Beruflich Dokumente

Kultur Dokumente

Classes 6e & 6E

Hochgeladen von

manish_chaturvedi_60 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

58 Ansichten3 SeitenClasses 6e & 6E

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenClasses 6e & 6E

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

58 Ansichten3 SeitenClasses 6e & 6E

Hochgeladen von

manish_chaturvedi_6Classes 6e & 6E

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

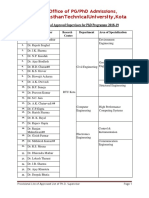

6e and 6E Pitch Diameter Allowances

Provide Space for Heavy Coatings

Many of the newer, high-performance corrosion-resistant finishes are thicker than older

standard fastener finishes such as commercial electroplated zinc with clear or yellow

chromate. To achieve equal corrosion resistance, the new finishes containing trivalent

chrome are applied thicker than the hexivalent chrome finishes they are replacing.

The heavier application of finishes on threaded fasteners results in more problems

related to thread interference in assembly. Thread fit cannot be ignored when high

performance finishes are required. The design and manufacturing solutions to this

dilemma are to either make the internal thread pitch diameter larger, the external thread

pitch diameter smaller, or to revise both the internal and external thread pitch diameters

to provide the extra room needed to accommodate the heavier finish build-up between

the mating threads.

Several suppliers of threaded fasteners have addressed the heavy coating-thread

interference problem by making the internal threads to the thread class 6E instead of

6H and the external threads to the thread class 6e instead of 6g. The use of the

combination of 6E and 6e class threads instead of the most common combination of

6H with 6g thread classes provides approximately four time the space to

accommodate plating and/or coating build-up.

This article was published in FASTENER WORLD Magazine

Written by Joe Greenslade in June 2005

sales@greensladeandcompany.com

Internal thread class 6E provides a plating allowance where as the more common

thread class 6H does not provide any. The external thread class 6e provides

approximately twice the plating allowance than does the 6g thread class. The

illustrations in this article show the size relationships of the thread classes 6E to 6H

Greenslade & Company, Inc.

1 of 3

and 6e to 6g. The illustrations also show that the external thread pitch diameter

sizes must always remain smaller the basic pitch diameter size and the internal thread

pitch diameter size must always remain larger than the basic pitch diameter size to

assure a non-interference fit in assembly. Hopefully the example of M10 X 1.5

providing exact pitch diameter sizes makes the exact nature of these relationships more

clear for the reader.

This article was published in FASTENER WORLD Magazine

Written by Joe Greenslade in June 2005

sales@greensladeandcompany.com

Greenslade & Company, Inc.

2 of 3

This article was published in FASTENER WORLD Magazine

Written by Joe Greenslade in June 2005

sales@greensladeandcompany.com

Greenslade & Company, Inc.

3 of 3

Unfortunately, neither the American Society of Mechanical Engineers (ASME) or the

International Standards Organization (ISO) provide tables for the pitch diameter sizes

for internal thread class 6E or external thread class 6e. That leaves the task of using

the thread formulas to determine the 6E and 6e pitch diameter sizes to every

individual thread component manufacturer.

In an effort to make the use of the6E and 6e thread classes easier for manufacturing

before coating threads with greater allowance I have compiles the tables for those

thread classes in this article.

6e Pitch Diameter Tolerance and Position for External Threads

Size Basic es " 6" tol High PD Low PD

M6 X 1.0 5.350 -0.060 0.112 5.290 5.178

M8 X 1.0 7.350 -0.060 0.112 7.290 7.178

M8 X 1.25 7.188 -0.063 0.118 7.125 7.007

M10 X 1.0 9.350 -0.060 0.112 9.290 9.178

M10 X 1.25 9.188 -0.063 0.118 9.125 9.007

M10 X 1.5 9.026 -0.067 0.132 8.959 8.827

M12 X 1.25 11.188 -0.063 0.132 11.125 10.993

M12 X 1.5 11.026 -0.067 0.140 10.959 10.819

M12X 1.75 10.863 -0.071 0.150 10.792 10.642

6E Pitch Diameter Tolerance and Position for Internal Threads

Size Basic EI " 6" tol High PD Low PD

M6 X 1.0 5.350 0.060 0.150 5.560 5.410

M8 X 1.0 7.350 0.060 0.150 7.560 7.410

M8 X 1.25 7.188 0.063 0.160 7.411 7.251

M10 X 1.0 9.350 0.060 0.150 9.560 9.410

M10 X 1.25 9.188 0.063 0.160 9.411 9.251

M10 X 1.5 9.026 0.067 0.180 9.273 9.093

M12 X 1.25 11.188 0.063 0.180 11.431 11.251

M12 X 1.5 11.026 0.067 0.190 11.283 11.093

M12X 1.75 10.863 0.071 0.200 11.134 10.934

The final acceptance of threads after coating should be determined by using 6H GO

plug gages for internal threads and 6h GO ring gages for external threads. The use of

these class gages for final thread acceptance assures that thread interference will not

occur during product assembly.

For more information on this or other fastener technology or quality related issues

contact the author via e-mail at sales@greensladeandcompany.com.

Das könnte Ihnen auch gefallen

- Electrical Power System Fault Analysis PDFDokument60 SeitenElectrical Power System Fault Analysis PDFKumardeep MukhopadhyayNoch keine Bewertungen

- Power SystemsDokument47 SeitenPower Systemsmanish_chaturvedi_6Noch keine Bewertungen

- Switchgear Notes PDFDokument134 SeitenSwitchgear Notes PDFGorla RamuNoch keine Bewertungen

- Syllabus I YearDokument25 SeitenSyllabus I YearDipesh PatelNoch keine Bewertungen

- Electrical Power System Fault Analysis PDFDokument60 SeitenElectrical Power System Fault Analysis PDFKumardeep MukhopadhyayNoch keine Bewertungen

- Switchgear Notes PDFDokument134 SeitenSwitchgear Notes PDFGorla RamuNoch keine Bewertungen

- PS Lab ManualDokument25 SeitenPS Lab ManualPhani PhaniNoch keine Bewertungen

- PHD Thesis Format and GuidelinesDokument15 SeitenPHD Thesis Format and GuidelinesPranayNoch keine Bewertungen

- PHD Thesis Evaluation FormDokument2 SeitenPHD Thesis Evaluation Formmanish_chaturvedi_6Noch keine Bewertungen

- Supervisor 2018 19Dokument8 SeitenSupervisor 2018 19manish_chaturvedi_6Noch keine Bewertungen

- Syllabus I Year 2019 20 Onwards PDFDokument24 SeitenSyllabus I Year 2019 20 Onwards PDFRitik KalwarNoch keine Bewertungen

- PHD Thesis Format and GuidelinesDokument15 SeitenPHD Thesis Format and GuidelinesPranayNoch keine Bewertungen

- Ph.D. Pre Synopsis Seminar Examination ReportDokument4 SeitenPh.D. Pre Synopsis Seminar Examination Reportmanish_chaturvedi_6Noch keine Bewertungen

- Provisional List of Research Centers For The Session 2018 191Dokument4 SeitenProvisional List of Research Centers For The Session 2018 191manish_chaturvedi_6Noch keine Bewertungen

- PHD Oral Defence Evaluation FormDokument2 SeitenPHD Oral Defence Evaluation Formmanish_chaturvedi_6Noch keine Bewertungen

- Half Yearly Exam General Science Class 3Dokument3 SeitenHalf Yearly Exam General Science Class 3manish_chaturvedi_6Noch keine Bewertungen

- PHD Thesis Evaluation FormDokument2 SeitenPHD Thesis Evaluation Formmanish_chaturvedi_6Noch keine Bewertungen

- PHD Oral Defence Evaluation FormDokument2 SeitenPHD Oral Defence Evaluation Formmanish_chaturvedi_6Noch keine Bewertungen

- Counselor For Ist Year StudentsDokument1 SeiteCounselor For Ist Year Studentsmanish_chaturvedi_6Noch keine Bewertungen

- Ph.D. Pre Synopsis Seminar Examination ReportDokument4 SeitenPh.D. Pre Synopsis Seminar Examination Reportmanish_chaturvedi_6Noch keine Bewertungen

- Half Yearly Exam - Class3 - ComputerDokument5 SeitenHalf Yearly Exam - Class3 - Computermanish_chaturvedi_6Noch keine Bewertungen

- Ist Year Branchwise Batch AllottmentDokument1 SeiteIst Year Branchwise Batch Allottmentmanish_chaturvedi_6Noch keine Bewertungen

- Half Yearly Exam English - IDokument2 SeitenHalf Yearly Exam English - Imanish_chaturvedi_6Noch keine Bewertungen

- Half Yearly Exam - Class 3 - English 1Dokument3 SeitenHalf Yearly Exam - Class 3 - English 1manish_chaturvedi_6Noch keine Bewertungen

- Final Year Exam MATHS1Dokument2 SeitenFinal Year Exam MATHS1manish_chaturvedi_6Noch keine Bewertungen

- Half Yearly Exam - Deepta - Evs - 1Dokument3 SeitenHalf Yearly Exam - Deepta - Evs - 1manish_chaturvedi_6Noch keine Bewertungen

- Half Yearly Exam English - IDokument2 SeitenHalf Yearly Exam English - Imanish_chaturvedi_6Noch keine Bewertungen

- List of Officials of UTDDokument1 SeiteList of Officials of UTDmanish_chaturvedi_6Noch keine Bewertungen

- Ist Year Branchwise Batch AllottmentDokument1 SeiteIst Year Branchwise Batch Allottmentmanish_chaturvedi_6Noch keine Bewertungen

- Mba Brochure1 PDFDokument17 SeitenMba Brochure1 PDFMadhusudan DadhichNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- DOZC OL22420 en PDFDokument4 SeitenDOZC OL22420 en PDFปรีชาลิ่มเศรษฐกานต์Noch keine Bewertungen

- Manholes PolycreteDokument8 SeitenManholes PolycreteLuzmin DelaCruzNoch keine Bewertungen

- Agricultural Wastes As AggregateDokument8 SeitenAgricultural Wastes As Aggregatebaldocr7Noch keine Bewertungen

- LA Abrasion Test Determines Aggregate DurabilityDokument3 SeitenLA Abrasion Test Determines Aggregate DurabilityHarish Kumar GiriNoch keine Bewertungen

- Role of Japanese ODA Loans in KoreaDokument186 SeitenRole of Japanese ODA Loans in KoreaLee Zhi KangNoch keine Bewertungen

- Winter Project ReportDokument23 SeitenWinter Project ReportSARAVANANNoch keine Bewertungen

- Asahi India GlassDokument12 SeitenAsahi India GlassAman ChandelNoch keine Bewertungen

- DIN English - Aircraft and Space Vehicle Engineering Collection - IHSDokument3 SeitenDIN English - Aircraft and Space Vehicle Engineering Collection - IHSprashant.acharyahnrNoch keine Bewertungen

- Dmgt307 Total Quality ManagementDokument252 SeitenDmgt307 Total Quality ManagementAshu KunwarNoch keine Bewertungen

- Eaton Breather and Drains (Use This One) PDFDokument3 SeitenEaton Breather and Drains (Use This One) PDFmajesusNoch keine Bewertungen

- Effects of Partial Replacement of Cement With Marble Dust Powder On Properties of ConcreteDokument5 SeitenEffects of Partial Replacement of Cement With Marble Dust Powder On Properties of ConcreteIJIRSTNoch keine Bewertungen

- Global Productivity Aggregate DatabaseDokument81 SeitenGlobal Productivity Aggregate DatabaseESTEFANIARANGNoch keine Bewertungen

- Bulk Storage Feasibility Study FINAL 20140421 201404281032033243Dokument205 SeitenBulk Storage Feasibility Study FINAL 20140421 201404281032033243shwetankd_1Noch keine Bewertungen

- Everything You Need to Know About Ball MillsDokument14 SeitenEverything You Need to Know About Ball MillsLaxman Kumar100% (1)

- Examining RCM Vs TPMDokument16 SeitenExamining RCM Vs TPMcarrot123456Noch keine Bewertungen

- Kerney & Trecker AC, CH, &, CHL OperatorsManualDokument27 SeitenKerney & Trecker AC, CH, &, CHL OperatorsManualDavid100% (1)

- ProblemsDokument1 SeiteProblemsvivek100% (1)

- Reliability Centered MaintenanceDokument116 SeitenReliability Centered MaintenanceantonNoch keine Bewertungen

- Bs Sponge EiaDokument137 SeitenBs Sponge EiaAmarjeet YadavNoch keine Bewertungen

- Bill of Quantity For Silo FoundationDokument6 SeitenBill of Quantity For Silo Foundationlaxmi sunder libiNoch keine Bewertungen

- Introduction To Corrosion Assessment and ManagementDokument27 SeitenIntroduction To Corrosion Assessment and ManagementMohamad Faeze100% (1)

- Alkhrdaji - ACI 562 - Design Strength LimintsDokument26 SeitenAlkhrdaji - ACI 562 - Design Strength Limintseros100% (1)

- Steam Turbine Solutions: (Europe, Eurasia, Middle East, Africa)Dokument8 SeitenSteam Turbine Solutions: (Europe, Eurasia, Middle East, Africa)Mehmet ErenNoch keine Bewertungen

- Metal Composition of 1 Rs CoinDokument15 SeitenMetal Composition of 1 Rs Coinrupali parmarNoch keine Bewertungen

- Production and Operations ManagementDokument24 SeitenProduction and Operations ManagementEmjhaeMharieSherreidaraNoch keine Bewertungen

- Sheet Metal FormingDokument35 SeitenSheet Metal FormingAakash Singh100% (1)

- Quality steel E295 technical data sheetDokument1 SeiteQuality steel E295 technical data sheetNunoAfonsoNoch keine Bewertungen

- Section E Cooling SuppliesDokument138 SeitenSection E Cooling SuppliesalltheloveintheworldNoch keine Bewertungen

- Lean Supply Chain & Logistics ManagementDokument8 SeitenLean Supply Chain & Logistics ManagementjosegarreraNoch keine Bewertungen