Beruflich Dokumente

Kultur Dokumente

1 C. I. Weights 2 C. I. Weights 3 C. I. Weights 4 C. I. Weights

Hochgeladen von

Shiva Prakasam PernetiOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1 C. I. Weights 2 C. I. Weights 3 C. I. Weights 4 C. I. Weights

Hochgeladen von

Shiva Prakasam PernetiCopyright:

Verfügbare Formate

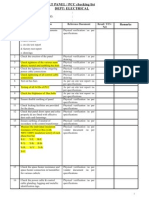

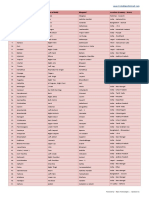

SR. NO.

EQUIPMENT

1 C. I. WEIGHTS

2 C. I. WEIGHTS

3 C. I. WEIGHTS

4 C. I. WEIGHTS

EQUIPMENT DISTRIBUTION WITH RESPONSIBILITIES

DEPARTMENT:INSTRUMENTATION

TAG NO. RESPONSIBILITY FREQUENCY

SH (1- 75) RAHUL ONCE IN 3 MONTHS

SH W11 ( 76- 80) RAHUL ONCE IN 3 MONTHS

PCI (1- 65) ARUN ONCE IN 3 MONTHS

SP (1- 5) AKHIL ONCE IN 3 MONTHS

EQUIPMENT DISTRIBUTION WITH RESPONSIBILITIES

DEPARTMENT:INSTRUMENTATION

Sub Zone Sub Sub Zone Sub Sub Zone leader Area Responsibility

Table1 Suresh

Table2 Pramod

Table3 Ahuja

Table4 Ravi

Table5 Subhaiya

Table6 Subhaiya

Table7 Shiva

Cupboard 1 Pramod

Cupboard 2 Abey/ Mahesh

Cupboard 3 Shiva

Cupboard 4 Subhaiya

Cupboard 5 Abey/ Mahesh

Cupboard 6 Ravi

AC's Rahul

Calibration room Rahul

2 Storage room PCI Shiva Tagged equipment room Arun

PCI inst office room All

PLC 01 panel Shift Engineer

PLC 11 panel Shift Engineer

PLC 21 panel Shift Engineer

PLC 22 panel Shift Engineer

PLC 31 panel Shift Engineer

PLC 32 panel Shift Engineer

PLC 33 panel Shift Engineer

PLC 34 panel Shift Engineer

PLC 35 panel Shift Engineer

PLC 36 panel Shift Engineer

PLC 37 panel Shift Engineer

3QAC Puffing panel Shift Engineer

3TAC Stock rod panel Shift Engineer

3VAC Distributor panel Shift Engineer

3DAC Sevo drive panel Shift Engineer

UPS1 Shift Engineer

UPS2 Shift Engineer

AC's Shift Engineer

PLC 23 panel Shift Engineer

PLC 24 panel Shift Engineer

PLC 25 panel Shift Engineer

PLC 26 panel Shift Engineer

PLC 27 panel Shift Engineer

Stock House PLC PC Shift Engineer

Hydraulic room Shift Engineer

1

Shiva 4

3

5S AREA DISTRIBUTION BF-3 WITH RESPONSIBILITIES

Engineers room

BF Main PLC room

BF 1

Subhaiya

Stock House/ Charging system

DEPARTMENT:INSTRUMENTATION

AC's Shift Engineer

Field panel/ Instruments Shift Engineer

PLC 12 panel Shift Engineer

Diesel engine panel Shift Engineer

CWPS PLC PC Shift Engineer

Gas analyser panel Shift Engineer

Flare stack panel Shift Engineer

Field panel/ Instruments Shift Engineer

Telephone system Shift Engineer

AC's Shift Engineer

PLC 41 Shift Engineer

PLC 42 Shift Engineer

11AC1 Weigh feeder Shift Engineer

11AC2 PCI Mill Shift Engineer

11AC3 PCI DD Shift Engineer

Gas analyser Shift Engineer

PLC 51 Shift Engineer

Blower PLC PC Shift Engineer

AC's Shift Engineer

Field panel/ Instruments Shift Engineer

Hydraulic room Shift Engineer

Fire hydrant panel/ Instruments Shift Engineer

Field panel/ Instruments Shift Engineer

PLC 13 panel Shift Engineer

PLC 14 panel Shift Engineer

PLC 15 panel Shift Engineer

Field panel/ Instruments Shift Engineer

Camera Shift Engineer

AC's Shift Engineer

Hydraulic system panel Shift Engineer

Lubraication system panel Shift Engineer

Camera Shift Engineer

Field panel/ Instruments Shift Engineer

7

PCM/ Cast house/ slag granulation Arun 8

HBS/ GCS/ Fire hydrant/ Fresh water system

Shiva 4

9

CWPS/ Gas Analyser/ Flarestack 5 Ratheesh BF 1

Stock House/ Charging system

6

BF top Shiva

Jasir PCI/ Blower House

Arun

Production Weigh bridge

Raw Material Weigh bridge

Dispatch Weigh bridge

Weigh bridge PC's

Main gate/ Raw material gate camera

LAN Network

AC's

Sub Sub Zone Sub Sub Zone leader Area Responsibility

Table 1 Shripad

Cupboard 11,12 Mayank

PLC Panels Mayank

UPS and battery banks Mayank

Static Switch Mayank

Isolation Transformers Mayank

Key Holder Mayank

AC's Mayank

Instrumenation table and PC Aniket

Engineers & Technicians lockers Aniket

Fan control PLC panel Aniket

Dedusting control PLC panels Aniket

AC's Aniket

3 KVA UPS and battery bank Aniket

Fan control PLC Panel Aniket

ESP control PLC panel Aniket

AC Aniket

12 Head end ESP PLC room Mayank Arya Head ESP PLC Panel Mayank

Fan control PLC panel Anup

Dedusting control PLC panel Anup

AC Anup

PLC Panels Anup

Table 1 Anup

UPS and battery banks Anup

Rahul Weigh bridge 10

BF 1

11 Main Sinter shop PLC room Mayank Arya

5S AREA DISTRIBUTION WITH RESPONSIBILITIES IN SINTER PLANT

12 Proportioning & Screening DD PLC room Aniket V Bhagat

Flux & fuel PLC room Anup Parab

14 Proportioning PLC room Anup Parab

11 Tail end ESP PLC room Aniket V Bhagat

SP

13

Isolation Transformers Anup

Cupboards Anup

AC's Anup

PLC Panel Aniket

Table Aniket

UPS, PC and battery banks Aniket

Gas analyser panel Aniket

Calibration cylinders Aniket

AC's Aniket

PLC Pannel Mayank

AC Mayank

14 Proportioning PLC room Anup Parab

16 Machine lubrication system PLC Room Mayank Arya

SP

Main Exhaust Fan and Gas Analyser room 15 Aniket V Bhagat

Remarks

Remarks

5S AREA DISTRIBUTION WITH RESPONSIBILITIES IN SINTER PLANT

INTERNAL

Slno Day Area

1 Monday BF Main PLC room

2 Tuesday Stock House/ Charging system

3 Wednesday CWPS/ Gas Analyser/ Flarestack

4 Thursday PCI/ Blower House

5 Friday HBS/ GCS/ Fire hydrant/ Fresh water system

6 Saturday PCM/ Cast house/ slag granulation,BF top

7 Sunday Weigh bridge

Slno Day Area

1 Monday Main Sinter shop PLC room

2 Tuesday Proportioning & screening DD PLC room

3 Wednesday Tail end ESP PLC room

4 Thursday Head end ESP PLC room,Flux & fuel PLC room

5 Friday Proportioning PLC room

6 Saturday , Main Exhaust Fan and Gas Analyser room

7 Sunday Machine lubrication system PLC Room

Person Review Responsibility

Jitin Shift engineer/Technician

Ayoob Shift engineer/Technician

Rateesh Shift engineer/Technician

Shiva Shift engineer/Technician

Hrushikesh Shift engineer/Technician

Arun Shift engineer/Technician

Rahul Shift engineer/Technician

Person Review Responsibility

Slno AREA Responsibility Insp frequency Remarks

1 PCI critical cupboard Pramod/Engineers Monthly/Weekly

2 Cupboard 01 Abey/Technicians Monthly/Weekly

3 Cupboard 02 Mahesh Hinde Monthly/Weekly

4 Shift Cupboard MCK Technicians Monthly/Weekly

5 Inst Calibration room Jithin/Techinicians Monthly/Weekly

6 PCI inst store room Shiva/Techinicians Monthly/Weekly

1 Monday PCI critical cupboard

2 Tuesday Cupboard 01

3 Wednesday Cupboard 02

4 Thursday Shift Cupboard

5 Friday Inst Calibration room

6 Saturday PCI inst store room

7 Sunday All areas checking

S.NO

SUB

ZONE SUB SUB ZONE S.NO CHECK POINTS

1 Condition of furniture

2 Indexing & labeling of records and cupboards

3 Conditions of electrical fittings

4 Cleanliness of floor & walls & ceiling

5 Condition of labeling & visual display

6 Arrangements in table drawers

7 List of spares

8 Condition Of Panels

9 Red tag & yellow tag area

10

Condition Of UPS,Batteries banks,Isolation

Transformers

11 Participation of all the employees

12 Instrumenation table and PC condition

13 Cleanliness of floor & walls & ceiling

14 Condition of labeling & visual display

15 Conditions of electrical fittings

16 Condition of UPS and batteries

17 Condition of labelling and visual Display

18 Proper Labelling of Lockers

19 Condition of PLC Panels

20 Condition of PLC Panels

21 Condition of electrical fittings

22

Proper labelling of each cupboard and personal

cupboards

23 Condition of labelling and visual Display

24 Cleanliness of floor & walls & ceiling

D Head ESP PLC panel 25 Condition of PLC Panel

26 Condition & Cleaning of floor

27 Conditions of electrical fittings

28 Condition of labelling and visual Display

29 Condition Of PLC panel

30 Condition & Cleaning of floor

31 Conditions of electrical fittings

32 Condition Of Furnitures

33 Condition of PLC Panels

34 Condition OF weighing Controllers Panel

35

Condition Of UPS,Batteries bank,Isolation

Transformers

36 Red tag & yellow tag area

37 Condition OF lockers and Listings of Spares

38 Condition Of Panels

39 Condition Of HMI PC

40 Condition of UPS,Batteries

41 Condition of Furnitures

42

Condition of floor ceiling and walls & electrical

fittings

43 Cleanliness of room.

44 Condition Of PLC panel

45 Condition of labeling & visual display

G Main Exhaust Fan And Gas Analyser Room

H Machine Lubrication System PLC Room

DEPARTMENT:INSTRUMENTATION

1

MAIN STORAGE AREA

A Main Sinter Shop PLC Room

B Proportioning And Screening DD PLC room

C Tail End ESP PLC Room

E Flux And Fuel PLC Room

F Proportioning PLC room

46 Proper Illumination

47 List of cupboard & racks pasted & updated

Total

Percentage

Date:

Auditor:

H Machine Lubrication System PLC Room

MARKS

ALLOTED Remark

DEPARTMENT:INSTRUMENTATION

MAIN STORAGE AREA

0

0

Sr.No

1

2

3

4

5

6

7

8

9

10

11

12

13

STANDARD PRACTICES FOR THE YEAR 2014-2015

STANDARD PRACTICES

All equipments coming from the field should be cleaned at site and tagged before keeping in yellow tag bin.

working and Repairing should be cleaned once the job is over

Common Area Cleaning should be done regularly.

PLC Program backup to be saved in Backup Folder Only

PC s to be Switched OFF before Leaving

Daily Round of in charge in Respective 5S Areas

All Spare lists to be updated regularly

Scrap Materials to be Scraped only after HOD Approval

Ensuring good housekeeping at all sites (Scrap materials to be kept in Scrap Bin or Scrap Area identified)

Ensuring Tools And Tackles in Good Working Condition

Calibration and maintenance to be done as per annual planner

Calibration Reports & stickers to be updated regularly

Rubbish Scrap generated should be kept in Rubbish Scrap Bin kept at various location in Plant

STANDARD PRACTICES FOR THE YEAR 2014-2015

Das könnte Ihnen auch gefallen

- Safety Checklist PointsDokument8 SeitenSafety Checklist PointsPravash MohantyNoch keine Bewertungen

- Model Work Place Check ListDokument5 SeitenModel Work Place Check ListT S VirdiNoch keine Bewertungen

- Checklist of DU250 & DU400Dokument9 SeitenChecklist of DU250 & DU400MadanBhadoriyaNoch keine Bewertungen

- PM Report: Basic DetailsDokument8 SeitenPM Report: Basic DetailsUsha RaniNoch keine Bewertungen

- Cat Compact Start Up and Commissioning ChecklistDokument19 SeitenCat Compact Start Up and Commissioning ChecklistAnonymous aufoLkcwhZ100% (1)

- 50hc - 02pd Carrier Tipo Paquete PDFDokument82 Seiten50hc - 02pd Carrier Tipo Paquete PDFmicerinosNoch keine Bewertungen

- EEELABDokument5 SeitenEEELABGopi KofyNoch keine Bewertungen

- 3500 Start Up and Commissioning ChecklistDokument23 Seiten3500 Start Up and Commissioning Checklistlquinter75100% (2)

- VA-HVAC-01M Hvac Inspection DescriptionDokument4 SeitenVA-HVAC-01M Hvac Inspection DescriptionWangunNoch keine Bewertungen

- Oral QuestionsDokument7 SeitenOral Questionsjohnmbatizaji003Noch keine Bewertungen

- 5s Audit PlanDokument3 Seiten5s Audit PlansomuanindianNoch keine Bewertungen

- Electrical & Instrumentation Punch List S.No DescriptionDokument6 SeitenElectrical & Instrumentation Punch List S.No DescriptionNisar AhmedNoch keine Bewertungen

- Equipments DiplomaDokument70 SeitenEquipments Diplomaputrde1Noch keine Bewertungen

- Check List For Fire Pump-Nfpa 20 Systems - General Submittal RequirementsDokument6 SeitenCheck List For Fire Pump-Nfpa 20 Systems - General Submittal Requirementspepitorodirguez86% (7)

- Book 1Dokument6 SeitenBook 1Jaime WalkerNoch keine Bewertungen

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Von EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Bewertung: 3.5 von 5 Sternen3.5/5 (3)

- Annexure 4 - TransformerDokument36 SeitenAnnexure 4 - TransformerBala MNoch keine Bewertungen

- AHU Val ProtocolDokument53 SeitenAHU Val ProtocolPalani Arumugam100% (1)

- The Session Will Start at 13:05 and Will Be Recorded: Please Login To Socrative Student: Room Name: Weston3103Dokument21 SeitenThe Session Will Start at 13:05 and Will Be Recorded: Please Login To Socrative Student: Room Name: Weston3103EMILY BLANDFORDNoch keine Bewertungen

- SQ Mark & 100ppm ChecklistDokument14 SeitenSQ Mark & 100ppm Checklistkarpags100% (2)

- M.P. Projects STP Master Drawing List Sl. No. Drg. No - Drg. TitleDokument7 SeitenM.P. Projects STP Master Drawing List Sl. No. Drg. No - Drg. TitleShubhankar SharmaNoch keine Bewertungen

- Refrigeration and Air ConditioningDokument22 SeitenRefrigeration and Air ConditioningSiddhrajsinh ZalaNoch keine Bewertungen

- Package 1Dokument2 SeitenPackage 1abhipatel.6381Noch keine Bewertungen

- G3430 90015Dokument390 SeitenG3430 90015Simone GiacomelliNoch keine Bewertungen

- Trinity Biotech Amax 190-200 - Maintenance ChecklistDokument2 SeitenTrinity Biotech Amax 190-200 - Maintenance ChecklistDenis SinedNoch keine Bewertungen

- BG-QA-CL-304 - 10-13 Check List For HVACDokument5 SeitenBG-QA-CL-304 - 10-13 Check List For HVACYousaf Richu100% (1)

- What An Instrument Engineer Should KnowDokument2 SeitenWhat An Instrument Engineer Should KnowHutama Putra Wibawa75% (4)

- D04Dokument7 SeitenD04Ahmed SoomroNoch keine Bewertungen

- Hvac SpecificationsDokument46 SeitenHvac SpecificationsAnkush Nayar100% (1)

- ChecklistDokument12 SeitenChecklistAranab Ray100% (2)

- Commissioning Report For RectifierDokument29 SeitenCommissioning Report For RectifierAnujGarg100% (1)

- Toaz - Info Cat Compact Start Up and Commissioning Checklist PRDokument19 SeitenToaz - Info Cat Compact Start Up and Commissioning Checklist PRKhaled Naseem Abu-SabhaNoch keine Bewertungen

- Ishaq Instruction To Bidders - Rev0Dokument38 SeitenIshaq Instruction To Bidders - Rev0ishaq ahmedNoch keine Bewertungen

- LT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateDokument3 SeitenLT PANEL / PCC Checking List Dept: Electrical: Equipment Tag No: Incoming PCC Feeder No.: DateVelmurugan Chakkravarthy100% (4)

- Scan Trouble Code Tanpa ScannerDokument8 SeitenScan Trouble Code Tanpa Scannergene_t007233Noch keine Bewertungen

- Authority Prepared by Reviewed L1 Reviewed L2 Approved byDokument33 SeitenAuthority Prepared by Reviewed L1 Reviewed L2 Approved byASHXQ39WNoch keine Bewertungen

- 21th Floor Snag ListDokument1 Seite21th Floor Snag ListNedunuri.Madhav MurthyNoch keine Bewertungen

- Data Sheet & SLDDokument22 SeitenData Sheet & SLDvaithy2011100% (1)

- Technical Manual 2340 - 2540 EVPDokument85 SeitenTechnical Manual 2340 - 2540 EVPJessica MuellerNoch keine Bewertungen

- Shameerpokkadan CVDokument5 SeitenShameerpokkadan CVShameerNoch keine Bewertungen

- 5 6075454784649822363marineDokument21 Seiten5 6075454784649822363marineDatsun FernandesNoch keine Bewertungen

- FMEADokument2 SeitenFMEAHeidi Dedication Pader NicolasNoch keine Bewertungen

- Maintenance Dept Skill Audit (Sheet 1 of 3) : CompetencyDokument20 SeitenMaintenance Dept Skill Audit (Sheet 1 of 3) : CompetencylawidipoNoch keine Bewertungen

- Usa Dishwasher Tech. TrainingDokument68 SeitenUsa Dishwasher Tech. TrainingJostin Castillo Hurtado50% (2)

- 22th Floor Snag ListDokument1 Seite22th Floor Snag ListNedunuri.Madhav Murthy100% (1)

- Advanced User Guide - G3430-90015Dokument398 SeitenAdvanced User Guide - G3430-90015bert_avitia_1Noch keine Bewertungen

- Basic OperationDokument34 SeitenBasic OperationAshis & FndzNoch keine Bewertungen

- SATR-J-6505-Rev 0 PDFDokument5 SeitenSATR-J-6505-Rev 0 PDFAdel KlkNoch keine Bewertungen

- Oral ExaminationDokument14 SeitenOral ExaminationClarence Clar100% (2)

- Logsheet Housekeeping AmurangDokument21 SeitenLogsheet Housekeeping AmurangPandu RhiNoz RespatiNoch keine Bewertungen

- How To Prepare For Vetting Inspection in The Engine Room?Dokument4 SeitenHow To Prepare For Vetting Inspection in The Engine Room?saket007iNoch keine Bewertungen

- Diagnostic Codes: MitsubishiDokument12 SeitenDiagnostic Codes: Mitsubishiน้องกอย่า วงศ์เครือNoch keine Bewertungen

- Piping and Instrumentation Diagram DevelopmentVon EverandPiping and Instrumentation Diagram DevelopmentBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsVon EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Modern Assembly Language Programming with the ARM ProcessorVon EverandModern Assembly Language Programming with the ARM ProcessorNoch keine Bewertungen

- A Practical Guide to Maintenance EngineeringVon EverandA Practical Guide to Maintenance EngineeringBewertung: 4 von 5 Sternen4/5 (6)

- Plant Microsoft Office Word DocumentDokument2 SeitenPlant Microsoft Office Word DocumentShiva Prakasam PernetiNoch keine Bewertungen

- Fmea - Main Air CompressorDokument78 SeitenFmea - Main Air CompressorShiva Prakasam Perneti100% (1)

- Linto RDokument3 SeitenLinto RShiva Prakasam PernetiNoch keine Bewertungen

- Sivaprakasam ReDokument3 SeitenSivaprakasam ReShiva Prakasam PernetiNoch keine Bewertungen

- AC SparesDokument2 SeitenAC SparesShiva Prakasam PernetiNoch keine Bewertungen

- MCK Appointment LetterDokument1 SeiteMCK Appointment LetterShiva Prakasam PernetiNoch keine Bewertungen

- Rca SopDokument4 SeitenRca SopShiva Prakasam PernetiNoch keine Bewertungen

- BF Proper Thermocouple HistoryDokument67 SeitenBF Proper Thermocouple HistoryShiva Prakasam PernetiNoch keine Bewertungen

- R F Admittance Point Level Switch ' Rfa'.: Instruction & Maintenance Manual FORDokument4 SeitenR F Admittance Point Level Switch ' Rfa'.: Instruction & Maintenance Manual FORShiva Prakasam PernetiNoch keine Bewertungen

- 11 Failure Mode AnalysisDokument2 Seiten11 Failure Mode Analysisஎன் கருத்துNoch keine Bewertungen

- Elamax ReportDokument2 SeitenElamax ReportShiva Prakasam PernetiNoch keine Bewertungen

- Online Co MonitorDokument1 SeiteOnline Co MonitorShiva Prakasam PernetiNoch keine Bewertungen

- Equipment Tuning Procedure For BoilersDokument8 SeitenEquipment Tuning Procedure For BoilersShiva Prakasam PernetiNoch keine Bewertungen

- BF Proper ThermocouplesDokument2 SeitenBF Proper ThermocouplesShiva Prakasam PernetiNoch keine Bewertungen

- BF Top ValvesDokument1 SeiteBF Top ValvesShiva Prakasam PernetiNoch keine Bewertungen

- GCP Level Switch ReportDokument18 SeitenGCP Level Switch ReportShiva Prakasam PernetiNoch keine Bewertungen

- SH Ded InputDokument1 SeiteSH Ded InputShiva Prakasam PernetiNoch keine Bewertungen

- BF Hydraulic Do DetailsDokument5 SeitenBF Hydraulic Do DetailsShiva Prakasam PernetiNoch keine Bewertungen

- Cable Used For Redundency SupplyDokument2 SeitenCable Used For Redundency SupplyShiva Prakasam PernetiNoch keine Bewertungen

- GST P-9910B Handheld ProgrammerDokument15 SeitenGST P-9910B Handheld ProgrammeretchegarayfNoch keine Bewertungen

- BF Proper ThermocouplesDokument2 SeitenBF Proper ThermocouplesShiva Prakasam PernetiNoch keine Bewertungen

- BFRV and Chute Operation/Troubleshooting Method I. Servo Drive Start Up Procedure After Power FailureDokument5 SeitenBFRV and Chute Operation/Troubleshooting Method I. Servo Drive Start Up Procedure After Power FailureShiva Prakasam PernetiNoch keine Bewertungen

- List of ISO Standards PDFDokument20 SeitenList of ISO Standards PDFKristal Newton80% (5)

- Electrical 1Dokument1 SeiteElectrical 1Shiva Prakasam PernetiNoch keine Bewertungen

- Rules AMIE ExaminationDokument6 SeitenRules AMIE ExaminationAjesh kumarNoch keine Bewertungen

- Temperature Viscosity Viscosity Temperature ViscosityDokument12 SeitenTemperature Viscosity Viscosity Temperature ViscosityShiva Prakasam PernetiNoch keine Bewertungen

- BF Inst Mis Report December 2016Dokument30 SeitenBF Inst Mis Report December 2016Shiva Prakasam PernetiNoch keine Bewertungen

- Cable List For CranesDokument2 SeitenCable List For CranesShiva Prakasam PernetiNoch keine Bewertungen

- AMIE Section B Electrical SyllabusVVVVVDokument17 SeitenAMIE Section B Electrical SyllabusVVVVVShiva Prakasam PernetiNoch keine Bewertungen

- Electrical 1Dokument1 SeiteElectrical 1Shiva Prakasam PernetiNoch keine Bewertungen

- Peethas ListDokument1 SeitePeethas ListChetan PrajapatiNoch keine Bewertungen

- Igcse ReadingDokument4 SeitenIgcse ReadingIvonne PuspakencanaNoch keine Bewertungen

- CHEM333 Syllabus 2020 2021Dokument4 SeitenCHEM333 Syllabus 2020 2021lina kwikNoch keine Bewertungen

- MECH0018.1 Assignment 2 QP Fall 2021Dokument17 SeitenMECH0018.1 Assignment 2 QP Fall 2021saleem razaNoch keine Bewertungen

- Factory Program Library List v1.0Dokument9 SeitenFactory Program Library List v1.0Ronaldo DamattaNoch keine Bewertungen

- Methodology of Static Pile Load TestDokument33 SeitenMethodology of Static Pile Load Testraju_420034520100% (1)

- Listening DictationDokument3 SeitenListening DictationThảo ĐinhNoch keine Bewertungen

- HLN Applications enDokument27 SeitenHLN Applications enClint TcNoch keine Bewertungen

- Ultrasonic Inspection of Welds in Tubes & Pipes: Educational NoteDokument13 SeitenUltrasonic Inspection of Welds in Tubes & Pipes: Educational NoteleonciomavarezNoch keine Bewertungen

- At Your Service: Affordable LandscapingDokument1 SeiteAt Your Service: Affordable LandscapingDamaris HigginsNoch keine Bewertungen

- SCSM 2022 Runners Information GuideDokument36 SeitenSCSM 2022 Runners Information GuideDollar SurvivorNoch keine Bewertungen

- Vein Type DepositDokument7 SeitenVein Type DepositHarisArmadiNoch keine Bewertungen

- 365-M - City Bus Route & Timings, Bangalore (BMTC) Map, First & Last BusDokument10 Seiten365-M - City Bus Route & Timings, Bangalore (BMTC) Map, First & Last BusER Aditya DasNoch keine Bewertungen

- Basic Pancakes Recipe - Martha StewartDokument37 SeitenBasic Pancakes Recipe - Martha Stewartkrishna kumarNoch keine Bewertungen

- Desert Magazine 1957 DecemberDokument44 SeitenDesert Magazine 1957 Decemberdm1937Noch keine Bewertungen

- Measuring Salinity in Crude Oils Evaluation of MetDokument9 SeitenMeasuring Salinity in Crude Oils Evaluation of Metarmando fuentesNoch keine Bewertungen

- Dynamic Test Report of DECR-S Excitation Devices: ExperimenterDokument14 SeitenDynamic Test Report of DECR-S Excitation Devices: ExperimenterSalmanEjazNoch keine Bewertungen

- bNSG9000 Datasheet 2Dokument3 SeitenbNSG9000 Datasheet 2RobertNoch keine Bewertungen

- Paradise Lost Epic Poem by John MiltonDokument9 SeitenParadise Lost Epic Poem by John MiltonSotero PoreNoch keine Bewertungen

- Comparative Superlative With Key PDFDokument1 SeiteComparative Superlative With Key PDFAnonymous 8AHCMsPuNoch keine Bewertungen

- PTFE HZ-2 HoerbigerDokument2 SeitenPTFE HZ-2 HoerbigerТатьяна ВасильеваNoch keine Bewertungen

- Nfpa 13d 2007 IndexDokument3 SeitenNfpa 13d 2007 Indexsaladin1977Noch keine Bewertungen

- Anaerobic Degradation of Palm Oil Mill Ef Uent (POME)Dokument8 SeitenAnaerobic Degradation of Palm Oil Mill Ef Uent (POME)HusainiNoch keine Bewertungen

- Buku Murid Bahasa Inggris - Student's Book My Next Word For Elementary School Unit 10 - Fase BDokument8 SeitenBuku Murid Bahasa Inggris - Student's Book My Next Word For Elementary School Unit 10 - Fase BKeni KenizaNoch keine Bewertungen

- CEPF640/CEBF640 CEFF640: N-Channel Enhancement Mode Field Effect Transistor FeaturesDokument4 SeitenCEPF640/CEBF640 CEFF640: N-Channel Enhancement Mode Field Effect Transistor FeaturesAngel FaneitezNoch keine Bewertungen

- CTL Project Developer Perspective Coal - To - Liquids CoalitionDokument27 SeitenCTL Project Developer Perspective Coal - To - Liquids Coalitiondwivediashish2Noch keine Bewertungen

- Super GisDokument535 SeitenSuper GisNegrescu MariusNoch keine Bewertungen

- AdsfatreewerwertgdsfDokument1 SeiteAdsfatreewerwertgdsfJhonel AguilarNoch keine Bewertungen

- VF (Kyhkkjrh VK Qfozkkulalfkku) - F'KDS"K) MRRJK (K.M& 249201Dokument3 SeitenVF (Kyhkkjrh VK Qfozkkulalfkku) - F'KDS"K) MRRJK (K.M& 249201RajaNoch keine Bewertungen

- Flood RateDokument367 SeitenFlood RatetpktpkNoch keine Bewertungen