Beruflich Dokumente

Kultur Dokumente

HR Chapter 13

Hochgeladen von

Anonymous Clyy9NOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

HR Chapter 13

Hochgeladen von

Anonymous Clyy9NCopyright:

Verfügbare Formate

CHAPTER 13.

0 TABLE OF CONTENTS

13.0 OVERHEAD AND GANTRY CRANES ................................................

........................ 3

13.1 SCOPE .....................................................................

....................................................... 3

13.2 GENERAL REQUIREMENTS ......................................................

................................. 4

13.3 IMPLEMENTATION ............................................................

.......................................... 4

13.4 INCONSISTENT STANDARDS ....................................................

................................ 4

13.5 HANFORD SPECIFIC REQUIREMENTS AND PRACTICES ...............................

..... 4

13.5.1 Load-Test Weight. .......................................................

............................................. 5

13.5.2 Load-Test Report. .......................................................

.............................................. 5

13.5.3 Crane Maintenance Files..................................................

......................................... 5

ATTACHMENTS

Attachment 13.1 Sample Overhead Crane Daily Inspection Checklist ...............

.......................... 6

This page left intentionally blank

13.0 OVERHEAD AND GANTRY CRANES

13.1 SCOPE

This chapter applies to the marking, construction, installation, inspection, tes

ting, maintenance

and operation of the following overhead and gantry cranes, including semi-gantry

, cantilever

gantry, wall cranes, bridge cranes, and others having the same fundamental chara

cteristics.

These cranes may be top-running, under-running, single- or double-girder. Hoist

units and

trolleys are most commonly electric powered, but can be air powered or hand-chai

n operated.

These cranes may be cab operated, pulpit operated, floor operated, or remotely o

perated. Such

cranes are grouped together because all have trolleys and similar travel charact

eristics.

The proper and safe use of overhead and gantry cranes is governed by the America

n Society of

Mechanical Engineers (ASME) standards and the Occupational Safety and Health

Administration (OSHA) regulations. This section implements required criteria fro

m DOE/RL-

92-36 Hanford Site Hoisting and Rigging Manual and the following standards:

.

ASME B30.2-2011 Overhead and Gantry Cranes (Top Running Bridge, Single or

Multiple Girder, Top Running Trolley Hoist)

.

ASME B30.17-2006 Overhead and Gantry Cranes (Top Running Bridge, Single Girder,

Underhung Hoist)

.

OSHA 29 CFR 1910.179 - Overhead and Gantry Cranes

.

OSHA 29 CFR 1926 Subpart CC Overhead and Gantry Cranes (only applies to

temporarily installed cranes)

The responsible engineer may invoke Rules for Construction of Overhead and Gantr

y Cranes

(Top Running Bridge, Multiple Girder) ASME NOG-1-2004 for crane used at nuclear

facilities.

ASME NOG-1 applies to the design, manufacture, testing, inspection, shipment, st

orage, and

erection of overhead and gantry cranes (Top Running Bridge, Multiple Girder).

The responsible engineer may invoke Rules for Construction of Cranes, Monorails,

and Hoists

(with Bridge or Trolley or Hoist of the Underhung Type) ASME NUM-1-2004 for cran

es used at

nuclear facilities. ASME NUM-1 applies to the design, manufacture, testing, insp

ection,

shipment, storage, and erection of monorails and hoists (with Bridge or Trolley

or Hoist of the

Underhung Type).

This section implements the following criteria and the applicable national stand

ards and/or

federal specifications that are mandatory requirements for each item.

.

ASME B30.2-2011 Overhead and Gantry Cranes (Top Running Bridge, Single or

Multiple Girder, Top Running Trolley Hoist),

o General Construction and Installation, Chapter 2-1

o Inspection, Testing, and Maintenance, Chapter 2-2

o Operation, Chapter 2-3

o Maintenance Training and Maintenance, Chapter 2-4

.

ASME B30.17-2006 Overhead and Gantry Cranes (Top Running Bridge, Single Girder,

Underhung Hoist)

o General Construction and Installation, Chapter 17-1

o Inspection, Testing, and Maintenance, Chapter 17-2

o Operation, Chapter 17-3

13.2 GENERAL REQUIREMENTS

Contractors shall access requirements via the following options:

1. IHS Engineering Standards, Regulations and Technical Specifications at

http://www.ihs.com/ . The contractor must have paid for access to the specific s

tandard.

To print IHS file go to http://www.ihs.com/

2. To purchase standards directly from ASME go to http://www.asme.org

3. To access OSHA 29 CFR 1910.179, Overhead and Gantry Cranes, go to the followi

ng

link

.

http://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=STANDARDS&p_id=983

0

4. To access OSHA 29 CFR 1926, Subpart CC, refer to either of the following

.

Chapter 19, OSHA 29 CFR 1926, Subpart CC

.

http://www.osha.gov/doc/cranesreg.pdf

13.3 IMPLEMENTATION

Contractors shall be compliant to OSHA, ASME, DOE/RL-92-36, and the overhead or

gantry

crane manufacturers requirements. It is the responsibility of the user of this Ma

nual to

implement all of the requirements from listed sources. When two standards set fo

rth inconsistent

requirements, the user shall adhere to the standard containing the most stringen

t requirements.

ASME standards provide the most comprehensive information. Users should contact

a Hanford

Site Hoisting and Rigging Committee (HHRC) representative or send an email to ^H

anford

Hoisting and Rigging for a formal interpretation. See Chapter 17.0 for process t

o be followed

when requesting an interpretation. Notify the Hanford Site Hoisting and Rigging

Committee

(HHRC) if any inconsistent standards are identified.

It is not the intent of this manual to require retrofitting of existing equipmen

t. However, when

any hoisting or rigging equipment is modified, its performance requirements shal

l be reviewed

relative to the requirements within the current manual. The need to meet the cur

rent

requirements shall be evaluated by a qualified person selected by the owner (use

r).

Recommended changes shall be made by the owner (user) within 1 year.

13.4 INCONSISTENT STANDARDS

No inconsistencies between standards currently identified

13.5 HANFORD SPECIFIC REQUIREMENTS AND PRACTICES

CAUTION: Working on or under a suspended load is prohibited, except when the loa

d can be

supported by blocking or cribbing, can be securely braced, or can be supported s

ubstantially by

some other means that would prevent the load from moving. Some loads being lifte

d and set in

place may require special handling control measures such as inspecting, landing,

setting, or

controlling the load, that may require personnel to position their hands or othe

r body parts under

the load when no other method is feasible. These special handling control activi

ties MUST BE

APPROVED by management and industrial safety PRIOR TO BEING PERFORMED.

13.5.1 Load-Test Weight.

The load-test weight should be within a tolerance of +0 percent, -5 percent and

shall be traceable

to a recognized standard or verified by engineering calculations. Any one of the

following

options will meet this requirement:

.

Use a calibrated (+0 percent, -5 percent) load-measuring device during the load

test

.

Determine the test load with a calibrated load-measuring device before the test

.

Calculate the test load based on known unit weights and dimensions of the test f

ixture

.

Dimensions and calculations have been checked (signed and dated) by a qualified

engineer and determined to be accurate within tolerance (+0 percent, -5 percent)

13.5.2 Load-Test Report.

After the test is completed, the load-test report shall be signed and dated by t

he person in charge

of conducting the load test. The person in charge shall ensure that the test is

placed in the crane

maintenance file.

13.5.3 Crane Maintenance Files

The crane maintenance file is a compilation of various documents and records rel

ating to

operation, maintenance, inspection, testing, evaluation, and repair of the equip

ment. The file may

be centrally located or proportioned into satellite holding areas. The methods s

elected for

establishing adequate information retention and retrieval shall be determined by

the equipment

custodian, who is the responsible person for ensuring that a safe and reliable m

aintenance

program is in place.

The crane maintenance file shall contain, as a minimum, the required current dat

ed periodic

inspection records and other documentation to provide the user with evidence of

a safe and

reliable maintenance program. Inspection records should be retained in a format

and location that

provides for ease in accessibility. Maintenance file information should provide

a source for

comparing present conditions with past conditions to determine whether existing

conditions

show a trending pattern of wear, deterioration, or other comparable factors that

may compromise

safe, continued use of the equipment. Length of record retention shall be determ

ined by the

equipment custodians established maintenance program.

See Attachment 13.1 on the next page for a Sample Overhead Crane Daily Inspectio

n Checklist

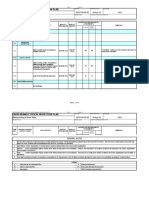

ATTACHMENT 13.1 - SAMPLE OVERHEAD CRANES DAILY INSPECTION CHECKLIST

BLDG:________ LOCATION:_____________ CRANE #: ____________ DATE: __/___/___ BY:

___________________

COMPONENT

N/A

OK

FAULTY

COMMENTS

Main Hoist

Controls

Push Buttons

Sounds Normal

Movement Smooth

Brakes Positive

Upper Limit

Lower Limit

Upper and Lower Blocks

Sheaves

Rope and Connections

Proper Drum Spooling

Hooks

Auxiliary Hoist

Controls

Pushbuttons

Sounds Normal

Movement Smooth

Brakes Positive

Upper Limit

Lower Limit

Upper and Lower Blocks

Sheaves

Rope and Connections

Proper Drum Spooling

Hooks

Trolley

Controls/Pushbutton

Travels Smooth

Sounds Normal

Brakes Positive

Trolley and Bridge Obstruction

Housekeeping

Ladders and Landings

Oil Leaks

Operation of Brakes

Loose Parts

Keepers in Place

Lubrication Requirements

Fire Extinguisher Locations

Retaining Latch(es) in Place

Hooks Swivel Freely

Obvious Hook Deformations

Bridge

Controls/Pushbuttons

Travels Smooth

Sounds Normal

Brakes Positive

Limits Working

Alarms

Lights

Rigging Capacity

Das könnte Ihnen auch gefallen

- 737 Performance Reference Handbook - EASA EditionVon Everand737 Performance Reference Handbook - EASA EditionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Multi-Engine Oral Exam Guide: The comprehensive guide to prepare you for the FAA checkrideVon EverandMulti-Engine Oral Exam Guide: The comprehensive guide to prepare you for the FAA checkrideBewertung: 5 von 5 Sternen5/5 (4)

- DOE/RL-92-36, Hanford Site Hoisting and Rigging Manual Chapter 13.0 - Overhead and Gantry Cranes March 21, 2013 Rev 1 PageDokument6 SeitenDOE/RL-92-36, Hanford Site Hoisting and Rigging Manual Chapter 13.0 - Overhead and Gantry Cranes March 21, 2013 Rev 1 PageAnonymous NUn6MESxNoch keine Bewertungen

- DOE/RL-92-36, Hanford Site Hoisting and Rigging Manual Rev 1 Page 1Dokument6 SeitenDOE/RL-92-36, Hanford Site Hoisting and Rigging Manual Rev 1 Page 1Nazhani RohaidinNoch keine Bewertungen

- OSHA Crane Inspection GuidelinesDokument11 SeitenOSHA Crane Inspection Guidelinesmisu110382100% (1)

- DOE Standard - Hoisting and Rigging - 2020 UpdateDokument39 SeitenDOE Standard - Hoisting and Rigging - 2020 UpdateLogic TurnipNoch keine Bewertungen

- Doe STD 1090 2011Dokument42 SeitenDoe STD 1090 2011Daniel FonsecaNoch keine Bewertungen

- Marine Hanging StagingDokument30 SeitenMarine Hanging StagingRajNoch keine Bewertungen

- Crane Tata SteelDokument39 SeitenCrane Tata Steelbabu maheshNoch keine Bewertungen

- DAC Requirements For ISO 17020Dokument25 SeitenDAC Requirements For ISO 17020Steve Morrison100% (4)

- The Lifting Device Safety ManualDokument36 SeitenThe Lifting Device Safety Manualrop703406Noch keine Bewertungen

- Rp-205 Crane Operation, Maintenance and TestingDokument30 SeitenRp-205 Crane Operation, Maintenance and TestingWilman Barrera Grados100% (1)

- Manual de Operatividad y Servicio Manlift 80hxDokument104 SeitenManual de Operatividad y Servicio Manlift 80hxRicky VilNoch keine Bewertungen

- OSHA Crane2 PDFDokument3 SeitenOSHA Crane2 PDFHatem JafouraNoch keine Bewertungen

- HR Chapter 03Dokument24 SeitenHR Chapter 03Metallurgist007Noch keine Bewertungen

- G01CRANESDokument11 SeitenG01CRANESjessaniNoch keine Bewertungen

- Recommended Practice For Machinery Installation and Installation Design Chapter 2-Rigging and LiftingDokument2 SeitenRecommended Practice For Machinery Installation and Installation Design Chapter 2-Rigging and LiftingshbaeerNoch keine Bewertungen

- AIS PR INS 29 Rev 01 Crane Inspection Procedure (Repaired)Dokument11 SeitenAIS PR INS 29 Rev 01 Crane Inspection Procedure (Repaired)aymenmoatazNoch keine Bewertungen

- Crane Hoist Safety ProgramDokument11 SeitenCrane Hoist Safety ProgramAssawin AnonuNoch keine Bewertungen

- Cps Crane MaintenanceDokument13 SeitenCps Crane MaintenanceTarek HareedyNoch keine Bewertungen

- Asme B.30.1 PDFDokument16 SeitenAsme B.30.1 PDFrzurabaeza100% (1)

- TB 43-0142 Safety Inspection and Testing of Lifting DevicesDokument36 SeitenTB 43-0142 Safety Inspection and Testing of Lifting DevicesChiheb KaanicheNoch keine Bewertungen

- Vertical and Horizontal Recirculator Packages: Form 120-200 IOM (MAR 2010)Dokument44 SeitenVertical and Horizontal Recirculator Packages: Form 120-200 IOM (MAR 2010)botaratoNoch keine Bewertungen

- RP 205Dokument30 SeitenRP 205Vasant Kumar VarmaNoch keine Bewertungen

- DOE-RL-92-36, Hanford Site Hoisting and Rigging Manual Chapter 16.0 - A-FRAMES AND TROLLEYS August 7, 2009 Rev 1 Page 1Dokument8 SeitenDOE-RL-92-36, Hanford Site Hoisting and Rigging Manual Chapter 16.0 - A-FRAMES AND TROLLEYS August 7, 2009 Rev 1 Page 1andresboy123Noch keine Bewertungen

- SPP 1910.179A Overhead Cranes and HoistsDokument15 SeitenSPP 1910.179A Overhead Cranes and HoistsAgung SetiawanNoch keine Bewertungen

- Planned Critical Lift Crane PermitDokument5 SeitenPlanned Critical Lift Crane PermitsurnaikNoch keine Bewertungen

- Model 6 - OSHADokument19 SeitenModel 6 - OSHAManoj JaiswalNoch keine Bewertungen

- BOMMI-PRD-07.0013-Rev.00 - Anchor Handling and Towing OperationsDokument10 SeitenBOMMI-PRD-07.0013-Rev.00 - Anchor Handling and Towing Operationsfundatia_gaudeamus100% (3)

- Properly Install, Inspect, and Load Test Overhead Patient/Resident Track LiftsDokument6 SeitenProperly Install, Inspect, and Load Test Overhead Patient/Resident Track LiftshammadNoch keine Bewertungen

- CranesDokument80 SeitenCranesjoenediath9345Noch keine Bewertungen

- Code of Practive For Safe Use and Operation of Suspended Working PlatformDokument62 SeitenCode of Practive For Safe Use and Operation of Suspended Working PlatformthowchinNoch keine Bewertungen

- Regulation IO-11.0 Lifting Equipment Protocol Rev. 00, Sep16Dokument11 SeitenRegulation IO-11.0 Lifting Equipment Protocol Rev. 00, Sep16qcnareshkumarariesNoch keine Bewertungen

- Mobile Crane Logbook Permanent Record: (OHS) ActDokument20 SeitenMobile Crane Logbook Permanent Record: (OHS) ActAltayeb YassinNoch keine Bewertungen

- Sparrows Crane Offshore Crane Operator and Banksman Integrated Safe Operating ProceduresDokument64 SeitenSparrows Crane Offshore Crane Operator and Banksman Integrated Safe Operating ProceduresTrần T Như Quyên78% (9)

- 1.06-Mechanical Seal Installation and Maintenance Instructions - IOMDokument16 Seiten1.06-Mechanical Seal Installation and Maintenance Instructions - IOMcavillalobosb8167Noch keine Bewertungen

- Regulation IO-11.0 EHS Lifting Equipment Protocol Rev. 00 Jan18Dokument18 SeitenRegulation IO-11.0 EHS Lifting Equipment Protocol Rev. 00 Jan18Revankar B R ShetNoch keine Bewertungen

- RP 3.0A For Structures, Drawworks and Rig CarrierDokument25 SeitenRP 3.0A For Structures, Drawworks and Rig CarrierDarshan MakwanaNoch keine Bewertungen

- Operation 3120685 04-20-00 ANSI EnglishDokument78 SeitenOperation 3120685 04-20-00 ANSI EnglishRolando RamirezNoch keine Bewertungen

- DOE/RL-92-36, Hanford Site Hoisting and Rigging Manual Chapter 5.0 - HOOKS August 7, 2009 Rev 1 Page 1Dokument4 SeitenDOE/RL-92-36, Hanford Site Hoisting and Rigging Manual Chapter 5.0 - HOOKS August 7, 2009 Rev 1 Page 1ProkopNoch keine Bewertungen

- Manual RS6 A5 - ENG EAB 2018-11-16 RadioshuttleDokument66 SeitenManual RS6 A5 - ENG EAB 2018-11-16 Radioshuttlerodrigo0% (1)

- D03MOORINGWINCHES CleanDokument9 SeitenD03MOORINGWINCHES CleanRao SgNoch keine Bewertungen

- RHN Owners Manual - HoistsDokument112 SeitenRHN Owners Manual - HoistsDaniel ConwayNoch keine Bewertungen

- Rigging and Lifting (Rev.1)Dokument33 SeitenRigging and Lifting (Rev.1)windell Patalinghug100% (2)

- Mobile Crane Inspection FormDokument6 SeitenMobile Crane Inspection FormSham AranNoch keine Bewertungen

- Qcs 2010 Section 11 Part 2.3.10 She Procedures - The Safe Use of CranDokument26 SeitenQcs 2010 Section 11 Part 2.3.10 She Procedures - The Safe Use of Cranbryanpastor106100% (7)

- TD MPI Inspection StandardDokument97 SeitenTD MPI Inspection StandardMohamed BadranNoch keine Bewertungen

- 4004EH Hard Wired 999980 0200Dokument61 Seiten4004EH Hard Wired 999980 0200AdamNoch keine Bewertungen

- Standardcsa Platform b354!2!2001 r2006Dokument3 SeitenStandardcsa Platform b354!2!2001 r2006nodolaemailNoch keine Bewertungen

- Ac - 35 - 37-1B Fatiga HeliceDokument25 SeitenAc - 35 - 37-1B Fatiga Helicemarco candoNoch keine Bewertungen

- OHDC Lifting ProcedureDokument12 SeitenOHDC Lifting ProcedureHamid Ali100% (1)

- Ac 145-9 CHG 1Dokument78 SeitenAc 145-9 CHG 1PhillipNoch keine Bewertungen

- 4818 DB1 OpsMan R0Dokument661 Seiten4818 DB1 OpsMan R0sep650cengrNoch keine Bewertungen

- Vessel Inspection PDFDokument18 SeitenVessel Inspection PDFAhmed Imtiaz Rao100% (1)

- Packing ProcedureDokument24 SeitenPacking ProcedureAditya NugrahaNoch keine Bewertungen

- W376 LMI ManualDokument33 SeitenW376 LMI ManualAnonymous yjK3peI7100% (1)

- Mobile CraneDokument18 SeitenMobile CraneHarris ShehzadNoch keine Bewertungen

- QP-REG-Q-001 Rev-4Dokument92 SeitenQP-REG-Q-001 Rev-4johnsonpinto80% (5)

- Iso4310 1981Dokument6 SeitenIso4310 1981somsak9100% (2)

- Aircraft Weight and Balance Handbook: FAA-H-8083-1AVon EverandAircraft Weight and Balance Handbook: FAA-H-8083-1ABewertung: 5 von 5 Sternen5/5 (1)

- FABRICATION OF AUTO ROTATING SOLAR PANEL 1st REVIEWDokument13 SeitenFABRICATION OF AUTO ROTATING SOLAR PANEL 1st REVIEWAnonymous Clyy9NNoch keine Bewertungen

- FABRICATION OF SOLAR THERMAL BATTERY WATER DISTILLATION IN SALT WATER 2nd REVIEWDokument14 SeitenFABRICATION OF SOLAR THERMAL BATTERY WATER DISTILLATION IN SALT WATER 2nd REVIEWAnonymous Clyy9NNoch keine Bewertungen

- FABRICATION OF PROPELLER SHAFT BICYCLE - 1st REVIEWDokument14 SeitenFABRICATION OF PROPELLER SHAFT BICYCLE - 1st REVIEWAnonymous Clyy9NNoch keine Bewertungen

- FABRICATION OF BIO GAS PRODUCTION IN COLLEGE CANTEEN WASTE 1st REVIEWDokument13 SeitenFABRICATION OF BIO GAS PRODUCTION IN COLLEGE CANTEEN WASTE 1st REVIEWAnonymous Clyy9NNoch keine Bewertungen

- FABRICATION OF GRAVITY POWER GENERATION 1st REVIEWDokument14 SeitenFABRICATION OF GRAVITY POWER GENERATION 1st REVIEWAnonymous Clyy9NNoch keine Bewertungen

- Coin Based Mobile Phone Charging System-ReviewDokument15 SeitenCoin Based Mobile Phone Charging System-ReviewAnonymous Clyy9NNoch keine Bewertungen

- 10.FABRICATION OF GEO THERMAL HEATING AND COOLING SYSTEM 1st REVIEWDokument13 Seiten10.FABRICATION OF GEO THERMAL HEATING AND COOLING SYSTEM 1st REVIEWAnonymous Clyy9NNoch keine Bewertungen

- Design and Fabrication of Leaf JigDokument9 SeitenDesign and Fabrication of Leaf JigAnonymous Clyy9NNoch keine Bewertungen

- Remote Control Based Ac or DC Motor Speed Control System - 1ST ReviewDokument15 SeitenRemote Control Based Ac or DC Motor Speed Control System - 1ST ReviewAnonymous Clyy9NNoch keine Bewertungen

- Fabrication of Concentric Tube Heat Exchanger 1ST ReviewDokument14 SeitenFabrication of Concentric Tube Heat Exchanger 1ST ReviewAnonymous Clyy9NNoch keine Bewertungen

- Finger Print Based Door Locking System - 1ST ReviewDokument15 SeitenFinger Print Based Door Locking System - 1ST ReviewAnonymous Clyy9NNoch keine Bewertungen

- Arrangement of Evaporator Body - 09.02.2020 (Elevation) PDFDokument1 SeiteArrangement of Evaporator Body - 09.02.2020 (Elevation) PDFAnonymous Clyy9NNoch keine Bewertungen

- Review On Fabrication of 3 Axis Spray Painting Machine Ijariie1981Dokument4 SeitenReview On Fabrication of 3 Axis Spray Painting Machine Ijariie1981Anonymous Clyy9NNoch keine Bewertungen

- Asderrfuwdbc DFDCDDokument10 SeitenAsderrfuwdbc DFDCDAnonymous Clyy9NNoch keine Bewertungen

- Lab ViewDokument4 SeitenLab ViewAnonymous Clyy9NNoch keine Bewertungen

- Fabrication of Wire Pealing Machine - SynopsisDokument2 SeitenFabrication of Wire Pealing Machine - SynopsisAnonymous Clyy9NNoch keine Bewertungen

- SPT Attach MagDokument6 SeitenSPT Attach MagAnonymous Clyy9NNoch keine Bewertungen

- Variable Speed Drilling Machine Without Gearbox - AbstractDokument1 SeiteVariable Speed Drilling Machine Without Gearbox - AbstractAnonymous Clyy9NNoch keine Bewertungen

- Design and Fabrication of Vehicles Multi Wheel Nuts Tightner and RemoverDokument6 SeitenDesign and Fabrication of Vehicles Multi Wheel Nuts Tightner and RemoverAnonymous Clyy9N100% (1)

- Wear Testing of High-Alloy Carbon Steel Used in Mining ToolsDokument24 SeitenWear Testing of High-Alloy Carbon Steel Used in Mining ToolsAnonymous Clyy9NNoch keine Bewertungen

- Proposed Plan For Mr.K.GanaprakashamDokument1 SeiteProposed Plan For Mr.K.GanaprakashamAnonymous Clyy9NNoch keine Bewertungen

- .Fabrication of Solar Air Cooler For Remote AreaDokument4 Seiten.Fabrication of Solar Air Cooler For Remote AreaAnonymous Clyy9NNoch keine Bewertungen

- Design On Automatic Spraying Robot System Based On PC-PLC Network ControlDokument6 SeitenDesign On Automatic Spraying Robot System Based On PC-PLC Network ControlAnonymous Clyy9NNoch keine Bewertungen

- Gears & Gear Manufacturing: Training ObjectiveDokument5 SeitenGears & Gear Manufacturing: Training ObjectiveAnonymous Clyy9NNoch keine Bewertungen

- Development of An Automated Impact Hammer For Modal Analysis of StructuresDokument33 SeitenDevelopment of An Automated Impact Hammer For Modal Analysis of StructuresAnonymous Clyy9NNoch keine Bewertungen

- D048021032 PDFDokument12 SeitenD048021032 PDFAnonymous Clyy9NNoch keine Bewertungen

- Introduction To Ansys SoftwareDokument49 SeitenIntroduction To Ansys SoftwareAnonymous Clyy9NNoch keine Bewertungen

- Paralleling Generators of Different Makes, Models and ManufacturersDokument3 SeitenParalleling Generators of Different Makes, Models and ManufacturersSohail ANoch keine Bewertungen

- Test Design Techniques: Istqb Certified Tester - Foundation LevelDokument112 SeitenTest Design Techniques: Istqb Certified Tester - Foundation LevelAnonymous Uk3rVZDVFNoch keine Bewertungen

- All About Stored Procedures - Database Administration Content From SQL Server ProDokument6 SeitenAll About Stored Procedures - Database Administration Content From SQL Server Prochand5c0Noch keine Bewertungen

- Heizer Om10 ModbDokument48 SeitenHeizer Om10 ModbbsaNoch keine Bewertungen

- Sensible Chinese Characters To WordsDokument27 SeitenSensible Chinese Characters To WordsrajualnNoch keine Bewertungen

- Tanzania - Roads Rehabilitation Upgrading Project - Appraisal ReportDokument52 SeitenTanzania - Roads Rehabilitation Upgrading Project - Appraisal Reportrsirsi3742Noch keine Bewertungen

- CV Ravi ShenkerDokument6 SeitenCV Ravi ShenkerRavi ShenkerNoch keine Bewertungen

- Software Requirements Specification - FlightDokument38 SeitenSoftware Requirements Specification - FlightrajiNoch keine Bewertungen

- Siebel Ecustomer White PaperDokument6 SeitenSiebel Ecustomer White PapervdaveNoch keine Bewertungen

- The Direct Analysis Method Made Simple: CSC IncDokument73 SeitenThe Direct Analysis Method Made Simple: CSC IncgayalamNoch keine Bewertungen

- MRT Bumiputera Main Work ContractorDokument2 SeitenMRT Bumiputera Main Work ContractoraridaconceptNoch keine Bewertungen

- HP Man ITGk-V5.0userguides-Usingworkbench PDFDokument68 SeitenHP Man ITGk-V5.0userguides-Usingworkbench PDFutkarsh_m83Noch keine Bewertungen

- Crane Components For Standard CraneDokument20 SeitenCrane Components For Standard CraneMacan SumatraNoch keine Bewertungen

- Saudi Aramco Typical Inspection Plan: Waterproofing of Roof Slabs SATIP-M-100-02 30-Apr-13 CivilDokument2 SeitenSaudi Aramco Typical Inspection Plan: Waterproofing of Roof Slabs SATIP-M-100-02 30-Apr-13 CivilSatheesh Rama SamyNoch keine Bewertungen

- Logistics Integration For Customer Satisfaction Distribution Cost Control and Customer ServiceDokument50 SeitenLogistics Integration For Customer Satisfaction Distribution Cost Control and Customer ServiceKanika GoyalNoch keine Bewertungen

- Circulation - Defining and Planning (May 2012)Dokument15 SeitenCirculation - Defining and Planning (May 2012)Briccio0% (1)

- BCI Castings & Forgings, FinalDokument24 SeitenBCI Castings & Forgings, FinalbranthamNoch keine Bewertungen

- Ductwork Order FormDokument5 SeitenDuctwork Order FormShaun SullivanNoch keine Bewertungen

- Autonomous TransactionsDokument9 SeitenAutonomous TransactionsdkmdipeshNoch keine Bewertungen

- Placement data-A.Y.:2014-15: Sr. No. Name of Company Number of Students Placed Salary Offered CTC in LpaDokument3 SeitenPlacement data-A.Y.:2014-15: Sr. No. Name of Company Number of Students Placed Salary Offered CTC in Lpasujeet guptaNoch keine Bewertungen

- Mysql WP DRBDDokument25 SeitenMysql WP DRBDNasim AkhtarNoch keine Bewertungen

- Parking Access Design Standards Handbook 2010Dokument25 SeitenParking Access Design Standards Handbook 2010Sopheak ThapNoch keine Bewertungen

- Alcohol DistillationDokument4 SeitenAlcohol DistillationprocesspipingdesignNoch keine Bewertungen

- VDR Website Supplier InstructionsDokument1 SeiteVDR Website Supplier InstructionszalzizaNoch keine Bewertungen

- Creating and Administering Analytics and Reports v13Dokument108 SeitenCreating and Administering Analytics and Reports v13sieger74Noch keine Bewertungen

- 11 Create WBS PDFDokument10 Seiten11 Create WBS PDFKhanh Dinh Duy100% (1)

- Chapter 2Dokument58 SeitenChapter 2addweb08Noch keine Bewertungen

- MTU BLUE VISION AdVANCED PDFDokument8 SeitenMTU BLUE VISION AdVANCED PDFomar alayash100% (1)

- CLL f399 Imp EngDokument73 SeitenCLL f399 Imp EngJesus CastroNoch keine Bewertungen

- Market Study On Maruti Suzuki SwiftDokument63 SeitenMarket Study On Maruti Suzuki SwiftNikesh BeradiyaNoch keine Bewertungen