Beruflich Dokumente

Kultur Dokumente

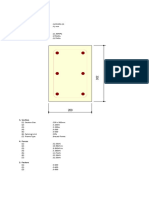

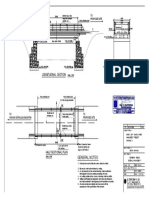

Job Information: Engineer Checked Approved Name: Date

Hochgeladen von

Zitheeq Umar0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

70 Ansichten17 SeitenThe document provides design details for a structural frame with 3 beams (M1, M2, M3) and 4 nodes. It includes information on the number of design groups and members, beam properties such as length and reinforcement, and design checks showing the frame is safe and meets code requirements. Reinforcement schedules and design calculations are also included for Beam M1.

Originalbeschreibung:

dgfg

Originaltitel

dgfgfg

Copyright

© © All Rights Reserved

Verfügbare Formate

DOCX, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThe document provides design details for a structural frame with 3 beams (M1, M2, M3) and 4 nodes. It includes information on the number of design groups and members, beam properties such as length and reinforcement, and design checks showing the frame is safe and meets code requirements. Reinforcement schedules and design calculations are also included for Beam M1.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

70 Ansichten17 SeitenJob Information: Engineer Checked Approved Name: Date

Hochgeladen von

Zitheeq UmarThe document provides design details for a structural frame with 3 beams (M1, M2, M3) and 4 nodes. It includes information on the number of design groups and members, beam properties such as length and reinforcement, and design checks showing the frame is safe and meets code requirements. Reinforcement schedules and design calculations are also included for Beam M1.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOCX, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 17

Job Information

Engineer Checked Approved

Name:

Date: 13-Aug-14

Structure Type SPACE FRAME

Number of Nodes 4 Highest Node 4

Number of Elements 3 Highest Element 3

Number of Plates 0 Highest Plate 0

Number of Design Groups 1

Number of Design Slabs 0

Number of Load Cases 1

Number of Design Briefs 1

Included in this printout are data for:

Design Group Design Brief Design Code Members

G1: Member Group 1 B1: Member1 BS8110 Beam M1

Design Group Summary - Member Group 1

Member Design Span Type Main Bars Shear

Bars

Span

Depth

Hog Sag

M1 Initial 1 Beam Ok Ok Ok Ok

2 Beam Ok Ok Ok Ok

3 Beam Ok Ok Ok Ok

Summary: the group is safe

Beam Spans

Cover

Member Span Type

Length

(m)

Top

(cm)

Btm

(cm)

Side

(cm)

Link Size

M1 1 Beam 3.200 3.0 3.0 3.0 8

2 Beam 4.200 3.0 3.0 3.0 8

3 Beam 4.000 3.0 3.0 3.0 8

Beam Supports

Member Node

Length

(m)

Support

Type

Col. Width

(cm)

M1 N1 3.200 Simple 0.0

N2 4.200 Simple 0.0

N3 4.000 Simple 0.0

N4 Simple 0.0

Member 1 - Main Steel Summary

Distance

(m)

Span

Moment

(kNm)

As Req.

(mm

2

)

As' Req.

(mm

2

)

Bottom Layers Top Layers

Bars Area Bars Area

0.000 1(s) 0.000 0 0 2H12 226 0

0.000 0 0

0.267 1 0.000 0 0 2H12 226 0

-8.319 132 0

0.533 1 0.000 0 0 2H12 226 0

-14.860 132 0

0.800 1 0.000 0 0 2H12 226 0

-19.623 132 0

1.067 1 0.000 0 0 2H12 226 0

-22.608 135 0

1.333 1 0.000 0 0 2H12 226 0

-23.816 142 0

1.600 1 0.000 0 0 2H12 226 0

-23.245 139 0

1.867 1 0.000 0 0 2H12 226 0

-20.898 132 0

2.133 1 0.000 0 0 2H12 226 0

-16.772 132 0

2.400 1 0.000 0 0 2H12 226 0

-10.868 132 0

2.667 1 0.000 0 0 2H12 226 2H12 226

-3.187 132 0

2.933 1 6.272 132 0 2H12 226 2H12 226

0.000 0 0

3.200 1(e) 17.509 132 0 0 2H12 226

0.000 0 0

3.200 2(s) 17.509 132 0 0 2H12 226

0.000 0 0

3.550 2 11.897 132 0 0 2H12 226

0.000 0 0

3.900 2 7.510 132 0 0 2H12 226

0.000 0 0

4.250 2 4.348 132 0 0 2H12 226

0.000 0 0

4.600 2 2.411 132 0 0 2H12 226

0.000 0 0

4.950 2 1.698 132 0 0 2H12 226

0.000 0 0

5.300 2 2.211 132 0 0 2H12 226

0.000 0 0

5.650 2 3.949 132 0 0 2H12 226

0.000 0 0

6.000 2 6.912 132 0 0 2H12 226

0.000 0 0

6.350 2 11.100 132 0 0 2H12 226

0.000 0 0

6.700 2 16.513 132 0 0 2H12 226

0.000 0 0

7.050 2 23.151 138 0 0 2H12 226

0.000 0 0

7.400 2(e) 31.014 185 0 0 2H12 226

0.000 0 0

7.400 3(s) 31.014 185 0 0 2H12 226

0.000 0 0

7.733 3 13.151 132 0 2H12 226 2H12 226

0.000 0 0

8.067 3 0.000 0 0 2H12 226 2H12 226

-1.933 132 0

8.400 3 0.000 0 0 2H12 226 0

-14.240 132 0

8.733 3 0.000 0 0 2H12 226 0

-23.769 142 0

9.067 3 0.000 0 0 2H12 226 0

-30.520 182 0

9.400 3 0.000 0 0 2H12 226 0

-34.493 206 0

9.733 3 0.000 0 0 2H12 226 0

-35.689 213 0

10.067 3 0.000 0 0 2H12 226 0

-34.107 203 0

10.400 3 0.000 0 0 2H12 226 0

-29.747 177 0

10.733 3 0.000 0 0 2H12 226 0

-22.609 135 0

11.067 3 0.000 0 0 2H12 226 0

-12.693 132 0

11.400 3(e) 0.000 0 0 2H12 226 0

0.000 0 0

Summary: the member is safe

Member 1 - Shear Results Summary

Distance

(m)

Span

Shear Force

(kN)

Shear Stress

(N/mm

2

)

Asv Required

(mm

2

)

0.000 1(s) 34.528 0.372 62

0.267 1 27.862 0.305 62

0.533 1 21.195 0.232 62

0.800 1 14.528 0.159 62

1.067 1 7.862 0.086 62

1.333 1 1.195 0.013 62

1.600 1 5.472 0.060 62

1.867 1 12.138 0.133 62

2.133 1 18.805 0.206 62

2.400 1 25.472 0.279 62

2.667 1 32.138 0.352 62

2.933 1 38.805 0.425 62

3.200 1(e) 45.472 0.498 62

3.200 2(s) 45.472 0.498 62

3.550 2 14.285 0.156 62

3.900 2 10.785 0.118 62

4.250 2 7.285 0.080 62

4.600 2 3.785 0.041 62

4.950 2 0.285 0.003 62

5.300 2 3.215 0.035 62

5.650 2 6.715 0.074 62

6.000 2 10.215 0.112 62

6.350 2 13.715 0.150 62

6.700 2 17.215 0.188 62

7.050 2 20.715 0.227 62

7.400 2(e) 24.215 0.265 62

7.400 3(s) 57.753 0.632 62

7.733 3 49.420 0.541 62

8.067 3 41.087 0.450 62

8.400 3 32.753 0.359 62

8.733 3 24.420 0.267 62

9.067 3 16.087 0.176 62

9.400 3 7.753 0.085 62

9.733 3 0.580 0.006 62

10.067 3 8.913 0.098 62

10.400 3 17.247 0.189 62

10.733 3 25.580 0.280 62

11.067 3 33.913 0.371 62

11.400 3(e) 42.247 0.455 71

Summary: the member is safe

Member 1 - Shear Zones Summary

Range

(m)

Asv Provided

(mm

2

)

Legs

Spacing

(cm)

0.001 - 3.199 101 2 30.0

3.199 - 7.399 101 2 30.0

7.399 - 11.399 101 2 30.0

Summary: the member is safe

Span / Effective Depth

Member Span

Length

(m)

Type

Basic

Limit

Modified

Limit

Span

Depth

M1 1 3.200 Beam 20.0 40.0 7.9

2 4.200 Beam 26.0 52.0 10.3

3 4.000 Beam 20.0 26.8 9.9

Summary: the group is safe

Members

Member Element

Node

A

Node

B

Property

Emt Length

(m)

O. Length

(m)

M1 1 1 2 224 x 449 3.200 11.400

2 2 3 4.200

3 3 4 4.000

Member 1 - Main Reinforcing Bars

Design Length

Bar Size

Start

(m)

End

(m)

Anchorage

(cm)

1 12 0.001 2.933 40.6

2 12 0.001 2.933 40.6

3 12 2.667 8.067 40.6

4 12 2.667 8.067 40.6

5 12 7.733 11.399 40.6

6 12 7.733 11.399 40.6

Member 1 - Scheduled Bars

Bar

Mark

Type and

size

No. of

bars

Bar Length

(mm)

Shape

code

A

(mm)

B

(mm)

C

(mm)

D

(mm)

E/R

(mm)

01 H12 2 3750 00

02 H12 2 6225 00

03 H12 2 4500 00

04 H8 37 1250 51 385 160 115

Member M1 Span 1

Detailed BS8110 Design Requirements

Section Property: 224 x 449

Span Length = 3.200 m Rectangular section

Width = 225 mm Depth = 450 mm

Covers: Top = 30 mm Bottom = 30 mm Side = 30 mm

Member M1 Span 1

Detailed BS8110 Main Reinforcement

Sagging: at 1.333 m from the start of the member

Moment applied to section = 23.82 kNm

Effective depth of tension reinforcement d = 406 mm

Depth to compression reinforcement d' = 58 mm

Redistribution < 10%, hence K' = 0.156 3.4.4.4

K = (M/bd

2

fcu) = 0.026

K s K' hence compression steel not required.

z = d ( 0.5 + [ 0.25 - (K/0.9)]

0.5

) s 0.95d = 385.70 mm

Asr = (M/0.87 fyz) = 142.02 mm

2

Tension Bars provided = 2H12

Actual area of tension reinforcement = 226.19 mm

2

Minimum area of tension reinforcement = 0.13 % 3.12.5.3

Maximum area of tension reinforcement = 4 % 3.12.6.1

Actual % of tension reinforcement = 0.22 %

Minimum horizontal distance between bars = hagg + 5mm = 25 mm 3.12.11.1

Smallest actual horizontal space between bars = 125 mm

Maximum spacing of tension bars = (47000/fs) s 300 = 225 mm 3.12.11.2.4

Largest actual space between tension bars = 125 mm

Maximum clear distance between beam face and nearest main bar in tension

= max tension bar spacing / 2 = 112 mm 3.12.11.2.5

Actual clear distance between beam face and nearest main bar in tension

= 38 mm

Actual neutral axis depth of section = 43.17 mm

Moment capacity of section = 38.02 kNm

OK

Hogging: at 3.200 m from the start of the member

Moment applied to section = 17.51 kNm

Effective depth of tension reinforcement d = 406 mm

Depth to compression reinforcement d' = 58 mm

Redistribution < 10%, hence K' = 0.156 3.4.4.4

K = (M/bd

2

fcu) = 0.019

K s K' hence compression steel not required.

z = d ( 0.5 + [ 0.25 - (K/0.9)]

0.5

) s 0.95d = 385.70 mm

Asr = (M/0.87 fyz) = 104.41 mm

2

Tension Bars provided = 2H12

Actual area of tension reinforcement = 226.19 mm

2

Minimum area of tension reinforcement = 0.13 % 3.12.5.3

Maximum area of tension reinforcement = 4 % 3.12.6.1

Actual % of tension reinforcement = 0.22 %

Minimum horizontal distance between bars = hagg + 5mm = 25 mm 3.12.11.1

Smallest actual horizontal space between bars = 125 mm

Maximum spacing of tension bars = (47000/fs) s 300 = 241 mm 3.12.11.2.4

Largest actual space between tension bars = 125 mm

Maximum clear distance between beam face and nearest main bar in tension

= max tension bar spacing / 2 = 121 mm 3.12.11.2.5

Actual clear distance between beam face and nearest main bar in tension

= 38 mm

Actual neutral axis depth of section = 43.17 mm

Moment capacity of section = 38.02 kNm

OK

Member M1 Span 1

Detailed BS8110 Span / Effective Depth Check

Basic span / effective depth ratio = 20.0 3.4.6.3

fs = (2fy As req/3As prov) (1/|b) = (2 500 138.6/3 226.2) 1 = 204.27 N/mm

2

3.4.6.5

Mod. factor for tension rft. = 0.55 + ((477 - fs)/120(0.9 + M/bd

2

)) s 2.0 = 2.00 3.4.6.5

Mod. factor for compression rft. = 1 + (100As

'

prov/bd) / [3 + (100As

'

prov/bd)] s 1.5 = 1.00 3.4.6.6

Hence, modified span / effective depth ratio = 40.00

Actual span / effective depth ratio = 7.88 SAFE

Member M1 Span 1

Detailed BS8110 Shear Reinforcement

Minimum links zone: 0.001 m to 3.199 m

Maximum shear force within zone, V = 45.47 kN

v = (V/bvd) = 0.50 N/mm

2

3.4.5.2

s 0.8 \fcu and 5 N/mm

2

hence dimensions adequate

vc = 0.79 [(100 As/bvd)]

1/3

[(400/d)]

1/4

/ m 3.4.5.4

= 0.79 0.25

0.33

1.00

0.25

/ 1.25 = 0.40 N/mm

2

0.5vc < v < (vc + 0.4), hence provide nominal links 3.4.5.3

spacing provided, sv = 300 mm

minimum area of links = 0.4 bv sv / 0.87 fyv = 62.10 mm

2

area of links provided (2H8), Asv = 100.53 mm

2

OK

Member M1 Span 2

Detailed BS8110 Design Requirements

Section Property: 224 x 449

Span Length = 4.200 m Rectangular section

Width = 225 mm Depth = 450 mm

Covers: Top = 30 mm Bottom = 30 mm Side = 30 mm

Member M1 Span 2

Detailed BS8110 Main Reinforcement

Hogging: at 3.200 m from the start of the member

Moment applied to section = 17.51 kNm

Effective depth of tension reinforcement d = 406 mm

Depth to compression reinforcement d' = 58 mm

Redistribution < 10%, hence K' = 0.156 3.4.4.4

K = (M/bd

2

fcu) = 0.019

K s K' hence compression steel not required.

z = d ( 0.5 + [ 0.25 - (K/0.9)]

0.5

) s 0.95d = 385.70 mm

Asr = (M/0.87 fyz) = 104.41 mm

2

Tension Bars provided = 2H12

Actual area of tension reinforcement = 226.19 mm

2

Minimum area of tension reinforcement = 0.13 % 3.12.5.3

Maximum area of tension reinforcement = 4 % 3.12.6.1

Actual % of tension reinforcement = 0.22 %

Minimum horizontal distance between bars = hagg + 5mm = 25 mm 3.12.11.1

Smallest actual horizontal space between bars = 125 mm

Maximum spacing of tension bars = (47000/fs) s 300 = 241 mm 3.12.11.2.4

Largest actual space between tension bars = 125 mm

Maximum clear distance between beam face and nearest main bar in tension

= max tension bar spacing / 2 = 121 mm 3.12.11.2.5

Actual clear distance between beam face and nearest main bar in tension

= 38 mm

Actual neutral axis depth of section = 43.17 mm

Moment capacity of section = 38.02 kNm

OK

Hogging: at 7.400 m from the start of the member

Moment applied to section = 31.01 kNm

Effective depth of tension reinforcement d = 406 mm

Depth to compression reinforcement d' = 58 mm

Redistribution < 10%, hence K' = 0.156 3.4.4.4

K = (M/bd

2

fcu) = 0.033

K s K' hence compression steel not required.

z = d ( 0.5 + [ 0.25 - (K/0.9)]

0.5

) s 0.95d = 385.70 mm

Asr = (M/0.87 fyz) = 184.94 mm

2

Tension Bars provided = 2H12

Actual area of tension reinforcement = 226.19 mm

2

Minimum area of tension reinforcement = 0.13 % 3.12.5.3

Maximum area of tension reinforcement = 4 % 3.12.6.1

Actual % of tension reinforcement = 0.22 %

Minimum horizontal distance between bars = hagg + 5mm = 25 mm 3.12.11.1

Smallest actual horizontal space between bars = 125 mm

Maximum spacing of tension bars = (47000/fs) s 300 = 172 mm 3.12.11.2.4

Largest actual space between tension bars = 125 mm

Maximum clear distance between beam face and nearest main bar in tension

= max tension bar spacing / 2 = 86 mm 3.12.11.2.5

Actual clear distance between beam face and nearest main bar in tension

= 38 mm

Actual neutral axis depth of section = 43.17 mm

Moment capacity of section = 38.02 kNm

OK

Member M1 Span 2

Detailed BS8110 Span / Effective Depth Check

Basic span / effective depth ratio = 26.0 3.4.6.3

fs = (2fy As req/3As prov) (1/|b) = (2 500 132.1/3 226.2) 1 = 194.62 N/mm

2

3.4.6.5

Mod. factor for tension rft. = 0.55 + ((477 - fs)/120(0.9 + M/bd

2

)) s 2.0 = 2.00 3.4.6.5

Mod. factor for compression rft. = 1 + (100As

'

prov/bd) / [3 + (100As

'

prov/bd)] s 1.5 = 1.00 3.4.6.6

Hence, modified span / effective depth ratio = 52.00

Actual span / effective depth ratio = 10.34 SAFE

Member M1 Span 2

Detailed BS8110 Shear Reinforcement

Minimum links zone: 3.199 m to 7.399 m

Maximum shear force within zone, V = 45.47 kN

v = (V/bvd) = 0.50 N/mm

2

3.4.5.2

s 0.8 \fcu and 5 N/mm

2

hence dimensions adequate

vc = 0.79 [(100 As/bvd)]

1/3

[(400/d)]

1/4

/ m 3.4.5.4

= 0.79 0.25

0.33

1.00

0.25

/ 1.25 = 0.40 N/mm

2

0.5vc < v < (vc + 0.4), hence provide nominal links 3.4.5.3

spacing provided, sv = 300 mm

minimum area of links = 0.4 bv sv / 0.87 fyv = 62.10 mm

2

area of links provided (2H8), Asv = 100.53 mm

2

OK

Member M1 Span 3

Detailed BS8110 Design Requirements

Section Property: 224 x 449

Span Length = 4.000 m Rectangular section

Width = 225 mm Depth = 450 mm

Covers: Top = 30 mm Bottom = 30 mm Side = 30 mm

Member M1 Span 3

Detailed BS8110 Main Reinforcement

Hogging: at 7.400 m from the start of the member

Moment applied to section = 31.01 kNm

Effective depth of tension reinforcement d = 406 mm

Depth to compression reinforcement d' = 58 mm

Redistribution < 10%, hence K' = 0.156 3.4.4.4

K = (M/bd

2

fcu) = 0.033

K s K' hence compression steel not required.

z = d ( 0.5 + [ 0.25 - (K/0.9)]

0.5

) s 0.95d = 385.70 mm

Asr = (M/0.87 fyz) = 184.94 mm

2

Tension Bars provided = 2H12

Actual area of tension reinforcement = 226.19 mm

2

Minimum area of tension reinforcement = 0.13 % 3.12.5.3

Maximum area of tension reinforcement = 4 % 3.12.6.1

Actual % of tension reinforcement = 0.22 %

Minimum horizontal distance between bars = hagg + 5mm = 25 mm 3.12.11.1

Smallest actual horizontal space between bars = 125 mm

Maximum spacing of tension bars = (47000/fs) s 300 = 172 mm 3.12.11.2.4

Largest actual space between tension bars = 125 mm

Maximum clear distance between beam face and nearest main bar in tension

= max tension bar spacing / 2 = 86 mm 3.12.11.2.5

Actual clear distance between beam face and nearest main bar in tension

= 38 mm

Actual neutral axis depth of section = 43.17 mm

Moment capacity of section = 38.02 kNm

OK

Sagging: at 9.733 m from the start of the member

Moment applied to section = 35.69 kNm

Effective depth of tension reinforcement d = 406 mm

Depth to compression reinforcement d' = 58 mm

Redistribution < 10%, hence K' = 0.156 3.4.4.4

K = (M/bd

2

fcu) = 0.038

K s K' hence compression steel not required.

z = d ( 0.5 + [ 0.25 - (K/0.9)]

0.5

) s 0.95d = 385.70 mm

Asr = (M/0.87 fyz) = 212.82 mm

2

Tension Bars provided = 2H12

Actual area of tension reinforcement = 226.19 mm

2

Minimum area of tension reinforcement = 0.13 % 3.12.5.3

Maximum area of tension reinforcement = 4 % 3.12.6.1

Actual % of tension reinforcement = 0.22 %

Minimum horizontal distance between bars = hagg + 5mm = 25 mm 3.12.11.1

Smallest actual horizontal space between bars = 125 mm

Maximum spacing of tension bars = (47000/fs) s 300 = 150 mm 3.12.11.2.4

Largest actual space between tension bars = 125 mm

Maximum clear distance between beam face and nearest main bar in tension

= max tension bar spacing / 2 = 75 mm 3.12.11.2.5

Actual clear distance between beam face and nearest main bar in tension

= 38 mm

Actual neutral axis depth of section = 43.17 mm

Moment capacity of section = 38.02 kNm

OK

Member M1 Span 3

Detailed BS8110 Span / Effective Depth Check

Basic span / effective depth ratio = 20.0 3.4.6.3

fs = (2fy As req/3As prov) (1/|b) = (2 500 205.7/3 226.2) 1 = 303.12 N/mm

2

3.4.6.5

Mod. factor for tension rft. = 0.55 + ((477 - fs)/120(0.9 + M/bd

2

)) s 2.0 = 1.34 3.4.6.5

Mod. factor for compression rft. = 1 + (100As

'

prov/bd) / [3 + (100As

'

prov/bd)] s 1.5 = 1.00 3.4.6.6

Hence, modified span / effective depth ratio = 26.84

Actual span / effective depth ratio = 9.85 SAFE

Member M1 Span 3

Detailed BS8110 Shear Reinforcement

Minimum links zone: 7.399 m to 11.399 m

Maximum shear force within zone, V = 57.75 kN

v = (V/bvd) = 0.63 N/mm

2

3.4.5.2

s 0.8 \fcu and 5 N/mm

2

hence dimensions adequate

vc = 0.79 [(100 As/bvd)]

1/3

[(400/d)]

1/4

/ m 3.4.5.4

= 0.79 0.25

0.33

1.00

0.25

/ 1.25 = 0.40 N/mm

2

0.5vc < v < (vc + 0.4), hence provide nominal links 3.4.5.3

spacing provided, sv = 300 mm

minimum area of links = 0.4 bv sv / 0.87 fyv = 62.10 mm

2

area of links provided (2H8), Asv = 100.53 mm

2

OK

Design Group: Member Group 1 - Brief Detail: Member1 BS8110 Beam

Group Data

Top cover 30 Aggregate size 20

Bottom cover 30 Concrete strength class C20/25

Side cover 30 Bond coefficients:

Envelope one Tension 0.50

Beam segments 12 Compression 0.64

Main Reinforcement

Main bars: 500.0 N/mm

2

Material Factor m: 1.15

Bar Size Min. Bend Radius Bar Size Min. Bend Radius

6 12.0 20 40.0

8 16.0 25 50.0

10 20.0 32 64.0

12 24.0 40 80.0

16 32.0 50 100.0

Anchorage provided by a bend = 12.0 diameters

Main Bar Criteria

Top Bar Criteria Bottom Bar Criteria

Min. bar size 10 10

Max. bar size 40 40

Link hanger size 8 8

Min. layer gap 32 32

Side bars controlled by minimum size of 12

Shear Reinforcement

Max. shear considered at Centre of supports

Enhanced shear at supports Excluded

Axial load effects Excluded

Shear Bar Criteria

Shear bars: 500.0 N/mm

2

Material Factor m: 1.15

Bar Size Min. Bend Radius Bar Size Min. Bend Radius

6 12.0 20 40.0

8 16.0 25 50.0

10 20.0 32 64.0

12 24.0 40 80.0

16 32.0 50 100.0

Anchorage provided by a bend = 12.0 diameters

Min. size 8 Min. spacing 25 mm

Min. number of legs 2 Link style Closed

List of Design Groups - Structure3

Design Group Brief

G1 Member Group 1 Member1

List of Design Briefs - Structure3

Brief Code

1 Member1 BS8110 Beam

Brief Detail:

There is no data of this type.

Das könnte Ihnen auch gefallen

- Anchor and Base Plate CalculationDokument6 SeitenAnchor and Base Plate Calculationselahattin_erturk06Noch keine Bewertungen

- Splice Connection - Full CapacityDokument14 SeitenSplice Connection - Full Capacitykalpanaadhi75% (4)

- PC I Girder Pretensioned HS20 44 SIDokument10 SeitenPC I Girder Pretensioned HS20 44 SIAnonymous vHUAr5Lp100% (1)

- asset-v1-CornellX+ENGR2000X+2T2016+type@asset+block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Dokument42 Seitenasset-v1-CornellX+ENGR2000X+2T2016+type@asset+block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Axel DominiqueNoch keine Bewertungen

- Asset-V1 CornellX+ENGR2000X+2T2016+Type@Asset+Block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2Dokument26 SeitenAsset-V1 CornellX+ENGR2000X+2T2016+Type@Asset+Block@F-1 Engine Model Calculations Non-Proprietyary Non-ITAR Rev2salehmashrur 98Noch keine Bewertungen

- Design of Welded Splice Connection (DET.-D-04) : From Staad OutputDokument10 SeitenDesign of Welded Splice Connection (DET.-D-04) : From Staad Outputvikas WaghmareNoch keine Bewertungen

- Al Fanar Bare CopperDokument2 SeitenAl Fanar Bare CopperMOHAMMEDNoch keine Bewertungen

- AS CelluloseDokument7 SeitenAS CelluloseDenesh MohandNoch keine Bewertungen

- TORREDokument5 SeitenTORRELuis Miguel MitaNoch keine Bewertungen

- Jabel-Beam Capacity ReportDokument5 SeitenJabel-Beam Capacity Reportjamesbeth162Noch keine Bewertungen

- Tapr 40 CeDokument1 SeiteTapr 40 CesusmitpatelNoch keine Bewertungen

- Sectional Properties of Rolled Steel Joists (Ref: Is: 808 - 1989 & Is: 12778 - 2004)Dokument49 SeitenSectional Properties of Rolled Steel Joists (Ref: Is: 808 - 1989 & Is: 12778 - 2004)rohitnrgNoch keine Bewertungen

- EN6114Dokument14 SeitenEN6114akayirNoch keine Bewertungen

- Tabular Presentation of Basic Technical Data RMC ConductorsDokument2 SeitenTabular Presentation of Basic Technical Data RMC ConductorsBuyme1 CNC BIZNoch keine Bewertungen

- PORTICOSDokument90 SeitenPORTICOSExleider Sanchez PerezNoch keine Bewertungen

- Tensile TestingDokument12 SeitenTensile TestingAhmed ElqazazNoch keine Bewertungen

- M.TECH-CASAD (BATCH-2019/20) Experimental Techniques in Structural Engineering (3Cl1202)Dokument6 SeitenM.TECH-CASAD (BATCH-2019/20) Experimental Techniques in Structural Engineering (3Cl1202)bhavik modiNoch keine Bewertungen

- Hitungan Mekanika Fluida Rev01Dokument19 SeitenHitungan Mekanika Fluida Rev01misfat nawalNoch keine Bewertungen

- Cladiri Inalte ModelDokument42 SeitenCladiri Inalte ModelBogdan BîngăNoch keine Bewertungen

- Llogaritja Hidraulike e Kanaleve SEG - 3Dokument2 SeitenLlogaritja Hidraulike e Kanaleve SEG - 3Armend AvdiuNoch keine Bewertungen

- Table 1.16.. Permissible Stress in Concrete (IS: 456-2000) ADokument4 SeitenTable 1.16.. Permissible Stress in Concrete (IS: 456-2000) Asree ganesh constructionsNoch keine Bewertungen

- Water Ret DesignDokument13 SeitenWater Ret DesignasrafNoch keine Bewertungen

- RCC Design Based in Indian CodesDokument43 SeitenRCC Design Based in Indian Codeschaos_atulNoch keine Bewertungen

- Tensile TestDokument5 SeitenTensile TestNabeel J. AwadNoch keine Bewertungen

- ScratchDokument1 SeiteScratchesi ekmiNoch keine Bewertungen

- 2FC1Dokument4 Seiten2FC1Jefferd PaetNoch keine Bewertungen

- Aquarius+ UPVC Industrial Pipe & FittingsDokument16 SeitenAquarius+ UPVC Industrial Pipe & Fittingspanchal harnishNoch keine Bewertungen

- Steel Wire Rope Din 3055Dokument1 SeiteSteel Wire Rope Din 3055GAGAN SHARMANoch keine Bewertungen

- RCC Design Programmed by OthersDokument43 SeitenRCC Design Programmed by OthersJessie Radaza TutorNoch keine Bewertungen

- Perhitungan BlockDokument102 SeitenPerhitungan BlockShinta SabrinaNoch keine Bewertungen

- 8.BCW - N (466) - M (1196,356)Dokument3 Seiten8.BCW - N (466) - M (1196,356)carloNoch keine Bewertungen

- Secant Pile ReinforcementDokument8 SeitenSecant Pile ReinforcementghansaNoch keine Bewertungen

- Consol Mich22Dokument46 SeitenConsol Mich22Kofi DanielNoch keine Bewertungen

- Tendons 4+579Dokument13 SeitenTendons 4+579soujanya rajeshNoch keine Bewertungen

- Local Buckling Analysis Based On DNV-OS-F101 2000Dokument4 SeitenLocal Buckling Analysis Based On DNV-OS-F101 2000shervinyNoch keine Bewertungen

- StressDokument13 SeitenStressLenielle AmatosaNoch keine Bewertungen

- Erthquake Module 12Dokument7 SeitenErthquake Module 12dash1991Noch keine Bewertungen

- Stiffness MethodexDokument5 SeitenStiffness MethodexabbasNoch keine Bewertungen

- Connection DesignDokument17 SeitenConnection Designrekcah ehtNoch keine Bewertungen

- Mechanical Properties: QT-900 Technical Data SheetDokument2 SeitenMechanical Properties: QT-900 Technical Data SheetIshmael WoolooNoch keine Bewertungen

- Coiled Tubing Calculation: Sws - Career Development System (Phase - I) Coiled Tubing Service Class Room TrainingDokument16 SeitenCoiled Tubing Calculation: Sws - Career Development System (Phase - I) Coiled Tubing Service Class Room TrainingNardo AvalosNoch keine Bewertungen

- LlooDokument4 SeitenLlooPrem SharmaNoch keine Bewertungen

- Anchor Chair Design CheckDokument5 SeitenAnchor Chair Design CheckManish542Noch keine Bewertungen

- Tank DesignDokument89 SeitenTank DesignDietrich von BismarckNoch keine Bewertungen

- British Commercial Computer Digest: Pergamon Computer Data SeriesVon EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNoch keine Bewertungen

- Samsung Galaxy S23 Series (Galaxy S23, S23 Plus and S23 Ultra) User Guide for Beginners and SeniorsVon EverandSamsung Galaxy S23 Series (Galaxy S23, S23 Plus and S23 Ultra) User Guide for Beginners and SeniorsBewertung: 1 von 5 Sternen1/5 (1)

- The Spectra and Dynamics of Diatomic Molecules: Revised and Enlarged EditionVon EverandThe Spectra and Dynamics of Diatomic Molecules: Revised and Enlarged EditionNoch keine Bewertungen

- Practical Variable Speed Drives and Power ElectronicsVon EverandPractical Variable Speed Drives and Power ElectronicsBewertung: 5 von 5 Sternen5/5 (3)

- Practical Power Distribution for IndustryVon EverandPractical Power Distribution for IndustryBewertung: 2.5 von 5 Sternen2.5/5 (2)

- Troubleshooting Optical Fiber Networks: Understanding and Using Optical Time-Domain ReflectometersVon EverandTroubleshooting Optical Fiber Networks: Understanding and Using Optical Time-Domain ReflectometersBewertung: 5 von 5 Sternen5/5 (2)

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsVon EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNoch keine Bewertungen

- Materials Science and Technology of Optical FabricationVon EverandMaterials Science and Technology of Optical FabricationNoch keine Bewertungen

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- Practical Grounding, Bonding, Shielding and Surge ProtectionVon EverandPractical Grounding, Bonding, Shielding and Surge ProtectionBewertung: 4 von 5 Sternen4/5 (15)

- Materials Data for Cyclic Loading: Low-Alloy SteelsVon EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsBewertung: 5 von 5 Sternen5/5 (2)

- Hyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationVon EverandHyrdoacoustic Ocean Exploration: Theories and Experimental ApplicationNoch keine Bewertungen

- LoggingDokument25 SeitenLoggingZitheeq UmarNoch keine Bewertungen

- Curriculum Vitae: NameDokument2 SeitenCurriculum Vitae: NameZitheeq UmarNoch keine Bewertungen

- Book 1Dokument8 SeitenBook 1Zitheeq UmarNoch keine Bewertungen

- R.R.J.R. Jayakody, Tel. 0813818517 Licensed Surveyor, 0777-248313 442/1, Gampola Road, Peradeniya Reg. No. 19831073Dokument1 SeiteR.R.J.R. Jayakody, Tel. 0813818517 Licensed Surveyor, 0777-248313 442/1, Gampola Road, Peradeniya Reg. No. 19831073Zitheeq UmarNoch keine Bewertungen

- Handbook To British Standard 8110 PDFDokument2 SeitenHandbook To British Standard 8110 PDFZitheeq Umar50% (2)

- 01 Lwin AbstractDokument1 Seite01 Lwin AbstractZitheeq UmarNoch keine Bewertungen

- A View From The Bridge Exam QuestionsDokument1 SeiteA View From The Bridge Exam QuestionsZitheeq UmarNoch keine Bewertungen

- Longitudinal Section: General NotesDokument1 SeiteLongitudinal Section: General NotesZitheeq UmarNoch keine Bewertungen

- Comparison Between Column Supported Esr and Shaft Supported EsrDokument27 SeitenComparison Between Column Supported Esr and Shaft Supported EsrZitheeq UmarNoch keine Bewertungen

- Detali Check List Mach & EquipDokument2 SeitenDetali Check List Mach & EquipZitheeq UmarNoch keine Bewertungen

- Weekl Monthly Check ListDokument7 SeitenWeekl Monthly Check ListZitheeq UmarNoch keine Bewertungen

- Jfe Engineering Corporation Kandy City Waste Water Management Project, Package 1 Daily Check List For Concrete Pump Car ThisDokument2 SeitenJfe Engineering Corporation Kandy City Waste Water Management Project, Package 1 Daily Check List For Concrete Pump Car ThisZitheeq UmarNoch keine Bewertungen

- Weekl Monthly Check ListDokument7 SeitenWeekl Monthly Check ListZitheeq UmarNoch keine Bewertungen

- Fersner PpsDokument23 SeitenFersner PpsZitheeq UmarNoch keine Bewertungen

- CPC 6th Council MemebersDokument5 SeitenCPC 6th Council MemebersZitheeq UmarNoch keine Bewertungen

- Certification MPS BridgeDokument1 SeiteCertification MPS BridgeZitheeq UmarNoch keine Bewertungen

- Concrete TechnologyDokument2 SeitenConcrete TechnologyT Chaitanya Srikrishna Asst. ProfessorNoch keine Bewertungen

- Perilaku Lentur Balok Beton Bertulang Dengan Tulangan Rotan Dan Tulangan Besi PolosDokument13 SeitenPerilaku Lentur Balok Beton Bertulang Dengan Tulangan Rotan Dan Tulangan Besi PolosHilman AbdullahNoch keine Bewertungen

- 064 Method Statement For Construction of Air-Cooled CondensDokument13 Seiten064 Method Statement For Construction of Air-Cooled CondensMohd NasharuddinNoch keine Bewertungen

- Trial Mix Two (420,430)Dokument14 SeitenTrial Mix Two (420,430)Tewodros TadesseNoch keine Bewertungen

- Iron Ore TalingsDokument8 SeitenIron Ore TalingsUday BoddepalliNoch keine Bewertungen

- National Oil Corporation: Rev Date Description Checked ApprovedDokument24 SeitenNational Oil Corporation: Rev Date Description Checked ApprovedYousab JacobNoch keine Bewertungen

- Ph.D. Course Work Syllabus in Civil Engg.Dokument15 SeitenPh.D. Course Work Syllabus in Civil Engg.arunachelamNoch keine Bewertungen

- Concrete TestingDokument41 SeitenConcrete Testingeunice19970315Noch keine Bewertungen

- Rapid Hardening CementDokument3 SeitenRapid Hardening CementneekrissNoch keine Bewertungen

- METHOD Statement For Citadel Fence and Concrete Removal at The IGRF LOPDokument8 SeitenMETHOD Statement For Citadel Fence and Concrete Removal at The IGRF LOPoaklamNoch keine Bewertungen

- 5-Aci 8855Dokument10 Seiten5-Aci 8855aliNoch keine Bewertungen

- Lucky Internship ReportDokument29 SeitenLucky Internship Reportسید عاصم علی شاہNoch keine Bewertungen

- Construction ChemicalsDokument23 SeitenConstruction Chemicalsatolye2Noch keine Bewertungen

- METHOD STATEMENT BridgeDokument2 SeitenMETHOD STATEMENT BridgeSyira100% (2)

- Vol42No10 FullDokument84 SeitenVol42No10 FullMarco PalmaNoch keine Bewertungen

- PAES 419 - 2015 Warehouse For Bagged Storage For GrainDokument16 SeitenPAES 419 - 2015 Warehouse For Bagged Storage For GrainFarouk PagsNoch keine Bewertungen

- Reinforced Concrete Design - LESSON 1.1 PDFDokument20 SeitenReinforced Concrete Design - LESSON 1.1 PDFBeerRideNoch keine Bewertungen

- Materials System SpecificationDokument10 SeitenMaterials System SpecificationMoustafa Bayoumi100% (1)

- Simplified Estimate by Max FajardoDokument300 SeitenSimplified Estimate by Max FajardoRyan David MacayanNoch keine Bewertungen

- 2 MixDesign CLC EN PDFDokument3 Seiten2 MixDesign CLC EN PDFCyril Jean-Baptiste100% (1)

- Concrete Tank SpreadsheetDokument3 SeitenConcrete Tank SpreadsheetMai CNoch keine Bewertungen

- 4 MaterialsDokument72 Seiten4 MaterialsCt Kamariah Md SaatNoch keine Bewertungen

- Determination of Size Independent Fracture Energy of Mixes by 2 MethodsDokument7 SeitenDetermination of Size Independent Fracture Energy of Mixes by 2 MethodsSai Asrith PylaNoch keine Bewertungen

- SLP-1 Construction Guide For Storage Magazines: ForewordDokument22 SeitenSLP-1 Construction Guide For Storage Magazines: ForewordNTAMBO KABEKENoch keine Bewertungen

- Swastik Cements FloricultureDokument3 SeitenSwastik Cements FloriculturecvwNoch keine Bewertungen

- Cross Section Cross Section: Bureau of DesignDokument1 SeiteCross Section Cross Section: Bureau of DesignMNoch keine Bewertungen

- Difference BETWEEN OLD STRUCTURE AND NEW STRUCTURE ON SAME BUILDINGDokument6 SeitenDifference BETWEEN OLD STRUCTURE AND NEW STRUCTURE ON SAME BUILDINGSudarshan PatilNoch keine Bewertungen

- Punching ShearDokument7 SeitenPunching SheardagetzNoch keine Bewertungen

- Ready Mix Concrete PlantDokument134 SeitenReady Mix Concrete Plantsalman100% (1)

- Analysis of Rates 8Dokument1 SeiteAnalysis of Rates 8Aman ThakurNoch keine Bewertungen