Beruflich Dokumente

Kultur Dokumente

2013 SGS ISO9001 Audit Non Confirmation Record

Hochgeladen von

Dustin RobertsonCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

2013 SGS ISO9001 Audit Non Confirmation Record

Hochgeladen von

Dustin RobertsonCopyright:

Verfügbare Formate

Others secondary interaction processes as per the audit plan was followed through and where appropriate the

activities and functions were reviewed and highlighted as either as non-conformities and/or opportunities for

improvement points

1. Nonconformities

NonConformity N 1 of 4 Major Minor

epartment /

!unction"

#urchasing $tandard

%ef."

&$O'((1")((* +lause ,.4

ocument %ef." %elated &ssue / %ev.

$tatus"

+urrent

etails of

Nonconformity"

1. $upplier -valuation %ating for .uster #recision -ngineering /an )(1)-ecem0er

)(1) was incorrect 0ased on the 1uality data provided. PIC: CC Lim

2. On time delivery has not 0een defined clearly 2 monitored as some 0uyer is 0ased

on 1uantity delivered and other is 0ased on delivery date3 however on the form is

defined as line down cases. -g. /$ +omponent3 4-3 .uster.

PIC: Eguchi san/ Jennifer

%oot +ause 1. id not follow $upplier -valuation %ating 5uideline to evaluate supplier

performance.

). ifferent #&+ has their own understanding of the $upplier -valuation %ating

+orrective 4ction 1. +oncerned #&+ to follow $upplier -valuation %ating 5uideline 6$upplier 7uality

#erformance judged 0y each month for how many #%.% issued 0y &ncoming8

).1 %eview and revise the $upplier -valuation %ating 5uidelines

).) 4ll purchaser to practise/ follow the revised guidelines

NonConformity N ) of 4 Major Minor

epartment /

!unction"

+ustomer +omplaints $tandard

%ef."

&$O'((1")((* +lause *.9.)

ocument %ef." %elated &ssue / %ev.

$tatus"

+urrent

etails of

Nonconformity"

No evidence that any verification of effectiveness was carried out for customer

complaints :51-1;(1-(1 2 :51-1;(1-(). PIC: Cathrine

%oot +ause #&+ not clear a0out the re1uirements

+orrective 4ction #&+ to update customer complaints +4/ #4 effectiveness result and .ot no. verified

NonConformity N ; of 4 Major Minor

epartment /

!unction"

#roduction $tandard

%ef."

&$O'((1")((* +lause ,.9.1

ocument %ef." %elated &ssue / %ev.

$tatus"

+urrent

etails of

Nonconformity"

1. aily .ine +hec< $heet for $M= .ine ; was not completed on the 1(/>/)(1; 2

1*/>/)(1;. PIC: Govin

2. &ssue date for thawing la0el for solder paste in use at $M= .ine * running Model

?>1((-11 .ot No. ,>,,/119( was incorrect. PIC: Govin

3. $etting for $pray flu@er flu@ flow was at )1.>cc/min3 however upon verification of the

specification it was found that the setting should 0e 1(-1*cc/min. PIC: J !an

%oot +ause 1. =here are a total of 4 reports to 0e completed 0y operator daily. Aowever the

operator miss-out to fill-up one of the reports - aily .ine +hec< sheet.

2. =he leader wrongly written the date. 4ctual date should 0e 1*.(>.1; 0ut wrongly

written as ).19 am3 1,.(>.1;.6 early morning 1,.(>.1; is an off day 8

/o0 n" MB(1;** %eport date" 4s per 4udit #lan Cisit =ype" $urveillance Cisit n" )

CONFIDENTIAL ocument" 5$(;(4 &ssue n" 1; #age n" 1 of ;

;. ipping =ech miss to confirm the spec when he tune the flu@er flow to achieve good

solder 1uality. ue to the #+? design structure to achieve good soldering 1uality3 we

need to set the spray flu@er flu@ flow at upper range D1*cc/min. ?ased on the ##M data

collected 0y machine setting at )1.>cc/min will achieve 0etter result .

+orrective 4ction 1. $upervisor 2 foreman to daily monitor the recording of the chec< sheet.

2. $econd confirmation will 0e done 0y foreman/supervisor 2 a0ove3 during issuing to

production.

;.1 %eview all the individual model spray flu@er flu@ flow setting vs solder dipping ##M

result.

;.) %evise the flu@er flu@ flow specification accordingly 0ased on the solder dipping

##M result.

NonConformity N 4 of 4 Major Minor

epartment /

!unction"

+ali0ration $tandard

%ef."

&$O'((1")((* +lause ,.>

ocument %ef." %elated &ssue / %ev.

$tatus"

+urrent

etails of

Nonconformity"

1. No evidence that the push gauge used at $M= to test the glue strength was

cali0rated. PIC: "# Lo$

2. -1uipment used for !inal &nspection to test the =ransformer after the Carnish

#rocess is not cali0rated. PIC: Na%ri/ "# Lo$

%oot +ause ?oth e1uipments were classified under cali0ration not re1uired

+orrective 4ction %eview and send the cali0ration re1uired e1uipments for cali0ration

). 5eneral O0servations 2 Opportunities for &mprovement

Genera& comments an' (ositive o)servation note':

=he overall 7uality Management $ystem was generally ade1uate and effectively maintained. =he

continual improvement activities and preventive action/s are on-going. 4ll personnel are cooperative and

positive throughout the whole audit process. =hus3 the audit was completed satisfactorily without delay.

Im(ortant o)servations * o((ortunities for Im(rovement:

1. &dentification and segregation of <itting parts3 pending issuance to production parts 2 raw material to

0e improved in the raw material store. PIC: Lee

+4" =o identify parts status 0y using sign0oard 6-@ample" 4uto :itting #art3 #art awaiting for storage3

:itting 4ssy part sign0oard8

2. &nstruction to carry out internal verification of e1uipment to 0e documented 6-g. Erist $trap =ester

Cerification3 Cerification of dummy sample8. PIC: "# Lo$

+4" =o prepare Erist $trap ummy/ =ester Cerification wor< instruction/ send it for e@ternal cali0ration.

3. =o further improve on the understanding of the personnel carrying out the verification of the

cali0ration certificate results on the acceptance tolerance. PIC: "# Lo$

+4" %evised :7# 19 +ali0ration 2 Maintenance3 clause >.1.,

+. 4 copy of the evidence of !4& approval for localiFed parts as well as the pre-production approval of

the final product should 0e <ept. PIC: ,a%&i

+4" %evised :7#1) clause >.).> to attach :5// A7 supporting documents for !4 %eport

6-g. =:+1)(( #+? !4 %eport8

/o0 n" MB(1;** %eport date" 4s per 4udit #lan Cisit =ype" $urveillance Cisit n" )

CONFIDENTIAL ocument" 5$(;(4 &ssue n" 1; #age n" ) of ;

-. etailed evidence of verification of effectiveness of +4%/customer complaints to 0e clearly indicated.

6-g. .ot no. verified8 PIC: .ashi'

+4" #&+ to update customer complaints +4/ #4 effectiveness result and .ot no. verified

/. #lacement of E&# #+?4 after the wave solder on the tray can 0e improved to prevent any possi0le

component <noc< off reject. PIC: J !an

+4" +hange the #+?4 tray type current 1(mm slot type to 19mm slot type. =his will <eep #+?4 9mm

gap distance.

0. =arget for A% on #rovide 1((G New Operator Orientation 2 +ertification to review as the target has

0een achieved for since )((*. =o consider new target for continual improvement. PIC: Jenny

+4"

1. %eview of 7uality #olicy in the Management %eview to 0e clearly identified in the meeting minutes

PIC: Isa

+4"

/o0 n" MB(1;** %eport date" 4s per 4udit #lan Cisit =ype" $urveillance Cisit n" )

CONFIDENTIAL ocument" 5$(;(4 &ssue n" 1; #age n" ; of ;

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Dam Lecture 14 - Design Criteria Earth DamsDokument4 SeitenDam Lecture 14 - Design Criteria Earth DamsCarolineMwitaMoseregaNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- 2017 THE BLUE WAY Visual PDFDokument54 Seiten2017 THE BLUE WAY Visual PDFAlex KappelNoch keine Bewertungen

- Drug AbuseDokument33 SeitenDrug AbuseharshulnmimsNoch keine Bewertungen

- KSP-45 Operator Training ProcedureDokument2 SeitenKSP-45 Operator Training ProcedureDustin Robertson50% (2)

- Cash and Cash Equivalents ReviewerDokument4 SeitenCash and Cash Equivalents ReviewerEileithyia KijimaNoch keine Bewertungen

- OA Standard 050505Dokument75 SeitenOA Standard 050505fido_dagemNoch keine Bewertungen

- Data Management For Human Resource Information SystemDokument14 SeitenData Management For Human Resource Information SystemRajeshsharmapurangNoch keine Bewertungen

- Quinta RuedaDokument20 SeitenQuinta RuedaArturo RengifoNoch keine Bewertungen

- Science 9-Quarter 2-Module-3Dokument28 SeitenScience 9-Quarter 2-Module-3Mon DyNoch keine Bewertungen

- PHOTO OF Defect PWB (Qty 1) : PCB Overcut and R1 Scratch (Cavity 1)Dokument1 SeitePHOTO OF Defect PWB (Qty 1) : PCB Overcut and R1 Scratch (Cavity 1)Dustin RobertsonNoch keine Bewertungen

- 2) Cap Cera Exposed Land Are Not BalanceDokument2 Seiten2) Cap Cera Exposed Land Are Not BalanceDustin RobertsonNoch keine Bewertungen

- Hacking: Name: Farah Hanani Binti Mohd Isa I.C. NUMBER: 890418-02-6192 Class: 4 Fikrah Ict Teacher: Pn. DzulianaDokument3 SeitenHacking: Name: Farah Hanani Binti Mohd Isa I.C. NUMBER: 890418-02-6192 Class: 4 Fikrah Ict Teacher: Pn. DzulianaDustin RobertsonNoch keine Bewertungen

- Kaga - SOEM KL QualityDel Performance Review - FY13Dokument13 SeitenKaga - SOEM KL QualityDel Performance Review - FY13Dustin RobertsonNoch keine Bewertungen

- Toto Controller Rework Flow 20140724Dokument1 SeiteToto Controller Rework Flow 20140724Dustin RobertsonNoch keine Bewertungen

- Wrong Part Supplied by SupplierDokument6 SeitenWrong Part Supplied by SupplierDustin RobertsonNoch keine Bewertungen

- PHOTO Bare Board 1-734-376-21Dokument3 SeitenPHOTO Bare Board 1-734-376-21Dustin RobertsonNoch keine Bewertungen

- Yamaha Ddcon Measurement: Terminal Protrude 0.1 0.2Mm Terminal Same Level As The BodyDokument1 SeiteYamaha Ddcon Measurement: Terminal Protrude 0.1 0.2Mm Terminal Same Level As The BodyDustin RobertsonNoch keine Bewertungen

- Lead LengthDokument1 SeiteLead LengthDustin RobertsonNoch keine Bewertungen

- c4 CrackDokument15 Seitenc4 CrackCheryl McgeeNoch keine Bewertungen

- Aseptic TechniquesDokument3 SeitenAseptic TechniquesMacy MarianNoch keine Bewertungen

- #1 - The World'S Oldest First GraderDokument6 Seiten#1 - The World'S Oldest First GraderTran Van ThanhNoch keine Bewertungen

- Transmission Line Loading Sag CalculatioDokument25 SeitenTransmission Line Loading Sag Calculatiooaktree2010Noch keine Bewertungen

- PaintballDokument44 SeitenPaintballGmsnm Usp MpNoch keine Bewertungen

- 2022.08.09 Rickenbacker ComprehensiveDokument180 Seiten2022.08.09 Rickenbacker ComprehensiveTony WintonNoch keine Bewertungen

- Ifm Product Innovations PDFDokument109 SeitenIfm Product Innovations PDFJC InquillayNoch keine Bewertungen

- Tracheo Esophageal FistulaDokument6 SeitenTracheo Esophageal Fistulablast2111Noch keine Bewertungen

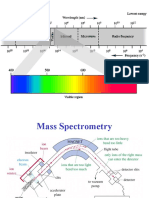

- Mass SpectrometryDokument49 SeitenMass SpectrometryUbaid ShabirNoch keine Bewertungen

- D05 Directional Control Valves EngineeringDokument11 SeitenD05 Directional Control Valves EngineeringVentas Control HidráulicoNoch keine Bewertungen

- Phenotype and GenotypeDokument7 SeitenPhenotype and GenotypeIrish Claire Molina TragicoNoch keine Bewertungen

- Management of Developing DentitionDokument51 SeitenManagement of Developing Dentitionahmed alshaariNoch keine Bewertungen

- The Integration of Technology Into Pharmacy Education and PracticeDokument6 SeitenThe Integration of Technology Into Pharmacy Education and PracticeAjit ThoratNoch keine Bewertungen

- Editorship, Dr. S.A. OstroumovDokument4 SeitenEditorship, Dr. S.A. OstroumovSergei OstroumovNoch keine Bewertungen

- Practice Problems Mat Bal With RXNDokument4 SeitenPractice Problems Mat Bal With RXNRugi Vicente RubiNoch keine Bewertungen

- Edgie A. Tenerife BSHM 1108: Page 1 of 4Dokument4 SeitenEdgie A. Tenerife BSHM 1108: Page 1 of 4Edgie TenerifeNoch keine Bewertungen

- Gintex DSDokument1 SeiteGintex DSRaihanulKabirNoch keine Bewertungen

- Marine Advisory 03-22 LRITDokument2 SeitenMarine Advisory 03-22 LRITNikos StratisNoch keine Bewertungen

- The Ego and Analysis of Defense-Jason Aronson, Inc. (2005) Paul GrayDokument356 SeitenThe Ego and Analysis of Defense-Jason Aronson, Inc. (2005) Paul GrayClinica MonserratNoch keine Bewertungen

- NCP On DiabetesDokument2 SeitenNCP On DiabetesShumaila AlviNoch keine Bewertungen

- PD 984Dokument38 SeitenPD 984mav3riick100% (2)

- Mapeh 9 Aho Q2W1Dokument8 SeitenMapeh 9 Aho Q2W1Trisha Joy Paine TabucolNoch keine Bewertungen

- SAT Subject Chemistry SummaryDokument25 SeitenSAT Subject Chemistry SummaryYoonho LeeNoch keine Bewertungen