairways Grating:

Galvanized steel - non-painted

FRP - non-painted (light color)

o Main Pipe way shall be painted in Ice Gray (MUNSELL N 8).

Pipe, cable trays support: follows the adjacent deck, deck underside

and/or bulkhead color.

o Equipment, vessels and tanks support foundation (by shipyard): follows the

adjacent deck and/or bulkhead color. Crane Pedestal shall be painted in Ice

Gray (MUNSELL N 8).

o Curb or salient structure where it is needed to call attention (risk to hit or

flooring someone) shall be painted in Safety Yellow (MUNSELL 5 Y 8/12).

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 12 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

o Front-ending of ladder steps shall be painted in Safety Yellow (MUNSELL 5 Y

8/12).

o Vertical or inclined Ladders, Stairways, Walkways and Platforms shall be

painted in Safety Yellow (MUNSELL 5 Y 8/12).

o Safety cages, handrails, railing, guardrail, etc. shall be painted in Safety

Yellow (MUNSELL 5 Y 8/12).

o The steps of stairway that is part of the escape route, follows the escape route

color.

o Caisson shall be painted in Ice Gray (MUNSELL N8)

o Davit for Lifeboat and Rescue Boat: Safety-Orange (MUNSELL 2,5 YR 8/14);

Alternatively, each davit may be painted following the corresponding lifeboat

station color code.

o Fenders (supply boat area) shall be painted in Light Gray (MUNSELL N 6.5)

7.3.1.2. Internal (Machinery, Utility and similar spaces, Pump rooms, Void spaces).

Bulkheads including all faces of secondary steel, stiffeners, penetrations, etc. shall

be painted in White (MUNSELL N 9.5).

Doors shall be painted in White (MUNSELL N 9.5), see item Safety.

Ceiling, including all faces of secondary steel, stiffeners, penetrations, etc. shall be

painted in White (MUNSELL N 9.5).

Bracings, columns, void spaces, trunks, cofferdams shall be painted in White

(MUNSELL N 9.5).

Column Shaft, Lift shaft, shall be painted in White (MUNSELL N 9.5).

Decks shall be painted in Ice Gray (MUNSELL N 8).

Outfitting like stairways and others, follow the same color coding for external

structures.

7.3.1.3. Structural Tanks

Potable Water, Industrial Water, Fuel, shall be painted in White (MUNSELL N 9.5).

Cargo tanks, Slop tank shall be painted in White (MUNSELL N 9.5).

Note: The top color shall be applied to the tank full extension (bottom, sides and tank

top, internal side).

7.3.1.4. Non-Structural Tanks:

External shall be painted in Ice Gray (MUNSELL N 8) with identification color

according to table 3.

Internal shall be painted in White (MUNSELL N 9.5) with identification color

according to table 3.

7.3.1.5. Accommodation Modules

External and internal, including all corridors walls and ceiling shall be painted in

White (MUNSELL N 9.5).

Internal corridor deck, internal rooms deck shall be painted White (MUNSELL N 9.5).

The corridors shall be identified at each stairway front, doors accessing outside area

and exits at both sides, with signs indicating (Portuguese and English):

o 1Andar (1st Floor)

o 2Andar (2nd Floor)

o 3Andar (3rd Floor), etc.

The architectural items, linings colors, etc. shall be according to the specific Project

document. Exception: aluminum superstructure and outfitting require no painting

over external side, unless otherwise defined in the specific Project document.

Internal technical areas like HVAC ducts and electric cable trunks, require no

painting, unless otherwise defined in the specific Project document.

For helideck, see item 7.3.10.

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 13 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

7.3.1.6. Topside Modules

Follow the same standard for external structure, equipment, etc.

7.3.2. Process, Utilities and Pressure Vessels

All vessels and tanks shall be final color painted following the adjacent structure

(internal: white, external ice gray) color, except hydrocarbon content, which shall be

aluminum.

Vessels and tanks shall be internally painted White.

Besides the Tag number and Function identified by letters as above, each vessel and

tank shall be identified with color stripes, according to main fluid content, in accordance

with table 2, table 3 and annex B.

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 14 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

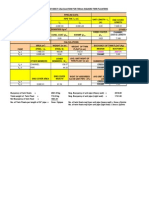

TABLE 2

7.3.3. Piping, Valves and Accessories

All piping shall be final color painted following the adjacent structure (internal shall be

painted in white and external shall be painted in ice gray) color, except for hydrocarbon

piping which shall be aluminum. Three stripes shall identify all piping (except fire

fighting lines), where the first and the third stripes indicate the Fluid or System (Primary)

and the second stripe indicates the Function or specific characteristic (Secondary

Stripe). See figure 1 and Table 3.

COLOR IDENTIFICATION FOR PROCESS AND UTILITIES EQUIPMENT

SYSTEM EQUIPAMENT COLOR

Process

Heat Exchange

Aluminum

Pressure Vessel

Launcher/Receiver Pig

Gas Process Knock Out Drum (Safety Gas)

General

(Non Flammable Fluid)

Pressure Vessel and Heat Exchanger

Follow the adjacent

structure/floor

Water Treatment

Fresh Water Generator [RC]

Hydrophoric Tank

Plate Exchanger

Tank for Hypochlorite Safety-Orange

Cooling Water

Expansion Vessel

(Pressurized with Air)

Heat Exchanger

External place: Ice Gray

Expansion Vessel Ice Gray

Chemical Products Injection Safety-Orange

Heating Water

Expansion Vessel

Ice Gray

Fresh Water Heater

Expansion Vessel

(Pressurized with Gas)

Aluminum

Diesel fuel

Diesel Filter

Diesel Tank (internal & external)

Centrifugal Purifier [RC] Light Green

Compressed Air

Instrument Air Vessel

Ice Gray

Sealing Air Vessel

BDV/ADV/SDV Air Vessel

Air Dryer [RC]

Service Air Vessel

Dampers Control Air Vessel

Starting Air Vessel

Lubricating Oil Oil Filter Aluminum

Slop Tank

(non-structural)

Oily Water Tank external

(internal white)

Aluminum Slop Tank

Flare System

High Flare Vessel

Low Pressure Flare Drum

Hydraulic System Hydraulic Fluid Accumulator [RC] Ice Gray

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 15 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

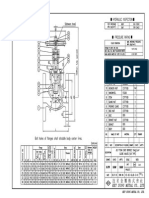

FIGURE 1

Fire fighting lines shall be painted full length with the PIPING COLOR.

All piping shall be painted or have taped stripe placed in such a way that everybody in

the working staff would see and identify the piping and the product that it contains and

shall be easily visible from the deck, platform or access walkway.

These stripes and arrows shall also be placed each 9 meters length, maximum

wherever necessary (see Annex A) for identification at:

o branches,

o close to all control valves/maneuver equipment, section isolation valves and

supply point, hose stations, receiving ends,

o close to inlets and outlets of the equipments (suction and discharge lines at

pumps, compressors, etc.),

o by inlet and outlet of process train (vessels, tanks, etc.),

o on each side of bulkhead or deck penetration points,

o at the start and end of pipe racks; and on elevated pipes, markers shall be

positioned adjacent to stairways and platforms.

The Contractor shall supply additional marking upon request from OSX.

All stripes colors shall be painted (or marked by tape in internal areas) in accordance

with the specified colors of the Table 3.

Line tags and arrows to indicate flow direction shall be painted (or marked by tape in

internal areas). Text height shall be 20 mm for thru 2piping diameters and 50 mm

for piping diameters above 2 diameters.

Marking Color

o Light colored piping, arrow/tag shall be painted in Black (Munsell N 1)

o Dark colored piping, arrow/tag shall be painted in White (Munsell N 9.5)

o Alternatively to painting, in external areas not subjected to oil spills and fluid

temperature below 60 C, a weather- and UV-resistant adhesive tape may be

used for piping markings.

All the valves and piping accessories including filters shall be painted with the same

color of the piping.

The insulated piping shall be identified in the same manner. On insulated piping with

hidden electrical heat tracing, an additional warning label shall be added in Safety

Yellow, with the words Cuidado Heat Tracing Eltrico; letters shall be Black.

All piping inside tanks shall be identified with TAG and painted stripes. Adhesive tapes

shall not be applied.

The piping tags shall be according to Project P&I drawings.

All Piping shall be painted with color identification stripes according to following table 3.

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 16 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

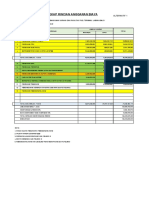

TABLE 3

WASTE MEDIA

Service

Pipe Color Stripes Pipe

Piping Primary Stripe Secondary Stripe

Black Water

Note 1 Black Safety Blue

Waste Oil/Used Oil

Note 1 Black Brown

Bilge Water

Note 1 Black Green

Open Drain

Note 1 Black Green

Grey Water (sanitation rooms, provision

rooms, ventilation rooms, cargo holds

and decks, excluding black water)

Note 1 Black White

Sewage contaminated (excluding black

and grey water)

Note 1 Black Safety Yellow

FRESH WATER

Service

Pipe Color Stripes Pipe

Piping Primary Stripe Secondary Stripe

Potable Water

Note 1 Green Safety Blue

Potable Hot Water

Note 1 Green Safety Red

Chilled Water (HVAC)

Note 1 Green Light Green

FRESH WATER

Service

Pipe Color Stripes Pipe

Piping Primary Stripe Secondary Stripe

Industrial, Cooling Fresh Water

Note 1 Green Light Cream

Hot Water Process, Utility

Note 1 Green Aluminum

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 17 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

FUEL

Service

Pipe Color Stripes Pipe

Piping Primary Stripe Secondary Stripe

Diesel Fuel

Aluminum Brown Safety Yellow

Fuel Gas

Aluminum Brown White

Aviation Kerosene

Aluminum Brown Safety Blue

SEA WATER

Service

Pipe Color Stripes Pipe

Piping Primary Stripe Secondary Stripe

Ballast Water

Note 1 Green White

Cooling Sea Water

Note 1 Green Safety Yellow

De-Aerated/Aerated Sea Water

Injection

Note 1 Green Light Gray

COMPRESSED AIR

Service

Pipe Color Stripes Pipe

Piping Primary Stripe Secondary Stripe

Compressed Air, General Service

Note 1 Safety Blue White

Compressed Air, Instrument,

Control Air

Note 1 Safety Blue Safety Yellow

OTHER NON-FLAMMABLE GASES

Service

Pipe Color Stripes Pipe

Piping Primary Stripe Secondary Stripe

Inert Gas

Note 1 Light Gray Brown

Nitrogen

Note 1 Light Gray Green

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 18 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

OIL OTHER THAN FUELS

Service

Pipe Color Stripes Pipe

Piping Primary Stripe Secondary Stripe

Lubricating oil

Note 1 Safety Orange Cream

Hydraulic fluid, LP, HP

Note 1 Safety Orange Light Gray

STEAM

Service

Pipe Color Stripes Pipe

Piping Primary Stripe Secondary Stripe

Steam

Aluminum Safety Blue Safety Red

Steam, Condensate

Aluminum Safety Blue White

FIRE FIGHTING

Service

Pipe Color Stripes Pipe

Piping Primary Stripe Secondary Stripe

Fire Mains

Safety Red NA NA

Fire Fighting Foam

Safety Red Safety Orange NA

Carbon Dioxide, CO

2

Safety Red White NA

CHEMICAL

Service

Pipe Color Stripes Pipe

Piping Primary Stripe Secondary Stripe

Chemical Injection

Note 1 Safety Orange White

Biocide Sodium Hypochlorite

Note 1 Safety Orange Green

Biocide (Others)

Note 1 Safety Orange Black

Glycol

Note 1 Safety Orange Safety Yellow

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 19 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

PROCESS

Service

Pipe Color Stripes Pipe

Piping Primary Stripe Secondary Stripe

Auxiliary/Main Cargo System

Aluminum Black Light Gray

Hydrocarbon Liquid, Oil

Aluminum Black Safety Yellow

Closed Drain (Hydrocarbon

discharge)

Aluminum Black Brown

Safety System and Flare

Aluminum Safety Yellow Light Gray

Process (Hydrocarbon Non-Corrosive

Liquid)

Aluminum Black Ice Gray

Process (Non-Corrosive LP )

Aluminum Safety Blue Light Gray

Process (Non-Corrosive HP Gas)

Aluminum PB Green Ice Gray

Process (Hydrocarbon Corrosive

Liquid)

Aluminum Safety Orange Black

Process (Corrosive Gas)

Aluminum Safety Orange Safety Yellow

Ignition Line

Aluminum Safety Red Light Gray

TANK VENTING & SOUNDING PIPE

Service

Pipe Color Stripes Pipe

Piping Primary Stripe Secondary Stripe

Diesel Fuel

Aluminum Brown Safety Yellow

Ballast, Water Tanks

Note 1 Green White

Fresh Water

Note 1 Green Safety Blue

Slop tank

Aluminum Black Aluminum

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 20 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

Void Space

(Hazardous rea)

Aluminum Safety Yellow Safety Red

Note: 1

o Hydrocarbon piping shall be painted in Aluminum.

o Fire fighting piping shall be painted in Safety Red.

o Other fluids:

Internal area shall be painted in White (following compartment color)

External area shall be painted in Ice Gray (following adjacent structure)

Observation:

o The colors may be distorted depending upon the color settings of screen and/or printers.

7.3.4. Marine Systems

Pull-in winch shall be painted in Safety Yellow (MUNSELL 5 Y 8/12).

Fairleader shall be painted in accordance with the adjacent structure.

Vent Post shall be painted in Aluminum (without MUNSELL notation).

7.3.5. Mechanical, Cargo Handling and Package Equipment

Pumps shall be painted in Light Green (MUNSELL 5 G 8/4), except fire-fighting system.

Air compressors [RC], Air Dryers [RC] shall be painted in Light Green (MUNSELL 5 G

8/4).

Note: Acoustic Hood for engines: According to compartment color.

o Internal White (MUNSELL N 9.5).

o External Ice Gray (MUNSELL N 8).

Diesel engines [RC] shall be painted in Light Green (MUNSELL 5 G 8/4).

Boilers and Furnace shall be painted in Aluminum.

Exhaust gas pipe/ducts for turbine, engines, boiler, furnace shall be painted in

Aluminum.

Hydraulic Unit [RC] shall be painted in Light Green (MUNSELL 5 G 8/4).

Diesel Oil Centrifugal Purifier [RC] shall be painted in Light Green (MUNSELL 5 G 8/4).

Cranes shall be painted in Safety Yellow (MUNSELL 5 Y 8/12).

Bumpers for heavy vehicles (combined with black stripes), portable, transportable, non-

fixed special tools for handling pipes and heavy devices shall be painted in Safety

Yellow (MUNSELL 5 Y 8/12).

Equipment Skids Package Unit Skid Beam (suppliers structural steel which carries the

equipment shall be painted in Ice Gray (MUNSELL N8)

Hoisting Devices (monorails, frames, trolleys, trolley beams, lifting lugs, etc.) shall be

painted in Safety Yellow (MUNSELL 5 Y 8/12).

Structural Pad Eyes (Lifting lugs) shall be painted in Safety Yellow (MUNSELL 5 Y

8/12).

Guards and Protective cover for dangerous moving, rotating parts of Equipment &

Machines shall be painted in Safety Orange (MUNSELL 2.5 Y R 6/14).

Dangerous moving, rotating exposed parts of machinery shall be painted in Safety

Orange (MUNSELL 2.5 Y R 6/14).

Internal parts of the machinery hoods that can be removed or opened shall be painted

in Safety Orange (MUNSELL 2.5 Y R 6/14).

Cut and Press equipment shall be painted in Safety Orange (MUNSELL 2.5 Y R 6/14).

External face of Pulleys and Exposed Gears shall be painted in Safety Orange

(MUNSELL 2.5 Y R 6/14).

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 21 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

Potable Water Maker [RC] shall be painted in Light Green (MUNSELL 5 G 8/4).

Sewage Treatment Unit [RC] shall be painted in Light Green (MUNSELL 5 G 8/4).

7.3.6. Safety

Fire-fighting Pumps and Drives shall be painted in Safety Red (MUNSELL 5 R 4/14).

Fire-fighting Systems Equipment in general shall be painted in Safety Red (MUNSELL 5

R 4/14).

Fire-fighting Valves and Piping Accessories, Sprinkler shall be painted in Safety Red

(MUNSELL 5 R 4/14).

Foam Tank shall be painted in Safety Red (MUNSELL 5 R 4/14).

Carbon Dioxide: CO2 Bottle, piping and diffuser shall be painted in Safety Red

(MUNSELL 5 R 4/14).

Portable fire extinguisher shall be painted in Safety Red (MUNSELL 5 R 4/14).

Life-Saving shall be painted in Safety Orange (MUNSELL 2.5 YR 6/14).

Lifeboat in accordance with information below:

o External shall be painted in Safety Orange (MUNSELL 2.5 YR 6/14).

o Internal shall be painted in White (MUNSELL N 9.5).

Rescue Boat shall be painted in Safety Orange (MUNSELL 2.5 YR 6/14).

First aid equipment box shall be painted in Green (MUNSELL 2.5 G 5/10).

Breathing apparatus lockers shall be painted in Green (MUNSELL 2.5 G 5/10).

Safety Showers and Stretchers, Eye-wash Unit shall be painted in Green (MUNSELL

2.5 G 5/10).

Escape Route shall be painted in Green (MUNSELL 2.5 G 5/10) in anti-slippery coating,

surrounded on each side by 100 mm width stripes and having arrows spaced at

maximum 3000 mm. Arrows and stripes shall be in White (MUNSELL N 9.5).

Emergency exit doors shall be painted in Safety-Red (MUNSELL 5 R 4/14) with marking

Sada de Emergncia, Emergency Exit (red letters) over horizontal 500mm height

White stripe.

Escape Hatches shall be painted in Safety-Red (MUNSELL 5 R 4/14).

Wall at the end of no-way out corridors shall be painted in Safety Yellow (MUNSELL 5

8/12).

Hospital entrance door shall be painted in Green (MUNSELL 2.5 G 5/10).

Area on the deck surrounding safety equipment, firefighting equipment or other

emergency equipment shall be painted in White (MUNSELL N 9.5).

Area on the deck surrounding electric switchgear/panels shall be signalized by painting

a 100mm yellow stripe in the electric arc protection area.

7.3.7. HVAC

Ventilating & Exhaust Fan shall be painted in accordance with the compartment color.

o White (MUNSELL N 9.5).when located internal side

o Ice Gray (MUNSELL N 8) when located outdoor.

Fan Mushrooms, Dampers, Filter frame shall be painted in White (MUNSELL N 9.5).

Note: Watertight, Fire tight dampers handles for manual operation shall be painted in

Safety Orange (MUNSELL 2.5 Y R 6/14).

Ducts in carbon steel shall be painted in accordance with the compartment color :

o Internal in White (MUNSELL N 9.5)

o External in Ice Gray (MUNSELL N 8).

Air-conditioning Package Units [RC], Chillers [RC] shall be painted in Light Green

(MUNSELL 5 G 8/4).

7.3.8. Electrical Equipment

Generator shall be painted Light Gray (MUNSELL N6.5).

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 22 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

Motors shall be painted in Light Gray (MUNSELL N6.5)., except fire-fighting pump and

small motors assembled in Package Units.

Transformer enclosure shall be painted in Light Gray (MUNSELL N6.5).

Electric Switchboard, Distribution Board Enclosure shall be painted in Light Gray

(MUNSELL N6.5).

UPS [RC], Converters [RC], Rectifiers [RC] shall be painted in Light Gray (MUNSELL

N6.5).

Control Gear [RC], Control Panel for Package Equipment [RC] shall be painted in Light

Gray (MUNSELL N6.5).

Cable Tray, Steel Conduit shall be painted in accordance with below:

o Carbon Steel according to compartment color

Internal shall be painted in White.

External shall be painted in Ice Gray.

o FRP: (no coating).

Lighting Fixtures and Junctions Boxes:

o Carbon Steel Parts [RC] shall be painted in White (MUNSELL N 9.5).

o FRP: non-painted.

Note: Inner components mounting plate and/or inner door/safety barrier of Electrical

Panels referred above shall be painted in Safety Orange (MUNSELL 2.5 YR

6/14)

7.3.9. Instrumentation

Instruments shall follow the piping or equipment color.

Control Panels [RC] shall be painted in Light Cream (MUNSELL 2.5 Y 9/4), except

Stainless Steel Panels.

Actuators for instrumentation valves shall follow the valve color.

7.3.10. Helideck Landing Area

According to NORMAM 01 and 27.

7.3.11. Miscellaneous

Stripe at the elevators entrance floor shall be painted Safety Yellow (MUNSELL 5 Y

8/12)

SOPEP KIT box shall be painted in Safety Orange (MUNSELL 2.5 Y R 6/14) with

marking KIT SOPEP (black letters)

8. APPLICATION PROCESS

8.1. BRUSH

The paintbrush shall be of natural vegetal or animal fibers, in order to avoid the releasing of fiber

during the paint work. They shall be kept clean and free from any residues.

They shall be used for painting welded areas, irregular surfaces, sharp corners and cavities,

except in case of inorganic silicate base paints.

The paintbrush shall be 125 mm(5) wide at most.

The application shall be carried out in such a manner that the film of paint does not show any

brush marks after drying.

Runs or ways streaks shall be corrected at once with the paintbrush.

On weld fillets paint shall always be applied by paintbrush.

8.2. ROLLER

Rollers shall be a maximum of 175mm (7) long.

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 23 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

Rollers shall be used for painting extensive flat, cylindrical and spherical areas of considerable

radius of curvature, except where inorganic silicate base paints are being used.

Paint shall be applied in parallel runs, starting from the upper part of the structure, and with the

next stroke being given crosswise to the previous one.

REMARK: Irregular portions of the surface or those that cannot be reached with the roller shall be

painted by paintbrush or by spray gun.

Two (2) adjacent strips of the same coat of paint shall be overlapped a minimum of 5cm.

Paint shall be applied in all cases so that the film does not display blisters, tearing the previous

coat or impregnation with hairs falling off the roller.

8.3. CONVENTIONAL SPRAY GUN

This system shall be used for painting extensive areas or where high productivity is desired.

The compressed air used in the spray gun shall be free from water or oil. The equipment shall

be provided with separators, containing silica gel and activated carbon, so as to remove water

and oil respectively.

Separators shall be of suitable size and type and shall be periodically drained during the

painting operation.

Painting equipment shall be fitted with air and paint pressure regulators and gauges.

Compressed air hoods, nozzles and needle valves shall be the ones recommended by the

manufactures of the equipment for the particular type of paint to be sprayed on.

Pressure on the paint in the tank and the pressure of the air on the spray gun shall be adjusted

in accordance with the kind of paint that is being sprayed.

The air pressure on the paint in the tank shall be adjusted whenever necessary so as to offset

variations in the height at which the spray gun is raised above the tank.

Air pressure in the spray gun shall be high enough to atomize the paint but not so high as to

cause excessive misting, excessive evaporation of solvent or losses due to excessive

pulverization.

During application the spray gun shall be held perpendicular to the surface and at a constant

distance such as ensures the depositing of a damp coat of paint, and the paint shall impinge on

the surface still in the form of a spray.

This method of application shall not be used in places subject to strong wind or on extremely

thin structures, which would lead to a great wastage of paint.

8.4. AIRLESS SPRAY GUN

The airless spray gun should always be used where practicable; being the preferred method of

application.

Painting equipment shall have air and paint pressure regulators and gauges.

The pressure of the pneumatic pump in the painting equipment shall be adjusted in accordance

with the particular type of paint being sprayed on.

During application, the spray gun shall be held perpendicular to the surface and at a constant

distance that ensures the depositing of a damp film of paint, and the paint shall impinge on the

surface still in form of a spray.

On weld fillets paint shall always be applied by paint brush.

8.5. HIGH VOLTAGE ELECTROSTATIC EQUIPMENT

A high-voltage electrostatic equipment (90.000V) shall be used;

The cure shall be made in a stove with an approximated temperature of 200 C during 20

minutes.

8.6. OPERATOR QUALIFICATION

All operators shall demonstrate ability and knowledge of pertinent items of this specification by

successfully executing a written test and performing related tasks using approved procedures. The

written test shall be based on NACEs Guide to Qualification of Tradesman Industrial Painters.

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 24 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

VENDOR shall notify in advance the qualification testing schedule in order to allow OSX witness

the testing.

Records of testing and current qualifications of operators shall be maintained.

8.7. APPLICATION CONTROL

No paint shall be applied if the ambient or plate temperature or ambient relative humidity at the

time of application is not in accordance with allowable values mentioned in this specification.

Water or product shall not be put in contact with the paint until it is fairly dry.

9. PAINTING SURFACES

9.1. SURFACES TO BE PAINTED

9.1.1. All surfaces, other than those listed in item 9.2, shall be coated in accordance to this technical

specification.

9.1.2. The coating for stainless steel parts and elements shall not contain metallic zinc.

9.2. SURFACES NOT TO BE PAINTED

9.2.1. Unless otherwise specified in the Project Coating Specification, the following surfaces shall not

be coated:

Stainless steel surfaces (see item 9.2.2),

Non-insulated high Nickel alloys,

Non-ferrous metal surfaces (e.g. brass, copper) excluding aluminum and ABS plastic that

shall be coated,

Pipes internal surfaces unless specified otherwise,

Surfaces which shall not be coated: name plates, valve stems, shafts, mechanically finished

surfaces, gauges, windows and all other regions that the paint affect the component or

equipment use according OSX,

Flange faces where contact with gasket occurs,

Hub connector seal ring contact surface,

Plastic coated surfaces,

Surfaces to be protected by wrapping,

Contact surfaces of assemblies to be tied together with high-strength bolts, Anodes.

9.2.2. Painting of stainless steel: see Table 2 for special requirements.

Table 2 - Painting of stainless steel materials

Material Indoor Outdoor

(1)

Austenitic SS

(AISI 316)

Coat required if temperature 60C.

For temperatures 60C see note

(2).

Duplex SS No coating No coating if T 100C Coat required if T 100C

Super Duplex SS No coating No coating if T 110C Coat required if T 110C

Notes:

(1) The temperature quoted is the metal surface outer wall temperature (T).

(2) No coating is required when:

Substrate surface T 30C or,

Substrate surface 30C T 60C and relative humidity is higher than 41%.

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 25 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

9.2.2.1. Special requirements for painting of stainless steel operating at high risk of External Stress

Chloride Corrosion (ESCC):

Any austenitic SS (AISI 316) insulated pipe system or equipment operating temperature

range critical to External Stress Chloride Corrosion (ESCC) of 60 to 175C shall be

thermal sprayed with aluminum.

Any DUPLEX SS (UNS 31803) insulated pipe system or equipment operating

temperature range critical to External Stress Chloride Corrosion (ESCC) of 100 to 175C

shall be thermal sprayed with aluminum.

Any SUPER DUPLEX SS (UNS 32750 or 32760) insulated pipe system or equipment

operating temperature range critical to External Stress Chloride Corrosion (ESCC) of

110 to 175C shall be thermal sprayed with aluminum

10. PAINTING SYSTEM REQUIREMENTS

10.1. TEMPORARY PAINTING

10.1.1. Temporary painting for all new parts (plates, scantlings etc.):

10.1.1.1. Paint systems A

The following procedures shall be adopted:

The surface preparation shall be done by Dry Blasting or Slurry Blasting to grade Sa 2

according to ISO 8501 Parts 1 to 3: Preparation of steel substrates before application of

paints and related products. - Visual assessment of surface cleanliness, followed by low

pressure water cleaning (2000 to 3000 psi), and finally application of a Surface Tolerant

Solvent Free Epoxy Paint Cured with Polyamine, in minimum dry film thickness of

150m per coat.

10.1.1.2. Paint systems B:

The following procedures shall be adopted:

a) Prior the abrasive blasting operation all surfaces shall be washed with detergent to

remove oil and grease, followed by water jetting rinsing;

b) Air-drying;

c) Dry Blasting or Slurry Blasting the surface to grade Sa 2 according to ISO 8501

Parts 1 to 3: Preparation of steel substrates before application of paints and related

products. - Visual assessment of surface cleanliness,

d) Application of a High Thickness Epoxy Polyamine Paint in minimum dry film

thickness of 150 m per coat.

10.1.2. Temporary painting: in case of modules of New Building Units using automatic shop priming

plants, the following procedures shall be adopted:

New plates shall be washed with detergent to remove oil and grease, followed by water

rinsing;

Air-drying;

Surface preparation according to grade ISO 8501-1 Sa 2 , surface profile 50 to 70 m and

apply one coat of Primer Epoxy according paint system A or B (see item 17.1.1) at the

painting cabinet;

After assembly and mounting works, welds, sharp edges and damaged coatings shall be

treated with mechanical tools grade St-3 ISO 8501-1. Before painting, whole surface shall be

hydro blasted at 20000 psi and shall follow the specified painting system further this

document.

10.1.3. All cleaned surfaces shall be primed before rust bloom occurs.

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 26 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

10.2. SURFACE PREPARATION

10.2.1. Prior to paint application the metallic surface shall be free of Oil or Grease contamination.

10.2.2. Surface preparation for all items, unless noted otherwise in annex A or B, shall be as follows:

Surface preparation according to level Sa 2 (ISO 8501-1) or WJ2 (NACE SSPC-SP12)

over total area. A finish shall be obtained corresponding to at least one of the Sa 2

illustrations in standard ISO 8501-1 or WJ2 from NACE SSPC-SP12. For surface tolerant,

solvent free paint systems, when using abrasive air blasting for surface profile, clean the

surface with water jet prior before the application of first coat.

The maximum acceptable water-soluble salts on abrasive blasted surfaces before paint

application, measured according ISO 8502 Parts 1 to 10: Preparation of steel substrates

before application of paints and related products. - Test for the assessment of surface

cleanliness, shall be according to Table 3.

Roughness profile must be between 30-75m.

Table 3 - Maximum acceptable water-soluble salts contamination

Surface material Maximum acceptable water-soluble salts

Stainless steel 3g/cm

2

Any other materials surface on Im-2 environment

(1)

3g/cm

2

Any other materials surface on C5-M environment

(1)

5g/cm

2

Note (1): Environmental classification according item 2.

10.2.2.1. Hydro blasting remove more efficiently salts from surface than abrasive dry blasting

(see Table 4 - Comparison of salts removal obtained by different cleaning methods), so

hydro blasting is recommended for surface preparation.

Table 4 - Comparison of salts removal obtained by different cleaning methods

Method Remaining salts (mg/m

2

) % Extracted

Blasting

Dry

With abrasive (Sa 2) 440-680 83

With abrasive (As 2 ) 33 84

With abrasive (Sa 3) 32-34 90,2

Wet

With abrasive 0-32 96,2

Ultra High Pressure

(Waterjet)

16-18 93,5

Source: de La Fuente, D. et all The effects of soluble salts at the Metal/Paint interface: Advances in

knowledge, Portugaliae Electrochimica Acta, v. 24, 2006, p. 191-206.

10.2.3. Surface preparation for galvanized, aluminum, copper-nickel, bronze, cast iron, stainless steel,

surfaces nonmetallic materials and metalized surfaces.

10.2.3.1. General requirements:

a) Clean with green solvents (not harmful to environment) the regions contaminated with

oil, grease or fat;

b) Clean with 3000 psi water cleaning jet to remove salts and other impurities;

c) Surface preparation: according the paint system procedure.

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 27 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

10.2.3.2. Specific requirements:

a) For galvanized steel surfaces use surface preparation according to ASTM D 6386.

During the abrasive sweep or brush blasting cleaning, the blast nozzle must be at a

distance of 350 mm to 400 mm from the surface of the work piece and at an angle no

greater than 45 to the surface (never at 90).

10.3. SPECIFIC PAINT SYSTEMS

10.3.1. In Table 5 and ANNEXES A or B the surfaces to be painted and the specific paint systems

required by this technical specification.

10.3.1.1. Any surface or equipment not mentioned in Table 5 -PAINT SYSTEMS must be painted

with a paint system mentioned in ANNEX A or B.

10.3.1.1.1. OSX is responsible for the paint system selection.

10.3.1.1.2. No extra cost is due when the paint system is one of those mentioned in ANNEX A

or B.

10.3.2. Characteristics of ready products for application and of dry film are described in Table 6 and

Table 7.

10.3.3. Hot Dip Galvanizing

NOTE: Within all documents, specifications, drawings etc., the term GALVANIZING and equivalent

expressions are used to state that HOT DIP GALVANIZING shall be applied.

10.3.3.1. Scope:

10.3.3.1.1. This item covers the galvanizing coating applied to general steel articles,

structural sections, angles, channels, beams, columns, fabricated steel assemblies, and

other steel components.

10.3.3.1.2. This item does not apply to the galvanized coating on semi finished products

such as wire, tube or sheet, galvanized in specialized or automatic plants.

10.3.3.1.3. Coating: The minimum average coating mass (and equivalent thickness) on

any individual test area of the hot dip galvanized articles shall be as follows:

Steel 5 mm thick and over: 600 g/m

2

(84 m);

Steel under 5 mm thick but not less than 2 mm: 450 g/m

2

(63 m);

Steel less than 2 mm: 350 g/m

2

(49 m);

Centrifuged work: 300 g/m

2

(42 m);

Threaded work: 300 g/m

2

(42 m);

Gray and malleable iron casting: 600 g/m

2

(84 m).

10.3.3.2. Galvanized surfaces shall be externally painted as required in Table 5.

10.3.3.3. Standards: the following standards shall be applied on galvanized products:

American (ASTM) standards:

A123 for structural and piping components,

A153 for threaded components;

10.3.3.4. ISO standards: ISO 1461. In no case materials with yield strength greater than 400

MPa shall be galvanized.

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 28 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

10.3.3.5. HDG coatings shall not be used on Flares top platform due the risk of Liquid Metal

Embrittlement of stainless steel pipes in case of flame impingement (in such circumstance,

molten zinc droplets can drip on SS pipes).

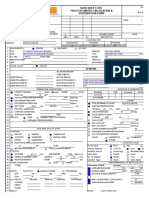

Table 5 - Paint Systems

N Item

Substrate service

temperature

Paint System A or B

Carbon Steel

paint system

Stainless

steel paint

system

1 Offshore platform structure

1.2 Topside (Structure) T 80C 1 N.A.

1.3 Moonpool

1.4 Splash zone T 80C 12 N.A.

1.5 Underwater zone T 80C No painting

(i)

N.A.

2 Deck

2.1 Deck Area (Floor) T 80C 2 N.A.

2.2 Supply Boat Handling

Area

T 80C 2 N.A.

2.3 Flare Tower

2.3.1 Top Part 200 C T 600C Thermal Spray Aluminum

2.3.2 Middle Part 80C T 200C 3 N.A.

2.3.3

Lower Part (up to required

height)

T 80C 1 N.A.

2.4 Helideck Structure T 80C 1 N.A.

2.5 Helideck Landing Area T 80C 11 N.A.

2.5.1 Helideck Surface T 80C 11 N.A.

2.5.2

Helideck Landing Circle Top-

coating

T 80C 11 N.A.

2.5.3

Helideck other Markings Top-

coating

T 80C 11 N.A.

2.6 Misc. Support Structure

2.6.1 Process Module Supports T 80C 1 N.A.

2.6.1.1 Module Supports T 80C 1 N.A.

2.6.2 Deck Cranes Supports

2.6.2.1 Deck Box T 80C 1 N.A.

2.6.2.2 Pedestal T 80C 1 N.A.

2.6.2.3 Crane Outside T 80C 1 N.A.

2.6.2.4 Crane Inside T 80C 8 N.A.

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 29 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

N Item

Substrate service

temperature

Paint System A or B

Carbon Steel

paint system

Stainless

steel paint

system

2.6.2.5 Crane Boom T 80C Thermal Spray Aluminum

2.6.3 Vent Masts T 80C 1 N.A.

2.6.4 Lifeboat Platforms & Davits T 80C 1 N.A.

2.6.5 Offloading Platform T 80C 1 N.A.

2.6.6 Handrails T 80C HDG + 5 N.A.

2.6.7 Escape Route Borders T 80C 2 N.A.

3

Deck / Skid Structures of

Process Modules

T 80C 1 N.A.

4

Local Equipment Rooms +

Laboratory

T 80C 1 N.A.

5 Pressure Vessels, Heat Exchangers, Coolers etc.

5.1 Un-insulated Surfaces

5.1.1

Shell, Heads, Nozzles,

Manholes, Skirts, Legs,

Saddles, Davits

T 60C 1 1

60CT90C 1 1

90C T 200C 3 3

200C T 600C Thermal Spray Aluminum

5.1.2 Access Platforms, Walkways T 80C 1 N.A.

5.1.3 Cage Ladders, Handrails

Grating

T 80C HDG N.A.

5.2 Insulated Surfaces

60C T 90C 1 1

90CT200C 3 3

200C T 600C Thermal Spray Aluminum

6 Piping (Note: exceptions stated in 8.2)

6.1 Un-insulated Surfaces

6.1.1

Pipes, Fittings, Valves, Steam

traps, Strainers, In-line

instruments

T 60C 1 1

60CT90C 1 1

90CT200C 3 3

200C T600C Thermal Spray Aluminum

6.1.2 Fire and Foam lines T 80C 1 N.A.

6.1.3

Central Pipe Rack, Pipe

Supports on Modules, Steel

Structures

T 80C 1 N.A.

6.1.4 Misc. Pipe Supports T 80C 1

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 30 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

N Item

Substrate service

temperature

Paint System A or B

Carbon Steel

paint system

Stainless

steel paint

system

6.1.5 HDG Pipes Exterior T 60C HDG + 4 N.A.

6.2 Insulated Surfaces

60C T 90C 1 1

90CT200C 3 3

200CT600C Thermal Spray Aluminum

7 Accommodation Block

7.1 Outside Surfaces T 80C 1 N.A.

7.2 Handrails T 80C HDG + 4 N.A.

7.3 Funnel T 80C 1 N.A.

7.4 Inside Surfaces

7.4.1

Walls and ceilings covered by

panels

T 80C 5 N.A.

7.4.2 Uncovered walls and ceilings T 80C 6 N.A.

7.4.3

Covered floors except those

defined in items 7.4.4 and 7.4.5

of this table.

T 80C 5 N.A.

7.4.4

Covered floors in rest rooms,

changing rooms, galley, mess

room and laundry

T 80C 7 N.A.

7.4.5 Uncovered floors T 80C 8 N.A.

8 Engine Room/ Pump Room

8.1 Floor T 80C 6 N.A.

8.2 Walls and Ceilings Bare Steel T 80C 6 N.A.

8.3

Walls and Ceilings under

Insulation

T 80C 5 N.A.

8.4

Structure below lowest Grating

and Foundations

T 80C 1 N.A.

8.5 Ventilation Trunks

8.5.1

Ventilation Trunk Interior

T 80C 7 N.A.

8.5.2

Ventilation Trunk Exterior

T 80C 6 N.A.

8.6

Boiler Casing

T 80C 6 N.A.

9

Rotary Equipment: Pumps, Filters, Compressors, Fans, Blowers, Turbines, Diesel

engines, others

9.1

Un-insulated Surfaces

T 60C 1 1

60CT 90C 1 1

90CT 200C 3 3

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 31 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

N Item

Substrate service

temperature

Paint System A or B

Carbon Steel

paint system

Stainless

steel paint

system

200C T 600C Thermal Spray Aluminum

9.2

Insulated Surfaces

60C T90C 1 1

90C T 200C 3 3

200C T 600C Thermal Spray Aluminum

9.3

Fire Water & Jockey Pumps

T 60C 1 N.A.

9.4

Submerged Seawater Lift

Pumps (Caisson mounted):

Interior

T 60C 1 N.A.

10 Tanks and Voids

10.1

Fresh Water Tanks

T 60C 10 N.A.

10.2

Fresh Water Tanks

T 60C

Thermal Spray

Aluminum

N.A.

10.3 Diesel Oil & HDO Tanks T 60C 9 N.A.

10.4 Fuel Oil Tanks T 60C 9 N.A.

10.5 Chain Lockers T 80C 2 N.A.

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 32 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

Table 6 Characteristics of paint, ready to apply.

ANTI-

FOULING

PAINTS

POLYURETHA

NE PAINTS

EPOXY

ISOCYANATE

IRON OXIDE

PAINTS

PRIMER

EPOXY

POLYAMINE

SILICONE

PAINT

ANTI-

SLIPPERY

PAINTS

Specific

Weight

1.45 g/cm

(min) - 1.85

g/cm (max)

1.0 g/cm

1.2 g/cm

3

(max)

Solids by

mass (min)

32 %

by weight

50%

45%

by weight

98%

Solids by

volume

(min)

45 % 60 % 17 % 20 %

Pigment

content

20.5% mass

(min)

Drying time

to touch

30 min (max) 1 hour (max) 20 min (max)

at 25C

10 min (max)

at 25C

30 min (max)

at 25C

12 h (max)

Drying time

to repaint

12 hours

(min)

6 hours (min) 12 hours

at 25C

24-72 h

(max)

72 hours (max)

Drying time

to tack free

(max)

4 hours

at 25C

30 min (max)

Total cure

time (max)

7 days

Pot life of

mix at 25C

(min)

5 hours 12 hours

Viscosity,

Ford cup #4

14 s (min) 40 sec

25 s (max)

Fineness of

grain (max)

35 m

Thickness

per coat

(min)

150 m 50 m

15 m (min) -

20 m (max)

25 m (min) 25 m

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 33 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

Table 7 Characteristics of paint, ready to apply (cont.)

HIGH ABRASION

EPOXY PAINTS

SEALANT PAINT EPOXY PHENOLIC

Specific Weight 1.25 g/cm

3

(max)

1.20 g/cm (min) - 1.30

g/cm (max)

1.45 g/cm

3

(max)

Solids by volume (min) 55 % 80%

Drying time to touch 1 hour (max)

Drying time to repaint 12 hours (min) 16-72 hours

Drying time to tack free

(max)

at 25C

6 min (max)

at 25C

8 hours (max)

Total cure time (max) 7 days 7 days

Pot life of mix at 25C

(min)

30 min 30 min

Viscosity, Ford cup #4

Fineness of grain (max)

Thickness per coat

(min)

400 m 80 micra

N TECHNIP REV. PAGE

F70072-000-SP-2300-001 0 34 of 60

N TECHINT

6859-M-SP-20001003

N OSX

ET-WHP02-0000-MEC-TPB-1003

P70072-000-FO-002 Rev.3

Table 8 Characteristics of dry film

COAL-

TAR

EPOXY

PAINTS

POLYUR-

ETHANE

PAINTS

ANTI-

FOULING

PAINTS

EPOXY

ISOCYANATE

IRON OXIDE

PAINTS

PRIMER

EPOXY

POLYAMI

NE

HIGH

ABRASION

EPOXY

PAINTS

ANTI-

SLIPPERY

PAINTS

Resistan

ce to salt

spray

(min)

480 hours 48 hours

50 m

240 hours

3000 hours

(1mm)

4000 hours

no film

defects

Resistan

ce to

100%

relative

humidity

(min)

480 hours 24 hours 240 hours 2000 hours

Adhesion

4 B (min) ASTM

D-3359; the test

shall be done

on a galvanized

carbon steel

specimen

N TECHNIP REV. PAGE