Beruflich Dokumente

Kultur Dokumente

Tran Studyelectrical 2012A

Hochgeladen von

Ramesh AnanthanarayananOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tran Studyelectrical 2012A

Hochgeladen von

Ramesh AnanthanarayananCopyright:

Verfügbare Formate

Study of Electrical Usage and Demand at the

Container Terminal

by

Thanh Khanh Tran (BEng, MSc)

Submitted in fulfilment of the requirements for the

degree of Doctor of Philosophy

Deakin University

July, 2012

To Tam, Matthew and Chloe

i

Acknowledgements

I am particularly indebted to my principal supervisor Professor Alfred Deakin

Professor Saeid Nahavandi for his constant guidance and support throughout this

PhD. I am very grateful for his insights, assistance, patience and support over the last

few years. This thesis would not be completed without his encouragement and

support.

I also would like to thank my associate supervisor Dr. Doug Creighton for the

valuable guidance and advice he provided me during the course of my PhD.

I would especially like to thank Robert Reid of Robert Reid and Associates, a mentor

and colleague who arranged for permissions to collect data at Melbourne container

terminals for this study. He also provided access to data of overseas container

terminals for validating the results.

I acknowledge Patrick Stevedores, P&O Ports, Hutchison Port Holdings and Maher

Terminal Holding Corp. for their assistance in providing the data.

ii

ABSTRACT

Modeling and simulation techniques are the tools to be used for optimizing the

operation and fully utilize access of a container terminal for a projected container

throughput. The container terminal operator uses these study results to make

decisions and planning for the redevelopment and/or expansion of the terminal.

Usually, a new terminal layout with new truck traffic and more container handling

machines is required to cope with the projected container throughput. It is then the

electrical engineers task to calculate the terminal maximum electrical load demand

and design the electrical infrastructure accordingly.

A container terminal is a specific engineering field and currently there is no standard

or guidance for electrical engineers to accurately calculate the maximum electrical

demand. This study of electrical usage and demand at the container terminal was a

practical approach to:

addressing the problem of how to estimate/calculate the maximum electrical

demand of a container terminal with known number of electrical equipment

and

contributing to the understanding of regenerative energy issue of container

handling cranes at the container terminal.

Operation and electrical data at a Melbourne container terminal were daily collected

for more than two (2) years for this study. Collected operation data was analysed

according to the number of containers, their weights and set temperature for

refrigerated containers (reefers). Container weights were used to calculate the

iii

electrical demand of the container handling cranes. Collected daily electrical data

was correlated to the number of reefers to determine the electrical demand of these

reefers. Maximum electrical demands of container handling cranes and reefers were

determined by analysing all calculated values over the whole data collection period.

Maximum electrical demand of the container terminal was then calculated by adding

the other loads at the terminal: office, lightings and workshop.

The maximum electrical demands of several container terminals in Australia, USA,

Canada and China were calculated using the results of this study and the other

method (the diversity factor method). These calculated maximum electrical demands

were compared with the actual electrical demands with pleasing results: whilst at

least 34% less than the value calculated using the other method, the electrical

demand calculated using the results of this study was indeed the MAXIMUM

DEMAND and still with ample spare capacity of at least 20% for the safety margin

and future expansion of the terminal.

iv

Tables of Contents

Table of Contents iv

List of Abbreviations viii

List of Figures ix

List of Tables xiii

List of Formula xiv

1. Introduction 1

1.1 Background information 1

1.2. Research aims and objectives 4

1.3. Outline of the thesis 6

2. Literature Review 7

2.1 Overview Papers 7

2.2 Electrical Energy Usage and Demand Papers 9

2.3 Formula for Electrical Power calculation 11

3. Electrical Assets Identification and Set up Data Collection Scheme 19

3.1 Identification of electrical assets at container terminal 20

3.1.1 Processes at container terminal 20

3.1.2 Electrical assets at container terminal 26

3.2 Definition of Electrical Demand 28

3.2.1 Definition from the Utilities 28

3.2.2 Definition from Electricity Bills and measured energy 29

3.2.3 Definition from Digital Power Meters 32

3.3 Focusing study on average electrical demand 34

v

3.3.1 Reasons for focusing study on average demand instead of peak

demand 35

3.3.2 Decision of focusing the study on average demand 36

3.4 Set up at Melbourne Container Terminal for collecting data 36

3.5 Conclusions 40

4. Container Handling Cranes 42

4.1 Brief Discussion of container handling cranes 43

4.2 Load Profiles of Quay Crane Comparison between AC and DC drive

systems 47

4.2.1 AC and DC quay cranes under study 48

4.2.2 Study results 49

4.2.3 Study conclusions 57

4.3 Container Weight Analysis 57

4.3.1 Weight of container container ship and ISO standard 57

4.3.2 Weight of container at Melbourne Container Terminal 60

4.3.3 Results of analysing data collection 63

4.3.4 Conclusions of weight analysis 63

4.4 Calculate Demand & Energy usage of container handling cranes 67

4.4.1 Quay Crane and Maximum Electrical Demand 67

4.4.2 RMG and ASC and maximum Electrical Demand 70

4.5 Conclusions 72

5. Refrigerated Container 74

5.1 Brief Description of Refrigerated Container 74

5.2 Estimate Electrical Demand of Refrigerated Container 76

5.2.1 Maximum Demand of a Reefer Stack 77

vi

5.2.1.1 Demand calculation using Australian Standard AS3000 77

5.2.1.2 Demand calculation using diversity factor 80

5.2.1.3 Other demand calculation method 81

5.2.1.4 Reefer demand information from Container Handbook 82

5.2.1.5 Demand calculation based on heat transfer & required cooling 83

5.3 Measure the actual reefer electrical demand 88

5.3.1 Description 88

5.3.2 Data collection and analysing 89

5.3.3 Results of analysing data collection 95

5.4 Comparison of maximum demand calculated by different methods 104

5.5 Conclusions 108

6. Reducing electrical maximum demand and energy usage 109

6.1 Reducing electrical maximum demand 109

6.1.1 Improving power factor to reduce maximum demand 109

6.1.2 Using cranes with DC drive system to reduce maximum

Demand 112

6.2 Reducing electrical energy usage 113

6.2.1 Using cranes with DC drive system to reduce energy usage 113

6.2.2 Utilisation of the regenerative energy to reduce energy usage 114

6.2.3 Reduce energy usage by lighting 123

6.2.4 Energy Storage and Peak Lopping 126

6.3 Conclusions 130

7. Verification of this study results 131

7.1 Calculation of the maximum demand at container terminal 132

7.1.1 Calculation to AS/NZS 3000:2007 133

vii

7.1.2 Calculation using diversity factors 134

7.1.3 Calculation using findings of this study 135

7.2 Maximum demand at Container Terminals 136

7.3 Comparison of the results 140

7.4 Conclusions 149

8. Conclusions and directions for future research 150

8.1 Conclusions 151

8.2 Directions for future research 153

Appendix

Appendix A Daily Container Report, Code of Excel macro & Results 155

Appendix B Daily Reefer Report, Code of Excel macro & Results 161

Appendix C Specific Heat Capacity of various Products 173

Appendix D Calculated Reefer Electrical Demand using Heat transfer and

Cooling require Method 174

Appendix E Data Volume 183

References 184

viii

List of Abbreviations

AC Alternating Current

AGV Automatic Guided Vehicle

ASC Automatic Stacking Crane

DC Direct Current

ESCAP Social Commission for Asia and the Pacific

EMS Energy Management System

RMG Rail Mounted Gantry

RTG Rubber Tyred Gantry

QC Quay Crane

SC Straddle Carrier

STS Ship to Shore Crane

SWL Safe Working Load

ix

List of Figures

3.1 Stowage plan of a container ship

20

3.2 Quay cranes

21

3.2 Straddle Carrier

21

3.4 Container ship unloading plan

21

3.5 Melbourne Container Terminal storage stack

22

3.6 Straddle Carrier deliver container to truck

23

3.7 Container ship loading

24

3.8 Processes at Container Terminal

25

3.9 Port Botany Terminal November 2010 Electricity bill

29

3.10 Single Line Diagram with measuring devices locations

38

3.11 Energy Management System Layout

39

4.1 Different forms of quay cranes

44

4.2 Quay Cranes - Type of Lifts

45

4.3 Rail Mounted Gantries

46

4.4 Automatic Stacking Cranes

46

4.5 AC quay crane Graph of powers vs. time (second)

50

4.6 DC quay crane Graph of powers vs. time (second)

50

4.7 AC quay crane Graph of powers vs. time (second) for one

loading cycle

51

4.8 DC quay crane Graph of powers vs. time (second) for one

loading cycle

51

4.9 AC quay crane Graph of power factor vs. time (second) for one

loading cycle

54

x

4.10 DC quay crane Graph of power factor vs. time (second) for one

loading cycle

54

4.11 AC quay crane Graph of THD (%) vs. time (second) for one

loading cycle.

56

4.12 DC quay crane Graph of THD (%) vs. time (second) for one

loading cycle.

56

4.13 Drawing showing stacking area at Melbourne Container Terminal

60

4.14 Number of container at Melbourne Container Terminal in 2007

2008

66

4.15 Percentage of 40 container, empty container and heavy container

at Melbourne Container Terminal in 2007 2008

66

4.16 Average weight of container and TEU at Melbourne Container

Terminal in 2007 2008

67

4.17 Calculation of average electrical demand of quay crane

69

4.18 Calculation of average electrical demand of RMG/ASC

71

5.1 Refrigeration supply system for porthole container

75

5.2 Clip on unit for transport by road

75

5.3 Portholes at the end of a porthole container

75

5.4 Integral refrigerated containers

76

5.5 Photo showing Reefer location at Melbourne Container Terminal

89

5.6 Drawing showing Reefer location at Melbourne Container

Terminal

89

5.7 Electrical Demand per Reefer in 2007

96

5.8 Electrical Demand per TEU in 2007

98

5.9 Electrical Demand per Reefer in 2008

99

xi

5.10 Electrical Demand per TEU in 2008

100

5.11 Electrical Demand per Reefer in 2009

101

5.12 Electrical Demand per TEU in 2009

102

5.13 Mix Reefer sizes in storage at Melbourne Container Terminal

107

6.1 Reducing electrical demand by improving power factor

112

6.2 Single line diagram of substation D

117

6.3 Energy consumption without utilization of regenerative energy

120

6.4 Energy consumption without utilization of regenerative energy

121

6.5 High mast lighting at container terminal

124

6.6 Container terminal at night

124

6.7 Quay Crane load profile

128

6.8 Proposal from Powercorp using flywheel technology to limit peak

demand at 500kW and allow 100kW regenerative energy to be

utilized by other load

129

6.9 Proposal from S and C using super capacitor technology to limit

peak demand at 400kW and capture all regenerative energy

129

7.1 East Swanson Dock terminal actual and calculated maximum

electrical demands

140

7.2 West Swanson Dock terminal actual and calculated maximum

electrical demands

141

7.3 Swanson Dock terminals actual and calculated maximum

electrical demands

142

7.4 Port Botany terminal actual and calculated maximum electrical

demands

143

7.5 Fisherman Islands terminal actual and calculated maximum

electrical demands

144

xii

7.6 China Yantian terminal actual and calculated maximum

electrical demands

145

7.7 Canada Fairview terminal actual and calculated maximum

electrical demands

146

7.8 USA Maher terminal actual and calculated maximum electrical

demands

147

xiii

List of Tables

3.1 Port Botany Terminal Meter 1 data for November 2010

30

3.2 Port Botany Terminal Meter 2 data for November 2010

31

3.3 Port Botany Terminal Summary of Electricity foe November 2010

32

4.1 Main data of Quay cranes under observation

48

4.2 Results of measurement

53

4.3 Container ship capacity and deadweight

58

4.4 Dimension and Payload of container

59

4.5 Sample of Container daily Report

61

4.6 Results of running CONTAINERS macro

63

4.7

Weight Analysis of container at Melbourne Container Terminal 65

5.1 Maximum Demand non-domestic Electrical Installation

70

5.2 Cooling capacity of Reefer Power Unit

85

5.3 Calculated Average Electrical Demand of different reefer cargo

88

5.4 Example of Reefer daily Report

91

5.5 Example of Reefer power Report

92

5.6 Results (temperature analysis) of running REEFERS macro

94

5.7 Results (weight analysis) of running REEFERS macro

95

5.8

Reefer Electrical Average demand 97

5.9 Maximum Demand calculated using different methods

104

6.1 Extract from Yantian 2005 report on QC CONSUMPTION STUDY

115

6.2 Recorded consumed real energies at substation D

119

7.1 Calculated maximum demand at Australian Container Terminal

138

7.2 Calculated maximum demand at Overseas Container Terminal

139

7.3 Comparison of calculated and actual maximum Electrical Demand 148

xiv

List of Formulas

2.1 Basic motion formula Distance

12

2.2 Basic motion formula Distance

12

2.3 Hoist Power with Load

12

2.4 Lower Power with Load

12

2.5 Hoist acceleration Power with Load

13

2.6 Hoist deceleration Power with Load

13

2.7 Lower acceleration Power with Load

13

2.8 Lower deceleration Power with Load

13

2.9 Hoist motor acceleration Power with Load

13

2.10

Hoist motor deceleration Power with Load

13

2.11 Lower motor acceleration Power with Load

13

2.12 Lower motor deceleration Power with Load

13

2.13 Hoist total acceleration Power with Load

13

2.14 Hoist total Power with Load

13

2.15 Hoist total deceleration Power with Load

13

2.16 Lower total acceleration Power with Load

13

2.17 Lower total Power with Load

13

2.18 Lower total deceleration Power with Load

13

2.19 Hoist Power without Load

14

2.20 Lower Power without Load

14

2.21 Hoist acceleration Power without Load

14

2.22 Hoist deceleration Power without Load

14

2.23 Lower acceleration Power without Load

14

xv

2.24 Lower deceleration Power without Load

14

2.25 Hoist motor acceleration Power without Load

14

2.26 Hoist motor deceleration Power without Load

14

2.27 Lower motor acceleration Power without Load

14

2.28 Lower motor deceleration Power without Load

14

2.29 Hoist total acceleration Power without Load

14

2.30 Hoist total Power without Load

14

2.31 Hoist total deceleration Power without Load

14

2.32 Lower total acceleration Power without Load

14

2.33

Lower total Power without Load

14

2.34 Lower total deceleration Power without Load

15

2.35 Friction Load with Load

15

2.36 Wind Load with Load

15

2.37 Main Hoist rope inflexibility with Load

15

2.38 Static Power in Adverse Wind with Load

15

2.39 Static Power in favourable wind with Load

16

2.40 Trolley acceleration Power

16

2.41 Trolley deceleration Power with Load

16

2.42 Trolley motor acceleration Power with Load

16

2.43 Trolley motor deceleration Power with Load

16

2.44 Cross travel total acceleration Power in adverse wind with Load

16

2.45 Cross travel total Power in adverse wind with Load

16

2.46 Cross travel total deceleration Power in adverse wind with Load

16

2.46 Cross travel total acceleration Power in favourable wind with Load

16

2.48 Cross travel total Power in favourable wind with Load

16

xvi

2.49 Cross travel total deceleration Power in favourable wind with Load

16

2.50 Friction Load without Load

16

2.51 Wind Load without Load

17

2.52 Main Hoist rope inflexibility without Load

17

2.53 Static Power in Adverse Wind without Load

17

2.54 Static Power in favourable wind without Load

17

2.55 Trolley acceleration Power without Load

17

2.56 Trolley deceleration Power without Load

17

2.57 Trolley motor acceleration Power without Load

17

2.58 Trolley motor deceleration Power without Load

17

2.59 Cross travel total acceleration Power in adverse wind without Load

17

2.60 Cross travel total Power in adverse wind without Load

17

2.61 Cross travel total deceleration Power in adverse wind without Load

17

2.62 Cross travel total acceleration Power in favourable wind without

Load

17

2.63 Cross travel total Power in favourable wind without Load

17

2.64 Cross travel total deceleration Power in favourable wind without

Load

18

3.1 Total consumed Energy

31

3.2

Real Demand 31

3.3 Reactive Demand

31

3.4 Apparent Demand

32

3.5 Maximum Electrical Demand

32

5.1 Increase Temperature due to Heat transfer

86

5.2 Refrigerating Capacity for Cooling

86

5.3 Average Electrical Demand

87

xvii

7.1 Maximum Electrical Demand

133

7.2 AS/NZS:3000 calculation method Reefer Load Demand

133

7.3 AS/NZS:3000 calculation method Crane Load Demand

133

7.4 Diversity Factor Method 20 Reefer Load Demand

134

7.5 Diversity Factor Method 40 Reefer Load Demand

134

7.6 Diversity Factor Method Reefer Load Demand

135

7.7 Diversity Factor Method Crane Load Demand

135

7.8 Results from this study Reefer load Demand

136

7.9 Results from this study Crane load Demand

136

1

CHAPTER ONE

Introduction

1.1 Background information

Containerization is the use of transport containers to unitize cargo for supply,

transportation and storage without the need for intermediate handling of the content.

Since the introduction in 1956 [84], containerization of cargoes is becoming ever

more widespread worldwide and almost all products are now transported by

container.

In the Container Traffic Forecast [65] published by United Nation Economic and

Social Commission for Asia and the Pacific (ESCAP), container traffic has grown

substantially from 28.7 million twenty-foot equivalent units (TEUs) in 1990 to

113.6 million TEUs in 2005. This is corresponding to an average annual compound

growth of 9 percent. The forecast suggest continued trend of increasing of the

container traffic of annual compound of 7.6 percent till 2015 taking into account the

World Economic Crisis 2008/2009. It is expected a traffic of 235.7 million TEUs in

2015.

The growth in the container traffic leads to the growth in the capacity of the

container ship as the shipping lines prefer to use larger container ship to lower the

costs. It is claimed that the transportation cost per container for the sixth generation

container ship (Post-Suezmax) may be about 30% lower than that of a typical

2

5,000-6,000 TEUs container ship. Historical development of container ships [20,

22] is shown below:

1. First generation Small Feeder <1,000 TEUs

2. Second generation Feeder 1,000 - 2,500 TEUs

3. Third generation Panamax 2,500 - 4,500/5,000 TEUs (draught of 12m)

4. Fourth generation Post-Panamax 4,500/5,000 - 10,000 TEUs (draught

of 13m)

5. Fifth generation Suezmax 10,000 - 12,000 TEUs (draught of 16.4m)

6. Sixth generation Post-Suezmax >12,000 TEUs (draught of 21m)

With the intended increase of the cross section breadth and depth of the Suez Canal

over the coming ten years, the 18,000 TEUs container ship will also be able to pass

the Suez Canal [50]. On the other hand, a future container ship with a draught of 21

m would require existing ports to be dredged. Today, only the ports of Singapore

and Rotterdam are deep enough.

Given the expected growth of container traffic, most container terminals around the

world have terminal expansion and development projects that are either planned or

currently underway. Deploying more container handling machines, leasing more

land, changing operation mode are examples of such plans. Before spending any

money, all container terminal operators like to optimize their operation and fully

utilize their access (land, machines, labours etc.) to produce the maximum

3

productivity [33, 41, 68, 71, 86]. Modelling and simulation appear to be the best

tool for this optimization task.

A lot of simulations have been done to study and optimize the operation of existing

container terminal [23, 25, 27, 32, 35, 73, 74, 81, 83, 90, 108, 130, 174, 201] or

even design a new one. These simulations are carried out to find the impacts of

terminal layout [151], allocating berthing for ship [129, 131, 132, 152, 153, 154],

predicting number of cranes for certain handling rate [127], rail logistic, truck

logistic and even impact on in land transportation. However, none have been done

for the electricity power demand and consumption or the utilization of electrical

infrastructure of a container terminal.

Planing for a new container terminal or expanding an existing container terminal

must include the power demand at the initial design stage of such development.

Increasing number and size of container handling machines: Quay Cranes (QCs),

Rail Mounted Gantries (RMGs), Automatic Stacking Cranes (ASCs) and

Refrigerated Containers (Reefers) have brought a significant increase in electrical

power demand for container terminals [112]. Accurate assessment of the projected

electrical load is of critical importance as this electrical demand is used for:

- sizing and selection of principal electrical assets, thus impacting on the

capital cost of the electrical infrastructure,

- request an update or new electrical supply from the electrical power supply

company. Capital cost of electrical supply could be very high if the current

electrical network can not provide the requested demand.

4

1.2. Research aims and objectives

As container terminal is a specific engineering field and currently there is no

standard or guidance for electrical engineers to accurately calculate the electrical

demand [6], all are depended on the experiences of those engineers for this

estimation. This would normally lead to an over design of electrical infrastructure

and resulting in a very costly exercise if a new electrical switching station would be

built to supply the projected load demand. For example, in a recent re-development

of a container terminal in Australia, a load demand of 16MVA was stated for this

container terminal with 8 QCs, 5 RMGs and 800 refrigerated containers. A new

electrical switching station was required to supply such demand with a total cost of

around AUD 10 million. A similar size container terminal in Australia has an actual

load demand of only 4MVA.

There are number of private studies of energy consumption and power supply at

several container terminals that concern about their electrical bills [95].

Presentations [18] and information [70, 98, 136] about electrical demand and

energy usage of electrical machines are now a requirement as part of technical

documents to be submitted to electrical supply tenders called by all container

terminal operators.

The main aims of this research are: how to estimate/calculate the maximum

electrical demand of a container terminal with known number of electrical

equipments? What is the likely electrical energy usage for a container terminal with

a known through put? A practical approach is used to find out the answers:

5

With the permission of the container terminal management, installing a

power monitoring system consist of a server and number of digital power

meters for logging electrical data. At the same time, details of containers at

the terminal are provided for every day and monthly electrical invoices are

also obtained for comparison. . The monthly electrical invoices are also

obtained for confirmation of the analysed results. Data have been collected

for over two (2) years.

Learning the spreadsheet simulation technique from simulation conferences

papers [165, 166, 168, 169, 171, 177, 178, 179, 181, 182, 183, 184].

Calculation and spread sheet simulation are performed to estimate the

electrical load of the machine. Examining the working of the smart meter,

how power supply company calculate the demand and analysing the

collected data. Results are used for estimating the total demand of the

terminal.

Electrical energy consumptions at several other container terminals around

the world are also obtained to confirm the study results.

The environment concern of green house emission is also looked at by investigating

how to reduce such electrical demand end energy consumption - the design of

electrical network, the application of the new technical innovations such as

synchronizing operation of multiple machines and using peak lopping device.

This research looks into the gap left by previous researches and studies related to

container terminals. Hopefully, it will clarify some electrical issues contribute to

the knowledge of designing and operation of the container terminals.

6

1.3. Outline of the thesis

This thesis consists of eight chapters. In the next chapter, an introduction to

electrical power demand and energy usage at a container terminal and review of

related literature are presented. Chapter 3 outlines the operating environment of

container terminal, identifies the electrical assets to be studied, investigate how

electrical consumption is measured and charged then describe the set up of data

collection scheme. Chapter 4 looks at the container handling machines group

consists of Quay Cranes (QCs), Rail Mounted Gantries (RMGs) and Automatic

Stacking Cranes (ASCs). A brief discussion and focus on what would be studied

followed by obtaining the quay cranes specifications and profiles, discusses the

drive systems (DC and AC) and analysing the weights of containers in stack of

Melbourne Container Terminal from collected data and finally calculate the

electrical demand and energy usage of the container handling machines group.

Chapter 5 investigates the refrigerated containers, methods of calculating the

refrigerated containers electrical demand, describes another way of calculation.

The actual (more than two years) measurements and calculation results are

tabulated for comparison. Chapter 6 discusses several ways of reducing the

maximum electrical demand and energy usage at container terminal ranging from

the design of electrical network to utilise the regenerative energy, requesting for net

metering scheme, the use of energy storage and peak lopping devices and lighting

level at the container terminal. Chapter 7 verifies the finding of this study by

showing the comparison between the actual electrical demand and the calculated

maximum electrical demand of several container terminals around the world.

Finally, chapter 8 will summarised the thesis, make concluding remarks as well as

recommendations for future research.

7

CHAPTER TWO

Literature Review

To the best of the authors knowledge from the literature review and long time

working in the port, there was no published academic research into the electrical

energy usage and demand at container terminal. Literatures [49, 51, 52, 118, 195,

196, 197, 200, 205] on the rail/traction area had also been reviewed to find any

applicable information for use. Because of the lack of published research in this

field, the author had to rely on the commercial articles written for magazines

specialised in this field, the presentation at commercial conference as well as the

internal reports of various container terminal operators and electrical supply

companies for review and gather information.

The reviewed papers are grouped into following categories:

container terminal overview papers to provide an understanding of the

operation of container terminal,

electrical energy usage and demand papers to find what have been done in

this field and

formulas for electrical power demand calculation.

2.1 Overview Papers

A detailed literature review on the transhipment of containers at a container

terminal was given by Vis and Koster in 2002 [135]. Different type of material

8

handling as well as planning and control level involving the movement of

containers. The processes at container terminal are discussed next with the detailed

descriptions of each process with reference to relevant information when required.

These pre berth allocation, unload and loading of container ships, transportation of

containers from ship to storage area, stacking these containers and delivering them

to owner directly or by inter-terminal transportation. In the conclusion, they stated

that the majority of published papers only address single type of handling machine

so that the future work shall be concentrate in addressing multiple types of handling

machines for optimising the operation at container terminal.

On the same topic, Stahlbock and Vob [54] provided a comprehensive literature

review of research on optimising methods applied to container terminal operations.

The paper began with an update on the new challenges that the container terminal

operators have to overcome, especially with the requirement of handling new mega

size container ships capable of carrying 10,000 TEU to 12,000 TEU. They then

discussed the container terminal operation system and its sub system such as the

handling equipment, human recourses and supporting system. Research on

optimising methods was discussed in details of few particular subsystems that have

big impact on the operation such as berth allocation and stacking logistics. They

concluded the review with a summary; they also identified and suggested a number

of promising and interesting topics for future research.

9

2.2 Electrical Energy Usage and Demand Papers

It was reported early this year (March 2012) in the Port Technology International

[7] that a simulation model had been developed by Kim Le of AECOM for studying

the electric power of yard cranes. The concern about the increasing of required

electrical demand, especially when a large number of cranes are installed and

connected to the electrical grid at the container terminal, and the lack of suitable

method for calculating this demand was the reason for such study. The most

interesting result from this simulation study is that for 36 yard cranes with 700 KW

demand each totalling of 25,200 kW, the average demand of all 36 machines is only

1,000 kW and for a percentile of 99%, a demand of 3,240 kW is required. However,

the critical information is not provided: yard crane electrical data, container weight,

travel distances etc. for the readers to make use of the results. To an electrical

engineer reader, it appeared to have mixed up between electrical energy

consumption (kWHr) and electrical demand (kW) terminologies.

In the Efficient use of energy in container cranes article of the same magazine

Port Technology International, edition 48 [26], Fredrik J ohanson of ABB described

the regenerative energy issue of electrical powered cranes and suggested ways for

utilising this energy especially for automatic stacking cranes.

In the Driving innovation: high handling efficiency, low energy use article of the

Port Technology International, edition 47 [28], Gottwald Port Technology described

a successful innovation for its mobile crane using energy storage system to

capture the regenerative energy when the crane lowering and discharge this energy

when the crane hoisting.

10

Another useful information was described in the Crane life cycle costs in the Port

Technology International edition 20 [128] by Gerhard Fischer of Siemens that the

average net amount of energy required to move a container was 1.94 kWHr.

At the Terminal Operators Conference in 2005, Robert Reid of Robert Reid and

Associates had present a paper titled Design, Installation and Electrical

Management of Container Terminals with Large Electrical Demand [110]. An

overview of the electrical infrastructure of the container terminal and regulatory

requirements in Australia had been discussed. The finance impact as well as

benefits would be achieved by reducing the electrical demand. In discussion of the

electrical demand, the paper raised concern about the lack of accurate method for

calculating the maximum electrical demand. The actual facts were also presented:

average weight of container traffic, the large size of container handling cranes as

well as their characteristic, the affect of number of refrigerated containers in the

terminal, and the actual electrical energy consumption by the container terminal.

The paper concluded by stating that accurately calculating the maximum electrical

demand is really needed for designing a new container terminal or upgrading the

existing one.

In a presentation to DP World the terminal operator at Brisbane Port in 2011 [18]

for an Automatic Stacking Cranes (ASC) project, G Nordman of ABB presented an

Excel spreadsheet simulation for 12 ASCs. With a known operating characteristic of

one ASC, the simulation was performed with various operating conditions such as

fix hoisting delay between machines and assuming operating of multiple ASCs at

the same time would not cause any issue for the electrical supply network.

Following data is of interested:

11

For one ASC Maximum Demand 930 kW

Average Demand 69 kW

For 12 ASCs at hoisting delay of 20 seconds:

Maximum Demand 2,167 kW

Average Demand 822 kW

2.3 Formula for Electrical Power calculation

Part of tender documents submitted for bidding to supply container handling cranes

is that theoretical calculation of electrical power under pre-set operating conditions.

The author had access to the document of successful tenders providing the container

crane to various container terminals in Australia [70, 98, 136]. For this study,

electrical demand calculation would have to be performed and reviewing these

documents for formulas used in electrical power calculation has the advantage of all

needed formulas are available saving time in reviewing a lot of different text books

[121, 207, 210] for needed formulas.

When calculating the maximum electrical demand, boom hoist and long travel

motions can be ignored because:

the boom motion is only used to put the crane in the working position to

start loading/unloading containers and to stow the boom at the end of its

work,

other motions are not available when boom hoist is in use.

the booms electrical motor is not as large as the hoists electrical motor, the

demand is not the maximum demand

other motions are not available when long travel is in use

12

the long travels electrical motor is not as large as the hoists electrical

motor, the demand is not the maximum demand

Basic motion formulas:

vt s (Eq. 2.1)

t v at s

0

2

2

1

(Eq. 2.2)

Where v speed in m/sec

v

0

initial speed in m/sec

s travel distance in m

t travel time in second

The following naming index conventions are used on all formulas in this section:

N

xy

Power (in Watts) with:

x =1 for motion with load, x =2 for motion without load

y =1, 2, for different powers

P

wxyz

Total Power (in Watts) with:

w : w =1 for motion with load and w =2 for motion without

load

x : H for Hoisting, L for Lowering, XT for cross Travel and

LT for Long Travel.

y : A for acceleration, D for deceleration & nothing for motion

at constant speed

z : W for travel against wind, NW for travel with wind, nothing

for hoist motion

A. Hoist/Lower motion

The following formulas are used to calculate the average demand of the hoist

motion:

With load (lift container)

Hoist Power

u

V

g LS LL N

* 60

* * ) (

1

11

(Eq. 2.3)

13

Lower Power u

V

g LS LL N *

60

* * ) (

3

12

(Eq. 2.4)

Hoist acceleration Power

u t

V

LS LL N

*

) 60 / (

* ) (

1

2

1

13

(Eq. 2.5)

Hoist deceleration Power u

t

V

LS LL N *

) 60 / (

* ) (

2

2

1

14

(Eq. 2.6)

Lower acceleration Power u

t

V

LS LL N *

) 60 / (

* ) (

5

2

3

15

(Eq. 2.7)

Lower deceleration Power

u t

V

LS LL N

*

) 60 / (

* ) (

6

2

3

16

(Eq. 2.8)

Hoist motor accel. Power

1

2

1

2

17

* 1000

) 60 / * * 2 (

*

t

n

WK N

h

(Eq. 2.9)

Hoist motor decel. Power

2

2

1

2

18

* 1000

) 60 / * * 2 (

*

t

n

WK N

h

(Eq. 2.10)

Lower motor accel. Power

5

2

1 1 3

2

19

* 1000

) 60 / * ) / ( * * 2 (

*

t

n V V

WK N

h

(Eq. 2.11)

Lower motor decal. Power

6

2

1 1 3

2

20

* 1000

) 60 / * ) / ( * * 2 (

*

t

n V V

WK N

h

(Eq. 2.12)

Hoist accel. Power (W)

17 13 11 1

N N N P

HA

(Eq. 2.13)

Hoist Power (W)

11 1

N P

H

(Eq. 2.14)

Hoist decel. Power (W)

18 14 11 1

N N N P

HD

(Eq. 2.15)

Lower accel. Power (W)

19 15 12 1

N N N P

LA

(Eq. 2.16)

Lower Power (W)

12 1

N P

L

(Eq. 2.17)

Lower decel. Power (W)

20 16 12 1

N N N P

LD

(Eq. 2.18)

14

No load - without load

Hoist Power

u

V

g LS N

* 60

* *

2

21

(Eq. 2.19)

Lower Power u

V

g LS N *

60

* *

4

22

(Eq. 2.20)

Hoist acceleration Power

u t

V

LS N

*

) 60 / (

*

3

2

2

23

(Eq. 2.21)

Hoist deceleration Power u

t

V

LS N *

) 60 / (

*

4

2

2

24

(Eq. 2.22)

Lower acceleration Power u

t

V

LS N *

) 60 / (

*

7

2

4

25

(Eq. 2.23)

Lower deceleration Power

u t

V

LS N

*

) 60 / (

*

8

2

4

26

(Eq. 2.24)

Hoist motor accel. Power

3

2

2 2

27

* 1000

) 60 / * * 2 (

*

t

n

WK N

(Eq. 2.25)

Hoist motor decel. Power

4

2

2 2

28

* 1000

) 60 / * * 2 (

*

t

n

WK N

(Eq. 2.26)

Lower motor accel. Power

7

2 2

2 4

2

29

* 1000

)

60

* ) / ( * * 2 (

*

t

n

V V

WK N

(Eq.2.27)

Lower motor decel. Power

8

2 2

2 4

2

30

* 1000

)

60

* ) / ( * 14 . 3 * 2 (

*

t

n

V V

WK N (Eq. 2.28)

Hoist accel. Power (W)

27 23 21 2

N N N

HA

P (Eq. 2.29)

Hoist Power (W)

21 2

N

H

P (Eq. 2.30)

Hoist decel. Power (W)

28 24 21 2

N N N

HD

P (Eq. 2.31)

15

Lower accel. Power (W)

29 25 22 2

N N N

LA

P (Eq. 2.32)

Lower Power (W)

22 2

N

L

P (Eq. 2.33)

Lower decel. Power (W)

30 26 22 2

N N N

LD

P (Eq. 2.34)

Where

LL Weight of load (container) in tones

LS Weight of spreader & headblock (lifting device) in tones

V

1

Hoist speed with load in m/min

V

2

Hoist speed without load in m/min

V

3

Lower speed with load in m/min

V

4

Lower speed without load in m/min

t

1

Hoist acceleration time with load in seconds

t

2

Hoist deceleration time with load in seconds

t

3

Hoist acceleration time without load in seconds

t

4

Hoist deceleration time without load in seconds

t

5

Lower acceleration time with load in seconds

t

6

Lower deceleration time with load in seconds

t

7

Lower acceleration time without load in seconds

t

8

Lower deceleration time without load in seconds

n

1

Hoist motor speed with load in rpm

n

2

Hoist motor speed without load in rpm

WK

h

2

Total rotational inertia (include gearbox, drum, load) in kgm

2

u Overall efficiency

g Gravity (9.81m/sec

2

)

Constant Pi =3.14

N

1i

Hoist/Lower with load Power in Watts (i =1,2,3.9)

N

2i

Hoist/Lower without load Power in Watts (i =1,2,3.9)

B. Cross Travel motion

The following formulas are used to calculate the average demand of the hoist

motion:

With load (container)

Friction Load c LS LL TL L * ) (

11

(Eq. 2.35)

Wind Load Q A L *

1 12

(Eq. 2.36)

Main hoist rope inflexibility load

2

) ( * ) 1 ( * 1000

3

13

LS LL v

L

(Eq. 2.37)

Static power in adverse wind

u

V

g L L L N

xt

* 1000 * 60

* * ) (

13 12 11 11

(Eq. 2.38)

16

Static power in favourable wind

u

V

g L L N

xt

* 1000 * 60

* * ) (

13 11 12

(Eq. 2.39)

Trolley acceleration power

u t

V

LS LL TL N

xt

xt

*

)

60

(

* ) (

1

2

13

(Eq. 2.40)

Trolley deceleration power

1

2

14

* )

60

( *

xt

xt

t

u V

TL N (Eq. 2.41)

Motor acceleration power

1

2

2

15

* 1000

)

60

* * 2 (

*

xt

xt

xt

t

n

WK N

(Eq. 2.42)

Motor deceleration power

1

2

2

16

* 1000

)

60

* * 2 (

*

xt

xt

xt

t

n

WK N

(Eq. 2.43)

Cross travel acc. power in adverse wind (W)

15 13 11 1

N N N P

LXTAW

(Eq. 2.44)

Cross travel power in adverse wind (W)

11 1

N P

XTLW

(Eq. 2.45)

Cross travel deceleration power in adverse wind (W)

16 14 11 1

N N N P

XTDW

(Eq. 2.46)

Cross travel acc. power in favourable wind (W)

15 13 12 1

N N N P

XTANW

(Eq. 2.47)

Cross travel power in favourable wind (W)

12 1

N P

XTNW

(Eq. 2.48)

Cross travel decal. power in favourable wind (W)

16 14 12 1

N N N P

XTDNW

(Eq. 2.49)

Cross travel without load

17

Friction Load c LS TL L * ) (

21

(Eq. 2.50)

Wind Load Q A L *

2 22

(Eq. 2.51)

Main hoist rope inflexibility load

2

* ) 1 ( * 1000

3

23

LS v

L

(Eq. 2.52)

Static power in adverse wind (W)

u

V

g L L L N

xt

* 1000 * 60

* * ) 5 . 0 (

23 22 21 21

(Eq. 2.53)

Static power in favourable wind (W)

u

V

g L L N

xt

* 1000 * 60

* * ) (

23 21 22

(Eq. 2.54)

Trolley acceleration power (W)

u t

V

LS TL N

xt

xt

*

)

60

(

* ) (

2

2

23

(Eq. 2.55)

Trolley deceleration power (W)

2

2

24

* )

60

( * ) (

xt

xt

t

u V

LS TL N (Eq. 2.56)

Motor acceleration power (W)

12

2

2

25

* 1000

)

60

* * 2 (

*

xt

xt

xt

t

n

WK N

(Eq. 2.57)

Motor deceleration power (W)

2

2

2

26

* 1000

)

60

* * 2 (

*

xt

xt

xt

t

n

WK N

(Eq. 2.58)

Cross travel acc. power in adverse wind (W)

25 23 21 2

N N N P

XTAW

(Eq. 2.59)

Cross travel power in adverse wind (W)

21 2

N P

XTW

(Eq. 2.60)

Cross travel deceleration power in adverse wind (W)

26 24 21 2

N N N P

XTDW

(Eq. 2.61)

Cross travel acc. power in favourable wind (W)

25 23 22 2

N N N P

XTANW

(Eq. 2.62)

18

Cross travel power in favourable wind (W)

22 2

N P

XTNW

(Eq. 2.63)

Cross travel decal. power in favourable wind (W)

26 24 22 2

N N N P

XTDNW

(Eq. 2.64)

Where

LL Weight of load (container) in tones

LS Weight of spreader & headblock (lifting device) in tones

TL Weight of trolley in tones

A

1

Wind area with load in m

2

A

2

Wind area without load in m

2

Q Wind pressure in kg/m

2

v Sheave efficiency

V

xt

Trolley speed in m/min

t

xt1

Cross travel acceleration time in seconds

t

xt2

Cross travel deceleration time in seconds

n

xt

Cross travel motor speed in rpm

WK

xt

2

Total rotational inertia (include gearbox, drum, load) in kgm

2

u Overall efficiency

g Gravity (9.81m/sec

2

)

c Friction coefficient in kg/t

Constant Pi =3.14

N

1i

Cross Travel with load Power in Watts (i =1,2,3.9)

N

2i

Cross Travel

without load Power in Watts (i =1,2,3.9)

19

CHAPTER THREE

Electrical Assets Identification and Set up Data

Collection Scheme

Before any study of electrical usage and demand at the container terminal can be

started, all electric powered assets have to be identified. The term electric powered

asset or electrical asset refers to the asset that actual connects to electrical grid and

consumes electricity not asset that providing electric power. For example, quay

cranes are electrical assets but the high voltage switchgears connecting these cranes

to the electrical grid are not.

Understanding of how energy and demand are defined, measured and charged by

the power supply companies (the Utilities) is also important as it help to focus the

study as well as deciding what and how to collect data for this study.

Three main topics will be described and discussed in this chapter:

- Identification of all electric powered assets at container terminal,

- Electricity bills and measured data supplied by the Utilities to focus the

study and set up data collection scheme,

- Describe the data collection system at Melbourne Container Terminal.

20

3.1 Identification of electrical assets at container terminal

3.1.1 Processes at container terminal

The container terminal knows in advance the expected arrival time of a container

ship, the number of containers to be exchanged and the ship stowage plan so that a

unloading plan and/or loading plan can be prepared, equipment and labour can be

allocated to work on that container ship. Figure 3.1 shows a typical container ship

stowage plan that is the lay out of the ship and container positions.

When the container ship arrives, QCs as shown in Figure 3.2 working according to

a prepared unloading plan take the import containers off the ship and put on the

wharf. The containers are then transferred to the storage stack be transport vehicles

such as Forklifts or Straddle Carriers (SCs) Figure 3.3 - that travel between the

QCs and the storage stack.

Figure 3.1 Stowage plan of a container Ship

21

Figure 3.2 Quay Cranes Figure 3.3 Straddle Carrier

Figure 3.4 Container ship unloading plan

22

Equipment, such as straddle carriers (SCs), Rubber Tyred Gantries (RTGs), Rail

Mounted Gantries (RMGs) then put these containers into the storage stack

according to a prepared storage plan. Figure 3.4 shows a typical unloading plan

with container identification and details, position on the ship and unloading

sequence.

The storage stack consists of a number of lanes where containers can be stored for a

certain period. Dry cargo containers and refrigerated containers are stored in

different areas. Containers can be stored several high depend on the equipment used

in this storage stack. Melbourne Container Terminal use mainly SCs for container

transportation and stacking. Its storage stack is shown in Figure 3.5.

After a certain period the containers are retrieved from the stack and transported by

vehicles to transportation modes like trucks or trains to leave the container terminal.

Figure 3.6 shows SC delivers container to the truck.

Figure 3.5 Melbourne Container Terminal storage stack

23

Figure 3.6 Straddle Carrier deliver container to truck

To load export containers onto a ship, these processes are also executed in reverse

order. A typical loading plan is shown in Figure 3.7 and Figure 3.8 provides a

summary of container processes at a Container Terminal.

Most of the container terminals make use of manned equipments. However, a few

terminals are semi-automated using unmanned equipment for transport of

containers such as driver less SCs are used in Patrick Terminal in Brisbane, driver

less Rail Mounted Gantries (RTGs) are also tried at Patrick Terminal in Sydney,

some terminals in Rotterdam use Automated Guided Vehicles (AGVs) and

Automated Stacking Cranes (ASCs). Australian Container Terminals in Brisbane

and Sydney are currently re-developing their sites for use ASCs.

24

Figure 3.7 Container ship loading plan

25

Figure 3.8 Processes at Container Terminal

26

3.1.2 Electrical assets at container terminal

As a large electrical user and having a number of machines powered at high voltage

(HV) typically at 11kV level, container terminals are usually under HV tariff.

Following the above description, container terminal administration office is the first

area to look at for electrical assets. Typically, it consists of the following:

working areas and amenities (general office, first aid office, meeting room,

canteen, toilet, ) for its work forces,

control tower/room for computer system to observe and monitor all terminal

activities,

air conditioning, lighting and communication systems.

Electrical power at low voltage (three phase 415V in Australia) is required for these

services. Supply is normally via a step down transformer located near the office to

reduce the voltage drop.

Next type of electrical asset is the container handling equipment group: QCs, RTGs,

RMGs, ASCs, AGVs, SCs and Forklift. However, RTGs, AGVs, SCs and Forklift

are mobile machines which are either not electric powered or not connected to

electric grid. In other words, they are not electrical assets for the purposes of this

study. QCs, RMGs and ASCs are giant and very fast electric powered machines

which give the impression that they use a high amount of energy and require a very

high electrical demand. Due to their size and the capability of travel a relative long

distance (few hundreds meters), they are powered by HV, typically at 11kV.

27

Next electrical asset would be the refrigerated containers that require low voltage

electrical power to keep their cargo at the correct temperatures. Designated areas

with electrical infrastructure to allow these refrigerated containers to be connected

to the electrical grid are in the storage stack. These designated areas are normally

located close to the electrical substation to limit the voltage drop.

As container terminals are operated on 24 hours a day and 7 days a week basic,

lightings are required for night operation. Low voltage electrical supply to these

lightings is from the mention electrical substations.

A maintenance workshop is also a requirement at any container terminal; it is where

the repair and maintenance works to be carried out to keep all electrical assets in

good working order. Welding machines, lathes, power tools, measurement

instruments, spares,.. are in this workshop which required low voltage electric

power supply.

These electrical assets are divided into three groups for detailed study:

Container cranes group consists of QCs, RMGs and ASCs assets

Refrigerated containers group

Other load group consists of Office, Workshop and Lighting assets

Container group will be studied in Chapter 4, Chapter 5 investigates the refrigerated

container group. Demand of the other load group is well regulated and could be

calculated using the AS/NZS 3000 [62] or Construction handbook [21, 34] , it is the

responsibility of the building designer to provide the estimated demand; the

installed demand of this load group was taken as the maximum demand for this

study.

28

3.2 Definition of Electrical Demand

Electrical demand could mean different thing among the Utilities. As the purpose of

this study is to calculate the electrical maximum demand at the container terminal, it

is important that a clear definition of the term demand is needed ([99] provides

basic information). This was achieved by checking information provided by the

Utilities, analysing the actual electricity bill and examining measuring devices.

3.2.1 Definition from the Utilities

The following definitions are obtained from several different Utilities in Australia:

United Energy

Maximum Demand = Energy consumption over hr period/ Time (1/2 hr). The

Rolling Peak Demand Charge is based on the highest power (kVA at the highest

kW) delivered during Peak periods (defined as 7am to 7pm Local Time weekdays

excluding public holidays) over 12 months to the end of the billing period.

Powercor

Actual demand, which is measured as the energy consumption recorded over the

demand integration period divided by the demand integration period in hours (the

demand integration period is 15 minutes.

Energex

The customers connection point has a meter installed that is capable of measuring

energy consumption (kW.h) and demand (kW). This meter records total energy

consumption (kW.h) and demand over 30 minute periods. A customers demand is

the average demand (kW) over the 30 minute period.

Western Power

The metered demand (MD) is a rolling 12-month maximum haft-hourly demand.

29

The electrical demand is actually calculated as defined above was confirmed in the

next section by examining the electrical bills of the container terminal and the raw

measured electrical usage.

3.2.2 Definition from Electricity Bills and measured energy

Electricity bill of an industrial HV customer is different from a residential LV

customer. By law, all the different charges have to be disclosed. Figure 3.9 shows

the electricity bill of the container terminal in Port Botany Sydney for November

2010. For the purposes of this study, the following information is of interested:

Total energy usage: 826,565 kWh and Maximum demand: 2317.41 kVA

Figure 3.9 Port Botany terminal November 2010 Electricity bill

30

It was noted that there is no information on the feed back energy from the container

terminal (when container handling machine in lowering mode), by experience it is

small amount and ignored by the Utilities. The Utilities provided the electrical data

as requested by the container terminal operator to ensure the charges were correct.

As shown on the electricity bill, there are two meters so that two set of metered data

were provided. Data are time stamped for every 30 minutes during November 2010.

Table 3.1 and Table 3.2 list only part of the electrical data as full listing is not

necessary.

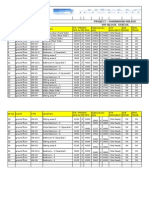

Table 3.1 Port Botany terminal Meter 1 data for November 2010

31

Table 3.2 Port Botany terminal Meter 2 data for November 2010

Calculation was performed to find the total energy usage and maximum demand

during November 2010. Calculations are:

kWh yUsage TotalEnerg (Eq. 3.1)

kWh

h

kWh

kW * 2 as h =30 minutes =0.5 hours (Eq. 3.2)

kVArh

h

kVArh

kVAr * 2 as h =30 minutes =0.5 hours (Eq. 3.3)

32

2 2

kVAr kW kVA (Eq. 3.4)

) (kVA MAX Demand

Max

(Eq. 3.5)

Calculations are also shown in Table 3.1 and Table 3.2 and the results are

summarised in Table 3.3

Table 3.3 Port Botany terminal Summary of Electricity November 2010

Electricity Bill Metered Data Unit

Energy Usage

Meter 1 559,913 559,840 kWh

Meter 2 266,652 266,636 kWh

Total 826,565 826,476 kWh

Max Demand 2317.41 2301.40 kVA

The same results were found for all the electricity bills and metered data in 2010. It

was concluded that as defined by the Utilities, electrical demand is indeed

calculated from the metered energies over a time period of 30 minutes.

Digital meters are now used by the Utilities to measure the electrical usage; they are

capable of measuring the electrical demand. Information of how the digital meters

measure the electrical demand was examining in the next section for the definition.

3.2.3 Definition from the Digital Power meters

All digital power meters installed at large users including container terminal are

capable of recording energy both ways: deliver (from the electrical grid to the

customer (positive)) and receive (from the customer to the electrical grid

33

(negative)). However, unless the received energy is from small source (solar) or

agreed generator set the Utilities would not recognize this feed back energy.

The maximum electrical demand is calculated from the measured energies over a

period of 30 minutes as shown in the previous section. It is known that digital

meters are capable measure and calculate a lot more electrical parameters especially

the electrical demand value. It is possible that some Utilities may use this value

instead of calculate as previous section. To ensure this possibility would not affect

the out come, definition of electrical demand measured by the digital meters was

examined in this section.

Following descriptions are extracted from the manuals of some of the digital

meters that used at container terminals around the world:

ION 7300 series Power & Energy Meter from Schneider Electric [69]

Demand is a measure of average power consumption over a fixed time

interval. Peak (or maximum) demand is the highest demand level recorded

over the billing period.

Quantum Q1000 Multifunction Meter from SchlumbergerSema [156]

Demand is the average value of a measured quantity over a specified time.

9300 Series Power Meter from Siemens [11]

The demand modules (both Thermal Demand modules and Sliding Window

Demand module) are configured to calculate the average current demand

and kW, kVAR and kVA demand.

34

Mk Genius and Mk6E Energy Meters from EDMI [114]

The demand for the period is simply the accumulated energy divided by the

fraction of an hour that the demand period is.

DIN Integra 500 Series from Crompton [3]

Most electricity utilities base their charges on power consumption,

historically using a thermal maximum demand indicator (MDI) to measure

peak power consumption averaged over a number of minutes, thus avoiding

artificially high readings caused by surges.

It was confirmed that the digital meters calculate the electrical demand in the same

manner as the Utilities do from their metered energy values. That means value of

electrical demand is the same either it was read from the digital meter or calculated

by the Utilities.

The important result from the study so far is that electrical demand is the average

demand over a measure period. The measure period is 30 minutes for Melbourne

Container Terminal and Sydney Port Botany Container Terminal.

3.3 Focusing study on average electrical demand

With the understanding of maximum electrical demand as discussed in previous

section, the maximum demand calculation in later section would be the calculation

of the maximum average demand instead of the peak demand. Reasons for this

decision were given below.

35

3.3.1 Reasons for focusing study on average demand instead of peak

demand

Recall from previous section, the electrical demand is the average demand over a

measure period that is normally 15 minutes or 30 minutes. Since the main purpose

of this study was to calculate the maximum electrical demand at container terminal

for negotiation the power supply contract either new supply or an upgrade one,

similar term (the average demand) should be used.

Some digital power meters do have the ability to calculate and record the

instantaneous maximum demand (secondly). However, as there is no way of

distinguishing between the actual electrical demand from the user and the network

disturbances; this ability of the meter was usually ignored.

An analogue maximum demand ammeter, such as BIQ96 from Ziegler, could also

be used to measure the maximum current demand then maximum power demand

could be calculated if required. Information from http://www.ziegler-

instruments.com/pdf/Bieq-c-ch.pdf (accessed on 22 May 2012) states that: The

thermal bimetallic movement indicates the mean rms value over 15 minutes

(optional 8 min.) And deflects a reset-table red slave pointer which shows the

maximum value reached. It was noted that peak demand was not measured.

Although peak electrical demand is important for any electrical network, it may

cause voltage flickering and trigger the supply interruption on a weak network, peak

demand is really the protection issue, which is out of this study scope. It is possible

to reduce this peak demand value to a manageable figure by using a synchronized

36

movements (central control) [42] scheme or using a peak lopping device that

would be discussed in Chapter 6.

3.3.2 Decision of focusing the study on average demand

A container terminal with a large number of container handling cranes would face a

very large value of maximum electrical demand if peak values were used.

Information of how electrical energy and demand were measure, calculated and

charged at container terminal together with the above reasons, using average

electrical demand was the correct way to calculate/estimate the maximum electrical

demand of a container terminal.

3.4 Set up at Melbourne Container Terminal for collecting data

With the approval and permission of Patrick management team, the new 11kV HV

reticulation with an Energy Management System (EMS) was designed and installed

at Swanson Dock in the Port of Melbourne. The change over from the old electrical

supply network to the new ones without interruption to the daily operation of the

terminal was completed in early 2006.

The selected EMS was the Power Logic System Management Software from

Schneider Electric (previously owned by Square D) because it was the only system

that provides a complete solution at that time. The EMS was designed for the ease

of communicating and collecting measured electrical data from a large range of

power meters, protection relays as well as tripping units of low voltage circuit

breakers especially for devices from Schneider Electric.

37

Figure 3.10 shows the HV single line diagram and location of measuring devices

while Figure 3.11 shows the layout of the EMS system.

For a fast changing electrical load, such that the QC, RMG and ASC, Schneiders

circuit monitor CM3250 was used. This device is a powerful power meter with in

built memory large enough to record electrical data every second for at least 5

hours.

For a slow changing or steady load, such as the refrigerated containers, metering

features of the digital protection relay (SEPAM series 40) and digital tripping

circuit of circuit breaker (MicroLogic 5) were utilised. These devices do not have

built-in memory, the required electrical values were measured and calculated then

pass on to the EMS server when there was a data collect signal was issued from

the EMS server. Electrical data collection period can be varied between 1 minute

and 1 hour.

Power Logic System Management Software version 4 was installed on a computer

server which runs Windows Server 2003 operating software. Electrical data,

voltages, currents, powers, energies, power factor and harmonics from each of the

devices (shown in Figure 3.11) were collected and save in a database every 15

minutes. Historical data could be archived when required.

The system was set up as a stand alone system that was not connected to the

container terminal computer network for security reasons. Remotely access was via

the World Wide Web by using the service of Iburst wireless network.

Unfortunately, the Iburst network was closed several years ago and the only way to

access this system was via local direct log in to the server.

3

8

F

i

g

u

r

e

3

.

1

0

S

i

n

g

l

e

L

i

n

e

D

i

a

g

r

a

m

w

i

t

h

m

e

a

s

u

r

i

n

g

d

e

v

i

c

e

s

l

o

c

a

t

i

o

n

s

3

9

F

i

g

u

r

e

3

.

1

1

E

n

e

r

g

y

M

a

n

a

g

e

m

e

n

t

S

y

s

t

e

m

l

a

y

o

u

t

40

With permission from management team of Patrick, the Melbourne Container

Terminal Operator, and utilizing the fast 1 second data recording feature of the

CM3250, load profiles of number of QCs were obtained. The QCs electrical

specifications, characteristic, measure conditions and results would be discussed in

Chapter 4.

The management team also permitted the daily weekday reports of number of

refrigerated containers and dry cargo containers that were in storage stack of the

terminal be generated and provided via email. These reports would be discussed in

Chapter 4 and Chapter 5.

Although all circuit monitor CM3250s and Power Logic System Management

Software V4 are still in working order providing invaluable data for the study and

any future work, they are discontinued and no longer available, Schneider Electric

claims latest software version, Power Logic ION Enterprise, and newer

measurement devices would be more user friendly and provide better results.

3.5 Conclusions

Understanding the processes at container terminals helps to identify the electrical

assets and focus the study on interested areas.

The definition of the electrical demand term that is referred to by the Utilities is

clarified by reviewing the Utilities electricity bills, examining the raw data of

measured electrical parameters and investigating how those electrical parameters

are defined in modern digital power meters (smart meters), it is confirmed that

41

electrical demand is the average demand over a measure period (usually 15

minutes or 30 minutes period) and is not the instantaneous demand. The tasks

of finding the maximum demand of electrical assets became easier with this

confirmation.

With the measurement scheme set up for data collection as described, the studyied

results could be verified. The electrical energy usage and maximum demand of

container cranes group would be investigated in the next chapter Chapter 4

Container Handling Crane.

42

CHAPTER FOUR

Container Handling Crane

With the electrical assets of container terminal have been identified in previous

chapter, the electrical demand and energy usage for the big machine group

container handling cranes could now be studied. These machines are used to:

move containers from container ship to ground or via versa (QCs),

move containers into stacking area, shuffle them within the stacking area or

move containers out of stacking area for delivery either with driver (RMGs)

or driverless (ASC).

This chapter began with a brief discussion on these machines and their operation

then investigates the following:

Quay crane profile record load profiles of similar quay cranes with AC

drive and DC drive and compare the results for contribution to the AC verus

DC drive debate,

Container weight payload of container, capacity and deadweight of

container ship and analysing actual weights of containers (daily data

collected more than one year) in stack of Melbourne Container Terminal for

contribution to the debate of what size (lifting capacity) of quay crane is

needed.

43

The reasons why this study was only focusing on the maximum average demand

instead of the peak instantaneous demand would be discussed before demand

calculations were performed and conclusions were drawn.

4.1 Brief Discussion of container handling cranes

A modern container terminal would be dominated by the giant quay cranes that can

reach out over the ships to load or unload containers. They are mounted on rails and

will be able to long travel up and down the quay to exactly align themselves with

the bays in or over the ships hold, where the container is to be handled. The

outreach of the horizontal boom permits a trolley to cross travel from over the quay

to over the ship, a spreader with four locks suspended from the trolley. These locks

nest into the four corners of the containers, make fast and enable the container to be

hoisted out of (or lowered into) the ship hold. A crane driver in his cab alongside

the trolley has an excellent view of the process he is controlling.

Apart from the sizes of the quay cranes that are capable of serving different type of

container ships (Panamax, Post Panamax,), quay cranes are different in look: A

frame quay cranes are the most common cranes as they are the lightest and

cheapest quay cranes that can be built. Articulated boom or goose neck quay cranes

are used when there is a restriction in cranes height. Under severe crane height

restriction due to the container terminal is on the adjacent airports flight path,

shuttle boom or low profile quay cranes have to be used. Figure 4.1 shows these

types of quay cranes.

44

Another way of classifying quay cranes is their lifting capability or safe working

load (SWL) and how they lift containers. As 30 tones is the SWL of each 20 or

40 container, latest design tandem lift quay crane capable of lifting 6 x 20

containers should have the rated load of 180 tones. Figure 4.2 shows different types

of lifts.

Figure 4.1 Different forms of quay cranes

45

Source : www.lifttech.net

Figure 4.2 Quay cranes - Types of Lifts

On the quay ground handling equipment (straddle carriers, fork lifts or automatic

guided vehicles) moves the containers from the quay cranes to the stack and via

versa. The container is then moved into stacking area by the rail mounted gantries

(RMGs) or driverless automatic stacking cranes (ASCs). The same machine will

deliver containers to the truck or rail when required. In general, these machines are

very similar to the quay cranes without the boom motion, hoist/lower and cross

46

travel motions are for a short distance only. RMGs are shown in Figure 4.3 and

ASCs are shown in Figure 4.4.

Figure 4.3 Rail Mounted Gantries

Figure 4.4 Automatic Stacking Cranes (no driver)

Due to the need to travel a long distance (few hundreds meters) and handle the

heavy containers that is drawing large current over a long cable, these machines are

electrical powered at high voltage level and the drive system can either be an AC

drive system or a DC drive system. Unless specified, all machines are now come

with AC drive system simply because they can operate at or close to unity power

factor.

47

It was not able to record load profiles for RMG or ASC as the Melbourne Container

Terminal does not have any of these machines. However, it was expected the load

profiles of RMG and ASC are very similar to that of the quay cranes as:

Hoist/Lower motion would be similar as the container loads are the same for

these machines,

The long travel motion would be the predominant one as RMGs and ASCs

need only hoist/lower a short distance but long travel a very long distance.

Demand and energy usage are also less than that of the quay crane due to the