Beruflich Dokumente

Kultur Dokumente

Lubrication and Maintenance: General Information

Hochgeladen von

Adán Castro GallegosOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lubrication and Maintenance: General Information

Hochgeladen von

Adán Castro GallegosCopyright:

Verfügbare Formate

LUBRICATION AND MAINTENANCE

CONTENTS

page page

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . 1

JUMP STARTING, HOISTING AND TOWING . . . 7

MAINTENANCE SCHEDULES . . . . . . . . . . . . . . . 3

GENERAL INFORMATION

INDEX

page page

GENERAL INFORMATION

CLASSIFICATION OF LUBRICANTS . . . . . . . . . . 1

FLUID CAPACITIES . . . . . . . . . . . . . . . . . . . . . . 2

INTERNATIONAL SYMBOLS . . . . . . . . . . . . . . . 1

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . 1

PARTS AND LUBRICANT RECOMMENDATIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

GENERAL INFORMATION

INTRODUCTION

Servi ce and mai ntenance procedures for compo-

nents and systems l i sted i n Schedul eA or B can be

found by usi ng the Group Tab Locator i ndex at the

front of thi s manual . I f i t i s not cl ear whi ch group

contai ns the i nformati on needed, refer to the i ndex at

the back of thi s manual .

There are two mai ntenance schedul es that show

proper servi ce based on the condi ti ons that the vehi -

cl e i s subjected to.

Schedul e A , l i sts schedul ed mai ntenance to be

performed when the vehi cl e i s used for general trans-

portati on.

Schedul e B , l i sts mai ntenance i nterval s for vehi -

cl es that are operated under the condi ti ons l i sted at

the begi nni ng of the Mai ntenance Schedul e secti on.

Use the schedul e that best descri bes your dri vi ng

condi ti ons.

Where ti me and mi l eage are l i sted, fol l ow the

i nterval that occurs fi rst.

PARTS AND LUBRICANT RECOMMENDATIONS

When servi ce i s requi red, Chrysl er Corporati on

recommends that onl y Mopar brand parts, l ubri -

cants and chemi cal s be used. Mopar provi des the

best engi neered products for servi ci ng Chrysl er Cor-

porati on vehi cl es.

INTERNATIONAL SYMBOLS

Chrysl er Corporati on uses i nternati onal symbol s to

i denti fy engi ne compartment l ubri cant and fl ui d

i nspecti on and fi l l l ocati ons (Fi g. 1).

CLASSIFICATION OF LUBRICANTS

Onl y l ubri cants that are endorsed by the fol l owi ng

organi zati on shoul d be used to servi ce a Chrysl er

Corporati on vehi cl e.

Soci ety of Automoti ve Engi neers (SAE)

Ameri can Petrol eum I nsti tute (API ) (Fi g. 2)

Nati onal Lubri cati ng Grease I nsti tute (NLGI )

(Fi g. 3)

Fig. 1 International Symbols

ENGINE OIL AUTOMATIC TRANSMISSION FLUID ENGINE COOLANT BRAKE FLUID POWER STEERING FLUID WINDSHIELD WASHER FLUID

J A LUBRICATION AND MAINTENANCE 0 - 1

ENGINE OIL

SAE GRADE RATING INDICATES ENGINE OIL VISCOSITY

An SAE vi scosi ty grade i s used to speci fy the vi s-

cosi ty of engi ne oi l . SAE 30 speci fi es a si ngl e vi scos-

i ty engi ne oi l . Engi ne oi l s al so have mul ti pl e

vi scosi ti es. These are speci fi ed wi th a dual SAE vi s-

cosi ty grade whi ch i ndi cates the col d-to-hot tempera-

ture vi scosi ty range.

SAE 30 = si ngl e grade engi ne oi l .

SAE 10W-30 = mul ti pl e grade engi ne oi l .

API QUALITY CLASSIFICATION

The API Servi ce Grade speci fi es the type of perfor-

mance the engi ne oi l i s i ntended to provi de. The API

Servi ce Grade speci fi cati ons al so appl y to energy con-

servi ng engi ne oi l s.

Use engi ne oi l s that are API Servi ce Certi fi ed.

5W-30 and 10W-30 MOPAR engi ne oi l s conform to

speci fi cati ons.

Refer to Group 9, Engi ne for engi ne oi l speci fi ca-

ti on.

GEAR LUBRICANTS

SAE rati ngs al so appl y to mul ti pl e grade gear

l ubri cants. I n addi ti on, API cl assi fi cati on defi nes the

l ubri cants usage.

LUBRICANTS AND GREASES

Lubri cati ng grease i s rated for qual i ty and usage

by the NLGI . Al l approved products have the NLGI

symbol (Fi g. 3) on the l abel . At the bottom NLGI

symbol i s the usage and qual i ty i denti fi cati on l etters.

Wheel beari ng l ubri cant i s i denti fi ed by the l etter

G. Chassi s l ubri cant i s i denti fi ed by the l atter L.

The l etter fol l owi ng the usage l etter i ndi cates the

qual i ty of the l ubri cant. The fol l owi ng symbol s i ndi -

cate the hi ghest qual i ty.

FLUID CAPACITIES

FUEL TANK

Al l . . . . . . . . . . . . . . . . . . . . . . . . . 60.5 L (16.0 gal .)

ENGINE OILWITH FILTER

2.0L, 2.5L V6 . . . . . . . . . . . . . . . . . . 4.25 L (4.5 qts.)

2.4L . . . . . . . . . . . . . . . . . . . . . . . . . . 4.7 L (5.0 qts.)

ENGINE OILWITHOUT FILTER

2.0L, 2.5L V6 . . . . . . . . . . . . . . . . . . . 3.8 L (4.0 qts.)

2.4L . . . . . . . . . . . . . . . . . . . . . . . . . . 4.3 L (4.5 qts.)

COOLING SYSTEM

2.0 L . . . . . . . . . . . . . . . . . . . . . . . . . 8.1 L (8.5 qts.)

2.4 L . . . . . . . . . . . . . . . . . . . . . . . . . 8.5 L (9.0 qts.)

2.5 L . . . . . . . . . . . . . . . . . . . . . . . . 9.9 L (10.5 qts.)

AUTOMATIC TRANSAXLE

Esti mated Servi ce Fi l l . . . . . . . . . . . . 3.8 L (4.0 qts.)

Overhaul Fi l l Capaci ty wi th Torque Converter Empty

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.6 L (9.1 qts.)

MANUAL TRANSAXLE

NV T350 . . . . . . . . . . . . . . . . . . . . . . 2.1 L (2.2 qts.)

Fig. 2 API Symbol

Fig. 3 NLGI Symbol

0 - 2 LUBRICATION AND MAINTENANCE J A

GENERAL INFORMATION (Continued)

MAINTENANCE SCHEDULES

INDEX

page page

GENERAL INFORMATION

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . 3

SCHEDULEA . . . . . . . . . . . . . . . . . . . . . . . . . 3

SCHEDULEB . . . . . . . . . . . . . . . . . . . . . . . . . 4

UNSCHEDULED INSPECTION . . . . . . . . . . . . . . 3

GENERAL INFORMATION

INTRODUCTION

There are two mai ntenance schedul es that show

the proper servi ce for Chrysl er vehi cl es. Use the

schedul e that best descri bes the condi ti ons under

whi ch the vehi cl e i s operated. Where ti me and mi l e-

age are l i sted, fol l ow the i nterval that occurs fi rst.

ScheduleA l i sts al l the schedul ed mai ntenance

to be performed under normal operati ng condi ti ons.

ScheduleB i s a schedul e for vehi cl es that are

operated under one or more of the fol l owi ng condi -

ti ons:

Day and ni ght temperatures are bel ow freezi ng.

Stop and go dri vi ng.

Long peri ods of engi ne i dl i ng.

Dri vi ng i n dusty condi ti ons.

Short tri ps of l ess than 5 mi l es.

Operati on at sustai ned hi gh speeds duri ng hot

weather, above 90F (32C).

Taxi , pol i ce or del i very servi ce.

Trai l er towi ng or heavy haul i ng.

EMISSION CONTROL SYSTEM MAINTENANCE

The schedul ed emi ssi on mai ntenance l i sted i n bold

type i n the Mai ntenance Schedul es must be done at

the speci fi ed mi l eage to assure the conti nued proper

functi oni ng of the emi ssi on control system. These,

and al l other mai ntenance servi ces i ncl uded i n thi s

manual , shoul d be done to provi de the best vehi cl e

performance and rel i abi l i ty. More frequent mai nte-

nance may be needed for vehi cl es i n severe operati ng

condi ti ons such as dusty areas and very short tri p

dri vi ng.

UNSCHEDULED INSPECTION

At Each Stop For Fuel

Check engi ne oi l l evel , add as requi red.

Check wi ndshi el d washer sol vent and add i f

requi red.

Once A Month

Check ti re pressure and l ook for unusual wear

or damage.

Check fl ui d l evel s of cool ant reservoi r, power

steeri ng and automati c transmi ssi on and add as

requi red.

Check al l l i ghts and al l other el ectri cal i tems for

correct operati on.

At Each Oil Change

I nspect exhaust system.

I nspect brake hoses.

I nspect the CV joi nts and front suspensi on com-

ponents.

Rotate the ti res at each oi l change i nterval

shown on Schedul eA (7,500 mi l es 12 000 km) or

every other i nterval shown on schedul eB (6,000

mi l es 10 000 km).

Check cool ant l evel , hoses and cl amps.

Check the manual transaxl e fl ui d l evel .

I f the mi l eage i s l ess than 7,500 mi l es (12 000

km) yearl y, repl ace the engi ne oi l fi l ter at each oi l

change.

SCHEDULEA

7,500 Miles (12 000 km) or at 6 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on 2.0 l i ter and 2.4 l i ter

engi nes.

15,000 Miles (24 000 km) or at 12 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter.

Adjust dri ve bel t tensi on.

22,500 Miles (36 000 km) or at 18 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on 2.0 l i ter and 2.4 l i ter

engi nes.

I nspect the front brake pads and rear brake l i n-

i ngs.

30,000 Miles (48 000 km) or at 24 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on al l engi nes.

Lubri cate front and rear suspensi on bal l joi nts.

Adjust dri ve bel t tensi on.

J A LUBRICATION AND MAINTENANCE 0 - 3

Replace air cleaner element.

Replace spark plugs on 2.0L and 2.4L

engines.

37,500 Miles (60 000 km) or at 30 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on 2.0 l i ter and 2.4 l i ter

engi nes.

45,000 Miles (72 000 km) or at 36 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on al l engi nes.

I nspect front brake pads and rear brake l i ni ngs.

Adjust dri ve bel t tensi on.

Fl ush and repl ace engi ne cool ant at 36 months,

regardl ess of mi l eage.

52,500 Miles (84 000 km) or at 42 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on 2.0 l i ter and 2.4 l i ter

engi nes.

Fl ush and repl ace engi ne cool ant i f not done at

36 months, regardl ess of mi l eage.

60,000 Miles (96 000 km) or at 48 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on al l engi nes.

Check and replace, if necessary***, the

PCV valve.**

Lubri cate front and rear suspensi on upper bal l

joi nts.

Repl ace dri ve bel ts.

Replace air cleaner element.

Replace ignition cables on 2.0 liter and 2.4

liter engines.

Replace spark plugs on 2.0L and 2.4L

engines.

67,500 Miles (108 000 km) or at 54 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on 2.0 l i ter and 2.4 l i ter

engi nes.

I nspect front brake pads and rear brake l i ni ngs.

75,000 Miles (120 000 km) or at 60 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on al l engi nes.

Adjust dri ve bel t tensi on.

Fl ush and repl ace engi ne cool ant i f i t has been

30,000 mi l es (48 000 km) or 24 months si nce l ast

change.

82,500 Miles (132 000 km) or at 66 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on 2.0 l i ter and 2.4 l i ter

engi nes.

Fl ush and repl ace engi ne cool ant i f i t has been

30,000 mi l es (48 000 km) or 24 months si nce l ast

change.

90,000 Miles (144 000 km) or at 72 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on al l engi nes.

Check and replace, if necessary***, the

PCV valve.**

Lubri cate front and rear suspensi on upper bal l

joi nts.

I nspect front brake pads and rear brake l i ni ngs.

Adjust dri ve bel t tensi on.

Replace air cleaner air cleaner element.

Replace spark plugs on 2.0L and 2.4L

engines.

97,500 Miles (156 000 km) or at 78 months

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on 2.0 l i ter and 2.4 l i ter

engi nes.

100,000 Miles (160 000km)

Replace spark plugs and ignition cables on

2.5L engines.

105,000 Miles (168 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on al l engi nes.

Replace engine timing belt on 2.0 liter and

2.4 liter California vehicles.

SCHEDULEB

3,000 Miles (5 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on 2.0 l i ter and 2.4 l i ter

engi nes.

6,000 Miles (10 000 km)

Change engi ne oi l

Repl ace engi ne oi l fi l ter on al l engi nes.

9,000 Miles (14 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on 2.0 l i ter and 2.4 l i ter

engi nes.

12,000 Miles (19 000 km)

Change engi ne oi l

Repl ace engi ne oi l fi l ter on al l engi nes.

I nspect front brake pads and rear brake l i ni ngs.

15,000 Miles (24 000 km)

Change engi ne oi l

Repl ace engi ne oi l fi l ter on 2.0 l i ter and 2.4 l i ter

engi nes.

0 - 4 LUBRICATION AND MAINTENANCE J A

GENERAL INFORMATION (Continued)

Adjust dri ve bel t tensi on.

Change automati c transaxl e fl ui d and fi l ter.*

18,000 Miles (29 000 km)

Change engi ne oi l

Repl ace engi ne oi l fi l ter on al l engi nes.

21,000 Miles (34 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on 2.0 l i ter and 2.4 l i ter

engi nes.

24,000 Miles (38 000 km)

Change engi ne oi l

Repl ace engi ne oi l fi l ter on al l engi nes.

I nspect front brake pads and rear brake l i ni ngs.

27,000 Miles (43 000 km)

Change engi ne oi l

Repl ace engi ne oi l fi l ter on 2.0 l i ter and 2.4 l i ter

engi nes.

30,000 Miles (48 000 km)

Change engi ne oi l

Repl ace engi ne oi l fi l ter on al l engi nes.

Check and replace, if necessary, the PCV

valve.**

Lubri cate front and rear suspensi on upper bal l

joi nts.

Adjust dri ve bel t tensi on.

Replace air cleaner element.

Replace spark plugs on 2.0L and 2.4L

engines.

Change automati c transmi ssi on fl ui d and fi l ter.*

33,000 Miles (53 000 km)

Change engi ne oi l .

repl ace engi ne oi l fi l ter on 2.0 l i ter and 2.4 l i ter

engi nes.

36,000 Miles (58 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on al l engi nes.

Fl ush and repl ace engi ne cool ant.

I nspect front brake pads and rear brake l i ni ngs.

39,000 Miles (62 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on 2.0 l i ter and 2.4 l i ter

engi nes.

42,000 Miles (67 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on al l engi nes.

45,000 Miles (72 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on 2.0 l i ter and 2.4 l i ter

engi nes.

Adjust dri ve bel t tensi on.

Change automati c transaxl e fl ui d and fi l ter.*

48,000 Miles (77 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on al l engi nes.

I nspect front brake pads and rear brake l i ni ngs.

51,000 Miles (82 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on 2.0 l i ter and 2.4 l i ter

engi nes.

Fl ush and repl ace engi ne cool ant.

54,000 Miles (86 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on al l engi nes.

57,000 Miles (91 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on 2.0 l i ter and 2.4 l i ter

engi nes.

60,000 Miles (96 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on al l engi nes.

Check and replace, if necessary***, the

PCV valve.**

Lubri cate front and rear suspensi on upper bal l

joi nts.

Repl ace dri ve bel ts.

Replace air cleaner element.

Replace ignition cables on 2.0 liter and 2.4

liter engines.

Replace spark plugs on 2.0 liter and 2.4

liter engines.

Change automati c transaxl e fl ui d and fi l ter.*

I nspect front brake pads and rear brake l i ni ngs.

63,000 Miles (101 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on 2.0 l i ter and 2.4 l i ter

engi nes.

66,000 Miles (106 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on al l engi nes.

69,000 Miles (110 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on 2.0 l i ter and 2.4 l i ter

engi nes.

J A LUBRICATION AND MAINTENANCE 0 - 5

GENERAL INFORMATION (Continued)

72,000 Miles (115 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on al l engi nes.

I nspect front brake pads and rear brake l i ni ngs.

75,000 Miles (120 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on 2.0 l i ter and 2.4 l i ter

engi nes.

Adjust dri ve bel t tensi on.

Replace the spark plugs and ignition

cables on 2.5 liter engines.

Change automati c transaxl e fl ui d and fi l ter.*

78,000 Miles (125 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on al l engi nes.

81,000 Miles (130 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on 2.0 l i ter and 2.4 l i ter

engi nes.

Fl ush and repl ace the engi ne cool ant.

84,000 Miles (134 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on al l engi nes.

I nspect front brake pads and rear brake l i ni ngs.

87,000 Miles (139 000 km)

Change engi ne oi l .

Repl ace engi nes oi l fi l ter on 2.0 l i ter and 2.4

l i ter engi nes.

90,000 Miles (144 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on al l engi nes.

Check and replace, if necessary***, the

PCV valve.**

Lubri cate front and rear suspensi on upper bal l

joi nts.

Adjust dri ve bel t tensi on.

Replace air cleaner element.

Replace spark plugs on 2.0 liter and 2.4

liter engines.

Change automati c transaxl e fl ui d and fi l ter.*

93,000 Miles (149 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on 2.0 l i ter and 2.4 l i ter

engi nes.

96,000 Miles (154 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on al l engi nes.

I nspect front brake pads and rear brake l i ni ngs.

99,000 Miles (158 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on 2.0 l i ter and 2.4 l i ter

engi nes.

105,000 (168 000 km)

Change engi ne oi l .

Repl ace engi ne oi l fi l ter on al l engi nes.

Replace the engine timing belt on 2.0 liter

and 2.5 liter engines.

NOTE: * Police, taxi, or delivery service usage and

trailer towing requires the more frequent transaxle

service indicated with a * in schedule - B. Perform

these services if you usually operate your vehicle

under these conditions.

NOTE: **This maintenance is recommended by

Chrysler to the owner but is not required to main-

tain the warranty on the PCV valve.

NOTE: ***This maintenance is not required if the

PCV valve was previously replaced.

0 - 6 LUBRICATION AND MAINTENANCE J A

GENERAL INFORMATION (Continued)

J UMP STARTING, HOISTING AND TOWING

INDEX

page page

SERVICE PROCEDURES

HOISTING RECOMMENDATIONS . . . . . . . . . . . 8

JUMP STARTING PROCEDURE . . . . . . . . . . . . . 7

TOWING RECOMMENDATIONS . . . . . . . . . . . . . 8

SERVICE PROCEDURES

JUMP STARTING PROCEDURE

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS IN GROUP 8A, BATTERY/START-

ING/CHARGING SYSTEMS DIAGNOSTICS. DO NOT

JUMP START A FROZEN BATTERY, PERSONAL

INJURY CAN RESULT. DO NOT JUMP START WHEN

MAINTENANCE FREE BATTERY INDICATOR DOT IS

YELLOW OR BRIGHT COLOR. DO NOT JUMP

START A VEHICLE WHEN THE BATTERY FLUID IS

BELOW THE TOP OF LEAD PLATES. DO NOT

ALLOW JUMPER CABLE CLAMPS TO TOUCH

EACH OTHER WHEN CONNECTED TO A BOOSTER

SOURCE. DO NOT USE OPEN FLAME NEAR BAT-

TERY. REMOVE METALLIC JEWELRY WORN ON

HANDS OR WRISTS TO AVOID INJURY BY ACCI-

DENTAL ARCING OF BATTERY CURRENT. WHEN

USING A HIGH OUTPUT BOOSTING DEVICE, DO

NOT ALLOW BATTERY VOLTAGE TO EXCEED 16

VOLTS. REFER TO INSTRUCTIONS PROVIDED

WITH DEVICE BEING USED.

CAUTION: When using another vehicle as a

booster, do not allow vehicles to touch. Electrical

systems can be damaged on either vehicle.

TO J UMP START A DISABLED VEHICLE:

(1) Rai se hood on di sabl ed vehi cl e and vi sual l y

i nspect engi ne compartment for:

Battery cabl e cl amp condi ti on, cl ean i f necessary.

Frozen battery.

Yel l ow or bri ght col or test i ndi cator, i f equi pped.

Low battery fl ui d l evel .

Generator dri ve bel t condi ti on and tensi on.

Fuel fumes or l eakage, correct i f necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When usi ng another vehi cl e as a booster

source, park the booster vehi cl e wi thi n cabl e reach.

Turn off al l accessori es, set the parki ng brake, pl ace

the automati c transmi ssi on i n PARK or the manual

transmi ssi on i n NEUTRAL and turn the i gni ti on

OFF.

(3) On di sabl ed vehi cl e, pl ace gear sel ector i n park

or neutral and set park brake. Turn off al l accesso-

ri es.

(4) Connect jumper cabl es to booster battery. RED

cl amp to posi ti ve termi nal (+). BLACK cl amp to neg-

ati ve termi nal (-). DO NOT al l ow cl amps at opposi te

end of cabl es to touch, el ectri cal arc wi l l resul t.

Revi ew al l warni ngs i n thi s procedure.

(5) On di sabl ed vehi cl e, connect RED jumper cabl e

cl amp to posi ti ve (+) termi nal . Connect BLACK

jumper cabl e cl amp to engi ne ground as cl ose to the

ground cabl e attachi ng poi nt as possi bl e (Fi g. 1).

(6) Start the engi ne i n the vehi cl e whi ch has the

booster battery, l et the engi ne i dl e a few mi nutes,

then start the engi ne i n the vehi cl e wi th the di s-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Al l ow battery i n di sabl ed vehi cl e to charge to

at l east 12.4 vol ts (75% charge) before attempti ng to

start engi ne. I f engi ne does not start wi thi n 15 sec-

onds, stop cranki ng engi ne and al l ow starter to cool

(15 mi n.), before cranki ng agai n.

Fig. 1 Jumper Cable Clamp Connections

ENGINE GROUND NEGATIVE JUMPER CABLE BATTERY NEGATIVE CABLE POSITIVE JUMPER CABLE BATTERY POSITIVE CABLE BATTERY TEST INDICATOR

J A LUBRICATION AND MAINTENANCE 0 - 7

DISCONNECT CABLE CLAMPS AS FOLLOWS:

Di sconnect BLACK cabl e cl amp from engi ne

ground on di sabl ed vehi cl e.

When usi ng a Booster vehi cl e, di sconnect

BLACK cabl e cl amp from battery negati ve termi nal .

Di sconnect RED cabl e cl amp from battery posi ti ve

termi nal .

Di sconnect RED cabl e cl amp from battery posi -

ti ve termi nal on di sabl ed vehi cl e.

HOISTING RECOMMENDATIONS

Refer to Owners Manual provi ded wi th vehi cl e for

proper emergency jacki ng procedures.

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN THE ENGINE OR REAR SUSPENSION

IS REMOVED FROM A VEHICLE, THE CENTER OF

GRAVITY IS ALTERED MAKING SOME HOISTING

CONDITIONS UNSTABLE. PROPERLY SUPPORT OR

SECURE VEHICLE TO HOISTING DEVICE WHEN

THESE CONDITIONS EXIST.

CAUTION: Do not position hoisting device on sus-

pension components, damage to vehicle can result.

TOWING RECOMMENDATIONS

RECOMMENDED TOWING EQUIPMENT

To avoi d damage to bumper fasci a and ai r dams

use of a fl at bed towi ng devi ce or wheel l i ft (Fi g. 3) i s

recommended. When usi ng a wheel l i ft towi ng devi ce,

be sure the unl i fted end of di sabl ed vehi cl e has at

l east 100 mm (4 i n.) ground cl earance. I f mi ni mum

ground cl earance cannot be reached, use a towi ng

dol l y. I f a fl at bed devi ce i s used, the approach angl e

shoul d not exceed 15 degrees.

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels

removed, install lug nuts to retain brake drums or

rotors.

A towed vehi cl e shoul d be rai sed unti l the l i fted

wheel s are a mi ni mum 100 mm (4 i n.) from the

ground. Be sure there i s at l east 100 mm (4 i n.)

cl earance between the tai l pi pe and the ground. I f

necessary, remove the wheel s from the l i fted end of

the vehi cl e and l ower the vehi cl e cl oser to the

ground, to i ncrease the ground cl earance at the rear

of the vehi cl e. I nstal l l ug nuts on wheel attachi ng

studs to retai n brake drums or rotors.

LOCKED VEHICLE TOWING

When a l ocked vehi cl e must be towed wi th the

front wheel s on the ground, use a towi ng dol l y or fl at

bed haul er.

FLAT TOWING WITH TOW BAR

3-speed automati c transaxl e vehi cl es can be fl at

towed at speeds not to exceed 40 km/h (25 mph) for

not more than 25 km (15 mi l es). The steeri ng col umn

must be unl ocked and gear sel ector i n neutral .

5-speed manual transaxl e vehi cl es can be fl at

towed at any l egal hi ghway speed for extended di s-

tances. The gear sel ector must be i n the neutral posi -

ti on.

Fig. 2 Hoisting And Jacking Points

DRIVE ON LIFT

FRAME CONTACT LIFT (SINGLE POST)

CHASSIS LIFT (DUAL POST)

OUTBOARD LIFT (DUAL POST)

FLOOR JACK

Fig. 3 Recommended Towing Equipment

WHEEL LIFT FLAT BED

0 - 8 LUBRICATION AND MAINTENANCE J A

SERVICE PROCEDURES (Continued)

WARNINGS AND PRECAUTIONS

WARNING: DO NOT ALLOW TOWING ATTACH-

MENT DEVICES TO CONTACT THE FUEL TANK OR

LINES, FUEL LEAK CAN RESULT. DO NOT LIFT OR

TOW VEHICLE BY FRONT OR REAR BUMPER, OR

BUMPER ENERGY ABSORBER UNITS. DO NOT

VENTURE UNDER A LIFTED VEHICLE IF NOT SUP-

PORTED PROPERLY ON SAFETY STANDS. DO NOT

ALLOW PASSENGERS TO RIDE IN A TOWED VEHI-

CLE. USE A SAFETY CHAIN THAT IS INDEPENDENT

FROM THE TOWING ATTACHMENT DEVICE.

CAUTION: Do not damage brake lines, exhaust

system, shock absorbers, sway bars, or any other

under vehicle components when attaching towing

device to vehicle. Do not attach towing device to

front or rear suspension components. Do not

secure vehicle to towing device by the use of front

or rear suspension or steering components.

Remove or secure loose or protruding objects from

a damaged vehicle before towing. Refer to state and

local rules and regulations before towing a vehicle.

Do not allow weight of towed vehicle to bear on

lower fascia, air dams, or spoilers.

FLAT BED TOWING TIE DOWNS

CAUTION: Do not tie vehicle down by attaching

chains or cables to suspension components or

engine mounts, damage to vehicle can result.

JA vehi cl es can be ti ed to a fl at bed devi ce usi ng

the rei nforced l oops l ocated under the front and rear

bumpers on the dri vers si de of the vehi cl e. There are

al so four rei nforced el ongated hol es for T or R-hooks

l ocated on the bottom of the front frame rai l torque

boxes behi nd the front wheel s and forward of the

rear wheel s i nboard of the rocker panel wel d seam.

TOWINGFRONT WHEEL LIFT

Chrysl er Corporati on recommends that a vehi cl e be

towed wi th the front end l i fted, whenever possi bl e. A

90 cm (36 i n.) l ength of 4x4 wood beam can be pl aced

between the wheel l i ft devi ce and the bottom of the

fasci a to prevent damage to vehi cl e duri ng the l i fti ng

operati on. The beam can removed after l i fti ng the

front of the vehi cl e.

TOWINGREAR WHEEL LIFT

I f a vehi cl e cannot be towed wi th the front wheel s

l i fted, the rear wheel s can be l i fted provi ded the fol -

l owi ng gui de l i nes are observed.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

Unl ock steeri ng col umn and secure steeri ng

wheel i n strai ght ahead posi ti on wi th a cl amp devi ce

desi gned for towi ng.

Pl ace front wheel s on a towi ng dol l y.

J A LUBRICATION AND MAINTENANCE 0 - 9

SERVICE PROCEDURES (Continued)

Das könnte Ihnen auch gefallen

- 00 - Lubrication and MaintenanceDokument12 Seiten00 - Lubrication and MaintenanceMarkitos LopezNoch keine Bewertungen

- Lubrication and Maintenance: LubricantsDokument12 SeitenLubrication and Maintenance: Lubricantsblackjeep44Noch keine Bewertungen

- Lubrication and Maintenance: LubricantsDokument0 SeitenLubrication and Maintenance: Lubricantsluistorres19Noch keine Bewertungen

- 9.4. Lubrication and MaintenanceDokument15 Seiten9.4. Lubrication and MaintenanceChristian Icaza SamaniegoNoch keine Bewertungen

- URXS 7 ($ (: $XWRPDWLF 7udqvd (Oh 6ShhgDokument67 SeitenURXS 7 ($ (: $XWRPDWLF 7udqvd (Oh 6ShhgccbulgariaNoch keine Bewertungen

- 454 Short Block Crate Engine 12498778Dokument18 Seiten454 Short Block Crate Engine 12498778fariaseulisesNoch keine Bewertungen

- ls9 Crate Engine Control System 19354338Dokument40 Seitenls9 Crate Engine Control System 19354338Sebastian OlayaNoch keine Bewertungen

- Elgin-Product-Catalog (2021 - 01 - 27 20 - 16 - 46 UTC)Dokument89 SeitenElgin-Product-Catalog (2021 - 01 - 27 20 - 16 - 46 UTC)wade.hynesoutlook.comNoch keine Bewertungen

- ZJ Obdi CodesDokument2 SeitenZJ Obdi Codesoğuzhan_tekceNoch keine Bewertungen

- Lubrication and MaintenanceDokument8 SeitenLubrication and MaintenanceJahanzeb KhanNoch keine Bewertungen

- 2005 Chevrolet Blazer Owners PDFDokument436 Seiten2005 Chevrolet Blazer Owners PDFryan jaridNoch keine Bewertungen

- Yukon Build SheetDokument4 SeitenYukon Build SheethomeyclownNoch keine Bewertungen

- Replacement Parts Catalog: Automatic TransmissionDokument180 SeitenReplacement Parts Catalog: Automatic TransmissionCarlos HT Tmberto Tranamil Barros100% (2)

- EXJ - 19A99 Jeep XJ Service ManualDokument12 SeitenEXJ - 19A99 Jeep XJ Service ManualhottubdocNoch keine Bewertungen

- Tahoe NavigationDokument86 SeitenTahoe NavigationFAKESIGNUPACCOUNTNoch keine Bewertungen

- GMC Full Size Pickup 2002: Remote Start / Security / GPSDokument1 SeiteGMC Full Size Pickup 2002: Remote Start / Security / GPSChristian Icaza SamaniegoNoch keine Bewertungen

- 2008 WK PartsDokument607 Seiten2008 WK Partsdigidigi2212Noch keine Bewertungen

- 2008 Chevrolet Tahoe Owners PDFDokument542 Seiten2008 Chevrolet Tahoe Owners PDFServiceComputersNoch keine Bewertungen

- LS9 Crate Engine 19244099Dokument17 SeitenLS9 Crate Engine 19244099Karanveer SinghNoch keine Bewertungen

- 2k13fullsizetrk Nav1Dokument106 Seiten2k13fullsizetrk Nav1ecstacy7Noch keine Bewertungen

- Vin Plate Decoding InformationDokument553 SeitenVin Plate Decoding InformationGeorge PanicaNoch keine Bewertungen

- 2014 Chevrolet Silverado Owner Manual MDokument542 Seiten2014 Chevrolet Silverado Owner Manual MpanchocabreraNoch keine Bewertungen

- Lubrication and MaintenanceDokument12 SeitenLubrication and MaintenanceArt DoeNoch keine Bewertungen

- 2004 Neon SX2Dokument922 Seiten2004 Neon SX2jetdedeNoch keine Bewertungen

- 02wgeb PDFDokument782 Seiten02wgeb PDFAlex BoxNoch keine Bewertungen

- Owner's ManualDokument419 SeitenOwner's Manualpanu suwannakoodNoch keine Bewertungen

- 350-HO Long Block SpecsDokument30 Seiten350-HO Long Block SpecsClif CunninghamNoch keine Bewertungen

- 0 Lubrication & MaintenanceDokument12 Seiten0 Lubrication & Maintenancesteve90 benNoch keine Bewertungen

- 2002JeepKJServiceManual PDFDokument2.033 Seiten2002JeepKJServiceManual PDFAaron MontoyaNoch keine Bewertungen

- Power Door Locks Chevrolet S10Dokument11 SeitenPower Door Locks Chevrolet S10Maxi Sardi100% (1)

- 31 5310 GMC Sierra Installation Instructions CaridDokument4 Seiten31 5310 GMC Sierra Installation Instructions CaridenthonytopmakNoch keine Bewertungen

- Transtar 2007 370-027 KH PDFDokument20 SeitenTranstar 2007 370-027 KH PDF楊亞凡Noch keine Bewertungen

- Owner's ManualDokument511 SeitenOwner's Manualبوخال الليبيNoch keine Bewertungen

- Aisin Warner AW4 Automatic Transmission PDFDokument120 SeitenAisin Warner AW4 Automatic Transmission PDFRichard Andrianjaka LuckyNoch keine Bewertungen

- Identifying BorgWarner Transfer CasesDokument4 SeitenIdentifying BorgWarner Transfer Casesrobertoperez525Noch keine Bewertungen

- Lubrication and Maintenance: Engine OilDokument18 SeitenLubrication and Maintenance: Engine Oilprueba5Noch keine Bewertungen

- 2012 Credit Parts MAF Sensor CatalogDokument15 Seiten2012 Credit Parts MAF Sensor CatalogHermes Heli Retiz AlvarezNoch keine Bewertungen

- Vwunlli 8 PP 2 S 69 Niim 8Dokument415 SeitenVwunlli 8 PP 2 S 69 Niim 8viper_oneNoch keine Bewertungen

- 2004 Dodge Neon: Vin Plate Decoding InformationDokument440 Seiten2004 Dodge Neon: Vin Plate Decoding InformationAdrian ZawadaNoch keine Bewertungen

- 7F Rev 10 HD FS Ck-Pucc 21 D1Dokument96 Seiten7F Rev 10 HD FS Ck-Pucc 21 D1plane.tech1833Noch keine Bewertungen

- 94 Chevrolet Diesel SM SuppDokument433 Seiten94 Chevrolet Diesel SM SuppRolf G MichelsenNoch keine Bewertungen

- 2005 Chevrolet Tahoe/Suburban Owner ManualDokument530 Seiten2005 Chevrolet Tahoe/Suburban Owner ManualClaudio Hernández PobleteNoch keine Bewertungen

- 2014 Elec HD FS CKTruck 100713 ChevroletDokument247 Seiten2014 Elec HD FS CKTruck 100713 ChevroletREINALDO GONZALEZNoch keine Bewertungen

- 2015 HD Catalog ApplicationSectionDokument173 Seiten2015 HD Catalog ApplicationSectionCarlos ReconcoNoch keine Bewertungen

- Rs Wiring DiagramDokument594 SeitenRs Wiring DiagramRuben Castro100% (1)

- 1958-2006 Automotive Light Bulb GuideDokument318 Seiten1958-2006 Automotive Light Bulb GuideFred RuizNoch keine Bewertungen

- 2007-2013 Chevy Silverado + GMC TrucksDokument5 Seiten2007-2013 Chevy Silverado + GMC TrucksCmoNoch keine Bewertungen

- AEV JK HEMI BOM Non VVTDokument4 SeitenAEV JK HEMI BOM Non VVTBryanNoch keine Bewertungen

- 5.7 Parts ManualDokument73 Seiten5.7 Parts ManualdavinmaximusNoch keine Bewertungen

- 2018 Chevrolet Silverado 1500 SSV Order GuideDokument41 Seiten2018 Chevrolet Silverado 1500 SSV Order GuiderfffffNoch keine Bewertungen

- 1993 GMC Jimmy OwnersDokument372 Seiten1993 GMC Jimmy Ownersdanielwilson100% (1)

- 2000 DurangoDokument193 Seiten2000 DurangoErnest PetermanNoch keine Bewertungen

- 200 CherokeeDokument2.119 Seiten200 CherokeeVinte RemodelarNoch keine Bewertungen

- 05tj Parts GuideDokument392 Seiten05tj Parts GuideGromit32Noch keine Bewertungen

- Competitve OEM Interchange 6-30-17Dokument193 SeitenCompetitve OEM Interchange 6-30-17Asep setiawanNoch keine Bewertungen

- 1997 XJ Service BookDokument1.724 Seiten1997 XJ Service Bookdane5502Noch keine Bewertungen

- Jeep Cherokee Service Manual 2000Dokument1.528 SeitenJeep Cherokee Service Manual 2000pitchao1100% (9)

- Workshop - NeonDokument1.200 SeitenWorkshop - NeonEddieNoch keine Bewertungen

- 73 Dit Power StrokeDokument78 Seiten73 Dit Power StrokeNic Price100% (1)

- Maintenance and LubricationDokument34 SeitenMaintenance and Lubricationtoppen_76100% (1)

- Ice Series Cubers Service Parts Manual: Includes 50Hz. UnitsDokument19 SeitenIce Series Cubers Service Parts Manual: Includes 50Hz. UnitsAdán Castro GallegosNoch keine Bewertungen

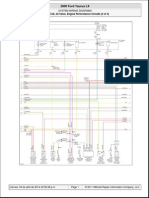

- Engine Electrical Wiring Explorer 91Dokument1 SeiteEngine Electrical Wiring Explorer 91Adán Castro GallegosNoch keine Bewertungen

- K-1800 Ice Kube Machine: WarrantyDokument2 SeitenK-1800 Ice Kube Machine: WarrantyAdán Castro GallegosNoch keine Bewertungen

- Motor 1 de 4 24 ValDokument1 SeiteMotor 1 de 4 24 ValAdán Castro GallegosNoch keine Bewertungen

- Motor 1 de 4 24 ValDokument1 SeiteMotor 1 de 4 24 ValAdán Castro GallegosNoch keine Bewertungen

- 2000 Ford Taurus LX 2000 Ford Taurus LXDokument1 Seite2000 Ford Taurus LX 2000 Ford Taurus LXAdán Castro GallegosNoch keine Bewertungen

- Motor 2 de 4 24 ValDokument1 SeiteMotor 2 de 4 24 ValAdán Castro GallegosNoch keine Bewertungen

- 1999 Chrysler 300M 1999 Chrysler 300M: System Wiring Diagrams System Wiring DiagramsDokument1 Seite1999 Chrysler 300M 1999 Chrysler 300M: System Wiring Diagrams System Wiring DiagramsAdán Castro GallegosNoch keine Bewertungen

- CodigosDokument6 SeitenCodigosAdán Castro GallegosNoch keine Bewertungen

- 2000 Ford Taurus LX 2000 Ford Taurus LXDokument1 Seite2000 Ford Taurus LX 2000 Ford Taurus LXAdán Castro GallegosNoch keine Bewertungen

- Engine 2 of 4Dokument1 SeiteEngine 2 of 4Adán Castro GallegosNoch keine Bewertungen

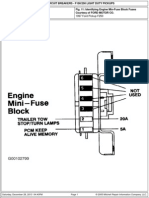

- Caja Fusibles Tribute 2001Dokument5 SeitenCaja Fusibles Tribute 2001Adán Castro Gallegos0% (1)

- Diagramas Motor Explorer Sport Trac 2001Dokument8 SeitenDiagramas Motor Explorer Sport Trac 2001Adán Castro Gallegos100% (5)

- Engine MiniFuses BlockDokument1 SeiteEngine MiniFuses BlockAdán Castro GallegosNoch keine Bewertungen

- Engine 1 of 4Dokument1 SeiteEngine 1 of 4Adán Castro GallegosNoch keine Bewertungen

- Primary Baterry FusesDokument1 SeitePrimary Baterry FusesAdán Castro GallegosNoch keine Bewertungen

- Power Windows CircuitDokument1 SeitePower Windows CircuitAdán Castro GallegosNoch keine Bewertungen

- Localizacion de Componentes Explorer Sport Trac 2001 IIDokument15 SeitenLocalizacion de Componentes Explorer Sport Trac 2001 IIAdán Castro GallegosNoch keine Bewertungen

- Baterai EnergizierDokument4 SeitenBaterai EnergizierbidangNoch keine Bewertungen

- MTR Bump Test ProcedureDokument1 SeiteMTR Bump Test ProcedureMac BoothNoch keine Bewertungen

- Pick-Up and Drop-Off DirectionsDokument2 SeitenPick-Up and Drop-Off DirectionsTibi TibiNoch keine Bewertungen

- Report 1Dokument50 SeitenReport 1pramo_dassNoch keine Bewertungen

- Trator Murray 24,0 - NovoDokument19 SeitenTrator Murray 24,0 - NovoDiário Da dudaNoch keine Bewertungen

- Body-mounting-Manual HINODokument217 SeitenBody-mounting-Manual HINOAlex Consuegra Medina100% (1)

- Product Catalogue INKA November 2020-CompressedDokument29 SeitenProduct Catalogue INKA November 2020-CompressedIrvan Pratama PutraNoch keine Bewertungen

- Testing and Commissioning Procedure No 4 Lift Escalator Passenger ConveyorDokument50 SeitenTesting and Commissioning Procedure No 4 Lift Escalator Passenger ConveyorknsbNoch keine Bewertungen

- Code of Practice For Temporary Traffic Management (Copttm) : Traffic Control Devices ManualDokument51 SeitenCode of Practice For Temporary Traffic Management (Copttm) : Traffic Control Devices ManualBen SuttonNoch keine Bewertungen

- The LNG Process: Step One: Liquefaction Step Three: TransportDokument1 SeiteThe LNG Process: Step One: Liquefaction Step Three: TransportHabibNoch keine Bewertungen

- Assignment of FreeboardDokument18 SeitenAssignment of FreeboardBharatiyulam100% (4)

- Latihan Soal UAS Bahasa Inggris Kelas 11 Semester 1Dokument10 SeitenLatihan Soal UAS Bahasa Inggris Kelas 11 Semester 1muga sdaNoch keine Bewertungen

- Vijayawada Chennai: DT79PH CompleteDokument5 SeitenVijayawada Chennai: DT79PH CompleteKoteswar MandavaNoch keine Bewertungen

- Track: ExpressDokument1 SeiteTrack: ExpressTinny SavageNoch keine Bewertungen

- China and The New Silk Road 2020Dokument219 SeitenChina and The New Silk Road 2020YUDHA PAMUNGKAS 201923179Noch keine Bewertungen

- Main Parameters of XCMG Wheel Loader LW300KDokument2 SeitenMain Parameters of XCMG Wheel Loader LW300KRAMON CALDERONNoch keine Bewertungen

- 2016 Suzuki Swift Sport BrochureDokument2 Seiten2016 Suzuki Swift Sport BrochureDiego Ruiz ToledoNoch keine Bewertungen

- Dhubri Phulbari Project RFI-283 - R1Dokument12 SeitenDhubri Phulbari Project RFI-283 - R1Dip100% (1)

- BOQ - Land Devt - CalambaDokument7 SeitenBOQ - Land Devt - CalambaSebastian AbordoNoch keine Bewertungen

- Golf Cart Liability WaiverDokument1 SeiteGolf Cart Liability Waiveritargeting100% (2)

- LH Pre-Intermediate Teacher's Book WorksheetsDokument70 SeitenLH Pre-Intermediate Teacher's Book Worksheetssevilakyul0Noch keine Bewertungen

- RR - TU41 - Phantom Extended EU - 20210125Dokument7 SeitenRR - TU41 - Phantom Extended EU - 20210125SallyNoch keine Bewertungen

- Boeing CLEEN Projects BriefingDokument32 SeitenBoeing CLEEN Projects BriefingVictor BettNoch keine Bewertungen

- MYK4600 HMB Datasheet A4 QshaftDokument96 SeitenMYK4600 HMB Datasheet A4 QshaftDerek LeeNoch keine Bewertungen

- Crimson Tide SummaryDokument3 SeitenCrimson Tide SummaryPragya AgarwalNoch keine Bewertungen

- Plaridel Bypass DPWHDokument2 SeitenPlaridel Bypass DPWHHenson CoNoch keine Bewertungen

- Lap RecordsDokument5 SeitenLap RecordsFelix GomuliaNoch keine Bewertungen

- D K Sanyal Marine Diesel EnginesDokument253 SeitenD K Sanyal Marine Diesel EnginesG SaiNoch keine Bewertungen

- LISTA AGENTIILOR DE TURISM LICENTIATE Actualizare 28.03.2022Dokument486 SeitenLISTA AGENTIILOR DE TURISM LICENTIATE Actualizare 28.03.2022Graziella DanNoch keine Bewertungen

- Uilited Perlite Corporatioii: High Strength, Lightweight AggregateDokument4 SeitenUilited Perlite Corporatioii: High Strength, Lightweight AggregateMark Roger II HuberitNoch keine Bewertungen

- Edward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsVon EverandEdward's Menagerie New Edition: Over 50 easy-to-make soft toy animal crochet patternsNoch keine Bewertungen

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerVon EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerBewertung: 4.5 von 5 Sternen4.5/5 (54)

- House Rules: How to Decorate for Every Home, Style, and BudgetVon EverandHouse Rules: How to Decorate for Every Home, Style, and BudgetNoch keine Bewertungen

- Treasure Bookmaking: Crafting Handmade Sustainable JournalsVon EverandTreasure Bookmaking: Crafting Handmade Sustainable JournalsNoch keine Bewertungen

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiVon Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiBewertung: 5 von 5 Sternen5/5 (2)

- 100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesVon Everand100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesNoch keine Bewertungen

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestVon EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestBewertung: 4 von 5 Sternen4/5 (28)

- Modern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeVon EverandModern Crochet Style: 15 Colourful Crochet Patterns For You and Your HomeBewertung: 5 von 5 Sternen5/5 (1)

- The Martha Manual: How to Do (Almost) EverythingVon EverandThe Martha Manual: How to Do (Almost) EverythingBewertung: 4 von 5 Sternen4/5 (11)

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiVon EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiBewertung: 4 von 5 Sternen4/5 (3)

- Swatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersVon EverandSwatch This, 3000+ Color Palettes for Success: Perfect for Artists, Designers, MakersBewertung: 3.5 von 5 Sternen3.5/5 (3)

- Fairytale Blankets to Crochet: 10 Fantasy-Themed Children's Blankets for Storytime CuddlesVon EverandFairytale Blankets to Crochet: 10 Fantasy-Themed Children's Blankets for Storytime CuddlesBewertung: 5 von 5 Sternen5/5 (3)

- Amigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)Von EverandAmigurumi Cats: Crochet Sweet Kitties the Japanese Way (24 Projects of Cats to Crochet)Noch keine Bewertungen

- Edward's Menagerie: Dogs: 50 canine crochet patternsVon EverandEdward's Menagerie: Dogs: 50 canine crochet patternsBewertung: 3 von 5 Sternen3/5 (5)

- Crochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsVon EverandCrochet Creatures of Myth and Legend: 19 Designs Easy Cute Critters to Legendary BeastsBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastVon EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastBewertung: 5 von 5 Sternen5/5 (1)

- Hello Hexie!: 20 Easy Crochet Patterns from Simple Granny HexagonsVon EverandHello Hexie!: 20 Easy Crochet Patterns from Simple Granny HexagonsBewertung: 5 von 5 Sternen5/5 (3)

- Crochet in a Weekend: 29 Quick-to-Stitch Sweaters, Tops, Shawls & MoreVon EverandCrochet in a Weekend: 29 Quick-to-Stitch Sweaters, Tops, Shawls & MoreBewertung: 4 von 5 Sternen4/5 (6)

- Crochet Impkins: Over a million possible combinations! Yes, really!Von EverandCrochet Impkins: Over a million possible combinations! Yes, really!Bewertung: 4.5 von 5 Sternen4.5/5 (10)

- Crochet Iconic Women: Amigurumi Patterns for 15 Women Who Changed the WorldVon EverandCrochet Iconic Women: Amigurumi Patterns for 15 Women Who Changed the WorldBewertung: 4.5 von 5 Sternen4.5/5 (30)

- The Fellowship of the Knits: Lord of the Rings: The Unofficial Knitting BookVon EverandThe Fellowship of the Knits: Lord of the Rings: The Unofficial Knitting BookBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Radical Sewing: Pattern-Free, Sustainable Fashions for All BodiesVon EverandRadical Sewing: Pattern-Free, Sustainable Fashions for All BodiesNoch keine Bewertungen

- Textiles Transformed: Thread and thrift with reclaimed textilesVon EverandTextiles Transformed: Thread and thrift with reclaimed textilesNoch keine Bewertungen

- Creative Polymer Clay: Over 30 Techniques and Projects for Contemporary Wearable ArtVon EverandCreative Polymer Clay: Over 30 Techniques and Projects for Contemporary Wearable ArtNoch keine Bewertungen

- Modern Crochet Sweaters: 20 Chic Designs for Everyday WearVon EverandModern Crochet Sweaters: 20 Chic Designs for Everyday WearBewertung: 5 von 5 Sternen5/5 (1)

- Crochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsVon EverandCrochet Cute Dolls with Mix-and-Match Outfits: 66 Adorable Amigurumi PatternsBewertung: 4 von 5 Sternen4/5 (5)

- Supersize Crochet Animals: 20 Adorable Amigurumi Sized to SnuggleVon EverandSupersize Crochet Animals: 20 Adorable Amigurumi Sized to SnuggleBewertung: 5 von 5 Sternen5/5 (2)

- Colorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsVon EverandColorful Crochet Knitwear: Crochet sweaters and more with mosaic, intarsia and tapestry crochet patternsNoch keine Bewertungen