Beruflich Dokumente

Kultur Dokumente

Pm130 Plus

Hochgeladen von

Anonymous vcadX45TD7Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Pm130 Plus

Hochgeladen von

Anonymous vcadX45TD7Copyright:

Verfügbare Formate

PM130 PLUS Power met er Seri es

PM130P/PM130E/PM130EH

Inst allat ion and Operat ion Manual

BG0425 Rev. A11

2 PM130 PLUS Powermeters Series

LIMITEDWARRANTY

Themanufactureroffersthecustomera24-monthfunctionalwarrantyontheinstrumentfor

faultyworkmanshiporpartsfromdateofdispatchfromthedistributor.Inallcases,this

warrantyisvalidfor36monthsfromthedateofproduction.Thiswarrantyisonareturnto

factorybasis.

Themanufacturerdoesnotacceptliabilityforanydamagecausedbyinstrument

malfunction.Themanufactureracceptsnoresponsibilityforthesuitabilityoftheinstrument

totheapplicationforwhichitwaspurchased.

Failuretoinstall,setuporoperatetheinstrumentaccordingtotheinstructionshereinwill

voidthewarranty.

Onlyadulyauthorizedrepresentativeofthemanufacturermayopenyourinstrument.The

unitshouldonlybeopenedinafullyanti-staticenvironment.Failuretodosomaydamage

theelectroniccomponentsandwillvoidthewarranty.

Thegreatestcarehasbeentakentomanufactureandcalibrateyourinstrument.However,

theseinstructionsdonotcoverallpossiblecontingenciesthatmayariseduringinstallation,

operationormaintenance,andalldetailsandvariationsofthisequipmentarenotcovered

bytheseinstructions.

Foradditionalinformationregardinginstallation,operationormaintenanceofthis

instrument,contactthemanufactureroryourlocalrepresentativeordistributor.

WARNING

Readtheinstructionsinthismanualbeforeperforminginstallationandtake

noteofthefollowingprecautions:

EnsurethatallincomingACpowerandotherpowersourcesareturnedOFF

beforeperforminganyworkontheinstrument.ProtectthemeasurementACInputs

voltage(V1,V2,V3)with2Aexternalovercurrentprotectiondeviceandthepower

supplysourceinputswith5Aexternalovercurrentprotectiondevice,locatedclose

totheequipment.

Beforeconnectingtheinstrumenttothepowersource,checkthelabelsonthe

backoftheinstrumenttoensurethatyourinstrumentisequippedwiththe

appropriatepowersupplyvoltage,inputvoltagesandcurrents.Failuretodoso

mayresultinseriousorevenfatalinjuryand/orequipmentdamage.

Undernocircumstancesshouldtheinstrumentbeconnectedtoapower

sourceifitisdamaged.

Topreventpotentialfireorshockhazard,donotexposetheinstrumentto

rainormoisture.

Thesecondaryofanexternalcurrenttransformermustneverbeallowedtobe

opencircuitwhentheprimaryisenergized.Anopencircuitcancausehigh

voltages,possiblyresultinginequipmentdamage,fireandevenseriousorfatal

injury.Ensurethatthecurrenttransformerwiringissecuredusinganexternal

strainrelieftoreducemechanicalstrainonthescrewterminals,ifnecessary.

Onlyqualifiedpersonnelfamiliarwiththeinstrumentanditsassociatedelectrical

equipmentmustperformsetupprocedures.

Donotopentheinstrumentunderanycircumstanceswhenitisconnectedtoa

powersource.

Donotusetheinstrumentforprimaryprotectionfunctionswherefailureofthe

devicecancausefire,injuryordeath.Theinstrumentcanonlybeusedfor

secondaryprotectionifneeded.

Readthismanualthoroughlybeforeconnectingthedevicetothecurrentcarrying

circuits.Duringoperationofthedevice,hazardousvoltagesarepresentoninput

terminals.Failuretoobserveprecautionscanresultinseriousorevenfatalinjury

ordamagetoequipment.

Thisequipmentdoesnotrequirecleaningforproperoperation

Alltrademarksarepropertyoftheirrespectiveowners.Copyright2007

PM130 PLUS Powermeters Series 3

Quick Start Guide

Thissectioncanbeusedbyalicensedelectriciantoinstallandperform

basicPM130PLUSPowermetersetup.FormoredetailedPM130PLUS

setupanduseinstructions,seetheinstallationandoperationmanual

followingchapters.

Thisquickstartguidewillassistyoutohavetheunitrunningforthefirsttime.

DuringtheoperationofthePowermeter,hazardousvoltagesarepresentin

theinputterminals.Failuretoobserveprecautionscanresultinseriousor

evenfatalinjury,ordamagetoequipment.

Forcompleteandaccuratein-depthinstructions,refertothefollowing

chaptersinthismanual.

1. Installing the PM130 PLUS

Mounting the PM130 PLUS Unit

TomountthePM130PLUS:

1. PositionthePM130PLUSunitinthesquareorroundcutout.Iftwo

PLM130PLUSarepositionedsidebyside,takecareofproperinterval

betweenthem.

2. AttachthePM130PLUSunitusingwashersandnuts.Makesurethat

theunitissecurelyattachedintothewallorcabinetfixture.

MountingthePM130PLUS(SquareorRoundCut-out)

4 PM130 PLUS Powermeters Series

MountingtwoPM130PLUSsidebyside

2. Connecting the PM130 PLUS

ToconnectthePM130PLUS:

1. EnsurethatallincomingpowersourcesareOFF.

2. Checkthatyouhavetheappropriatepowersupply.

3. ConnecttotheexternalCTbypassingtheexternalCTwirethroughthe

meterCTcore.Observethearrowthatindicatesthecurrentdirection.

IncaseofaretrofitapplicationwhereeachexternalCTendswithtwo

wires:

PassonewirethroughthemeterCTcore.

Connectthewiretooneofthemeter

terminationscrews.

Connectthesecondwirefromtheexternal

CTtotheterminationscrew.

4.Connectthemeasuredvoltageinputs

5. ConnectCOM1RS-485communicationport

6. ConnectthePowerSupplyinputsusing1.5mm

2

/14AWG-dedicatedwires.

PM130 PLUS Powermeters Series 5

CommonWiringMode:4LL3or4L-n3

CTwiring

ToassembleOptionmodule:

7. Assemblethe4DI/2DOmodule.

8. Assemblethe4AOmodule.

9.AssembletheTOUmodule.

9. AssembletheETHmodule

10. AssemblethePROfibusmodule.

6 PM130 PLUS Powermeters Series

11. AssembletheRS-232/422-485module.

Assemblingmodule

12. PowerthePM130PLUSuniton.

TooperatethePM130PLUS:

13.Performdevicediagnostics.

14.ConfigurethedevicethroughthePM130PLUSunitfrontpaneldisplays.

3. Configuring the PM130 PLUS remotely

1. InstallthePASapplicationsoftwareonyourPC.

2. ConfigurethePASdatabase.

3. Configurethecommunicationssettings.

4. SetupthemeteronyourPCusingthePASapplicationsoftware.

5. ConfigureyoursecuritysettingsthroughtheAuthorizationdialogbox.

6. ConfigureSummaryEnergyandTOUregisters.

7. ConfiguretheModbuspointmapping.

8. Changethe32-bitregisterformat.

9.ConfigureDNP3.

10.Configureremoteaccess.

11.Upgradeyourfirmwareifanewversionisavailable.

12Atthisstage,thePM130PLUSshouldbereadyforoperation.

PM130 PLUS Powermeters Series 7

Table of Contents

Chapter 1 General Information............................................. 10

1.1 Features...........................................................................................11

1.2 Available Options ..............................................................................12

1.2.1 Digital I/O Option.........................................................................................12

1.2.2 Analog Output Option...................................................................................12

1.2.3 Additional Communication Port Option COM2..............................................12

1.2.4 TOU - Battery-Operated Clock Unit Option.....................................................12

1.3 Customized Options...........................................................................13

1.3.1 Device Resolution.........................................................................................13

1.3.2 Energy Rollover............................................................................................13

1.3.3 Display Options............................................................................................13

Chapter 2 Installation........................................................... 16

2.1 Site Requirements.............................................................................16

2.2 Package Contents .............................................................................16

2.3 Mechanical Installation......................................................................17

2.3.1 Panel Mounting............................................................................................18

2.3.2 DIN Rail Mounting........................................................................................19

2.4 Electrical Installation.........................................................................20

2.4.1 Typical Installation.......................................................................................20

2.4.2 Terminals ....................................................................................................21

2.4.3 Power Source Connection.............................................................................21

2.4.4 Voltage Input connection..............................................................................22

2.4.5 Current Input Connection .............................................................................22

2.4.6 Wiring Diagrams ..........................................................................................23

2.5 I/O Connections................................................................................28

2.5.1 4DI/2DO Module..........................................................................................28

2.5.2 4AO Module - Analog Outputs.......................................................................30

2.5.3 TOU module RTC and 4 Digital Inputs ........................................................31

2.6 Communications Connections.............................................................32

2.6.1 COM1 RS-485 Connection.............................................................................33

2.6.2 ETH module COM2 Ethernet Connection.....................................................34

2.6.3 PRO module COM2 Profibus Connection......................................................35

2.6.4 RS-232/422-485 module COM2 Connection.................................................36

Chapter 3 Display Operations............................................... 38

3.1 Indicators and Controls......................................................................38

3.1.1 Device Diagnostics .......................................................................................38

3.1.2 Numeric LED Display....................................................................................38

3.1.3 Load Bar Graph............................................................................................39

3.1.4 Energy Pulse LED.........................................................................................39

3.1.5 Port Activity LEDs.........................................................................................39

3.1.6 Navigation Buttons.......................................................................................39

3.2 Data Display.....................................................................................40

3.2.1 Display Features...........................................................................................40

3.2.2 Navigation Buttons.......................................................................................41

3.2.3 Simple Reset of Accumulated Data................................................................42

3.2.4 Common Measurements Display....................................................................42

3.2.5 Min/Max and Maximum Demand Display........................................................43

3.2.6 Harmonics Display........................................................................................44

3.2.7 Energy Display.............................................................................................45

3.3 Status Display...................................................................................47

8 PM130 PLUS Powermeters Series

3.3.1 Pulse and Time Counters..............................................................................48

3.3.2 Alarm Display...............................................................................................49

3.3.3 Diagnostics Display.......................................................................................49

3.4 Using the Menus...............................................................................50

3.4.1 Navigation Buttons.......................................................................................50

3.4.2 Selecting Menus...........................................................................................50

3.4.3 Entering the Password..................................................................................51

3.4.4 Selecting a Menu Entry.................................................................................52

3.4.5 Viewing and Changing Setup Items...............................................................52

3.5 Menu Operations...............................................................................53

3.5.1 Basic Device Settings....................................................................................53

3.5.2 Device Options.............................................................................................54

3.5.3 Communication Ports....................................................................................56

3.5.4 Network Address..........................................................................................57

3.5.5 Digital Input Setup.......................................................................................58

3.5.6 Relay Output Setup......................................................................................60

3.5.7 Counters Setup............................................................................................62

3.5.8 Alarm/Control Setpoints Setup......................................................................63

3.5.9 Analog Outputs Setup...................................................................................65

3.5.10 Display Setup.............................................................................................66

3.5.11 Meter Security............................................................................................68

3.5.12 Setting the Device Clock.............................................................................69

3.5.13 Resetting Accumulators and Maximum Demands..........................................70

Chapter 4 PAS Application Software..................................... 72

4.1 Configuring the Database ..................................................................72

4.2 Setting up Communications................................................................73

4.2.1 Communicating through a Serial Port.............................................................74

4.2.2 Communicating through the Internet.............................................................75

4.3 Setting Up the Meter .........................................................................76

4.3.1 Downloading Setup to the Meter ...................................................................77

4.3.2 Uploading a Setup from the Meter.................................................................78

4.4 Authorization....................................................................................78

4.5 Configuring Communications in the Meter ...........................................78

4.5.1 Setting Up Communication Ports...................................................................78

4.5.2 Setting Up Ethernet......................................................................................80

4.6 General Meter Setup..........................................................................81

4.6.1 Basic Meter Setup........................................................................................81

4.6.2 Device Options.............................................................................................83

4.6.3 Local Settings ..............................................................................................85

4.6.4 Using Digital Inputs......................................................................................86

4.6.5 Using Relay Outputs.....................................................................................88

4.6.6 Programming Analog Outputs .......................................................................89

4.6.7 Using Counters.............................................................................................92

4.6.8 Using Control Setpoints ................................................................................93

4.7 Configuring Summary Energy and TOU Registers.................................95

4.7.1 Setting up Total and Tariff Registers .............................................................96

4.7.2 Configuring the Daily Tariff Schedule.............................................................97

4.7.3 Configuring the Season Tariff Schedule..........................................................98

4.8 Configuring Communication Protocols.................................................99

4.8.1 Configuring Modbus ................................................................................... 100

4.8.2 Configuring DNP3....................................................................................... 101

4.9 Remote Device Control ....................................................................103

4.9.1 Remote Relay Control................................................................................. 103

4.9.2 Device Diagnostics ..................................................................................... 104

4.9.3 Resetting Accumulators.............................................................................. 105

4.9.4 Updating the Clock..................................................................................... 106

4.10 Administration...............................................................................106

PM130 PLUS Powermeters Series 9

4.10.1 Changing a Password ............................................................................... 106

4.11 Upgrading Device Firmware............................................................107

4.12 Monitoring Your Meters..................................................................109

4.12.1 Viewing Real-time Data............................................................................. 109

4.12.2 Viewing Min/Max Log................................................................................ 109

4.12.3 Viewing Real-time Waveforms................................................................... 110

4.12.4 Viewing Harmonic Spectrum and Synthesized Waveforms........................... 110

Appendix A Technical Specifications................................... 115

Appendix B Analog Output Parameters.............................. 122

Appendix C Setpoint Triggers and Actions.......................... 123

Appendix D Parameters for Data Monitoring...................... 125

Appendix E Data Scales ...................................................... 132

Appendix F Device Diagnostic Codes.................................. 133

Designations used in the manual:

EH - available in the PM130EH

E - available in the PM130E

Chapter 1General Information

10 PM130 PLUS Powermeters Series

Chapter 1 General Information

ThePM130PLUSPowermeterseriesisacompact,multi-function,three-phaseAC

powermeterspeciallydesignedtomeettherequirementsofusersrangingfrom

electricalpanelbuilderstosubstationoperators.

ThePM130PLUSPowermeterseriesmeasuringandpowersupplyinputs

complywithMeasuringCategoryII

ThePM130PLUSPowermeterSeriescomprisesoftwotypesofmodels:

PM130P:thebasicmodelwhichoffersstandardvoltage,current,powerand

frequencymeasurements,andcontrolcapabilities

PM130E:offersallthefeaturesofthebasicmodelplusenergymeasurements

PM130EH:offersallthefeaturesofthebasicmodelplusenergymeasurements

andharmonicanalysiscapabilities.

ThePM130PLUSPowermeterSeriesunitsinclude:

Abright3-rowLEDdisplayenablingeasyreadingoflocalmeters.

AstandardRS-485communicationportandasecondoptionalEthernetor

Profibusport.Theseportsallowlocalandremoteautomaticmeterreadingsand

setupthroughthesupplementalcommunicationoruserdataacquisitionsoftware.

Differentcommunicationoptionsforremotecommunicationswiththemeter.

TheseoptionsenableLANandInternetcommunicationwiththeunit.

Bothmodelsaresuitableformountingonboth4-inchroundand92x92mmsquare

cutouts.

Chapter 1General Information

PM130 PLUS Powermeters Series 11

1.1 Features

ThePM130PLUSPowermeterSeriesincludesthefollowingfeaturesand

functionalities:

3voltageinputsand3currenttransformer-isolatedACinputsfordirect

connectiontopowerlineorviapotentialandcurrenttransformers

Amulti-function3-phasemeter(trueRMS,volts,amps,power,powerfactor,

neutralcurrent,voltage,andcurrentunbalance,frequency)

Anembeddedharmonicanalyzer,voltageandcurrentTHD,currentTDDandK-

Factor,upto40thorderharmonic(PM130EH)

Real-timescopemodewaveformmonitoringcapability;simultaneous6-channel

one-cyclewaveformcaptureatarateof64samplespercycle

Voltageandcurrentharmonicspectrumandangles(PM130EH)

AnAmpere/Voltdemandmeter

Class0.5Sfour-quadrantenergymeter;three-phasetotalandperphaseenergy

measurements;active,reactiveandapparentenergycounters(PM130Eand

PM130EH)

Time-of-Use,4totalizationandtariffenergy/demandregistersx4tariffs,4

seasonsx4typesofdays,8tariffchangesperday,easyprogrammabletariff

schedule(PM130EandPM130EHwithTOUplug-inmodule)

Embeddedprogrammablecontroller;16controlsetpoints;programmable

thresholdsanddelays;relayoutputcontrol(seetheOrderOptionssection);1-

cycleresponsetime

Easytoread3-row(2x4characters+1x5characters)brightLEDdisplay,

adjustableupdatetimeandbrightness,auto-scrolloptionwithadjustablepage

expositiontime,auto-returntoadefaultpage

LEDbargraphshowingpercentloadwithrespecttouser-definablenominalload

current

25/50/60/400Hzmeasurementcapabilities

Internalclockwitha30-secondbackup;optionalbattery-backedclockunitwith6-

monthretentiontime,seetheOrderOptionssection

Standard2-wireRS-485communicationport;ModbusRTU,DNP3,and

proprietaryASCIIcommunicationprotocols

Optionalsecondcommunicationport,seetheOrderOptionssection

Easy-to-upgradefielddevicefirmwarethroughthecommunicationport.

Chapter 1General Information

12 PM130 PLUS Powermeters Series

1.2 Available Options

ThePM130canbeprovidedwithanoptionalsingleexpansionmodulefromthe

followinglist:

DigitalI/O

Analogoutputs

Ethernetcommunicationport

ProfibusDPcommunicationport

TOU-Battery-operatedclockunit

RS-232orRS-422/485communicationport

1.2.1 Digital I/ O Option

ThePM130digitalI/Oexpansionmoduleprovides:

4drycontactdigitalinputs(DI)tomonitorexternalcontacts,andreceivepulses

fromenergy,water,andgasmeters

Programmablede-bouncetime;1-msscantime.

2electro-mechanicalorsolid-staterelayoutputs(RO)foralarmsandcontrols,

andforoutputenergypulses;unlatched,latchedandpulseoperations,failsafe

operationforalarmnotifications;programmablepulsewidth;directremoterelay

controlthroughcommunications;1-cycleupdatetime.

1.2.2 Analog Output Option

ThePM130analogoutput(AO)expansionmoduleprovides:

4opticallyisolatedanalogoutputswithaninternalpowersupply;optionsfor

0-20mA,4-20mA,0-1mA,and1mAoutput;1-cycleupdatetime.

1.2.3 Additional Communication Port Option COM2

AsecondCOM2communicationportcanbeorderedasanexpansionmodule.

COM2communicationportoptionsavailable:

Ethernet10/100BaseT

ProfibusDP

RS-232orRS-422/485port

Communicationprotocolsavailable:Modbus/TCP,DNP3/TCP,ProfibusDP.

1.2.4 TOU - Battery-Operated Clock Unit Option

ThePM130TOUmoduleprovides:

Anoptionalpreciseinternalclockwithabackupbatterycanbeordered,asan

alternatepowersourcefortheclockmetertomaintainthecurrenttimeanddate

Chapter 1General Information

PM130 PLUS Powermeters Series 13

foratleast36monthswhilethemainpowerismissing.

TheTOUoptionisonlyavailableinthepresenceofthebatterybackupunit.

4drycontactdigitalinputs(DI)formonitoringexternalcontacts,andreceiving

pulsesfromenergy,waterandgasmeters;programmablede-bouncetime;1-ms

scantime.

1.3 Customized Options

Presentationofdataonthefrontdisplayandviacommunicationscanbecustomized

tobestsuittheuserapplication.

1.3.1 Device Resolution

Aloworhigh-resolutionoptioncanbeselectedforthepresentationofvoltage,

current,andpowerforuseinhighandlowpowerapplications.SeeMeasurement

Unitsformoreinformation.

1.3.2 Energy Rollover

Theenergyrolloverlimitcanbechangedinthemetertoprovide4-digitto9-digit

energyresolution.SeeDeviceOptionsinChapter3fordetails.Themeterdisplayis

capableofshowingfull9-digitenergycountersusingtwoLEDwindows.

1.3.3 Display Options

Differentdisplayoptionsareavailableforcustomizationtobeusedindarkornon-

safelocations,orinplacesthatarehardlyaccessibleforobservation.SeeDisplay

SetupinChapter3formoreinformation.

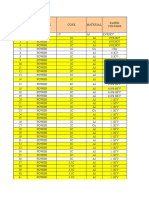

Table 1: Measured and Displayed Parameters

Parameter Display Comm. Analog Pulse Alarm

1-cycle Real-time Measurements

RMS Voltage per phase

RMS Current per phase

kW per phase

kvar per phase

kVA per phase

Power Factor per phase

Total kW

Total kvar

Total kVA

Frequency

Neutral Current

Total Power Factor

Voltage & Current unbalance

1-sec Average Measurements

RMS Voltage per phase

RMS Current per phase

kW per phase

kvar per phase

kVA per phase

Power Factor per phase

Total kW

Total kvar

Chapter 1General Information

14 PM130 PLUS Powermeters Series

Parameter Display Comm. Analog Pulse Alarm

Total kVA

Total Power Factor

Frequency

Neutral Current

Voltage & Current unbalance

Amps & Volt Demands

Ampere & Volt Demand per phase

Ampere Maximum Demand per phase

Voltage Maximum Demand per phase

Power Demands

E, EH

kW Accumulated Demand Import & Export

kvar Accumulated Demand Import & Export

kVA Accumulated Demand

kW Demand Import & Export

kvar Demand Import & Export

kVA Demand

kW Sliding Demand Import & Export

kvar Sliding Demand Import & Export

kVA Sliding Demand

kW Predicted Demand Import & Export

kvar Predicted Demand Import & Export

kVA Predicted Demand

kW Maximum Demand Import

kW Maximum Demand Export

kvar Maximum Demand Import

kvar Maximum Demand Export

kVA Maximum Demand

Total Energy

E, EH

Total kWh Import & Export

Total kvarh Import & Export

Total kvarh Net

Total kVAh

Energy per Phase

E, EH

kWh Import per phase

kvarh Import per phase

kVAh per phase

TOU Registers

E, EH

4 TOU energy registers (kWh and kvarh

import & export, kVAh, 4 pulse sources)

4 TOU maximum demand registers

4 tariffs, 4 seasons x 4 types of day

Harmonic Measurements

EH

Voltage THD per phase

Current THD per phase

Current TDD per phase

K-factor per phase

Voltage harmonics per phase up to order 40

Current harmonics per phase up to order 40

Voltage harmonic angles up to order 40

Current harmonic angles up to order 40

Fundamental Component

EH

Voltage and Current per phase

kW, PF per phase

kvar, KVA per phase

Total kW, PF

Total kvar, KVA

Min/ Max Logging

Min/Max A, V, total kW, kvar, kVA, PF

Min/Max Frequency, Neutral current

Chapter 1General Information

PM130 PLUS Powermeters Series 15

Parameter Display Comm. Analog Pulse Alarm

Phase Rotation

Voltage and Current Phase Angles

Day and Time

Pulse Counters

Digital I nputs (optional)

Relay Outputs (optional)

Remote Relay Control (optional)

Alarm Triggers/ Setpoints

Self-diagnostics

Chapter 2Installation

16 PM130 PLUS Powermeters Series

Chapter 2 Installation

ThischapterdiscussesthefollowingtypesofphysicalinstallationsforthePM130

PLUSPowermeter:

MechanicalInstallation

ElectricalInstallation

I/OConnections

COMPortConnections.

2.1 Site Requirements

SeeTechnicalSpecificationsinAppendixAformoredetails

Environmentalconditions:asspecifiedinTechnicalSpecificationsinAppendixA

Electricalrequirements:asspecifiedinTechnicalSpecificationsinAppendixA

2.2 Package Contents

ThePM130PLUSPowermeterpackagecontainsthefollowingitems:

PM130PLUSPowermeterunit

TechnicalDocumentationCD

Optionalaccessories(dependingontheoptionsordered,ifany)

Cables

Chapter 2Installation

PM130 PLUS Powermeters Series 17

2.3 Mechanical I nstallation

Refertothefiguresprovidedinthissectiontoproperlyperformthemechanical

installation.

Figure 2-1. Dimensions

Chapter 2Installation

18 PM130 PLUS Powermeters Series

2.3.1 Panel Mounting

Tomountthemeterincutout(ANSI4"roundorDIN92x92mmsquarecutout):

1. Positionthemeterinthecutout.

2. Affixthemeterusingwashersandnuts.(AddshorttextonPanelMounting,a

headingshouldalwayshavetext)

Figure 2-2. Mounting

Chapter 2Installation

PM130 PLUS Powermeters Series 19

2.3.2 DIN Rail Mounting

ThePM130canbemountedona35-mmDINrail.

Figure 2-3. Dimensions

Figure 2-4. DI N Rail Mounting

Chapter 2Installation

20 PM130 PLUS Powermeters Series

2.4 Electrical Installation

Theequipmentinstallationshallconformtothefollowinginstructions:

a)aswitchorcircuit-breakershallbeincludedinthebuildinginstallation;

b)Itshallbeincloseproximitytotheequipmentandwithineasyreach

oftheOPERATOR;

c)Itshallbemarkedasthedisconnectingdevicefortheequipment.

Beforeinstalling,ensurethatallincomingpowersourcesareshutOFF.

Failuretoobservethispracticecanresultinseriousorevenfatalinjury

anddamagetoequipment.

2.4.1 Typical Installation

Figure 2-5. Typical I nstallation Diagram

Chapter 2Installation

PM130 PLUS Powermeters Series 21

2.4.2 Terminals

Figure 2-6. Terminals - Rear View

2.4.3 Power Source Connection

Theequipmentinstallationshallconformtothefollowinginstructions:

a)aswitchorcircuit-breakershallbeincludedinthebuildinginstallation;

b)Itshallbeincloseproximitytotheequipmentandwithineasyreach

oftheOPERATOR;

c)Itshallbemarkedasthedisconnectingdevicefortheequipment.

Beforeinstalling,ensurethatallincomingpowersourcesareshutOFF.

Failuretoobservethispracticecanresultinseriousorevenfatalinjury

anddamagetoequipment.

Thepowersourcecanbeadedicatedfuse,oramonitoredvoltageifitiswithinthe

instrumentpowersupplyrange.

ToconnectanACpowersupply:

1. ConnecttheLinewiretoterminalL/+.

2. ConnecttheNeutralwiretoterminalN/-.

ToconnecttoaDCpowersupply:

1. ConnectthepositivewiretoterminalL/+

2. ConnectthenegativewiretoterminalN/-.

Chapter 2Installation

22 PM130 PLUS Powermeters Series

2.4.4 Voltage Input connection

Theequipmentinstallationshallconformtothefollowinginstructions:

a)aswitchorcircuit-breakershallbeincludedinthebuildinginstallation;

b)Itshallbeincloseproximitytotheequipmentandwithineasyreach

oftheOPERATOR;

c)Itshallbemarkedasthedisconnectingdevicefortheequipment.

Beforeinstalling,ensurethatallincomingpowersourcesareshutOFF.

Failuretoobservethispracticecanresultinseriousorevenfatalinjury

anddamagetoequipment.

690VInputs(Standard):

V

1

V

2

V

N

V

3

V

1

V

2

V

3

Voltages

690

690

690 400

400

400

690Vinputsareusuallyusedwithdirectconnection.Useanyofthesevenwiring

configurationsshowninFigures2-8through2-15.

120VInputs(OptionU):

V

1

V

2

V

N

V

3

V

1

V

2

V

3

Voltages

120

120

120 120

120

120

120Vinputsusuallyimplyuseofapotentialtransformer(PT).ThePTrequiresuse

ofanyofthefourwiringconfigurationsshowninFigures2-7through2-10.

2.4.5 Current Input Connection

ThePM130 doesnothavecurrentterminals.

ToconnecttotheexternalCT,passtheexternalCTwirethroughthemeterCTcore,

seeFigure 2-7fordetailsandobservethearrowthatindicatesthecurrentdirection.

IncaseofaretrofitapplicationwhereeachexternalCTendswithtwowires:

1. PassonewirethroughthemeterCTcore.

Chapter 2Installation

PM130 PLUS Powermeters Series 23

2. Connectthewiretooneofthemeter

terminationscrews.

3. ConnectthesecondwirefromtheexternalCT

totheterminationscrewtoclosetheloop.

Figure 2-7. Current Input Connection

2.4.6 Wiring Diagrams

ForACinputratings,seeTechnicalSpecificationsinAppendixAformoredetails.

Table2presentstheavailablewiringconfigurationsinthemeter.Formoredetails,

see Basic Device Settings in Chapter 3.

Table 2: Wiring Configurations

Wiring Configuration Setup Code Figure

3-wire 2-element Direct connection using 2 CTs 3dir2 2-8

4-wire Wye 3-element direct connection using 3 CTs 4Ln3 or 4LL3 2-9

4-wire Wye 3-element connection using 3 PTs, 3 CTs 4Ln3 or 4LL3 2-10

3-wire 2-element Open Delta connection using 2 PTs, 2 CTs 3OP2 2-11

4-wire Wye 2 -element connection using 2 PTs, 3 CTs 3Ln3 or 3LL3 2-12

3-wire 2 -element Open Delta connection using 2 PTs, 3 CTs 3OP3 2-13

4-wire 3-element Delta direct connection using 3 CTs 4Ln3 or 4LL3 2-14

3-wire 2-element Broken Delta connection using 2 PTs, 3 CTs 3bLn3 or 3bLL3 2-15

Chapter 2Installation

24 PM130 PLUS Powermeters Series

Figure 2-8. 3-Wire 2-Element Direct Connection Using 2 CTs - Wiring Mode = 3dir2

Figure 2-9. 4-Wire Wye 3-Element Direct Connection Using 3 CTs - Wiring Mode = 4LL3 or 4Ln3

Chapter 2Installation

PM130 PLUS Powermeters Series 25

Figure 2-10. 4-Wire Wye 3-Element Connection Using 3 PTs, 3 CTs - Wiring Mode = 4LL3 or 4Ln3

Figure 2-11. 3-Wire 2-Element Open Delta Connection Using 2 PTs, 2 CTs - Wiring Mode = 3OP2

Chapter 2Installation

26 PM130 PLUS Powermeters Series

Thisconfigurationprovidesaccuratepowermeasurementsonlyifthevoltagesarebalanced.

Figure 2-12. 4-Wire Wye 2-Element Connection Using 2 PTs, 3 CTs - Wiring Mode = 3LL3 or 3Ln3

Figure 2-13. 3-Wire Open 2-Element Delta Connection Using 2 PTs, 3 CTs - Wiring Mode = 3OP3

Chapter 2Installation

PM130 PLUS Powermeters Series 27

Figure 2-14. 4-Wire 3-Element Delta Direct Connection Using 3 CTs - Wiring Mode = 4LL3 or 4Ln3

Figure 2-15. 3-Wire 2-Element Broken Delta Connection Using 2 PTs, 3 CTs - Wiring Mode =

3bLn3 or 3bLL3

Chapter 2Installation

28 PM130 PLUS Powermeters Series

2.5 I / O Connections

BeforeI/OModuleinstallationensurethatallincomingpowersources

areshutOFF.Failuretoobservethispracticecanresultinseriousor

evenfatalinjuryanddamagetoequipment.

Figure 2-16. Module with Cover Before Module Assembly

ForI/Oratings,seeTechnicalSpecificationsinAppendixA.

2.5.1 4DI/ 2DO Module

Figure 2-17. 4DI/ 2DO Module Assembly

2.5.1.1 Relay Outputs

Therearetworelayoutputsprovidedforenergypulsing,alarms,orremotecontrol.

Figure 2-18. Relay Output Connection

Chapter 2Installation

PM130 PLUS Powermeters Series 29

2.5.1.2 Digital Inputs

Fouropticallyisolatedstatusinputsareprovidedforstatusmonitoring,pulse

counting,externalpowerdemandperiod,andtimesynchronization.

Figure 2-19. Digital Input Connection

Chapter 2Installation

30 PM130 PLUS Powermeters Series

2.5.2 4AO Module - Analog Outputs

The4AOmodulehasfouropticallyisolatedanalogoutputswithaninternalpower

supplyandcurrentoutputoptionsof0-20mAand4-20mA(currentlooploadofup

to500Ohm),0-1mAand1mA(2mA100%overload,currentlooploadofupto5

kOhm).

Figure 2-20: Analog Output Connection

ItisrecommendedtoconnectunusedAnalogoutputchannelsto

Commonterminal.

The4AOmoduleTERMINALisforuseonlywithequipmentwhich

hasnolivepartswhichareACCESSIBLE

TheRATINGoftheinsulationoftheexternalequipmentforuse

withthe4AOmodule,shallcomplyaccordingtoInstallation

CategoryIIforinsulationtobesuitableforSINGLEFAULT

CONDITION

TheexternalequipmentTERMINALconnectiontypeisnormally

terminalblockforwiresize14AWG(upto1.5mm2)

ThetypeofequipmentthatmightbeconnectedtotheTERMINAL

is:

ProgrammableLogicControllerforautomationPLC

DigitalorAnalogmeter

Chapter 2Installation

PM130 PLUS Powermeters Series 31

2.5.3 TOU module RTC and 4 Digital Inputs

TheTOUprovidesabattery-operatedrealtimeclock(RTC)withfouroptically

isolatedinputsforstatusmonitoring,timesynchronization,pulsecounting,and

externalpowerdemandperiod.

2.5.3.1 Digital Inputs

Figure 2-21: TOU Digital Input Connection

2.5.3.2 TOU Battery Replacement

WARNING!

Onlyqualifiedpersonnelfamiliarwiththeinstrumentanditsassociatedelectrical

equipmentmustperformtheRTCbatterybackupreplacement.

ToreplacetheCR1632RTCbattery:

1. RemovetheTOUmodulefromthePM130

PLUScompartment

2. OpentheTOUMODULEcasebyapplyinga

flatscrewdriveratthreesnap-inslit(1,2and

3),asshowninFigure 2-22.

3. Removetheoldbatterybyliftingupthebattery

holderretractabletab.

4. PlacethenewCR1632batteryintothebattery

holderwhileholdingupthebatteryholder

retractabletabinsuchawaythatthe(+)

batterypoleistowardthebatteryholder,as

showninFigure 2-22.

Chapter 2Installation

32 PM130 PLUS Powermeters Series

Figure 2-22: TOU RTC Battery Replacement

2.6 Communications Connections

BeforeinstallingtheCommunicationModule,ensurethatallincoming

powersourcesareshutOFF.Failuretoobservethispracticecanresult

inseriousorevenfatalinjuryanddamagetoequipment.

SeveralcommunicationoptionsareavailableforthePM130:

COM1:RS-485

COM2:

Ethernet10/100BaseT

ProfibusDP

RS-232orRS-422/485

AconnectiontotheEthernetconnectorismadethroughacableadaptorprovided

withyourmeter.

AfulldescriptionofthecommunicationprotocolsisfoundinthePM130protocol

guidesthatcomewithyourmeter.

Chapter 2Installation

PM130 PLUS Powermeters Series 33

2.6.1 COM1 RS-485 Connection

Figure 2-23: COM1 RS-485 2-Wire Connection

Theconnectorisremovablewithacaptured-wireand3terminals.

Chapter 2Installation

34 PM130 PLUS Powermeters Series

2.6.2 ETH module COM2 Ethernet Connection

Figure 2-24: COM2 Ethernet Connection

TheETHmoduleTERMINALisforuseonlywithequipmentwhich

hasnolivepartswhichareACCESSIBLE

TheRATINGoftheinsulationoftheexternalequipmentforuse

withtheETHmodule,shallcomplyaccordingtoInstallation

CategoryIIforinsulationtobesuitableforSINGLEFAULT

CONDITION

TheexternalequipmentTERMINALconnectiontypeisRJ-45

ThetypeofequipmentthatmightbeconnectedtotheTERMINAL

is:

PersonalComputerPCorLAPTOP

10/100Base-TLANHUBand/orSwitch

Chapter 2Installation

PM130 PLUS Powermeters Series 35

2.6.3 PRO module COM2 Profibus Connection

Figure 2-25: COM2 Profibus Connection

ThePROmoduleTERMINALisforuseonlywithequipmentwhich

hasnolivepartswhichareACCESSIBLE

TheRATINGoftheinsulationoftheexternalequipmentforusewith

thePROmodule,shallcomplyaccordingtoInstallationCategoryII

forinsulationtobesuitableforSINGLEFAULTCONDITION

TheexternalequipmentTERMINALconnectiontypeisDB9

ThetypeofequipmentthatmightbeconnectedtotheTERMINAL

is:

ProgrammableLogicControllerforautomationPLC

Chapter 2Installation

36 PM130 PLUS Powermeters Series

2.6.4 RS-232/ 422-485 module COM2 Connection

Figure 2-26: COM2 RS-232 connection

Figure 2-27: COM2 RS-422/ 485 connection

Chapter 2Installation

PM130 PLUS Powermeters Series 37

TheRS-232/422-485moduleTERMINALSareforuseonlywith

equipmentwhichhasnolivepartswhichareACCESSIBLE

TheRATINGoftheinsulationoftheexternalequipmentforusewith

TheRS-232/422-485module,shallcomplyaccordingtoInstallation

CategoryIIforinsulationtobesuitableforSINGLEFAULT

CONDITION

TheexternalequipmentTERMINALconnectiontypeisnormally

terminalblockforwiresize14AWG(upto1.5mm)RS-422/485

portandDB9male-to-femalecablemorethan22AWG(0.3mm)

ThetypeofequipmentthatmightbeconnectedtotheTERMINAL

is:

PersonalComputerPCorLAPTOP

Chapter 3Display Operations

38 PM130 PLUS Powermeters Series

Chapter 3 Display Operations

ThischapterprovidesPM130PLUSPowermeterseriesfrontpanelinformation,

defaultsettings,andoperatingprocedures.

Figure 3-1: PM130 PLUS Unit

3.1 I ndicators and Controls

3.1.1 Device Diagnostics

Afterapplyingpowertothemeter,aone-digitstart-updiagnosticcodeisshownfor1

secondonallLEDs.Code8indicatesanormalpower-upsequence.Youcan

observethelistofdevicediagnosticcodesrecordedduringrestartandmeter

operationviatheStatusDisplay.

Whenthemeterrecordsadiagnosticmessage,thediagnosticiLEDflashesuntil

youresetthedevicediagnosticsviatheStatusDisplay.ThediagnosticLEDcanbe

disabledorenabledviatheDisplaySetupmenu.

3.1.2 Numeric LED Display

Themeterhasasimpleuserinterfacethatallowsyoutoviewnumerous

measurementparametersbyscrollingthroughdifferentdisplaypages.Thenumeric

LEDdisplayshowsuptothreeparametersatatime.Smallrectangularorround

LEDsattherightandbelowthedisplayindicatethedisplayedparametersandtheir

measurementunits.

Thedisplaylayoutmaychangedependingonthemetertypeandmodeofoperation.

Chapter 3Display Operations

PM130 PLUS Powermeters Series 39

Therearethreemodesofdisplayoperation:

Datadisplay

Statusdisplay

Programmingmodedisplay.

3.1.3 Load Bar Graph

Theloadbargraphdisplaystheamount,inpercent(40%to110%),ofthepresent

currentloadwithrespecttouser-definednominalloadcurrent.Thereference

nominalcurrentcanbesetupinampsthroughtheDisplaySetupmenu.Ifitissetto

0(default),thecurrentloadisreferencedtothespecifiedCTprimarycurrent.

3.1.4 Energy Pulse LED

ThePM130EandPM130EHhavearedEnergyPulseLED.Itflashesataconstant

ratewhenaloadisappliedtothemeter.

TherearetwomodesofLEDoperation:

Normalmode:theLEDpulsesindicateimportedWhatarateof1,000pulsesper

kWh

Testmode:theLEDpulsesindicateeitherimportedWh,orimported(inductive)

varhatarateof10,000pulsesperkWh/kvarh

TheenergytestmodecanbeenabledthroughtheDeviceOptionsmenu.When

intestmode,theenergyanddemandaccumulatorsdonotaccountforconsumed

energy.

3.1.5 Port Activity LEDs

ThemeterhastwogreenLEDsRXandTX,whichindicateactivityontheCOM1

communicationport.TheLEDsflashwhentheportisreceivingortransmittingdata.

3.1.6 Navigation Buttons

ThePM130isprovidedwithsixpushbuttonsthatarenormallyusedtonavigate

betweendifferentmeasurementdisplays.

Inprogrammingmode,thebuttonsaccessthedevicesetupmenuswherethe

defaultfactory-setdevicesettingscanbechanged.

Chapter 3Display Operations

40 PM130 PLUS Powermeters Series

3.2 Data Display

Indatamode,thedisplayisnormallyupdatedonceeverysecond.Youcanadjust

thedisplayupdaterateviatheDisplaySetupmenu.

3.2.1 Display Features

3.2.1.1 Measurement Units

ThePM130hasaselectableresolutionforvolts,ampsandpowerspresentedonthe

frontdisplayandviacommunications.SeeDeviceOptionsinChapter3for

informationonselectingthedataresolutioninthePM130.

LowResolutionOption

Currentsaredisplayedinwholeamperesbelow10,000A,andinkiloamperes

above10,000A.

Measurementunitsforvoltageandpowerdependonthevoltageconnection

scheme:

Fordirectwiring(PT=1)orwiringviaPTwiththePTratiouptoandincluding4.0,

voltagesaredisplayedinvolts,andpowerinkilowatts.

ForthePTratioabove4.0,voltagesaredisplayedinkilovoltswiththreedecimal

places,andpowerinmegawattswiththreedecimalplaces.

HighResolutionOption

Currentsaredisplayedinampereswithuptotwodecimalplacesbelow10,000A,

andinkiloamperesabove10,000A.

Measurementunitsforvoltageandpowerdependonthevoltageconnection

scheme:

Whendirectwiringisused(PT=1),voltagesaredisplayedinvoltswithone

decimalplace,andpowerinkilowattswiththreedecimalplaces.

WhenwiringviaPTisusedwiththePTratiouptoandincluding4.0,voltagesare

displayedinvolts,andpowerinwholekilowatts.

ForthePTratioabove4.0,voltagesaredisplayedinkilovoltswiththreedecimal

places,andpowerinmegawattswiththreedecimalplaces.

ThesmallroundKiloandMegaLEDslightupshowingtheappropriate

measurementunitsforadisplayedpage.

3.2.1.2 Primary and Secondary Volts

Voltscanbedisplayedinprimary(default)orsecondaryunits.Thevoltsdisplay

modecanbechangedthroughtheDisplaySetupmenu.

3.2.1.3 Phase Power Readings

Inconfigurationswiththeneutralwire,inadditiontototalthree-phasepowers,the

metercanshowper-phasepowerreadings.Bydefault,theyaredisabled.See

DisplaySetuponhowtoenableper-phasepowerreadingsinyourmeter.

Chapter 3Display Operations

PM130 PLUS Powermeters Series 41

3.2.1.4 Fundamental Component

ThePM130EHcandisplaytotaldisplacementpowerfactorandactivepowerforthe

fundamentalcomponentifitisenabledthroughtheDisplaySetupmenu.

Whenphasepowerreadingsareallowed,thePM130EHalsodisplaysper-phase

displacementpowerfactorandactivepowerforthefundamentalcomponent.

3.2.1.5 Auto Return

Ifnobuttonsarepressedfor30secondswhilethedisplayAutoReturnoptionis

enabled,thedisplayautomaticallyreturnstothemainscreenfromanyother

measurementdisplay.

TheAutoReturnoptioncanbeenabledthroughtheDisplaySetupmenu.

3.2.1.6 Auto Scroll

Ifnobuttonsarepressedfor30secondswhileinthecommonmeasurements

display,andtheAutoScrolloptionisenabledinthemeter,thedisplayautomatically

scrollsthroughallavailablepages.Thescrollintervalcanbeadjustedthroughthe

DisplaySetupmenu.

Tostopautoscrolling,pressbrieflytheUPorDOWNbutton.

3.2.1.7 Brightness

ThePM130displayhasa3-leveladjustablebrightness.Itisnormallypresetatthe

factorytothehighestlevel.YoucanadjustthedisplaythroughtheDisplaySetup

menu.

3.2.2 Navigation Buttons

Figure 3-2: Navigation Buttons

InDataDisplaymode,thenavigationbuttonsfunctionasfollows.

TheMAX/MINbuttonswitchestotheMin/MaxandMaximumDemandsdisplay

pages.Whenbrieflypressedagain,itswitchesbacktothecommon

measurementsdisplay.

TheH/ESCbuttoninthePM130EHswitchesbetweentheTotalHarmonicsand

IndividualHarmonicspages.Whenbrieflypressedonceagain,itswitchesback

tothecommonmeasurementsdisplay.

TheUPandDOWNarrowbuttons,labeledbyarrowheads,scrollforwardsand

backwardsthroughthedisplaypages.Pressedbriefly,theymoveonepage

forwardorbackward.Ifyouholddownthebutton,thedisplaypagesarescrolled

atarateoftwicepersecond.

PressingboththeUPandDOWNarrowbuttonstogetherwillreturnyoutothe

firstpagewithinthecurrentdisplay.

TheSELECTbuttonoperatesonceitisreleased.Thebuttonhastwofunctions:

Whenpressedbriefly,itswitchestoprogrammingmode.

Chapter 3Display Operations

42 PM130 PLUS Powermeters Series

WhenpressedtogetherwiththeENTERbuttonformorethan5seconds,it

resetsMin/Maxregisters,maximumdemands,orenergiesdependingonthe

currentlydisplayedpage.Ifthemeterispasswordprotectedandasimple

resetofdatafromthedisplayisnotallowed,theactionhasnoeffect.

TheENERGYbuttonswitchestotheEnergydisplayinthePM130EHand

PM130E.InthePM130P,thebuttonisnotoperational.IfTOUregistersare

configuredinthemeter,youcanrepeatedlypressthisbuttontoscrollthroughall

availableTOUregisters.Whenbrieflypressedonceagain,itswitchesbacktothe

commonmeasurementsdisplay:

3.2.3 Simple Reset of Accumulated Data

YoucanresettheMin/Maxregisters,maximumdemandsandenergiesfromthe

datadisplaymodewithoutaccessingtheresetmenu.Thisisaccomplishedbyusing

thesimpletwo-buttonresetoptionifthemeterisnotpasswordprotectedorthe

metersecurityisoverriddenbythetwo-buttonresetmodesetting,seeDisplay

Setup:

1. Selectadisplaypagewherethedatayouwanttoresetisdisplayed:

Min/Maxlog:selectaMin/MaxpagefromtheMin/MaxDisplay

Ampereandvoltmaximumdemands:selecttheAmpereorVoltmaximum

demandpagefromtheMin/MaxDisplay.

Powermaximumdemands:selectthepowermaximumdemandpagefrom

theMin/MaxDisplay.

Totalandphaseenergies:selectatotalenergy,orphaseenergypagefrom

theEnergyDisplay.

2. WhileholdingtheSELECTbuttondown,pressandholdtheENTERbuttonfor

about5seconds.

Thedisplayeddataisresettozero.

3.2.4 Common Measurements Display

Scrollthroughpageswiththe UPand DOWNarrowbuttons.

Table 3: Common Measurements (Main Display)

1

L

V12

V23

V31

Line-to-line volts

2

P

V1

V2

V3

Line-to-neutral volts (in 4LN3, 3LN3,

3BLN3 configurations)

3 I1

I2

I3

Amps

4 kVA/MVA

PF

kW/MW

Total VA

Total PF

Total W

5

In

Hz

kvar/Mvar

Neutral current

Frequency

Total var

6

Ph.L1

PF

Phase L1 powers

(if enabled)

Chapter 3Display Operations

PM130 PLUS Powermeters Series 43

kW/MW

7

kVA/MVA

Ph.L1

kvar/Mvar

Phase L1 powers

(if enabled)

8

Ph.L2

PF

kW/MW

Phase L2 powers

(if enabled)

9

kVA/MVA

Ph.L2

kvar/Mvar

Phase L2 powers

(if enabled)

10

Ph.L3

PF

kW/MW

Phase L3 powers

(if enabled)

11

kVA/MVA

Ph.L3

kvar/Mvar

Phase L3 powers

(if enabled)

12

H01

PF

kW/MW

Fundamental total powers

(PM130EH, if enabled)

13

H1.L1

PF

kW/MW

Fundamental phase L1 powers

(PM130EH, if enabled)

14

H1.L2

PF

kW/MW

Fundamental phase L2 powers

(PM130EH, if enabled)

15

H1.L3

PF

kW/MW

Fundamental phase L3 powers

(PM130EH, if enabled)

16

U.Unb

V% unb

Voltage unbalance, percent

17

C.Unb

I% unb

Current unbalance, percent

3.2.5 Min/ Max and Maximum Demand Display

Figure 3-3: MAX/ MI N Button

1. PresstheMAX/MINbutton.

TheMIN,MAX,orMAXDMDLEDisilluminatedwhenintheMIN/MAXdisplay.

2. Usethe UPand DOWNarrow

buttonstoscrollthroughtheMin/MaxandMax.

Demandpages.

Toseethetimeanddateoftheeventoccurrence:

1. PresssimultaneouslytheSELECTandUP

buttons.

2. UsetheUPandDOWNarrowbuttonstoscroll

throughtheparametersdisplayedonthepage.

AcorrespondingLEDattherightisilluminated

Chapter 3Display Operations

44 PM130 PLUS Powermeters Series

showingtheparameterforwhichthe

timestampisdisplayed.

Thetimeisdisplayedinformathh.mm,andthedateinformatMM-DD-YY(default)

orinanyotherformatyoucanselectviatheDisplaySetupMenu.

NotethatVoltsreadingsareline-to-neutralin4LN3,3LN3and3BLN3wiringmodes,

andline-to-lineinothermodes.

Table 4: Min/ Max and Maximum Demands

1 MIN V1/V12

V2/V23

V3/V31

Minimum volts

2 MIN I1

I2

I3

Minimum amps

3 MIN kVA/MVA

PF

kW/MW

Minimum total VA

Minimum total PF (absolute)

Minimum total W

4 MIN In

Hz

kvar/Mvar

Minimum neutral current

Minimum frequency

Minimum total var

5 MAX V1/V12

V2/V23

V3/V31

Minimum volts

6 MAX I1

I2

I3

Maximum amps

7 MAX kVA/MVA

PF

kW/MW

Maximum total VA

Maximum total PF (absolute)

Maximum total W

8 MAX In

Hz

kvar/Mvar

Maximum neutral current

Maximum frequency

Maximum total var

9 MAX

DMD

V1/V12

V2/V23

V3/V31

Maximum volt demands

10 MAX

DMD

I1

I2

I3

Maximum ampere demands

11 MAX

DMD

kVA/MVA

PF

kW/MW

Maximum VA demand

PF at maximum VA demand

Maximum W demand

12 MAX

DMD

A neut.

var

Maximum neutral current demand

Maximum var demand

3.2.6 Harmonics Display

Figure 3-4: H/ ESC Button

1. PresstheH/ESCbuttoninthePM130EH.

TheTHD/TDDLEDisilluminated.

Chapter 3Display Operations

PM130 PLUS Powermeters Series 45

2. Usethe UPand DOWNarrow

buttonstoscrollthroughtotalharmonics

measurements.

3. PresstheH/ESCbuttonagaintomovetothe

individualharmonics.

Notethatvoltageharmonicsreadingsareline-to-neutralinthe4LN3,3LN3,3BLN3

wiringmodes,andline-to-lineinallothermodes.

Table 5: Total Harmonics

1

thd.

V1/V12 THD

V2/V23 THD

V3/V31 THD

Voltage THD

2

thd.

I1 THD

I2 THD

I3 THD

Current THD

3

tdd.

I1 TDD

I2 TDD

I3 TDD

Current TDD

4

HF

I1 K-Factor

I2 K-Factor

I3 K-Factor

Current K-Factor

Table 6: Individual Voltage Harmonics

1

3.

V1/V12 HD%

V2/V23 HD%

V3/V31 HD%

Order 3 harmonic distortion

2

5.

V1/V12 HD%

V2/V23 HD%

V3/V31 HD%

Order 5 harmonic distortion

19

39.

V1/V12 HD%

V2/V23 HD%

V3/V31 HD%

Order 39 harmonic distortion

Table 7: Individual Current Harmonics

1

3.

I1 HD%

I2 HD%

I3 HD%

Order 3 harmonic distortion

2

5.

I1 HD%

I2 HD%

I3 HD%

Order 5 harmonic distortion

19

39.

I1 HD%

I2 HD%

I3 HD%

Order 39 harmonic distortion

3.2.7 Energy Display

Figure 3-5: Energy Button

Chapter 3Display Operations

46 PM130 PLUS Powermeters Series

1. PresstheENERGYbutton.

ThekVAh,kvarh,orkWhLEDisilluminated.

2. IfTOUregistersareconfiguredinthemeter,

pressthebuttonagaintoscrollthroughall

activeTOUregisters.

3. UsetheUPandDOWNarrowbuttonstoscroll

throughenergypages.

Alongwithtotalenergies,perphaseenergyaccumulatorsaredisplayedifphase

energycalculationisenabledintheDeviceOptionsmenu.

Table 8: Total and Phase Energies

1

Ac.i

1234

56789

Total kWh import

2

rE.i

1234

56789

Total kvarh import

3

AP.

1234

56789

Total kVAh

4

Ac.E

1234

56789

Total kWh export

5

rE.E

1234

56789

Total kvarh export

6

Ac.i 1

1234

56789

Phase L1 kWh import

7

rE.i 1

1234

56789

Phase L1 kvarh import

8

AP. 1

1234

56789

Phase L1 kVAh

9

Ac.i 2

1234

56789

Phase L2 kWh import

10

rE.i 2

1234

56789

Phase L2 kvarh import

11

AP. 2

1234

56789

Phase L2 kVAh

12

Ac.i 3

1234

56789

Phase L3 kWh import

13

rE.i 3

1234

56789

Phase L3 kvarh import

14

AP. 3

1234

56789

Phase L3 kVAh

Chapter 3Display Operations

PM130 PLUS Powermeters Series 47

Table 9: TOU Energy Register 1

1

r1.t1

1234

56789

Tariff 1 reading

kWh

2

r1.t2

1234

56789

Tariff 2 reading

kWh

4

r1.t4

1234

56789

Tariff 4 reading

kWh

Table 10: TOU Energy Register 4

1

r4.t1

1234

56789

Tariff 1 reading

kWh

2

r4.t2

1234

56789

Tariff 2 reading

kWh

4

r4.t4

1234

56789

Tariff 4 reading

kWh

3.3 Status Display

Themeterhasaseparatestatusinformationdisplayaccessiblethroughtheprimary

devicemenu.Forinformationonnavigatinginthemenus,seeUsingtheMenus.

TheStatusDisplayshowsrarelyusedinformationthatisespeciallyhelpfulfor

troubleshootingorwhenconnectingthemetertoanexternalequipment.

ToaccesstheStatusDisplay:

1. FromtheDataDisplaymenu,presstheSELECTbuttontoaccesstheprimary

devicemenu.

TheStAwindowishighlighted.

3. PressENTERtoaccesstheStatusDisplay.

4. UsetheUPandDOWNarrowbuttonstoscroll

throughthestatuspages.

Figure 3-6: Status Display

Chapter 3Display Operations

48 PM130 PLUS Powermeters Series

ToexittheStatusDisplay:

1. PressESCtoreturntotheprimarydevicemenu.

2. PressESCtoreturntotheDatadisplay.

Table 11: Status Display Parameters

1

PhS

rot

POS/nEG/Err

Phase rotation order

2

A.

V1 angle

V2 angle

V3 angle

Voltage angles (180,

referenced to V1)

3

A.

I1 angle

I2 angle

I3 angle

Current angles (180,

referenced to V1)

4

rEL

1.2

00

Relay status (with a digital

I/O module)

5

St.In

1.2.3.4

0000

Status inputs (with a digital

I/O module)

6

Cnt.1

<hour>

12345

Counter #1 value (a time

counter in 0.1 hour units)

7

Cnt.2

<hour>

12345

Counter #2 value (a time

counter in 0.1 hour units)

8

Cnt.3

<hour>

12345

Counter #3 value (a time

counter in 0.1 hour units)

9

Cnt.4

<hour>

12345

Counter #4 value (a time

counter in 0.1 hour units)

10

Alar

SP.<Setpoint

Number>

<Alarm Trigger >

Setpoint alarms (see Alarm

Display below)

11

diAG

<Diagnostic Code>

<Diagnostic Message>

Device diagnostics (see

Diagnostics Display below)

12

SEr.n

1

23456

Device serial number

13

SoFt

11.

01.01

Firmware version number

3.3.1 Pulse and Time Counters

The5-digitmetercounterscountsetpointevents,externalpulses,orsetpoint

operationtime.

Timecountershavethehourlabelinthemiddlewindowanddisplaythesetpoint

operationtimeata0.1-hourresolution.SeeUsingTimeCountersinChapter4for

informationonprogrammingtimecounters.

Chapter 3Display Operations

PM130 PLUS Powermeters Series 49

Youcanclearacounterusingthesimpletwo-buttonresetoptionifthemeterisnot

passwordprotected,orifthemetersecurityisoverriddenbythetwo-buttonreset

modesetting(seeDisplaySetup).

Toclearacounter:

1. Selectacounterpage.

2. WhileholdingtheSELECTbutton,pressandholdtheENTERbuttonforabout5

seconds.

Thedisplayeddataisresettozero.

3.3.2 Alarm Display

Thealarmdisplayshowsalistofoperatedalarmsetpointsalongwiththealarm

triggerlabelsiftherearealarmsrecordedduringmeteroperation.

UsetheUPandDOWNarrowbuttonstoscrollthroughthealarmlist.

Thesetpointstatusislatchedintoanon-volatileregister,whichisnotaffectedby

lossofpowerandmayonlybeclearedviacommunicationsorfromthemeter

display.

Toclearalarms:

1. Selectanalarmpage.

2. WhileholdingtheSELECTbutton,pressandholdtheENTERbuttonforabout5

secondsuntilthealarmcodeisresettonone.

3.3.3 Diagnostics Display

Thediagnosticsdisplayshowsalistofthedevicediagnosticcodesrecordedasa

resultofthemeterself-testdiagnosticsduringstart-upandoperation.Whenthere

arerecordeddiagnosticmessages,theidiagnosticLEDonthefrontdisplaybriefly

flashestwotimestoindicatethatthemetermayrequireservicing.

ThediagnosticLEDcanbedisabledorenabledviatheDisplaySetupmenu.

UsetheUPandDOWNarrowbuttonstoscrollthroughthediagnosticmessagelist.

SeeDeviceDiagnosticCodesinAppendixFforthelistofdiagnosticcodesandtheir

meanings.

Frequenthardwarefailuresmaybetheresultofexcessiveelectricalnoiseinthe

regionofthedevice.Ifthemetercontinuouslyresetsitself,contactyourlocal

distributor.

Aconfigurationresetmayalsobearesultofthelegalchangesinthemeter

configurationwhenotherconfigurationdataisaffectedbythechanges.

Thediagnosticscodesarestoredinanon-volatileregister,whichisnotaffectedby

lossofpowerandmaybeclearedviacommunications(seeDeviceDiagnosticsin

Chapter4)orfromthemeterdisplay.

Toclearthemeterdiagnostics:

1. Selectadiagnosticspage.

2. WhileholdingtheSELECTbutton,pressandholdtheENTERbuttonforabout5

secondsuntilthediagnosticmessageisresettonone.

Chapter 3Display Operations

50 PM130 PLUS Powermeters Series

3.4 Using the Menus

3.4.1 Navigation Buttons

Figure 3-7: Navigation Buttons

ThePM130hasamenu-drivensetup.Toaccessthemenus,pressandreleasethe

SELECTbutton.

TheSELECTbuttonselects(highlights)anactivewindowinwhichyoucanselector

changearequiredmenuitem.Thebuttonoperatesonceitisbrieflypressedand

released.

TheUPandDOWNarrowbuttonsscrollthroughmenuitemsinthehighlighted

windowforwardsandbackwards.Itallowschangingahighlighteditemwhen

enteringnumbers.

TheENTERbuttonconfirmstheselectionofamenuitemoranumberinthe

highlightedwindow,thusallowingtoaccessasubmenuortostoreachangeditem.

TheESCbuttonisEscapeleavingthehighlighteditemunchangedorreturningto

theupperlevelmenu.

3.4.2 Selecting Menus

Toaccessthemetermenus,pressandreleasetheSELECTbutton.Theprimary

metermenuisdisplayedasshowninFigure 3-8.

Themenuhasthreeentries:

StA:StatusDisplayentry(seetheStatusDisplaysection)

OPS:Mainsetupmenuentryallowingtoreviewsetupoptions

CHG:Mainsetupmenuentryallowingtochangesetups

Figure 3-8: Menu Entries

ToaccesstheStatusDisplay:

1. IftheStAwindowisnothighlighted,usetheSELECTbuttontoactivateit.

2. PresstheENTERbuttontoaccesstheStatusDisplay

Toreviewthemetersetupoptions:

1. PresstheSELECTbuttontoactivatetheOPSwindow.

2. PresstheENTERbuttontoaccessthemainmenu.

Chapter 3Display Operations

PM130 PLUS Powermeters Series 51

Tochangethemetersetup,ortocleartheaccumulatedvalues:

1. PresstheSELECTbuttontoactivatetheCHGwindow.

2. PresstheENTERbuttontoaccessthemainmenu.

3.4.3 Entering the Password

TheSetupChangemenucanbesecuredbyafour-digituserpassword.

Themeterisprimarilyshippedwiththepasswordpresetto0andpassword

protectiondisabled.

YoucanchangethepasswordandenablepasswordprotectionthroughtheAccess

Controlmenu(seetheMeterSecuritysection).

Ifauthorizationisnotrequired,justpresstheENTERbuttontomovetotheMain

menu;otherwiseyoushouldenteracorrectpasswordtobeauthorizedtoaccessthe

metersetup.

Figure 3-9: Meter Setup

Toaccessthepassword:

1. AdjustthefirstdigitwiththeUPandDOWNarrowbuttons.

2. PresstheSELECTbuttontoadvancetothenextdigit.

3. Adjusttheremainingpassworddigitsinthesamemanner.

4. PressENTERtoconfirmthepassword.

Ifthepasswordenterediscorrect,movetotheMainmenu,otherwisereturntothe

previousmenu.

SelectingtheOPSorCHGentrymovesyoutotheMainmenuthatisrepresentedby

twoentries:

theupperwindowdisplaysasecondarymenulist

thebottomitemactsasanassistingexitwindow.

Chapter 3Display Operations

52 PM130 PLUS Powermeters Series

3.4.4 Selecting a Menu Entry

Toselectamenuentryfromthemenulist:

1. HighlighttheupperitembypressingtheSELECTbutton.

Figure 3-10: Selecting a Menu Entry

2. ScrollthroughthemenulistbypressingbrieflytheUPandDOWNarrowbuttons

untiltherequiredmenuentryappears.

3. PresstheENTERbutton.

3.4.5 Viewing and Changing Setup Items

Asecondlevelmenunormallyconsistsofthreeitems:

theupperstaticwindow-indicatesthemenuname

themiddlewindow-representsalistofsetupparametersyoucanscrollthrough

theloweritem-showsthepresentparametervalue.

Toselectaparameteryouwanttovieworchange:

1. HighlightthemiddlewindowbypressingtheSELECTbutton.

Figure 3-11: Selecting a Parameter

2. ScrollthroughtheparameterlistwiththeUPandDOWNbuttonsuntilthe

requiredparameternameappears.

Tochangetheselectedparameter:

1. PresstheSELECTbuttontohighlighttheloweritem.

Figure 3-12: Changing a Parameter

Chapter 3Display Operations

PM130 PLUS Powermeters Series 53

2. AdjustthenumbertotherequiredvaluewiththeUPandDOWNarrowbuttonsif

anumberrepresentstheparameter.

Whenbrieflypressed,thebuttonincrementsordecrementsthenumberbyone.

Whenthebuttonispressedcontinuously,thenumberischangedapproximately

twicepersecond.

3. Ifanamerepresentstheparameter,selecttherequiredoptionwiththeUPand

DOWNarrowbuttons.

4. Tostoreyournewselection,presstheENTERbutton.

5. Toleavetheparameterunchanged,presstheESCbutton.

6. Returntotheparameterlisttoselectanotherparameterorreturntothemain

menu.

7. PressESCtoexitthemenu.

3.5 Menu Operations

3.5.1 Basic Device Settings

Figure 3-13: Basic Device Settings

TheBasicDeviceSettingsmenuallowsyoutoconfigurethebasicmetersettings

thatdefinethegeneraloperatingcharacteristicsofthedevice.

ToaccesstheBasicDeviceSettingsmenu:

1. SelectthebaScentryfromthemainmenu.

2. PresstheENTERbutton.

UsingashortcuttotheBasicSetupmenu:

FromtheDataDisplay,pressandreleasetheSELECTbuttontoentertheprimary

metermenu(seeSelectingMenusinSection2.4.2),andthensimultaneouslypress

theSELECTandUPbuttons.YouaredirectlymovedtotheCTsettingentry.

Theshortcutisnotoperationalifthemeterispasswordprotected.

Toselectasetupoption:

1. PresstheSELECTbuttontoactivatethemiddlewindow.

2. UsetheUPandDOWNarrowbuttonstoscrolltotherequiredoption.

Tochangetheoption:

1. PresstheSELECTbuttontoactivatethelowerwindow.

2. UsetheUPandDOWNarrowbuttonstoselecttherequiredoption.

Chapter 3Display Operations

54 PM130 PLUS Powermeters Series

3. PressENTERtoconfirmyourchangesandtostoreyournewsettingorpress

ESCtodiscardchanges.

Toexitthemenu,pressESC.

Table12liststheBasicDeviceSettingsoptions.

Table 12: Available Options

Label Parameter Options Default Description

ConF Wiring connection

(configuration) mode

See Basic

Meter Setup

in Chapter 4

4Ln3 The wiring connection of the

device

Pt PT ratio 1.0-6500.0 1.0 The phase potential

transformers primary to

secondary ratio

Pt.F PT Ratio multiplier 1, 10 1 PT Ratio multiplication factor.

Used in extra high voltage

networks to accommodate the

PT ratio for 500 kV and higher

networks.

Ct CT primary current 1-50000 A 5 A The primary rating of the phase

current transformer

d.P Power block demand

period

E, EH

1, 2, 3, 5,

10, 15, 20,

30, 60 min,

E=external

sync

30 min The length of the demand

period for power demand

calculations. If the external

synchronization is selected, a

pulse front on the digital input

DI1 denotes the start of the

demand interval.

nd.P The number of blocks in

the sliding window

E, EH

1-15 1 The number of blocks to be

averaged for sliding window

demands

Ad.P Ampere and volt

demand period

0-1800 sec 900 sec The length of the demand

period for ampere, volt and

THD demand calculations

Freq Nominal frequency 50,60,25,

400 Hz

60 Hz The nominal line frequency

LoAd Maximum demand load

current

0-50000 A 0 The maximum demand load

current (0 = CT primary)

Alwaysspecifythewiringmodeandtransformerratingspriortosetting

upsetpointsandanalogoutputs.

ThemaximumvaluefortheproductofthephaseCTprimarycurrent

andPTratiois57,500,000.Iftheproductisgreater,powerreadingsare

zeroed.

3.5.2 Device Options

Figure 3-14: Device Options

TheDeviceOptionsmenuallowschanginguser-configurabledeviceoptionsor

puttingthemeterintoenergytestmode.

Chapter 3Display Operations

PM130 PLUS Powermeters Series 55

ToaccesstheDeviceOptionsmenu:

1. SelecttheOPtSentryfromthemainmenu.

2. PresstheENTERbutton.

Toselectasetupoption:

1. PresstheSELECTbuttontoactivatethemiddlewindow.

2. UsetheUPandDOWNarrowbuttonstoscrolltotherequiredoption.

Tochangetheoption:

1. PresstheSELECTbuttontoactivatethelowerwindow.

2. UsetheUPandDOWNarrowbuttonstoselecttherequiredoption.

3. PressENTERtoconfirmchangesandtostorenewsettingsorpressESCto

discardchanges.

Toexitthemenu,pressESC.

Table13listsavailableoptions.

Table 13: Available Device Options

Label Parameter Options Default Description

P.cAL Power

calculation

mode

rEAc (reactive power),

nAct (non-active

power)

Reactive The method used for

calculating reactive and

apparent powers. See

Power Calculation

Modes in Chapter 4

roLL Energy roll

value

E, EH

10.E4=10,000

10.E5=100,000

10.E6=1,000,000

10.E7=10,000,000

10.E8=100,000,000

10.E9=1,000,000,000

10.E8 The value at which

energy counters roll

over to zero

Ph.En Phase energy

option

E, EH

diS = disabled

En = enabled

Disabled Enables phase energy

calculations

U.Str Starting voltage 1.5-5.0% 1.5 The device starting

voltage in percent of FS

(120V or 400V)

U.ScL Voltage scale,

secondary volts

10-828 V 144 V The maximum voltage

scale allowed. See Data

Scales in Appendix E

C.ScL Current scale,

secondary amps

1.0-10.0 A 2 CT

secondary

The maximum current

scale allowed. See Data

Scales in Appendix E

rESL Device

resolution

Lo

Hi

Lo The voltage, current

and power resolution on

the front display (see

Measurement Units in

Chapter 3) and in

communications (see

the appropriate section

in the communication

guides)

tESt Energy test

mode

E, EH

OFF = disabled

Ac.Ei = Wh pulses

rE.Ei = varh pulses

Disabled Setting this option puts

the meter into the

energy test mode

Chapter 3Display Operations

56 PM130 PLUS Powermeters Series

3.5.3 Communication Ports

Figure 3-15: Communication Ports Options

TheCommunicationPortsOptionsmenusallowyoutoconfigureparametersfor

communicationportsCOM1andCOM2.

Toaccessthemenu:

1. SelectPrt.1forCOM1orPrt.2forCOM2from

themainmenu

2. PresstheENTERbutton.

Toselectasetupoption:

1. PresstheSELECTbuttontoactivatethemiddlewindow.

2. UsetheUPandDOWNarrowbuttonstoscrolltotherequiredoption.

Tochangetheoption:

1. PresstheSELECTbuttontoactivatethelowerwindow.

2. UsetheUPandDOWNarrowbuttonstoselecttherequiredoption.

3. PressENTERtoconfirmchangesandtostorenewsettingsorpressESCto

discardchanges.

4. PressESCtoexitthemenu.

Table14andTable15listCOMportsettings.

Table 14: COM1 Settings

Label Parameter Options Default Description

Prot Communications

protocol

ASCII = SATEC ASCII

rtu = Modbus RTU

dnP3 = DNP3

Modbus RTU The communications

protocol supported by

the port

rS Port interface 485 = RS-485 RS-485

Addr Device address SATEC ASCII: 0-99

Modbus RTU: 1-247

DNP3: 065532

1 Device network

address

bAud Baud rate 300-115200 bps 9600 bps The port baud rate

dAtA Data format and

parity

7E, 8N, 8E 8N 7E data format should

not be used with the

Modbus RTU and

DNP3 protocols

CPtb ASCII

compatibility

mode

Dis, En Dis Enables a low-

resolution device

emulation for ASCII

request 0 in high-

resolution devices

(see Device Options)

Chapter 3Display Operations

PM130 PLUS Powermeters Series 57

Table 15: COM2 Settings

Label Parameter Options Default Description

Prot Communications

protocol

1

rtu = Modbus/TCP

dnP3 = DNP3/TCP

PrFb = Profibus DP

Modbus/TCP The communications

protocol supported by

the port

rS Port interface Eth.= Ethernet

PrFb = Profibus DP

Eth. Not changeable;

automatically

detected by the meter

Addr Device address Modbus: 1-247

DNP3: 065532

Profibus DP: 0-126

1 Device network

address

3.5.4 Network Address

Figure 3-16: Network Address

TheNetworkAddressentryappearsonlyiftheoptionalEthernetmoduleisplugged

intothemeter.

TheNetworkAddressmenuallowsyoutoconfigurethedeviceIPaddressandthe

defaultgatewayaddressfortheEthernetport.

ToaccesstheNetworkAddressmenu:

1. SelectnEtfromthemainmenu.

2. PresstheENTERbutton.

TochangetheIPAddressandDefaultGateway:

1. TochangethedeviceIPaddress,selecttheAentryintheupperwindowusing

theUPandDOWNarrowbuttons.

2. Tochangethedefaultgatewayaddress,selecttheGentry.

2. PresstheSELECTbuttontoactivatethefirstaddressdigit.

3. UsetheUPandDOWNarrowbuttonstoadjustthedigit.

4. PresstheSELECTbuttontoadvancetothenextdigit.

1

Selecting the DNP3 protocol on the Ethernet port launches the DNP3/TCP server along with

the Modbus/TCP server. This allows simultaneous connections on both TCP ports. Selecting

the Modbus protocol for the port disables the DNP3/TCP server.

Chapter 3Display Operations

58 PM130 PLUS Powermeters Series

5. Adjusttheremainingaddressdigits.

6. PressENTERtoconfirmthenewsettingorpressESCtodiscardchanges.

7. PressESCtoexitthemenu.

3.5.5 Digital Input Setup

Figure 3-17: Digital I nput Setup

TheDigitalInputSetupoptionappearsonlyifthedigitalI/Omoduleispluggedinto

themetertheoptional.

ToaccesstheDigitalInputSetupmenu:

1. SelectthedinPentryfromthemainmenu.

2. PresstheENTERbutton.

3. UsetheUPandDOWNarrowbuttonstoscrolltotherequireddigitalinput.

Toselectadigitalinputparameter:

1. PresstheSELECTbuttontoactivatethemiddlewindow.

2. UsetheUPandDOWNarrowbuttonstoscrolltotherequiredparameter.

Tochangetheparametervalue:

1. PresstheSELECTbuttontoactivatethelowerwindow.

2. UsetheUPandDOWNarrowbuttonstoselecttherequiredvalue.

3. PressENTERtoconfirmthenewparametersettingorpressESCtodiscard

changes.

4. Youarereturnedtothemiddlewindowtoselectandconfigureanotherparameter

orconfirmthesettingsandexitthemenu.

Tostoreyournewsettings:

Chapter 3Display Operations

PM130 PLUS Powermeters Series 59

1. PresstheENTERbuttonwhenthemiddlewindowishighlighted.

2. Youarereturnedtotheupperwindowtoselectanotherdigitalinputorexitthe

menu.

3. pressESCtoexitthemenu.

Table16listsavailabledigitalsetupoptions.

Table 16: Available Digital Setup Options

Label Parameter Options Default Description

PuLS Pulse input

mode

PLS.A = Pulse

mode

PLS.C = KYZ

mode

PLS.A In pulse mode, either leading,

or trailing edge of the input

pulse is recognized as an

event. In KYZ mode, both

leading and trailing edges of

the input pulse are recognized

as separate events.

Polr Pulse polarity nor = Normal

(N.O.)

InS = Inverting

(N.C.)

nor For the normal polarity, the

open to closed transition is

considered a pulse. For the

inverting polarity, the closed

to open transition is

considered a pulse.

It has no meaning in KYZ

mode where both transitions

are used.

dbnc Debounce time 1-100 ms 10 ms The amount of time while the

state of the digital input

should not change to be

recognized as a new state.

Too low debounce time could