Beruflich Dokumente

Kultur Dokumente

UP56 Ultrasonic Level Sensor: Tough, Non-Contact, Pressure-Resistant

Hochgeladen von

Lisandra Camacho0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

45 Ansichten8 SeitenThe UP56 ultrasonic level sensor is tough, non-contact, and pressure-resistant up to 6 bar. It uses ultrasonic technology to measure level continuously or switch points in liquids and bulk solids. It has two output signals, allowing uses like measuring dry running and overflow in one device. Parameters are easy to set via display, PC, or connect+ adapter.

Originalbeschreibung:

Originaltitel

UP56 Ultrasonic

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThe UP56 ultrasonic level sensor is tough, non-contact, and pressure-resistant up to 6 bar. It uses ultrasonic technology to measure level continuously or switch points in liquids and bulk solids. It has two output signals, allowing uses like measuring dry running and overflow in one device. Parameters are easy to set via display, PC, or connect+ adapter.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

45 Ansichten8 SeitenUP56 Ultrasonic Level Sensor: Tough, Non-Contact, Pressure-Resistant

Hochgeladen von

Lisandra CamachoThe UP56 ultrasonic level sensor is tough, non-contact, and pressure-resistant up to 6 bar. It uses ultrasonic technology to measure level continuously or switch points in liquids and bulk solids. It has two output signals, allowing uses like measuring dry running and overflow in one device. Parameters are easy to set via display, PC, or connect+ adapter.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 8

UP56 Ultrasonic Level Sensor

Tough, non-contact, pressure-resistant

D

A

T

A

S

H

E

E

T

L E V E L SE NSORS | SI C K

Subject to change without notice

A

B

C

D

E

F

H

I

J

K

L

M

N

O

P

Q

R

S

T

8013615/2010-05-01

Level Sensors

2

UP56-2

Product description

The UP56 series of ultrasonic level

sensors is the ideal solution for deman-

ding applications. The tefon-protected

transducer handles overpressure up to

6 bar (87 psi) and is resistant against

numerous diffcult fuids. Wetted parts

can be chosen either as stainless steel

or PVDF, thus making the UP56 the

perfect solution for measurement in

aggressive, viscous, or abrasive liquids,

or bulk solids. By combining two output

signals in one device, new cost-effective

solutions can be created for measure-

ment and integration into the system.

With two switching outputs, the UP56

can measure dry running and overfow

in one device. Combining analog and

a switching output enables continuous

level measurement with a separate

overfow signal. Parameters are easy to

set via an integrated display, PC or the

connect+ adapter.

At a glance

Non-contact level measurement up

to 3.4 m operating distance / 8.0 m

limit scanning distance

Pressure resistant up to 6 bar (87

psi)

Transducer protected by PVDF cover

for increased resistance

3-in-1: continuous level measure-

ment, level switch and display

Analog output switchable between

4 20 mA and 0 10 V

Process connector thread G1 and G2

IP 67 enclosure rating

Easy to set parameters, also via

connect+

Your benefts

Non-contact measurement in pressu-

rized containers no wear over time

Easy to set parameters, saving time

Flexible measurement system for

different container sizes standardi-

zation and stock reduction

One product for point level and

continuous applications, reduces the

number of sensors required

Ultrasonic Level Sensor:

tough, non-contact, pressure-resistant

Additional information

Detailed technical data. . . . . . . . . . . . .2

Ordering information. . . . . . . . . . . . . . .4

Dimensional drawings . . . . . . . . . . . . .4

Connection type and diagram . . . . . . .5

Detection ranges. . . . . . . . . . . . . . . . . .5

Recommended accessories. . . . . . . . .5

L E V E L SE NSORS | SI C K

Subject to change without notice

A

B

C

D

E

F

H

I

J

K

L

M

N

O

P

Q

R

S

T

8013615/2010-05-01

Level Sensors

3

UP56-2

Detailed technical data

Features

UP56-211 UP56-212 UP56-213 UP56-214

Medium Fluids, Bulk solids

Measurement Continuous and point level measurement

Operating distance 30 mm ... 250 mm 85 mm ... 350 mm 200 mm ... 1,300 mm 350 mm ... 3,400 mm

Limiting scanning distance 30 mm ... 990 mm 85 mm ... 1,500 mm 200 mm ... 5,000 mm 350 mm ... 8,000 mm

Process pressure 0 bar ... 6 bar , gauge pressure

Process temperature 25 C ... +70 C

Performance

Accuracy

1)

2 %

Reproducibility

1)

0.15 %

1)

Of fnal value.

Mechanics

Process connection G 1 G 2

Housing material Stainless steel 1.4571, PBT, TPU Stainless steel

1.4571, PBT, TPU /

PVDF, PBT, TPU (de-

pending on type)

Weight 210 g 1,200 g / 350 g (de-

pending on type)

Electronics

UP56-211 UP56-212 UP56-213 UP56-214

Supply voltage

1)

9 V DC ... 30 V DC

Ripple 10 %

Power consumption

2)

80 mA

Electrical connection M12x1, 5-pin

Signal output 1x PNP

Hysteresis 3 mm 5 mm 20 mm 50 mm

Analog output

3)

4)

Qa: 4 mA ... 20 mA / 0 V ... 10 V

Signal voltage HIGH Uv - 3 V

Response time

5)

68 ms 84 ms 180 ms 240 ms

Switching frequency 11 Hz 8 Hz 5 Hz 3 Hz

Time delay before availability 300 ms

Enclosure rating IP 67

Ultrasonic frequency 320 kHz 180 kHz 120 kHz

Ultrasonic convertor PTFE coating, FFKM

1)

Reverse-polarity protected.

2)

Without load.

3)

Short-circuit protected, reversible.

4)

Automatic switching between voltage and current outputs dependent on load 4 mA ... 20 mA: RL <= 100/ at 9 V <= UB <= 20 V; RL <= 500/ at UB >= 20 V; 0 V ... 10

V: RL >= 100 k/ at UB >= 15 V, short-circuit protected.

5)

Recovery time 32 ms ... 180 ms according to EMC EN 60947-5-7.

Ambient data

Ambient temperature, operation

1)

25 C ... +70 C

Ambient temperature, storage 40 C ... +85 C

1)

Temperature compensation at 25 C 50 C, can be switched off.

L E V E L SE NSORS | SI C K

Subject to change without notice

A

B

C

D

E

F

H

I

J

K

L

M

N

O

P

Q

R

S

T

8013615/2010-05-01

Level Sensors

4

UP56-2

Ordering information

Process temperature: 25 C ... +70 C

Process pressure: 0 bar ... 6 bar

Housing material Process connection Operating distance Limiting scanning

distance

Type Part No.

Stainless steel 1.4571,

PBT, TPU

G 1

30 mm ... 250 mm 30 mm ... 990 mm UP56-211118 6041658

85 mm ... 350 mm 85 mm ... 1,500 mm UP56-212118 6041659

200 mm ... 1,300 mm 200 mm ... 5,000 mm UP56-213118 6041660

G 2 350 mm ... 3,400 mm 350 mm ... 8,000 mm UP56-214118 6041693

PVDF, PBT, TPU G 2 350 mm ... 3,400 mm 350 mm ... 8,000 mm UP56-214178 6039866

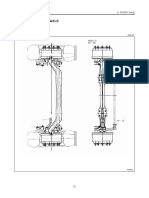

Dimensional drawings

UP56-211/ 212/ 213

10

(0.39)

M

1

2

x

1

G

1

12,5

(0.49)

103

(4.06)

57,5

(2.26)

90,5

(3.56)

SW41 / 41 (1.61) width A/F

Viton O-Ring

(34x2,5)

(1.34"x 0.1")

TouchControl LED-Display

2 Buttons / 2 Duo-LEDs

All dimensions in mm (inch)

UP56-214

M

1

2

x

1

G

2

38

(1.49)

109

(4.29)

15

(0.59)

38

(1.49)

71

(2.80)

Viton O-Ring

(62.8 x 2)

(2.47x 0.08)

65 (2.56) width A/F

TouchControl

LED-Display

2 Buttons

2 Duo-LEDs

All dimensions in mm (inch)

Connection type and diagram

1

L+

Q

A

2

4

5

Q

PNP

brn

wht

blk

3

Sync/Com

gra

blu

M

L E V E L SE NSORS | SI C K

Subject to change without notice

A

B

C

D

E

F

H

I

J

K

L

M

N

O

P

Q

R

S

T

8013615/2010-05-01

Level Sensors

5

UP56-2

1 Aligned plate 500 x 500 mm

2 Pipe diameter 10 mm

3 Pipe diameter 27 mm

Recommended accessories

Weld-in fange

Process connection Material Type Part No.

G 1 316L BEF-FL-316G10-UP56 4064295

G 2 316L BEF-FL-316G20-UP56 4063263

Weld-in fange G 1 Weld-in fange G 2

Confguration software

Software Product Type Part No.

CPA Connect Plus CPA Connect Plus 6037782

Detection ranges

UP56-211 UP56-212 UP56-213 UP56-214

100 50 0 50 100

[mm]

50

100

150

200

250

300

350

400

UP56-211118

250 mm

1

2

200 100 0 100 200

[mm]

100

200

300

400

500

600

700

800

UP56-212118

350 mm

1

3

800 400 0 400 800

[mm]

400

800

1200

1600

2000

2400

2800

3200

UP56-213118

1300 mm

1

3

1600 800 0 800 1600

[mm]

800

1600

2400

3200

4000

4800

5600

6400

UP56-2141_8

3400 mm

1

2

1

2

(

0

.

4

7

)

47

( 1.85)

G1

All dimensions in mm (inch)

3

7

(

1

.

4

7

)

G2

79,5

( 3.13)

All dimensions in mm (inch)

L E V E L SE NSORS | SI C K

Subject to change without notice

A

B

C

D

E

F

H

I

J

K

L

M

N

O

P

Q

R

S

T

8013615/2010-05-01

Level Sensors

6

UP56-2

Plug connectors and cables

Connector type Enclosure

rating

Flying leads Sheath material Cable length Type Part No.

Female connector IP 68

Straight PVC 2 m DOL-1205-G02M 6008899

Straight PUR halogen free 2 m DOL-1205-G02MC 6025906

Straight

PVC 5 m DOL-1205-G05M 6009868

PUR halogen free 5 m DOL-1205-G05MC 6025907

PVC 10 m DOL-1205-G10M 6010544

Straight PUR halogen free 10 m DOL-1205-G10MC 6025908

Angled PVC 2 m DOL-1205-W02M 6008900

Angled PUR halogen free 2 m DOL-1205-W02MC 6025909

Angled

PVC 5 m DOL-1205-W05M 6009869

PUR halogen free 5 m DOL-1205-W05MC 6025910

PVC 10 m DOL-1205-W10M 6010542

Angled PUR halogen free 10 m DOL-1205-W10MC 6025911

L E V E L SE NSORS | SI C K

Subject to change without notice

A

B

C

D

E

F

H

I

J

K

L

M

N

O

P

Q

R

S

T

8013615/2010-05-01

Level Sensors

7

UP56-2

Notes

8

0

1

3

6

1

5

/

2

0

1

0

-

0

5

-

0

1

D

I

V

0

9

/

F

D

(

2

0

1

0

-

0

5

)

W

B

U

S

m

o

d

d

e

3

5

Worldwide presence with

subsidiaries in the following

countries:

Australia

Belgium/Luxembourg

Brasil

Cesk Republika

China

Danmark

Deutschland

Espaa

France

Great Britain

India

Israel

Italia

Japan

Nederland

Norge

sterreich

Polska

Republic of Korea

Republika Slovenija

Romnia

Russia

Schweiz

Singapore

Suomi

Sverige

Taiwan

Trkiye

United Arab Emirates

USA/Canada/Mxico

Please fnd detailed addresses and

additional representatives and agencies

in all major industrial nations at

www.sick.com

Handed over by:

Factory automation

With its intelligent sensors, safety sys-

tems, and automatic identifcation appli-

cations, SICK provides comprehensive

solutions for factory automation.

Logistics automation

Sensors made by SICK form the basis

for automating material fows and the

optimization of sorting and warehousing

processes.

Process automation

Optimized system solutions from SICK

ensure effcient acquisition of envi-

ronmental and process data in many

industrial processes.

Our Business Segment Expertise

Non-contact detecting, counting,

classifying, and positioning of any

type of object

Accident protection and personal

safety using sensors, as well as

safety software and services

Automated identification with bar-

code and RFID reading devices for

the purpose of sorting and target

control in industrial material flow

Detecting volume, position, and con-

tours of objects and surroundings

with laser measurement systems

Precise measurement of gases,

liquids and dust concentrations for

continuous monitoring of emissions

and the acquisition of process data

in production processes

Gas flow measurements with maxi-

mum accuracy thanks to compact

gas meters

SICK AG | Waldkirch | Germany | www.sick.com

Das könnte Ihnen auch gefallen

- Beginning Digital Electronics through ProjectsVon EverandBeginning Digital Electronics through ProjectsBewertung: 5 von 5 Sternen5/5 (1)

- FT3.6.1 - Detector Prin Aspiratie - FAAST LTDokument2 SeitenFT3.6.1 - Detector Prin Aspiratie - FAAST LTABBYNoch keine Bewertungen

- "MPF" Modular Pressure Transmitter: ApplicationsDokument4 Seiten"MPF" Modular Pressure Transmitter: Applicationsgrincheu70Noch keine Bewertungen

- Sick WF Data SheetDokument8 SeitenSick WF Data SheetГомер МагазинNoch keine Bewertungen

- Transdutor Linear de Haste BTL7Dokument24 SeitenTransdutor Linear de Haste BTL7alamsyah_syamNoch keine Bewertungen

- FTU230EDokument4 SeitenFTU230Ejohn_ab12000Noch keine Bewertungen

- Ffus10-1g1io Flow SensorDokument12 SeitenFfus10-1g1io Flow SensorsujingthetNoch keine Bewertungen

- Microtol Online Turbidimeter BrochureDokument1 SeiteMicrotol Online Turbidimeter BrochureAqua Technology GroupNoch keine Bewertungen

- Level Sensors TDR Level Sensor: LFP0700-B4NMBDokument5 SeitenLevel Sensors TDR Level Sensor: LFP0700-B4NMBAnum QureshiNoch keine Bewertungen

- 18 Sensor Proximity SwitchDokument88 Seiten18 Sensor Proximity SwitchPrince Rao MuaazNoch keine Bewertungen

- SICK FFU Product InformationDokument12 SeitenSICK FFU Product InformationLuchito EbrNoch keine Bewertungen

- Multi-Function Measuring Instrument: Testo 435 - The Allrounder For Ventilation and Indoor Air QualityDokument8 SeitenMulti-Function Measuring Instrument: Testo 435 - The Allrounder For Ventilation and Indoor Air Qualityzivkovic brankoNoch keine Bewertungen

- Especificações Do Turbidímetro MicroTOLDokument4 SeitenEspecificações Do Turbidímetro MicroTOLBrunella Fernandes MileippNoch keine Bewertungen

- s710 CatalogDokument6 Seitens710 CatalogGaurav ChauhanNoch keine Bewertungen

- FN3280Dokument4 SeitenFN3280prykNoch keine Bewertungen

- BW25Dokument8 SeitenBW25msalem73Noch keine Bewertungen

- Teesa Group 24 Hits1402-Ww50 En-NopriceDokument8 SeitenTeesa Group 24 Hits1402-Ww50 En-NopriceksNoch keine Bewertungen

- 23 Sensor Pressure SwitchDokument28 Seiten23 Sensor Pressure SwitchموهاجيرينNoch keine Bewertungen

- Manual de Mantenimiento & Operacion OptekDokument63 SeitenManual de Mantenimiento & Operacion OptekLuis Tizoc100% (1)

- Sensor UltrasonicoDokument8 SeitenSensor UltrasonicoCristian LópezNoch keine Bewertungen

- Data Sheet Siemens MAG 8000Dokument17 SeitenData Sheet Siemens MAG 8000jairoNoch keine Bewertungen

- Bussmann TCP70 Series: 70Vdc Telecom FusesDokument5 SeitenBussmann TCP70 Series: 70Vdc Telecom FusesMuhammad Rauf AkramNoch keine Bewertungen

- Fluke 45Dokument1 SeiteFluke 45Luis BenavidesNoch keine Bewertungen

- Distance SensorDokument5 SeitenDistance Sensortuyetden613Noch keine Bewertungen

- x25 Laser TrackballDokument4 Seitenx25 Laser TrackballGPNoch keine Bewertungen

- 2.-West Serie P6010+Dokument4 Seiten2.-West Serie P6010+Ernesto VazquezNoch keine Bewertungen

- E560 23be50 DSDokument4 SeitenE560 23be50 DSSalvador FayssalNoch keine Bewertungen

- Photoelectric Sensors W280, Photoelectric Proximity Sensor, EnergeticDokument6 SeitenPhotoelectric Sensors W280, Photoelectric Proximity Sensor, Energeticluis_claudino6263Noch keine Bewertungen

- GS 12D06D05-01E (Ed 03) - ISC450GDokument8 SeitenGS 12D06D05-01E (Ed 03) - ISC450GJuan Jorge Pablo ValdiviaNoch keine Bewertungen

- Linear 210292 Micro Pulse PF BrochureDokument6 SeitenLinear 210292 Micro Pulse PF BrochureBalluff SensorsNoch keine Bewertungen

- Sen So ControlDokument80 SeitenSen So ControlJorge Andres PozoNoch keine Bewertungen

- Dme3000 DatashetDokument6 SeitenDme3000 DatashetFrancisco A. ValenzuelaNoch keine Bewertungen

- Medicion Fibra OpticaDokument16 SeitenMedicion Fibra OpticaJulio Cesar VPNoch keine Bewertungen

- Ultrasonic Level TransmitterDokument8 SeitenUltrasonic Level TransmitterTan Ren Zong100% (1)

- L-Dens 427F Ex Density Sensor SpecificationsDokument6 SeitenL-Dens 427F Ex Density Sensor Specificationsd1arsenovskiNoch keine Bewertungen

- 2716 CDokument2 Seiten2716 Cmihai.banicaNoch keine Bewertungen

- Modulos LutzeDokument11 SeitenModulos Lutzesrp1987Noch keine Bewertungen

- NDT1 220K Ultrasonic TransducerDokument4 SeitenNDT1 220K Ultrasonic TransducerJose Miguel Madrid ReinaNoch keine Bewertungen

- Sensor Color - CS84-P1112 - 20110815 - 1518Dokument6 SeitenSensor Color - CS84-P1112 - 20110815 - 1518GVS-ValentimNoch keine Bewertungen

- Series 3730 Electropneumatic Positioner Type 3730-1: ApplicationDokument6 SeitenSeries 3730 Electropneumatic Positioner Type 3730-1: ApplicationGuillermo A OMNoch keine Bewertungen

- System 8000Dokument10 SeitenSystem 8000ayad60Noch keine Bewertungen

- Sanitary TurbinaDokument4 SeitenSanitary TurbinaCindy MateusNoch keine Bewertungen

- m3814 OmegaDokument8 Seitenm3814 OmegaNelson GodoyNoch keine Bewertungen

- Fuji Semaphore NdicatorDokument8 SeitenFuji Semaphore NdicatorhieupqhNoch keine Bewertungen

- Sick w280Dokument14 SeitenSick w280cor01Noch keine Bewertungen

- Calorimetres SHARKY 775 Heat MeterDokument7 SeitenCalorimetres SHARKY 775 Heat MeterJoan AymerichNoch keine Bewertungen

- Turck Q TrackDokument13 SeitenTurck Q TrackTheodore GonzalezNoch keine Bewertungen

- Argus 8: Cutout Details DescriptionDokument4 SeitenArgus 8: Cutout Details Descriptionprabhakaran_hdecNoch keine Bewertungen

- Vibration SwitchesDokument12 SeitenVibration SwitchesAnonymous 1dVLJSVhtrNoch keine Bewertungen

- LMS153 10100Dokument6 SeitenLMS153 10100carldizNoch keine Bewertungen

- Continuous Level Measurement - Ultrasonic ControllersDokument8 SeitenContinuous Level Measurement - Ultrasonic ControllersknchnNoch keine Bewertungen

- Wattstopper Sensor The Most Advanced Energy Saving TechnologyDokument7 SeitenWattstopper Sensor The Most Advanced Energy Saving TechnologyDemo Only100% (1)

- Differential Pressure Transmitter: With Adjustable Span and ZeroDokument3 SeitenDifferential Pressure Transmitter: With Adjustable Span and ZeroVidya MuthukrishnanNoch keine Bewertungen

- 8888Dokument2 Seiten8888FastinecioNoch keine Bewertungen

- Model LF-100: Ultrasonic Micro Liquid Flow MeterDokument2 SeitenModel LF-100: Ultrasonic Micro Liquid Flow MeterCindy MateusNoch keine Bewertungen

- Model 1700 DatasheetDokument4 SeitenModel 1700 DatasheethermesperaNoch keine Bewertungen

- Surface Mount Schottky DiodesDokument10 SeitenSurface Mount Schottky DiodesWaleed SethiNoch keine Bewertungen

- CDA3000Dokument2 SeitenCDA3000Edilson AmilNoch keine Bewertungen

- High Voltage Megger Tester 2.5kvDokument1 SeiteHigh Voltage Megger Tester 2.5kvPrashanthNoch keine Bewertungen

- TWH LED Sell Sheet PDFDokument2 SeitenTWH LED Sell Sheet PDFPablo TlazaloNoch keine Bewertungen

- ECS 16-9-1 - 4 - 800981eeDokument9 SeitenECS 16-9-1 - 4 - 800981eeFlorin Daniel AnghelNoch keine Bewertungen

- 135ccoz 2Dokument109 Seiten135ccoz 2mujakesedzijaNoch keine Bewertungen

- Test SPARC M7 Processor and Product Over PDFDokument8 SeitenTest SPARC M7 Processor and Product Over PDFOswaldo ValienteNoch keine Bewertungen

- Advisory Circtigmar: Department of TransportationDokument11 SeitenAdvisory Circtigmar: Department of TransportationEdson Guerrero PeltrocheNoch keine Bewertungen

- Spipl PSM-550-260417Dokument4 SeitenSpipl PSM-550-260417sunilkrishnamurthy1Noch keine Bewertungen

- Cat G3516A: Natural Gas Generator SetsDokument5 SeitenCat G3516A: Natural Gas Generator SetsRecovery MailNoch keine Bewertungen

- Elite 5-ServiceManual 2016.01Dokument420 SeitenElite 5-ServiceManual 2016.01Валентин ПисаревNoch keine Bewertungen

- Fail Safe Break & Break Motor: Presented byDokument16 SeitenFail Safe Break & Break Motor: Presented byShubham GaikwadNoch keine Bewertungen

- Seminar PresentationDokument2 SeitenSeminar Presentationthurabudeen98Noch keine Bewertungen

- Non EngineDokument1 SeiteNon EngineLodyNoch keine Bewertungen

- Keithley 2460 High Current SourceMeter SMU DatasheetDokument15 SeitenKeithley 2460 High Current SourceMeter SMU DatasheetJohn CorralesNoch keine Bewertungen

- CTVT Trafindo 2010Dokument19 SeitenCTVT Trafindo 2010Ahmad Ikhsan KurniantoNoch keine Bewertungen

- Ont Axle 2 PDFDokument34 SeitenOnt Axle 2 PDFFrezgi BirhanuNoch keine Bewertungen

- List of MIPS Architecture Processors - WikipediaDokument6 SeitenList of MIPS Architecture Processors - WikipediaTechnical NoviceNoch keine Bewertungen

- Concealed Duct Spec Sheet A4 - Print CompressedDokument2 SeitenConcealed Duct Spec Sheet A4 - Print CompressedJames HillNoch keine Bewertungen

- Seminar1 PPTDokument10 SeitenSeminar1 PPTAditi DaberaoNoch keine Bewertungen

- Manual Abs WabcoDokument110 SeitenManual Abs WabcoRuanWheeling100% (1)

- Honda JAZZ Transmission Oil Fluid CheckDokument5 SeitenHonda JAZZ Transmission Oil Fluid CheckGaborJNoch keine Bewertungen

- 1974 MECL Integrated Circuits Series A Vol4 PDFDokument624 Seiten1974 MECL Integrated Circuits Series A Vol4 PDFjalmeida88Noch keine Bewertungen

- TSK50Dokument6 SeitenTSK50Manuel BerriosNoch keine Bewertungen

- MH-MK2 Series Motherboard Replacement Guide: Tools NeededDokument5 SeitenMH-MK2 Series Motherboard Replacement Guide: Tools Neededlaudith22Noch keine Bewertungen

- Metal Detector Robot Project ReportDokument27 SeitenMetal Detector Robot Project Reportniraj adhikari100% (1)

- Sepeda Thrill Katalog JULI 2020 (28-07-20)Dokument2 SeitenSepeda Thrill Katalog JULI 2020 (28-07-20)Leonardus Kadho SaputraNoch keine Bewertungen

- ABB WaterMaster User GuideDokument48 SeitenABB WaterMaster User GuideJan Richardo GultomNoch keine Bewertungen

- SANY SY750H Spec Sheet Single PagesDokument4 SeitenSANY SY750H Spec Sheet Single Pagesalesker.alekperov71Noch keine Bewertungen

- KEI Cables-1Dokument72 SeitenKEI Cables-1chandu1821Noch keine Bewertungen

- COA Lab FileDokument25 SeitenCOA Lab FileChetan MittalNoch keine Bewertungen

- DC Fan DatasheetDokument1 SeiteDC Fan DatasheetPhantom PNoch keine Bewertungen