Beruflich Dokumente

Kultur Dokumente

T1359 65

Hochgeladen von

Javad AmnianOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

T1359 65

Hochgeladen von

Javad AmnianCopyright:

Verfügbare Formate

VARIABLE SPEED FLUID COUPLINGS DRIVING

CENTRIFUGAL COMPRESSORS AND OTHER CENTRIFUGAL MACHINERY

by

Gunther H. Peikert

Regional Manager

Voith Transmissions, Incorporated

Houston, Texas

Gunther H. Peiker received his de

gree in Mechanical Engineering at the

Technical University of Kaiserslauter in

West Germany. He joined V oith in 1963

and worked for five years in the Re

search Department for Hydrodynamic

Fluid Couplings. Since 1968, he has as

sumed several international assignments

for Voith in France, Spain, and the

United States.

Mr. Peikert has been in Houston since

1981 as the Regional Manager for Voith Transmissions, the

U. S. subsidiary of Voith' s Power Transmission Departments.

ABSTRACT

In the past, large compressors in the petrochemical indus

try were mostly driven in one of two ways: by steam (or gas)

turbines or by constant speed electrical motors. If the fow of

the compressor had to be controlled, two ways were possible:

to control its speed or to control its suction. If flow control was

required, the steam (or gas) turbine was the right answer, since

in-plant steam could be produced at a rather low cost (gas could

be purchased for an equally low price). In the case of more

continuous, even fow rates, the constant speed electric motor

was a good alternative. For startup, the compressor was by

passed and, if a certain control was necessary, suction control

was used without even looking at the power consumption.

Highly increased fuel cost, especially for in-plant steam gener

ation, has made commercially available electric power from

large generating plants more attractive. On the other hand, for

the same reason, energy conservation makes speed control

much superior to suction control and last, but not least, the

more diversifed nature of feed stocks as well as more fluctuat

ing production rates call more ofen for compressors to be

controlled. The same is valid for other centrigal machines

such as boiler feed water pumps and pipeline loading pumps.

Today, more and more compressors are driven by variable

speed devices other than steam turbines. One way is to use

purely electric drives, which are, however, still in the trial

phase regarding large horsepower. Another, much more

proven way is to use, in connection with a standard constant

speed electric motor, a hydrodynamic, so-called, fuid cou

pling. The type of fluid coupling mostly used for this applica

tion is the one with integrated gears.

This kind of machine, relatively new to the petrochemical

community, has, however, proven its high reliability and

availability in thousands of applications in the power generat

ing industry, mostly with boiler feed pumps. Other applica

tions have included installations in oil producing and shipping

plants, on platforms ofshore and onshore, and with pipeline

and loading pumps. Successful compressor applications go

59

back some 15 years, with numbers increasing over the last

three to four years. These compressor applications go up to

10,000 hp, with output speeds reaching 12,000 rpm. Pump

applications with many more years of case history exist up to

30,000 hp, with designs available for 60,000 hp.

There are many more applications of the hydrodynamic

principle in numerous other industries, in the form of fluid

couplings and torque converters, as well as combined transmis

sions.

The intention herein is to describe the hydrodynamic

principle and its technical application in the following areas:

Basic function of hydrodynamic variable speed fluid

couplings

Advantages of using such couplings

Successfl designs of such couplings

Typical applications with centrifgal machines

Speed control options and instrumentation

Economic advantages of speed control

Installation and maintenance

Reliability and availability

Other types of variable speed drives

Thousands of variable speed fluid couplings in pump and

compressor applications worldwide have proven. the high de

gree of availability, the simple maintenance needs and the long

life of such wear-fee machines.

BASIC FUNCTION OF HYDRODYNAMIC

VARIABLE SPEED FLUID COUPLINGS

The hydrodynamic principle of power transmission was

discovered and developed by Professor Foettinger in the early

part of this century. His basic idea was to integrate a pump and

a turbine, both centrifgal, in the same machine (Figure 1).

The transmission fuid, usually a mineral oil, is accelerated in

the pump wheel, and goes then over into the turbine wheel,

where it is decelerated (Figure 2). In other words, in the pump

wheel, also called the primary wheel, the mechanical energy

fom the driver is converted into kinetic energy, which in turn

is reconverted into mechanical energ in the turbine wheel,

also called the secondary wheel, now turning the driven

machine. The geometrical form of both wheels as well as the

form and distribution of the radial blades within these wheels

refects the knowledge and experience of the manufacturer of

hydraulic machines.

This principle of hydrodynamic power transmissions ap

plies to all kinds of fluid couplings, whether they are constant

speed, drain type or variable speed type. The first group is

mostly used for soft starts, overload protection and gentle

acceleration. The second type is also used to separate the

driven machine from the driver, like a clutch, without losing

the advantages of the first group.

The third group, variable speed fluid couplings, is the

subject herein. In order to obtain the diferent speeds required

against a given load (i. e. , the parabola of a centrifugal pump),

60 PROCEEDINGS OF THE THIRTEENTH TURBOMACHINERY SYMPOSIUM

Figure 1. Foettinger Prnciple.

Figure Z. Hydrodynamic Power Transmission.

the varible speed coupling has to be adjusted in its flling so as

to change its torque versus speed characteristic (Figure 3). This

is basically done by superimposing an oil flow on the above

described oil circulation between the primary and the second

m wheels (Figure 4). In most fuid couplings this is done by

supplying an oil fow, which can be constant for smaller units,

but should be variable (dependent of the occurring heat load in

the coupling) for larger units, into the active part (bladed pump

and turbine wheel sections) of the fluid coupling.

Control of the degree of flling is obtained by introduction

of a variable overfow, which is in this case a so-called scoop

tube. The scoop tube is a more or less radially located tube

which has a curved opening directed against the direction of

rotation of the spinning oil ring within the coupling. It usually

runs in a separate annular chamber, which is connected by

axial bores within the active part of the fuid coupling, and

which will have the same oil level, due to the centrifgal force

in this working chamber.

The scoop tube is so designed and dimensioned that it

can, under all working conditions, pump out more oil than the

flling pump can supply. By this trick, the speed variation

comes down to the simple, mechanical positioning of the scoop

tube. A speed diference between the pump wheel and the

turbine wheel always has to exist, in order to create a circular

L

C

SCOOP TUBE POSITION

40

30

0

20

'

0

OUTPUT SPEED

Figure 3. Torque-Speed Characterstic of Variable Speed

Fluid Coupling.

Figure 4. Simple Cut-Away of a Variable Speed Fluid

Coupling.

oil flow between those two parts, by the diference in the

centrifgal forces, and so be able to transmit torque. The speed

diference between the pump wheel and the turbine wheel is

called slip and is expressed in percent of the pump wheel

speed. By inducing slip as the means of speed regulation, slip

losses are created within the freely circulating transmission oil,

which in turn can be very easily transported by this same oil

through the scoop tube, out of the coupling and into a heat

exchanger. Ater dissipating its heat either to water or to air,

the cooled oil flows back into the fuid coupling.

ADVANTAGES OF VARIABLE SPEED COUPUNGS

Load-free startup of driver

Steplessly adjustable startup as well as stepless speed

regulation

VARIABLE SPEED FLUID COUPLINGS DRIVING

CENTRIFUGAL COMPRESSORS AND OTHER CENTRIFUGAL MACHINERY

61

Dampening of torque peaks (and no harmonics) fom

either side and thus,

Decreasing mechanical stress in the whole drive line

Disconnecting driven machine possible while driver

keeps running

Torque limitation capabilities

Wear-free power transmission

Extreme high availability

Low maintenance needs

Very versatile regarding necessary accessories and in

strumentation, using standard models.

SUCCESSFUL DESIGNS OF SUCH COUPLINGS

For the purposes here, the multitude of existing couplings

of these types can be divided into three basic families.

Variable Speed Fluid Couplings With Anti-Friction Bearings

The diferent couplings with anti-friction bearings are

mostly used for small and medium horsepowers in what can

generally be referred to as industrial applications (Figure 5).

These couplings exist in both the horizontal as well as the

vertical versions. The simplest type has its rotating parts

supported by the driving and driven shafs. The other types are

fee standing, flly enclosed, with the housing being either of

the barrel type or horizontally split. These couplings have a

motor driven or mechanically driven oil pump, their scoop

tube is directly linked to a mechanical actuator, and the hot oil

fows into the sump. The oil cooler is normally located after the

oil sump.

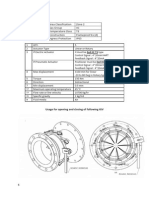

Figure 5. Variable Speed Fluid Coupling with Anti-Friction

Bearings. 1) primary wheel, 2) secondary wheel, 3) shell, 4)

scoop tube housing, 5) oil sump, 6) oil pump, 7) scoop tube.

Variable Speed Fluid Couplings With Sleeve Bearings

Variable speed couplings with sleeve bearings are used in

the power generating and petrochemical industries (Figure 6).

They also include both horizontal and vertical designs. One

type is mostly used for low speed applications, and has basical

ly the same features as the first group. The second design, for

higher speed (mostly with two pole motors), is typically driving

boiler feed pumps or compressors.

Figure 6. Variable Speed Fluid Coupling with Sleeve Bearings.

1) primary wheel, 2) secondary wheel, 3) shell, 4) coupling

housing, 5) scoop tube housing, 6) oil sump, 7) scoop tube, 8)

oil pump, 9) auxiliary lube pump.

This type shows two new features (Figure 7). The scoop

tube is no longer linked directly to the actuator, but to an

internal gear segment drive with a cam to be moved by the

actuator. This produces a linear behavior for the fluid coupling,

which means it can be adjusted in the plant to have a flly

linear response to the input control signal. The other feature is

a regulating valve which is mechanically linked to the scoop

tube control. This valve recirculates the working oil directly

back into the coupling, thus creating a closed circuit. In this

case, the cooler is located afer the scoop tube. The amount of

oil circulation in this closed circuit is regulated by the valve as a

function of the occurring heat losses, thus providing an even

temperature level and lowering mechanical losses within the

system.

Figure . Variable Speed Fluid Couplingfor Two Pole Electrc

Motor Applications.

Variable Speed Fluid Couplings With Incorporated Gears

Variable speed fluid couplings with incorporated gears are

the workhorses for higher horsepowers and/or speeds, and

combine variable speed couplings with sleeve bearings with

one or two steps of gear sets, all included in one housing

(Figure 8). It was basically developed for boiler feedwater

pump applications, but has also been successflly used for

62 PROCEEDINGS OF THE THIRTEENTH TURBOMACHINERY SYMPOSIUM

Figure 8. Typical Variable Speed Geared Fluid Couplings.

pipeline and loading pumps, fans, compressors and very re

cently for water injection pumps. This type of coupling in

cludes a hydraulic cylinder moving the scoop tube, thus allow

ing the use of smaller actuators and such additional features as

quick start or stop. More than 3,000 units of such drives, most

of them in the 2,000 hp to 30,000 hp range, are running

worldwide with output speeds between 900 rpm (fans) and

12,000 rpm (compressors). The use of this variable speed,

geared fluid coupling allows the use of simple, standard two or

better yet, four pole electric motors, matching most any com

pressor or pump speed, and results in a very compact, cost

saving solution.

Figure d. Varable Speed Geared Fluid Coupling-Basic De

sign. 1) oil sump, 2) auxiliary lube oil pump, 3) main lube oil

pump, 4) lube oil cooler, 5) double filter, 6) pressure switches

for auxiliary lube oil pump, 7) external lube oil for driving

and/or driven machine, 8) working oil pump, 9) regulating

valve, 10) working chamber (pump wheel+ turbine wheel), 11)

scoop tube governor, 12) scoop tube intake, 13) scoop tube, 14)

working oil cooler, 15) hydrulic cylinder.

A schematic of a section cut through a standard geared

variable speed fluid coupling with one step up gear set at the

input side is shown in Figure 9. The working oil and the lube

oil have separate systems, both using the same oil out of a

common oil sump. The combined pump set is mechanically

driven fom the input shaft.

Te working oil fows from the centrifgal flling pump

into the fow control valve, fom where it goes into the fluid

coupling's active part to take care of the power transmission.

During this process, its temperature increases. The now hot oil

is removed through the scoop tube and pumped through the

heat exchanger back to the flow valve. This sytem is a closed

circuit, where the filling pump only circulates oil and maintains

pressure. The lube oil pump, a positive displacement pump

backed up by a motor driven startup and standby pump, is

pumping oil through the lube oil heat exchanger and double

filter into the lube oil system, which also provides, if neces

sary, external lube oil for the driver and the driven machines.

It also provides the control oil for the hydraulic cylinder

controlling the scoop tube. This design allows the use of small,

compact actuators which only have to move the pair of cams

controlling the hydraulic governor piston as well as the fow

control valve.

Another type of variable speed fluid coupling (Figure 10)

includes two diferent hydrodynamic circuits in one system,

together with the appropriate gears, to cover two select parts of

the speed range with even higher eficiency. In this coupling,

the change from one circuit to the other is done in both

directions, while running, without interruption of the power

Figure 1. Double Circuit Variable Speed Geared Fluid

Coupling.

VARIABLE SPEED FLUID COUPLINGS DRIVING

CENTRIFUGAL COMPRESSORS AND OTHER CENTRIFUGAL MACHINERY

63

transmission. To avoid pumping, speed changes are made at

diferent speeds (going up at a higher speed, coming down at a

lower speed).

TPICAL APPLICATIONS WITH

CENTRIFUGAL MACHINES

Centrifugal Compressors

Historically, most larger compressors in the petrochemi

cal industry are either driven by turbines, or, when driven by

electric motors, suction throttle controlled. Suction throttle (or

bypass) control is no longer acceptable, due to the involved

power losses. Steam turbines, once so well fitted to do the

speed control, lose ground as the production of steam in small

in-house power plants becomes more and more expensive. On

the other side, electrical power can be purchased at a much

more acceptable cost. This is where the geared fluid coupling

has found a new feld of application over the last years (Figure

11).

Figure 11. Variable Speed Geared Fluid Coupling Between

Motor(4000 HP, 1490 RPM) and Ethylene Compressor(l2,604

RPM).

The fluid coupling allows the use of simple, but highly

eficient, electrical motors which can start basically unloaded.

The fluid coupling itself is, by nature of its fnction, of explo

sion proof design. The fluid coupling does not produce any

harmonics, and further, it also dampens any rotational vibra

tions by mechanically separating the driver fom the com

pressor.

In addition to the standard design which has proven its

high availability in several thousand applications, this type of

coupling is also built to American Petroleum Institute (API)

specifcations as far as applicable. In this case, the gear part is

calculated and manufactured following API 613, and the lube

oil system following API 614.

Speed control is generally realized by using two pneumat

ic cylinders which are mechanically positioned in-line. The

first one covers the startup range and is generally manually

controlled. This allows a quick startup through the first critical

speed of the compressor and the eventually needed regulation

of the compressor speed during the establishing of a chemical

process.

The second cylinder covers the remaining speed range

which is needed for normal production. In this case, the 3 psi

to 15 psi control signal can be spred out just for the production

speed range, thus giving a very sensitive and exact means of

control.

An additional feature of the fluid coupling is that in the

very undesired case of a problem with a compressor, the motor

can be disconnected very quickly by simple scoop tube action,

thus reducing the 01 of the system and decreasing the

rundown time.

The main reasons to use a fuid coupling, and especially a

geared fluid coupling, for the drive of a centrifgal compressor

are:

Use of a simple electric motor.

Unloaded starting of the motor.

Eficient speed regulation.

No harmonics induced by the drive.

Dampening of the rotational vibrations.

High availability.

Low maintenance.

Simple function.

Compact design.

No specialist needed, in-house servicing without long

expensive training.

Explosion proof within itself.

Easy to adapt to process needs.

Versatile with regard to accessories and

instrumentation.

No back efects on electric supply lines (mains).

No high peak torques after very short blackouts which

do not trip the system.

Competitive cost.

Boiler Feedwater Pumps

The main reason for utilizing fuid couplings for the boiler

feedwater pump application is to provide speed regulation at

the pump while using a simple constant speed electric motor.

The fluid coupling (Figure 12) allows a nearly unloaded quick

startup of this electric motor, thus reducing the time of high

inrush current to a fw seconds. If necessary, a quick start

device in the fuid coupling's scoop tube control allows the

pump to be brought to speed in eight to twelve seconds. The

incorporated gears of the coupling allow the pump manufactur

er to design the pump for best efciencies. The use of speed

regulation permits the user to operate the pump at better

efciency values for changing fows, and also reduces wear and

noise and increases the litime of the pump.

Figure 12. Variable Speed Geared Fluid Coupling Drving

Boiler Feedwater Pump (13,200 HP, 4850 RPM).

Loading Pumps

For loading pumps, fow variation is needed to adjust to

changes in suction pressure (tank levels) and load curves,

64 PROCEEDINGS OF THE THIRTEENTH TURBOMACHINERY SYMPOSIUM

depending on the tanker's intake system and capacity. In

addition, the fluid coupling also can be used to bring the pump

to a stop with the main motor running, thus decreasing the

number of starts for large electric motors.

SPEED CONTROL OPTIONS AND

INSTRUMENTATION

Speed Control

Only for some very few simple applications is a manual

control via lever (with locking device) or self-locking hand

wheel spindle drive suficient for speed control. The bulk of

industrial and power generation applications need at least an

electromechanical actuator (pneumatic actuator option for the

petroleum-related industry) with feedback for position control,

with additional signalling contacts and end stops, together with

a speed measuring and monitoring device. For more complex

situations, a positioning controller can also be supplied, which

will follow a signal from the customer's main controller. As

additional features, quick startup or stop devices can be in

cluded in the speed control.

Instrumentation

Standard instrumentation for fuid couplings (Figure 13)

includes oil temperature and pressure instruments for smaller

units, and additional bearing temperature thermometers and

pressure switches for larger units, as well as diferential pres

sure switches for double flters where applicable. For more

stringent applications, frequent options are RTDs or ther

mocouples in all bearings and oil lines, vibration and accelera

tion probes with the necessary accessories, oil level switches

and more.

Figure 13. Example of Instrmentation for Variable Speed

Fluid Coupling.

Options

When specifications are not met by the standard unit, the

following options are available:

Gear parts meeting American Gear Manufacturers As

sociation (AGMA) and/or API 613 specifications.

Fluid couplings without their own lube oil systems, can

be connected to common, oil supply units which gener

ally conform to API 614 specifcations.

If space is restricted, fluid couplings can utilize a flat

sump with a separate oil tank.

Sump heaters.

Double heat exchanger systems with solenoid valves.

Mirror-image geared variable speed fluid couplings for

retrofits.

ECONOMIC ADVANTAGES OF SPEED CONTROL

In comparison with the still widely used throttle control,

substantial energy savings can be realized using speed control

for the drive of centrifugal pumps. The somewhat higher

investment can be paid back within a relatively short term (one

to two years), in most cases. Throttle valves are also exposed to

high wear, whereas speed control diminishes wear in the pump

for obvious reasons.

In a very conservative example, which was based on the

following assumptions

50 hours at 100 percent flow,

5,000 hours at 89 percent fow,

2,800 hours at 71 percent flow,

the energy savings fr speed control versus throttle control

came to approximately one hundred thousand dollars per year,

not speaking of reduced wear, lower noise levels and other

advantages of the use of variable speed fluid couplings. Lang

and Rees detail this example.

For compressor drives, variable speed couplings have also

shown substantial savings, compared with suction control or

turbine drives. In a recent case, which has been operating for

several months, the complete cost of a retrofit from steam

turbine to constant speed electric motor-variable speed fuid

coupling, including completely new foundations, will be re

covered within three years. If an existing foundation can be

modified, the return time might be even lower.

INSTALLATION AND MAINTENANCE

During frst installation, the usual care has to be taken to

align motor, fuid coupling and driver, taking into considera

tion the heat growth fom ambient to operating temperatures.

Necessary pipe connections for the cooling system have to be

mounted free of stress, and be pickeled, neutralized and

fl ushed prior to connection to the fuid coupling after final

alignment.

Maintenance is mainly limited to the monitoring of instru

ments. At indicated intervals, oil levels have to be controlled

and flters checked and changed over and cleaned, if necessary.

Ater more frequent checks intially, oil checks and eventual oil

upgrading or changing are limited to once a year. Eventually,

the existing grease programs of the actuators have to be

followed.

RELIABILITY AND AVAILABILITY

Due to the wear-free power transmission and the absence

of any complicated mechanical or electronic components, a

well designed fuid coupling does provide excellent reliability

and availability. For straight type fuid couplings with anti

friction bearings, 361 units were observed for a period of five

years. A Mean Time Between Failures (MTBF) of 113,150

VARIABLE SPEED FLUID COUPLINGS DRIVING

CENTRIFUGAL COMPRESSORS AND OTHER CENTRIFUGAL MACHINERY

65

hours resulted from 2,828, 700 operating hours with 25 failures.

In a petrochemical plant, three screw compressors are

driven with such couplings. Two of these units have run

continuously since 1970, with loads between 75 percent and

100 percent. When the compressors are overhauled every 18

months, the oil in the fuid couplings is changed. Over one

hundred thousand hours have been accumulated without a

need to use the third (standby) unit.

For 52 other units using straight through fuid couplings

with sleeve bearings, two failures were observed in the period

between 1968 and 1979. The calculated MTBF is 217,000

hours.

For the variable speed geared couplings, fty-seven units

with powers between 11,500 kW and 20,000 kW have been

observed. Two failures were experienced in the time between

1971 and 1979. The resulting MTBF is 273,600 hours. The

repair of these failures was done in four days at ten hours for

each repair. The average operating time of these units was 5.05

years at the time of this study.

OTHER TYPES OF VARIABLE SPEED DRIVES

Hydroviscous drive systems, ofen mistakenly called fuid

couplings, have for very fundamental reasons a more com

plicated, and thus less reliable, control mechanism. Instead of

simply positioning a scoop tube, they have to continuously

hold a balance between the oil flm pressure in a rotating stack

of clutch faces, and the counteracting clamping force. Heat is

created, like in any other slip device (be it fluid coupling or

Eddy current coupling), but for this type of drive, heat is

generated in a thin oil flm which only theoretically may have

an even heat distribution. For obvious reasons, all the oil fow

has to be filtered, not only the lube oil.

Variable fequency systems, which have been frequently

discussed in recent times, are still in relatively early develop

ment, at least for larger horsepower and speeds. Their basic

characteristics are a very simple-looking motor confguration,

but rather large quantities of highly sensitive and not very

maintenance-free electronics. These electronics need separate,

protected and well-ventilated locations, with a filtered air

supply.

The torque of such drives is not always as smooth as

generally required by connection couplings, gears and other

mechanical components. These drives can cause tendencies to

create harmonics, and can induce high torque peaks ater

falling out of synchronous running, as in the case of a short

blackout which does not trip the unit. To service such units,

personnel with higher qualifications and longer training are

necessary. Until now, such drives did not give the high availa

bility fgures indicated earlier for fluid couplings.

Variable frequency systems are a very intersting alterna

tive, and will probably get a larger share of the variable speed

applications in the fture, depending on the specific use and

the location of the drive. Prospective engineers should not,

however, only compare eficiency numbres without also taking

into consideration the initial cost and the reliability side.

CONCLUSION

Variable speed geared hydrodynamic fluid couplings, a

proven means of speed variation, and with years of perfect case

histories in thousands of applications with centrifugal

machines, have been successflly used to control the fow of

centrifgal compressors. The reasons for this success are sim

ple fnction and robust design, low maintenance needs, high

reliability and availability at a very competitive system cost.

BIBLIOGRAPHY

Estner, S. R., "Hydrodynamic Variable Speed Couplings in

the Petrochemical Industry," Voith-reprint 541e, Voith

Turbo GmbH Co. KG, Crailsheim, West Germany

(1981).

Fechner, G., "Hydrodynamic Variable Speed Couplings -

Technical Position, Typical Duties," CR-536e, Voith

print, Voith Turbo BmbH Co. KG, Crailsheim, West

Germany.

Fechner, G. and Lang, V., "Wear and Operating Cost Reduc

tion of Slurry Pumps by Means of Hydrodynamic Variable

Speed Couplings," ASME Winter Annual Meeting,

ASME 80-WA/MH-3 (November 1980).

Gruschka, B., "Voith Variable Speed Couplings as Regulating

Equipment in Power Stations," Technische Mitteilungen,

7th Ed., Voith-Reprint CR-510e, Voith Turbo GmbH

Co. KG, Crailsheim, West Germany (1961).

Keller, R., "The Startup of Hydrodynamic Couplings," CR-

512e, Voith-reprint out of VDI-report No. 73, Voith Tur

bo GmbH Co., KG, Heidenheim, West Germany

(1963).

Lang, V. and Rees, D., "Economic Advantages of Using

Variable Speed Fluid Couplings in Pump Drives," 7th

Technical Conference of the British Pump Manufacturers'

Association, Voith-reprint, CR-542e, Voith Turbo GmbH

Co. KG, Crailsheim, West Germany (1981).

Rappold, W., "Installation of Variable Speed Geared Cou

plings as Centrifugal Compressor Drives," Berlin, West

Germany (December 1983).

Wiegmann, W., "Variable Frequency Drives Versus Hydrody

namic Couplings in Boiler FeFd Pump Applications,"

Voith Transmissions, Allendale, New Jersey (November

1982).

66 PROCEEDINGS OF THE THIRTEENTH TURBOMACHINERY SYMPOSIUM

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Axial and Radial Turbines - TMI 11-12 - P 32 PDFDokument1 SeiteAxial and Radial Turbines - TMI 11-12 - P 32 PDFJavad AmnianNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Dambreak: Volume of Fluid)Dokument12 SeitenDambreak: Volume of Fluid)Javad AmnianNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Research Article Stress Analysis of Nonhomogeneous Rotating Disc With Arbitrarily Variable Thickness Using Finite Element MethodDokument12 SeitenResearch Article Stress Analysis of Nonhomogeneous Rotating Disc With Arbitrarily Variable Thickness Using Finite Element MethodJavad AmnianNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Mechanical Properties of Pure Ni and Ni-Alloy Substrate Materials For Y-Ba-Cu-O Coated SuperconductorsDokument7 SeitenMechanical Properties of Pure Ni and Ni-Alloy Substrate Materials For Y-Ba-Cu-O Coated SuperconductorsJavad AmnianNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Lars Davidson: MTF270 Turbulence Modelling 77: t j t j j t ˜ ν t j b2 ˜ ν t j t j t t 1Dokument5 SeitenLars Davidson: MTF270 Turbulence Modelling 77: t j t j j t ˜ ν t j b2 ˜ ν t j t j t t 1Javad AmnianNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- MatlabDokument47 SeitenMatlabalkadyasNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Dynamical Modeling, Control and Simulation of Single Shaft Gas TurbineDokument8 SeitenDynamical Modeling, Control and Simulation of Single Shaft Gas TurbineJavad AmnianNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- JK DissDokument100 SeitenJK DissBheemesh GudelliNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Mechanical Properties of Pure Ni and Ni-Alloy Substrate Materials For Y-Ba-Cu-O Coated SuperconductorsDokument7 SeitenMechanical Properties of Pure Ni and Ni-Alloy Substrate Materials For Y-Ba-Cu-O Coated SuperconductorsJavad AmnianNoch keine Bewertungen

- Emvin PHD Introduction1Dokument68 SeitenEmvin PHD Introduction1Javad AmnianNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Rowen, Simplified Mathematic Representations of Heavy-Duty Gas Turbines PDFDokument17 SeitenRowen, Simplified Mathematic Representations of Heavy-Duty Gas Turbines PDFJavad AmnianNoch keine Bewertungen

- FluidDokument3 SeitenFluidJavad AmnianNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Spec Sheet - EquipmentDokument2 SeitenSpec Sheet - EquipmentJavad AmnianNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- An Educational Guide To Extract The Parameters of Heavy Duty Gas Turbines Model in Dynamic Studies Based On Operational DataDokument9 SeitenAn Educational Guide To Extract The Parameters of Heavy Duty Gas Turbines Model in Dynamic Studies Based On Operational DataJavad AmnianNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Thesis - An Approach To Ventilation DesignDokument79 SeitenThesis - An Approach To Ventilation DesignJavad AmnianNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Air Pak User GuideDokument939 SeitenAir Pak User GuideGowtham MechNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Tutorial On Turbo ExpanderDokument0 SeitenTutorial On Turbo ExpanderMajid Sattar100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- Dimensionless numbers and universal constants summaryDokument1 SeiteDimensionless numbers and universal constants summaryatiqNoch keine Bewertungen

- Cryostar Process Machinery PDFDokument0 SeitenCryostar Process Machinery PDFJavad AmnianNoch keine Bewertungen

- HTTPDokument3 SeitenHTTPJavad AmnianNoch keine Bewertungen

- Localized Dynamic Kinetic-Energy-based Models For Stochastic CoherentDokument14 SeitenLocalized Dynamic Kinetic-Energy-based Models For Stochastic CoherentJavad AmnianNoch keine Bewertungen

- GRT Steam Turbines PDFDokument2 SeitenGRT Steam Turbines PDFJavad AmnianNoch keine Bewertungen

- E3 10 03 03Dokument0 SeitenE3 10 03 03elrajilNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- E3 10 03 03Dokument0 SeitenE3 10 03 03elrajilNoch keine Bewertungen

- Actuator Datasheet for Zone 2 Hazardous AreaDokument1 SeiteActuator Datasheet for Zone 2 Hazardous AreaJavad AmnianNoch keine Bewertungen

- Marine Steam Turbine Generator GuideDokument55 SeitenMarine Steam Turbine Generator GuideDharmendra KumarNoch keine Bewertungen

- Bulletin PVS-80021011-TGS - Turbine Gland Seal SystemsDokument0 SeitenBulletin PVS-80021011-TGS - Turbine Gland Seal SystemsJavad AmnianNoch keine Bewertungen

- E3 10 03 03Dokument0 SeitenE3 10 03 03elrajilNoch keine Bewertungen

- MersDokument22 SeitenMersJavad AmnianNoch keine Bewertungen

- Industrial Spark-Ignited Generator Set: Standby Power RatingDokument6 SeitenIndustrial Spark-Ignited Generator Set: Standby Power Ratinganony88Noch keine Bewertungen

- Limiting Reactants and Gas Mixture CalculationsDokument2 SeitenLimiting Reactants and Gas Mixture CalculationsmohanrtamNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Mud EngineeringDokument151 SeitenMud EngineeringDinesh KumarNoch keine Bewertungen

- Corsa C Relay Box LayoutDokument11 SeitenCorsa C Relay Box LayoutKijo SupicNoch keine Bewertungen

- Service Manuel BW211D-40Dokument972 SeitenService Manuel BW211D-40Juan Perez93% (43)

- Electrical Thumb RuleDokument3 SeitenElectrical Thumb RuleSrinivasNoch keine Bewertungen

- Crude Oil - Petroleum ProductsDokument10 SeitenCrude Oil - Petroleum ProductsGeorge_Wabag_2014Noch keine Bewertungen

- MAN B&W (L35MC S35MC) engine spare parts listDokument12 SeitenMAN B&W (L35MC S35MC) engine spare parts listGales Sanowari Sakti100% (1)

- LIT-18616-02-91 2004 Yamaha Wave Runner VX110 Sport Serv ManualDokument347 SeitenLIT-18616-02-91 2004 Yamaha Wave Runner VX110 Sport Serv Manualbob_cotten75% (4)

- A-A-59326a (1) AcoplamentoDokument15 SeitenA-A-59326a (1) AcoplamentogilsonNoch keine Bewertungen

- Ppump PDFDokument12 SeitenPpump PDFnemoneoNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Design of Piston HeadDokument7 SeitenDesign of Piston HeadSouradeep BhattacharjaNoch keine Bewertungen

- Positive Displacement PumpsDokument6 SeitenPositive Displacement PumpsVignesh DuraiNoch keine Bewertungen

- Katalog Spesifikasi Produk GuardallDokument10 SeitenKatalog Spesifikasi Produk GuardallhendrobamaNoch keine Bewertungen

- Changes to excise duty rates on petroleum productsDokument4 SeitenChanges to excise duty rates on petroleum productsvinodNoch keine Bewertungen

- Manufacturing Process Flow DiagramDokument1 SeiteManufacturing Process Flow DiagramAqib KhanNoch keine Bewertungen

- CPI Materials 01Dokument223 SeitenCPI Materials 01Siddharth MittalNoch keine Bewertungen

- Mud Loss Prevention and ControlDokument372 SeitenMud Loss Prevention and ControlVamsee Kantaspurthi50% (2)

- Oceanis 473 ManualDokument43 SeitenOceanis 473 Manualg665013100% (1)

- 140h GlobalDokument20 Seiten140h GlobalGenaro CQ100% (2)

- 4 - Kerr Km-3250pt - Km-3300pt Service Manual 10-18-07Dokument43 Seiten4 - Kerr Km-3250pt - Km-3300pt Service Manual 10-18-07Alexandre Borges BorgesNoch keine Bewertungen

- 2.8 Combustion Air SystemDokument26 Seiten2.8 Combustion Air SystemDangolNoch keine Bewertungen

- Tds Molykote D-10 GBLDokument2 SeitenTds Molykote D-10 GBLrenatosuloycombrNoch keine Bewertungen

- 071 - 88 Ing.3Dokument18 Seiten071 - 88 Ing.3Leonardo SaggiomoNoch keine Bewertungen

- GAIKINDO - Mr. Kukuh KUMARA - The Future of Indonesia's Auto PDFDokument13 SeitenGAIKINDO - Mr. Kukuh KUMARA - The Future of Indonesia's Auto PDFPirhot NababanNoch keine Bewertungen

- Daily Inspection Report PC1250Dokument8 SeitenDaily Inspection Report PC1250Rois HananNoch keine Bewertungen

- ESP Design Calculation PDFDokument17 SeitenESP Design Calculation PDFMohammed Abdul Moied100% (1)

- Iec 60332-1Dokument4 SeitenIec 60332-1jose luis vargas50% (2)

- Tanque Fuel Oil 25000 BBL PDFDokument2 SeitenTanque Fuel Oil 25000 BBL PDFAlejo ZabalaNoch keine Bewertungen

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedVon EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedBewertung: 5 von 5 Sternen5/5 (1)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseVon EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseBewertung: 4.5 von 5 Sternen4.5/5 (50)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationVon EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationBewertung: 4 von 5 Sternen4/5 (18)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionVon EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionBewertung: 4.5 von 5 Sternen4.5/5 (3)