Beruflich Dokumente

Kultur Dokumente

50mm Size Ring Type: Large Encoder With 31mm Inside Diameter Even Takes A Small LCD

Hochgeladen von

shyhuOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

50mm Size Ring Type: Large Encoder With 31mm Inside Diameter Even Takes A Small LCD

Hochgeladen von

shyhuCopyright:

Verfügbare Formate

191

Metal

Shaft

Insulated

Shaft

Hollow

Shaft

Ring

Type

Detector

Slide

Push

Rotary

Encoders

Power

Dual-in-line

Package Type

TACT Switch

TM

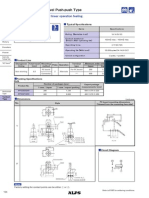

EC50A

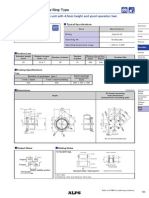

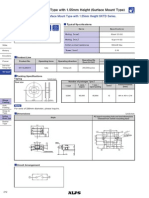

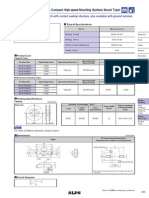

50mm Size Ring Type

Large encoder with 31mm inside diameter even takes a small LCD

Typical Specifications

Items Specifications

Rating 1mA 5V DC

Operating life 40,000cycles

Operating temperature range 40 to 85

Product Line

Product No.

17.5 9 18 40 20 EC50A0920403 200 400

Minimum order unit pcs.

Export Japan

Number of

detent

Number of

pulse

Actuator length

mm

Detent torque

mNm

Dimensions Unit:mm

Style

PC board mounting hole dimensions

(Viewed from mounting side)

Packing Specications

Tray

400 200

Number of packagespcs.

360 540 290

Export package

measurements

mm 1 case / Japan 1 case / export packing

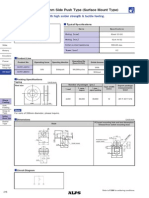

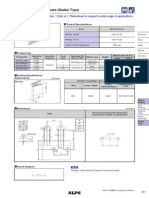

Output Wave Sliding Noise

V

1

=V

2

=2.5V max.

At R = 10k

Chattering : 5ms max. Bounce : 5ms max.

5V DC

R R

Terminal B Terminal A

Terminal C

Encoder

Test circuit

t t

V1

V2

5

V

ON ON OFF

Output waveform

Sliding direction

t : Masking time to avoid chattering Measurement conditionRotation speed 360/s

A signal

B signal ON

ON OFF

OFF

Detent stabillity position

CW direction

Refer to P.193 for soldering conditions.

2-1.5

6.5

17.5

3.5

2

-

3

.

5

3

-

3

.

1

3-6

3

6

.

8

2-20

2

5

2

5

3

1

1

2

0

1

2

0

2

-

5

0

.

8

3

-

0

.

8

3

-R

1

7

.7

2

6

2

-

5

.

1

4

2

.

9

2

-

1

.5

5

h

o

le

s

3-

1.05 holes

5

2-1.55

51.4

Mounting

surface

X X

A B C

2-1.5

6.5

17.5

3.5

2

-

3

.

5

3

-

3

.

1

3-6

3

6

.

8

2-20

2

5

2

5

3

1

1

2

0

1

2

0

2

-

5

0

.

8

3

-

0

.

8

3

-R

1

7

.7

2

6

2

-

5

.

1

4

2

.

9

2

-

1

.5

5

h

o

le

s

3-

1.05 holes

5

2-1.55

51.4

Mounting

surface

X X

A B C

Encoders

159

Metal

Shaft

Insulated

Shaft

Hollow

Shaft

Ring

Type

Detector

Slide

Push

Rotary

Encoders

Power

Dual-in-line

Package Type

TACT Switch

TM

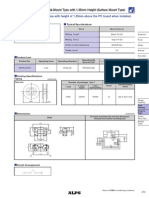

159

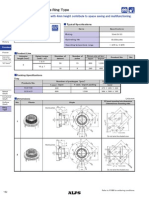

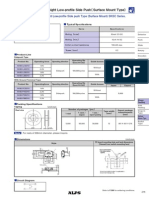

Type

Ring Type

40mm size 45mm size 50mm size 60mm size

Series EC40A EC45A EC50A EC60A

Photo

Output

Incremental

Two phase A and B

Absolute type

Incremental

Two phase A and B

Shaft types Ring type

Number of pulse /

Number of detent

15 / 30 31 positions 9 / 18 15 / 30

Dimensions

mm

W 40.4 44.5 50.8

61.8

D 43 45 50

H 9 6.5 11.5

Operating temperature range 40 to 85

Operating life 30,000 cycles 40,000 cycles 30,000 cycles

Automotive use

Life cycle (availability)

Electrical

performance

Rating 0.5mA 5V DC 1mA 5V DC 0.5mA 5V DC

Max./min. operating current

Resistive load

- - - -

Insulation resistance 10M min. 50V DC 10M min. 250V DC 10M min. 500V DC

Voltage proof 50V AC for 1 minute 50V AC for 1 minute or 60V AC for 2s 500V AC for 1 minute

Mechanical

performance

Detent torque 2011mNm 3616mNm 4020mNm

Push-pull

strength

Push 100N

Pull 50N

Shaft configuration Ring type

Terminal type Insertion

Switch

Specications

Switch type - - - -

Contact

arrangement

- - - -

Travel mm - - - -

Operating

force N

- - - -

Switch ON

position

- - - -

Ratational

torgue

- - - -

Rating - - - -

Contact

resistance

- - - -

Operating life - - - -

Page 189 190 191 192

Encoders Soldering Conditions 193

Encoders Cautions 194

Note

indicates applicability to all products in the series.

List of Varieties

193

Metal

Shaft

Insulated

Shaft

Hollow

Shaft

Ring

Type

Detector

Slide

Push

Rotary

Encoders

Power

Dual-in-line

Package Type

TACT Switch

TM

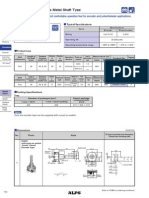

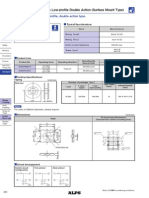

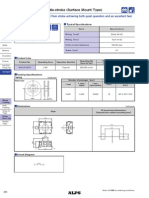

Encoders Soldering Conditions

Soldering surfacetemperature Soldering temperature Heating time Soldering time

No. of solders

3 s EC11J

EC10E, EC12D, EC12E

EC45A, EC60A

EC40A

EM20B

EC05E, EC09E, EC10E, EC111, EC11B,

EC11E, EC11G, EC11K, EC12D, EC12E,

EC18A, EC20A, EC21A, EC28A, EC35A,

EC35AH, EC35B, EC40A, EC45A, EC50A,

EC60A, EM20B

EC09E, EC11B, EC111, EC11E, EC11G,

EC11K, EC18A, EC20A, EC21A, EC28A,

EC35A, EC35AH, EC35B, EC50A

Series

Series

350 max. 3s max. 1 time

100 max. 2605 2 min. max. 51s 2 time max.

35010 2 time

100 max.

100 max.

110 max.

80 max.

2605

260 max.

260 max.

260 max.

1 min. max.

2 min. max.

1 min. max.

1 min. max.

31s

5s max.

10s max.

3s max.

2 time max.

2 time max.

1 time

2 time max.

Tip temperature Soldering time No. of solders

Preheating Dip soldering

Reference for Dip Soldering

Condition for Refow

Reference for Hand Soldering

EC05E

EC11J

Series

260 230 180 150 2 min.max. 3s 40s 4 min. max 2 time max.

250 min. 230 min. 180 150 60s to 120s 30s to 40s 2 time max.

A B C D E F G H No. of reows

Temperature profle

1

0

1.When using an infrared reow oven, solder may sometimes not be applied. Be sure to use a hot air reow oven or a

type that uses infrared rays in combination with hot air.

2.The temperatures given above are the maximum temperatures at the terminals of the potentiometer when

employing a hot air reow method. The temperature of the PC board and the surface temperature of the

potentiometer may vary greatly depending on the PC board material, its size and thickness. Ensure that the surface

temperature of the potentiometer does not rise to 250C or greater.

3.Conditions vary to some extent depending on the type of reow bath used. Be sure to give due consideration to this

prior to use.

Notes

300

200

100

A

B

C

Time (s)

G max.

F max.

H max.

E max.

Room

temperature

T

e

m

p

e

r

a

t

u

r

e

(

C

)

Pre-heating

D

Das könnte Ihnen auch gefallen

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- JV3-160S Maintenance Manual D500200 V1.00Dokument170 SeitenJV3-160S Maintenance Manual D500200 V1.00Jorge MartinsNoch keine Bewertungen

- Embedded Systems - Question Bank (AU-CBE, ECE-R2007)Dokument36 SeitenEmbedded Systems - Question Bank (AU-CBE, ECE-R2007)Dr. N.ShanmugasundaramNoch keine Bewertungen

- Beckwith Transformer-Tutorial-2011 PDFDokument96 SeitenBeckwith Transformer-Tutorial-2011 PDFaadi_sabujNoch keine Bewertungen

- Rotary Encoder GuideDokument3 SeitenRotary Encoder GuideshyhuNoch keine Bewertungen

- 60mm Size Ring Type: Large Ring Structure Contributes To MultifunctioningDokument3 Seiten60mm Size Ring Type: Large Ring Structure Contributes To MultifunctioningshyhuNoch keine Bewertungen

- 45mm Size Ring Type: Large Ring, Heavy Torque Device Perfect For Large Ring Knob DesignDokument3 Seiten45mm Size Ring Type: Large Ring, Heavy Torque Device Perfect For Large Ring Knob DesignshyhuNoch keine Bewertungen

- 35mm Ring Encoder GuideDokument3 Seiten35mm Ring Encoder GuideshyhuNoch keine Bewertungen

- 21mm Ring Encoder Guide with Specs & Soldering TipsDokument4 Seiten21mm Ring Encoder Guide with Specs & Soldering TipsshyhuNoch keine Bewertungen

- 20mm Metal Shaft Encoder & Potentiometer GuideDokument4 Seiten20mm Metal Shaft Encoder & Potentiometer GuideshyhuNoch keine Bewertungen

- Insulated Shaft Rotary EncodersDokument3 SeitenInsulated Shaft Rotary EncodersshyhuNoch keine Bewertungen

- EC35AH: 35mm Size ABC Switch TypeDokument4 SeitenEC35AH: 35mm Size ABC Switch TypeshyhuNoch keine Bewertungen

- SEO Rotary EncodersDokument4 SeitenSEO Rotary EncodersshyhuNoch keine Bewertungen

- 20mm Size Metal Shaft Magnetic TypeDokument4 Seiten20mm Size Metal Shaft Magnetic TypeshyhuNoch keine Bewertungen

- 35mm Size Composite Operation Type: Composite Operation Device That Integrates Both Ring Encoder and Self Return SwitchDokument3 Seiten35mm Size Composite Operation Type: Composite Operation Device That Integrates Both Ring Encoder and Self Return SwitchshyhuNoch keine Bewertungen

- Low-Profile Tri-Directional Operation TypeDokument3 SeitenLow-Profile Tri-Directional Operation TypeshyhuNoch keine Bewertungen

- Side Push Surface Mount Type With 1.55mm Height SKTD SeriesDokument3 SeitenSide Push Surface Mount Type With 1.55mm Height SKTD SeriesshyhuNoch keine Bewertungen

- High Operation Force, Low Contact Resistance Type (Surface Mount Type)Dokument3 SeitenHigh Operation Force, Low Contact Resistance Type (Surface Mount Type)shyhuNoch keine Bewertungen

- Total Hight of 3.1mm. Surface Mount Package With Ground TerminalDokument3 SeitenTotal Hight of 3.1mm. Surface Mount Package With Ground TerminalshyhuNoch keine Bewertungen

- 4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingDokument3 Seiten4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingshyhuNoch keine Bewertungen

- Spvq5: Micro Switch Type With Female Connector TerminalDokument3 SeitenSpvq5: Micro Switch Type With Female Connector TerminalshyhuNoch keine Bewertungen

- Side Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)Dokument3 SeitenSide Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)shyhuNoch keine Bewertungen

- Low-Profile, 1.2mm Height, Long Travel TypeDokument3 SeitenLow-Profile, 1.2mm Height, Long Travel TypeshyhuNoch keine Bewertungen

- Quiet Type With 0.9mm Stroke (Surface Mount Type)Dokument3 SeitenQuiet Type With 0.9mm Stroke (Surface Mount Type)shyhuNoch keine Bewertungen

- TACT Switch GuideDokument3 SeitenTACT Switch GuideshyhuNoch keine Bewertungen

- SPED2 Push Switch SpecsDokument3 SeitenSPED2 Push Switch SpecsshyhuNoch keine Bewertungen

- 9mm Size Metal Shaft Type: A Compact 9.5mm Size and Round Shape Contribute To Save SpaceDokument3 Seiten9mm Size Metal Shaft Type: A Compact 9.5mm Size and Round Shape Contribute To Save SpaceshyhuNoch keine Bewertungen

- 10mm Size Hollow Shaft Type: A Series of Compact and Long-Life Encoders With Unique Hollow Shaft DesignDokument3 Seiten10mm Size Hollow Shaft Type: A Series of Compact and Long-Life Encoders With Unique Hollow Shaft DesignshyhuNoch keine Bewertungen

- Snap-in Tact Switch Specs and Soldering GuideDokument3 SeitenSnap-in Tact Switch Specs and Soldering GuideshyhuNoch keine Bewertungen

- 7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsDokument3 Seiten7.8mm Square (Radial Type) : Varieties of 1mm, 1.2mm or 1.75mm-Travel To Support A Wide Range of ApplicationsshyhuNoch keine Bewertungen

- 4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeDokument3 Seiten4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeshyhuNoch keine Bewertungen

- SKEGDokument4 SeitenSKEGshyhuNoch keine Bewertungen

- EC18A 18mm Insulated Shaft EncoderDokument4 SeitenEC18A 18mm Insulated Shaft EncodershyhuNoch keine Bewertungen

- 6.6mm Square (Snap-In Type) : Dust Proof With Sharp Operational Feel Suitable For General PurposeDokument5 Seiten6.6mm Square (Snap-In Type) : Dust Proof With Sharp Operational Feel Suitable For General PurposeshyhuNoch keine Bewertungen

- INSULATED SHAFT TYPEDokument5 SeitenINSULATED SHAFT TYPEshyhuNoch keine Bewertungen

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Dokument3 SeitenSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNoch keine Bewertungen

- Snap-in switch documentDokument3 SeitenSnap-in switch documentshyhuNoch keine Bewertungen

- 6×3.5mm Compact (Snap-In Type) : Switch Contributing To High-Density Mounting, Available With Top or Side Push OperationDokument4 Seiten6×3.5mm Compact (Snap-In Type) : Switch Contributing To High-Density Mounting, Available With Top or Side Push OperationshyhuNoch keine Bewertungen

- 40-character for detector switch documentDokument3 Seiten40-character for detector switch documentshyhuNoch keine Bewertungen

- 1.25mm Height Low-Profile Side Push Surface Mount TypeDokument3 Seiten1.25mm Height Low-Profile Side Push Surface Mount TypeshyhuNoch keine Bewertungen

- 3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)Dokument3 Seiten3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)shyhuNoch keine Bewertungen

- 1.2 (H) MM, Single-Side Recoil TypeDokument4 Seiten1.2 (H) MM, Single-Side Recoil TypeshyhuNoch keine Bewertungen

- 5.2mm Square Low-Profile (Surface Mount Type)Dokument4 Seiten5.2mm Square Low-Profile (Surface Mount Type)shyhuNoch keine Bewertungen

- Quiet Surface Mount Switch SpecificationsDokument3 SeitenQuiet Surface Mount Switch SpecificationsshyhuNoch keine Bewertungen

- 12mm Square (Snap-In Type) : Joint Stem & Flat Stem With Stable Operation FeelingDokument4 Seiten12mm Square (Snap-In Type) : Joint Stem & Flat Stem With Stable Operation FeelingshyhuNoch keine Bewertungen

- Resistive Position Sensors Linear Type Specifications and VarietiesDokument5 SeitenResistive Position Sensors Linear Type Specifications and VarietiesshyhuNoch keine Bewertungen

- SKHH 6mm Square Tact Switch Product GuideDokument6 SeitenSKHH 6mm Square Tact Switch Product GuideshyhuNoch keine Bewertungen

- Datasheet Relay 12 V PDFDokument7 SeitenDatasheet Relay 12 V PDFturkceNoch keine Bewertungen

- 6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelDokument3 Seiten6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelshyhuNoch keine Bewertungen

- 10mm Square Water-proof Tact Switch SpecificationsDokument5 Seiten10mm Square Water-proof Tact Switch SpecificationsshyhuNoch keine Bewertungen

- b0615 PDFDokument6 Seitenb0615 PDFern_43Noch keine Bewertungen

- Linear Type Exclusively Used To Detect The Angle of Vehicle Head LightsDokument5 SeitenLinear Type Exclusively Used To Detect The Angle of Vehicle Head LightsshyhuNoch keine Bewertungen

- Spvq9: Water-Proof TypeDokument3 SeitenSpvq9: Water-Proof TypeshyhuNoch keine Bewertungen

- Large Capacitance Aluminum Electrolytic Capacitors: SpecificationsDokument4 SeitenLarge Capacitance Aluminum Electrolytic Capacitors: SpecificationsonafetsNoch keine Bewertungen

- 3.7mm Square Low-Profile (Surface Mount Type)Dokument3 Seiten3.7mm Square Low-Profile (Surface Mount Type)Hung KeeNoch keine Bewertungen

- List of Varieties: Detector Slide Push RotaryDokument5 SeitenList of Varieties: Detector Slide Push RotaryshyhuNoch keine Bewertungen

- Recoil Type For Single-Side and Both SidesDokument5 SeitenRecoil Type For Single-Side and Both SidesshyhuNoch keine Bewertungen

- SKQM 6 × 3.5mm Compact (Surface Mount TypeDokument3 SeitenSKQM 6 × 3.5mm Compact (Surface Mount TypeshyhuNoch keine Bewertungen

- PS2815-1, PS2815-4: PhotocouplerDokument14 SeitenPS2815-1, PS2815-4: PhotocouplerJuan Carlos H. SoriaNoch keine Bewertungen

- MCR100 Series Sensitive Gate Silicon Controlled Rectifiers: Reverse Blocking ThyristorsDokument7 SeitenMCR100 Series Sensitive Gate Silicon Controlled Rectifiers: Reverse Blocking ThyristorsErnestoGarciaMontanoNoch keine Bewertungen

- Spvqa: Water-Proof TypeDokument4 SeitenSpvqa: Water-Proof Typeshyhu100% (1)

- TemporizadoresDokument2 SeitenTemporizadoresPablo EmfNoch keine Bewertungen

- Hollow-Shaft Type That Enables Output Covering The Whole 360-Degree Angle Due To Adoption of 2-Phase OutputDokument4 SeitenHollow-Shaft Type That Enables Output Covering The Whole 360-Degree Angle Due To Adoption of 2-Phase OutputshyhuNoch keine Bewertungen

- Medijski linč Gorana JevtićaDokument64 SeitenMedijski linč Gorana JevtićashyhuNoch keine Bewertungen

- RDC40 RDC50 RDC90: Rotary TypeDokument6 SeitenRDC40 RDC50 RDC90: Rotary TypeshyhuNoch keine Bewertungen

- WM 00013Dokument127 SeitenWM 00013shyhuNoch keine Bewertungen

- Resistive Position Sensors Linear Type Specifications and VarietiesDokument5 SeitenResistive Position Sensors Linear Type Specifications and VarietiesshyhuNoch keine Bewertungen

- Resistive Position Sensors Specifications and Testing MethodsDokument4 SeitenResistive Position Sensors Specifications and Testing MethodsshyhuNoch keine Bewertungen

- List of Varieties: Resistive Position SensorsDokument1 SeiteList of Varieties: Resistive Position SensorsshyhuNoch keine Bewertungen

- Hollow-Shaft Type That Enables Output Covering The Whole 360-Degree Angle Due To Adoption of 2-Phase OutputDokument4 SeitenHollow-Shaft Type That Enables Output Covering The Whole 360-Degree Angle Due To Adoption of 2-Phase OutputshyhuNoch keine Bewertungen

- List of Varieties: Detector Slide Push RotaryDokument5 SeitenList of Varieties: Detector Slide Push RotaryshyhuNoch keine Bewertungen

- 265 6.1×3.7mm Compact Switch SpecsDokument3 Seiten265 6.1×3.7mm Compact Switch SpecsshyhuNoch keine Bewertungen

- TACT Switch GuideDokument3 SeitenTACT Switch GuideshyhuNoch keine Bewertungen

- Linear Type Exclusively Used To Detect The Angle of Vehicle Head LightsDokument5 SeitenLinear Type Exclusively Used To Detect The Angle of Vehicle Head LightsshyhuNoch keine Bewertungen

- SKQM 6 × 3.5mm Compact (Surface Mount TypeDokument3 SeitenSKQM 6 × 3.5mm Compact (Surface Mount TypeshyhuNoch keine Bewertungen

- 3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)Dokument3 Seiten3.5×3.2mm Low-Profile Double Action Type (Surface Mount Type)shyhuNoch keine Bewertungen

- List of Varieties: Detector Slide Push RotaryDokument5 SeitenList of Varieties: Detector Slide Push RotaryshyhuNoch keine Bewertungen

- 4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeDokument3 Seiten4.3×2.2mm Compact Low-Profile Double Action Surface Mount TypeshyhuNoch keine Bewertungen

- 6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeDokument4 Seiten6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeshyhuNoch keine Bewertungen

- 5.2mm Square Low-Profile (Surface Mount Type)Dokument4 Seiten5.2mm Square Low-Profile (Surface Mount Type)shyhuNoch keine Bewertungen

- Quiet Surface Mount Switch SpecificationsDokument3 SeitenQuiet Surface Mount Switch SpecificationsshyhuNoch keine Bewertungen

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Dokument3 SeitenSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNoch keine Bewertungen

- Quiet Type With 0.9mm Stroke (Surface Mount Type)Dokument3 SeitenQuiet Type With 0.9mm Stroke (Surface Mount Type)shyhuNoch keine Bewertungen

- 6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelDokument3 Seiten6.2mm Square With Middle-Travel (Surface Mount Type) : Rubber Stem Helps To Achieve Travel of 0.3 To 0.55mm & Over TravelshyhuNoch keine Bewertungen

- 4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingDokument3 Seiten4.5×3.55mm Side Push Type (Surface Mount Type) : Sidepush With High Solder Strength & Tactile FeelingshyhuNoch keine Bewertungen

- Side Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)Dokument3 SeitenSide Push Mid-Mount Type With 1.35mm Height (Surface Mount Type)shyhuNoch keine Bewertungen

- Total Hight of 3.1mm. Surface Mount Package With Ground TerminalDokument3 SeitenTotal Hight of 3.1mm. Surface Mount Package With Ground TerminalshyhuNoch keine Bewertungen

- 6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeDokument4 Seiten6.2 × 6.3mm (Surface Mount Type) : A Wide Variety of Products Including Dust-Proof TypeshyhuNoch keine Bewertungen

- Side Push Surface Mount Type With 1.55mm Height SKTD SeriesDokument3 SeitenSide Push Surface Mount Type With 1.55mm Height SKTD SeriesshyhuNoch keine Bewertungen

- Side Push Half-Mount Type With 1.6mm Height (Surface Mount Type)Dokument3 SeitenSide Push Half-Mount Type With 1.6mm Height (Surface Mount Type)shyhuNoch keine Bewertungen

- List of Varieties: Top Push Side PushDokument5 SeitenList of Varieties: Top Push Side PushshyhuNoch keine Bewertungen

- 1.25mm Height Low-Profile Side Push Surface Mount TypeDokument3 Seiten1.25mm Height Low-Profile Side Push Surface Mount TypeshyhuNoch keine Bewertungen

- Measuring Torque, Wobble, Voltage Withstand and Insulation of Rotating ShaftsDokument1 SeiteMeasuring Torque, Wobble, Voltage Withstand and Insulation of Rotating ShaftsshyhuNoch keine Bewertungen

- IN114xv: EMEA and Asia-Paci C RegionsDokument2 SeitenIN114xv: EMEA and Asia-Paci C RegionsEricson Kelvin N. OcampoNoch keine Bewertungen

- Lab 12 (Construction and Analysis of Multiplexer Circuits.)Dokument6 SeitenLab 12 (Construction and Analysis of Multiplexer Circuits.)Husnain 18Noch keine Bewertungen

- Enhanced GM User GuideDokument2 SeitenEnhanced GM User GuidegazebonaifNoch keine Bewertungen

- Asus X401U Repair GuideDokument5 SeitenAsus X401U Repair GuideSayua LalidiNoch keine Bewertungen

- Accelerometer BOM With SpecificationsDokument8 SeitenAccelerometer BOM With SpecificationsNitin MaliNoch keine Bewertungen

- PT2258Dokument15 SeitenPT2258zektor100% (1)

- PERIPHERAL AND MEMORY DEVICESDokument24 SeitenPERIPHERAL AND MEMORY DEVICESG.m. RajaNoch keine Bewertungen

- LA6 Self Liviling Device BpeDokument10 SeitenLA6 Self Liviling Device BpeKrum KashavarovNoch keine Bewertungen

- IET Circuits Devices Syst - 2016 - Ayachit - Transfer Functions of A Transformer at Different Values of CouplingDokument12 SeitenIET Circuits Devices Syst - 2016 - Ayachit - Transfer Functions of A Transformer at Different Values of CouplingVlad AlexNoch keine Bewertungen

- EFIS002 Fall 06Dokument52 SeitenEFIS002 Fall 06padmarao1Noch keine Bewertungen

- B.E. ECE Final-1 PDFDokument130 SeitenB.E. ECE Final-1 PDFShanmuga Raju SNoch keine Bewertungen

- Mega 169 PADokument387 SeitenMega 169 PAvliegenkristofNoch keine Bewertungen

- GH301 Heart Rate Sensor For WristbandsDokument30 SeitenGH301 Heart Rate Sensor For WristbandsGiuliano RebuliNoch keine Bewertungen

- Current Transducer LT 100-P I 100 ADokument3 SeitenCurrent Transducer LT 100-P I 100 AVinicius ReisNoch keine Bewertungen

- Llave de Comvinacion Electronic ADokument2 SeitenLlave de Comvinacion Electronic AyulanvpNoch keine Bewertungen

- CAD For VLSI Design - II: V. Kamakoti and Shankar BalachandranDokument18 SeitenCAD For VLSI Design - II: V. Kamakoti and Shankar Balachandran9964120626 ReddyNoch keine Bewertungen

- SEMIKRON DataSheet SKiiP 36NAB126V1 25230120Dokument4 SeitenSEMIKRON DataSheet SKiiP 36NAB126V1 25230120Merter TolunNoch keine Bewertungen

- Tabela de Varistores PanasonicDokument20 SeitenTabela de Varistores PanasonicLuis ArturNoch keine Bewertungen

- EVlink Smart Wallbox - 7.4-22 KW - T2 - RFID PDFDokument2 SeitenEVlink Smart Wallbox - 7.4-22 KW - T2 - RFID PDFfoxNoch keine Bewertungen

- Developing Affordable Mixed-Signal Power Systems For Battery Charger ApplicationsDokument11 SeitenDeveloping Affordable Mixed-Signal Power Systems For Battery Charger ApplicationsBao BaoNoch keine Bewertungen

- Vol. 53 - No. 11: Diamond PassivesDokument184 SeitenVol. 53 - No. 11: Diamond Passivesakumar_277Noch keine Bewertungen

- DC - Diode Circuit Analysis Using Ideal Diodes Exam Problem - Electrical Engineering Stack ExchangeDokument2 SeitenDC - Diode Circuit Analysis Using Ideal Diodes Exam Problem - Electrical Engineering Stack ExchangeNikhil KashyapNoch keine Bewertungen

- Aleph J ManualDokument6 SeitenAleph J ManualasenmtNoch keine Bewertungen

- Keypad Based Bank Locker Security System Using GSM TechnologyDokument6 SeitenKeypad Based Bank Locker Security System Using GSM TechnologyInternational Journal of Research in Engineering and ScienceNoch keine Bewertungen

- ComfortLine5 PDFDokument168 SeitenComfortLine5 PDFcdimisNoch keine Bewertungen

- 2SD745 2sd745a 2SD745BDokument3 Seiten2SD745 2sd745a 2SD745Bjsalinas78Noch keine Bewertungen

- Model: Promedia™ 5.1 SystemDokument8 SeitenModel: Promedia™ 5.1 SystemLucas BarcelosNoch keine Bewertungen