Beruflich Dokumente

Kultur Dokumente

PROF. NO.35 Project Profile On Bone Mill Unit

Hochgeladen von

முஹம்மது உவைஸ்Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

PROF. NO.35 Project Profile On Bone Mill Unit

Hochgeladen von

முஹம்மது உவைஸ்Copyright:

Verfügbare Formate

P.No.

35\1

PROF. NO.35

PROJECT PROFILE ON BONE MILL UNIT

1. INTRODUCTION

Unit, which crushes or converted bones into small pieces is known as bone mill. Bone

crusher crushed the raw bone into small bone pieces. Crushed bones used as fertilizer.

These bones also used in formulation of animal feed and poultry feed etc. Crushed

bones also used in purification of sugar.

2. MARKET DEMAND

Demand of crushed bone is directly proportional to the installed capacity of different

basic industries like sugar, cattle feed etc. the demand of these bones would increase

or decrease according to the production capacity of these industries. As per survey

small cattle / poultry feed manufacturing unit needs about 5-10 MT of bone meal every

month and the district has 5-7 such unit than the demand of the district is around 30- 50

MT and it would further increase with their increase in production.

3. PRODUCTION TARGETS

Basis of estimation: 300 Working Days in a Year

Single Shift basis

8 hours per shift

Crushed Bones of different Sizes

Quantity (MT) 270

Value (Rs) 16740000

4. MANUFACTURING PROCESS

The bones are cleaned from all types of outside material like flush and dust. These

bones crushed with the help of crushers and segregated according to size. Bone

powder also collected separately.

P.No.35\2

5. QUALITY CONTROL STANDARDS

Quality of the product must be as per customers demand and BIS standards.

6. LAND & BUILDING

1. Covered area Sq. Ft. 500

2. Uncovered area Sq. Ft. 1000

3. Total area Sq. Ft. 1500

4. Whether constructed or

Rented

Constructed

5. If constructed, constructed

value

Rs 100000

6. If Rented, Rental value

(per month)

Rs N.A.

7. MACHINERY AND EQUIPMENT

S.N

.

Description Qty. Value (Rs.)

1. Bone Crusher with 20 HP Motor 1 200000

2. Rotary Screen with 5 HP motor 1

3. Other accessories like weighing

balance etc.

L.S.

4. Hand Tools L.S.

5. Sales Tax, Freight & Insurance

etc.

20000

Total 220000

8. RAW MATERIAL (PER MONTH)

S.N

.

Particulars Quantity (MT) Value (Rs)

1. Raw Bones 25 75000

2. Packaging Materials. L.S. 1000

Total 76000

P.No.35\3

9. STAFF & LABOUR (PER MONTH)

S.N

.

Particulars Qty Rate Value (Rs)

A Administrative and

Supervisory

(i) Manager 1 3000 3000

(ii) Peon/ Chowkidar 1 2000 2000

B Technical (Skilled-Unskilled)

(i) Skilled Worker 1 3000 3000

(ii) Unskilled Worker 2 2000 4000

Sub-Total 12000

Plus perquisites @ 30% of salaries 3600

TOTAL 15600

9. OTHER EXPENSES (PER MONTH)

1. Rent of Land & Building

2. Electricity Charges 10000

3. Fuel Exp. 0

4. Advertisement & Travelling 1000

5. Transport 5000

6. Consumable & stores etc. 1000

7. Potage expenses/ telephones 1000

8. Stationery 1000

9. Repairs & Maintenances 1000

Total 20000

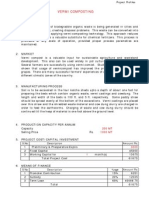

10. WORKING CAPITAL (FOR ONE MONTH)

SL.NO. DESCRIPTION AMOUNT(RS)

1 Raw material 76000

2 Salaries & Wages 15600

3 Other Expenses 20000

Total 111600

P.No.35\4

11. TOTAL CAPITAL INVESTMENT

Building & Other Civil Works 100000

Machinery & Equipment 220000

Working capital for one month 111600

Total 431600

12. COST OF PRODUCTION (PER ANNUM)

Total recurring cost per year 1339200

Depreciation on machinery &

equipment

30000

Interest on total investment @ 10% 43000

Total 1412200

13. SALES PROCEEDS (PER ANNUM)

S.N. Item Qty (MT) Value (Rs.)

1. Crushed Bone

Meal

270 16740000

Total 16740000

14. PROFITABILITY (BEFORE INCOME TAX)

1. Annual Gross Profit 261800

2. % of Profit on Sales 15.64%

3. Break Even Analysis

3.1 Annual Fixed Cost 427200

3.2 Annual Sales 16740000

3.3 Annual Variable Cost 912000

3.4 Break Even Point 56.06%

Break-Even Analysis

(% of Total Production envisaged)

Annual fixed cost X 100

-------------- ---------------- ------------- = %

Annual sales Annual variable costs

P.No.35\5

15. Manufactures/ Suppliers of Machinery

1. Ambica Engg. Works,

Ghopasni Road,

J odhpur.

2. V.A.P Corportion Ltd.

Industrial Area,

Udhna, Surat (Gujrat)

3. Bombay Machinery & Tools Syndicate

79, Siyaganj, Indore -452 007. Ph.- 536431,542067.

4. J itendra Agencies

5, shivsadan, sardar patel marg,

Indore.

5. Indore machinery stores

40, siyaganj, main road,

Indore 452 007

Ph. 534339

6. Huma Traders

Infront of shajanabad thana,

Shajanabad, Satna(m.p.)

7. Maruti Sales Corporation

Badshah Chamber,

45, J awahar Marg,

Indore (M.P.) 452 004

16. Suppliers of Raw Materials

From Local suppliers of raw bones of the area.

17. IMPLEMENTATION PERIOD

Proposed Project can commence production with in 6-8 weeks after sanction and first

disbursement of term loan.

P.No.35\6

18. ASSUMPTION FOR GENERATING PROJECT PROFITABILITY

1 Number of Working Days in a year 300 Days

2 Number of Shifts in a day 1 One

3 Hours in a Shift 8 hours

4 Plant Capacity Consider on Average production capacities

of plant.

5 Raw material Estimates Based upon product Mix

6 Raw Material Availability All districts of MP

7 Depreciation Straight Line Method

8 Manpower According to project Requirement

9 Rent estimate On the basis of current market prize of the

area.

10 Potential Area of Marketing the

products

Related industries demand of the area.

11 If project is funded, term loan

would be

60-80% of Total investment

12 Moratorium Period 6- 12 months

13 Repayment Period 5-7 years

14 Project may be established under PMEGP (GOI) / Tribal Self Employment

Scheme (NSTFDC) or Rani Durgawati

Scheme of MP

Das könnte Ihnen auch gefallen

- Cattle Feed PDFDokument6 SeitenCattle Feed PDFRangasamyNoch keine Bewertungen

- Agricultural Implements: Nsic Project ProfilesDokument3 SeitenAgricultural Implements: Nsic Project ProfilesJames WoodNoch keine Bewertungen

- Ground and Processed Spices and Cereals Project ReportDokument5 SeitenGround and Processed Spices and Cereals Project ReportGirish DaryananiNoch keine Bewertungen

- Hollow BlocksDokument6 SeitenHollow BlocksA Jaya Mala100% (1)

- Portfolio BagDokument5 SeitenPortfolio Bagpradip_kumarNoch keine Bewertungen

- Printing Ink Project ProfileDokument8 SeitenPrinting Ink Project Profilepraveen4ppkNoch keine Bewertungen

- Bolt Nuts MFG ProcessDokument5 SeitenBolt Nuts MFG ProcessscribddaduNoch keine Bewertungen

- Oil Mill: Nsic Project ProfilesDokument3 SeitenOil Mill: Nsic Project ProfilesSachin KharechaNoch keine Bewertungen

- Project Profile On Mini Flour Mill: Prod U CTDokument11 SeitenProject Profile On Mini Flour Mill: Prod U CTSunil ShawNoch keine Bewertungen

- CH 22Dokument5 SeitenCH 22ProfNDAcharyaNoch keine Bewertungen

- FRPDokument6 SeitenFRPsaisssms9116Noch keine Bewertungen

- Mini Rice MillDokument5 SeitenMini Rice MillShubham PandeyNoch keine Bewertungen

- PROF. NO.25 Project Profile On Phenol Manufacturing UnitDokument7 SeitenPROF. NO.25 Project Profile On Phenol Manufacturing UnitVikram UllalNoch keine Bewertungen

- Apex IndustriesDokument62 SeitenApex IndustriesAlpeshNoch keine Bewertungen

- Mini Flour Mill KarnalDokument9 SeitenMini Flour Mill KarnalAnand Kishore100% (2)

- Shamp PapadDokument5 SeitenShamp PapadRaj GiriNoch keine Bewertungen

- Flour Mill UnitDokument4 SeitenFlour Mill UnitKrishnamoorthy SureshNoch keine Bewertungen

- Mech - Mini Tool Room-Project ReportDokument10 SeitenMech - Mini Tool Room-Project ReportSushant Bhartiya50% (2)

- Pulses MillDokument2 SeitenPulses Millram100% (1)

- PROF. NO.27 Project Profile On Camphor Manufacturing UnitDokument6 SeitenPROF. NO.27 Project Profile On Camphor Manufacturing UnitBest BetterNoch keine Bewertungen

- HARIHARAN P 21297075 SubmersiblepumpDokument9 SeitenHARIHARAN P 21297075 SubmersiblepumpVenkyNoch keine Bewertungen

- Project Feasibility Studies ch7Dokument5 SeitenProject Feasibility Studies ch7Pradeep KrishnanNoch keine Bewertungen

- Stone Crusher: Nsic Project ProfilesDokument4 SeitenStone Crusher: Nsic Project ProfilesSachin BoradeNoch keine Bewertungen

- Ajustable Hospital Beds PsDokument11 SeitenAjustable Hospital Beds PsManish PoddarNoch keine Bewertungen

- PROF. NO.37 Project Profile On Card Board Boxes Manufacturing UnitDokument6 SeitenPROF. NO.37 Project Profile On Card Board Boxes Manufacturing UnitSumit SharmaNoch keine Bewertungen

- Fastener ProjectDokument10 SeitenFastener ProjectParam Saxena0% (1)

- Leather SandalDokument6 SeitenLeather Sandalpradip_kumarNoch keine Bewertungen

- Garlic & Ginger Paste Project ProfilesDokument7 SeitenGarlic & Ginger Paste Project ProfilesArshad SheikNoch keine Bewertungen

- Monolithic RefractoriesDokument11 SeitenMonolithic RefractoriesZafr Cetn100% (1)

- Design Handbook MAchine DesignDokument5 SeitenDesign Handbook MAchine DesignsouravNoch keine Bewertungen

- Leather BeltDokument4 SeitenLeather Beltpradip_kumarNoch keine Bewertungen

- Project of Rexin BagDokument11 SeitenProject of Rexin BagShayan Pitruja100% (1)

- Production ProcessDokument4 SeitenProduction ProcessVishal SharmaNoch keine Bewertungen

- Project Profile On Automobile WiresDokument8 SeitenProject Profile On Automobile WiresGirishNoch keine Bewertungen

- Mango Jelly NSIC ProjectDokument3 SeitenMango Jelly NSIC ProjectAnonymous EAineTizNoch keine Bewertungen

- App 29027949Dokument11 SeitenApp 29027949Manjunatha BNoch keine Bewertungen

- Ground and Processed SpicesDokument11 SeitenGround and Processed SpicesAnas MKNoch keine Bewertungen

- Hawai ChappalsDokument3 SeitenHawai ChappalsvambuNoch keine Bewertungen

- Stainless Steel Cooking UtensilsDokument9 SeitenStainless Steel Cooking UtensilsGopal AgrawalNoch keine Bewertungen

- Project Profile On Computerized Machine (Job Work) : Such Specification For This ProductDokument8 SeitenProject Profile On Computerized Machine (Job Work) : Such Specification For This ProductParijat RaiNoch keine Bewertungen

- Ice Cream Churner: Released By: The Development Commissioner (SSI), Ministry of SSI, New DelhiDokument9 SeitenIce Cream Churner: Released By: The Development Commissioner (SSI), Ministry of SSI, New DelhiBunty RathoreNoch keine Bewertungen

- Pen PPRDokument29 SeitenPen PPRVijay RaiyaniNoch keine Bewertungen

- Roll To Roll Lamination & Paper Plate Material Supply and Paper Plate DistributionDokument3 SeitenRoll To Roll Lamination & Paper Plate Material Supply and Paper Plate DistributionIndhu SharmaKSNoch keine Bewertungen

- PMTF Information MemorandumDokument50 SeitenPMTF Information Memorandumraj aryenNoch keine Bewertungen

- Annexure-I - Financial Outlay and Means of FinanceDokument15 SeitenAnnexure-I - Financial Outlay and Means of FinanceSandra SENoch keine Bewertungen

- Pulse Milling: 1.0 Product and Its ApplicationsDokument7 SeitenPulse Milling: 1.0 Product and Its ApplicationsAmol BondreNoch keine Bewertungen

- Adda Leaf PlatesDokument5 SeitenAdda Leaf PlatesSenkatuuka LukeNoch keine Bewertungen

- Vermi Composting: Nsic Project ProfilesDokument4 SeitenVermi Composting: Nsic Project Profilesdrumil_kananiNoch keine Bewertungen

- CH 25Dokument19 SeitenCH 25Shanawar AzamNoch keine Bewertungen

- Machine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryVon EverandMachine Tools, Metal Cutting Types World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- Miscellaneous Industrial Machinery World Summary: Market Values & Financials by CountryVon EverandMiscellaneous Industrial Machinery World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- Global Forest Sector Outlook 2050: Assessing Future Demand and Sources of Timber for a Sustainable EconomyVon EverandGlobal Forest Sector Outlook 2050: Assessing Future Demand and Sources of Timber for a Sustainable EconomyNoch keine Bewertungen

- Cutting Tool & Machine Tool Accessories World Summary: Market Values & Financials by CountryVon EverandCutting Tool & Machine Tool Accessories World Summary: Market Values & Financials by CountryBewertung: 2 von 5 Sternen2/5 (1)

- Industrial Machinery World Summary: Market Values & Financials by CountryVon EverandIndustrial Machinery World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- Commercial & Service Industry Machinery, Miscellaneous World Summary: Market Values & Financials by CountryVon EverandCommercial & Service Industry Machinery, Miscellaneous World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- Fractal Modernisation Model of Industrial Areas’ Environment in Developing CountriesVon EverandFractal Modernisation Model of Industrial Areas’ Environment in Developing CountriesNoch keine Bewertungen

- Miscellaneous General Purpose Machinery World Summary: Market Values & Financials by CountryVon EverandMiscellaneous General Purpose Machinery World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- Agricultural Implements World Summary: Market Values & Financials by CountryVon EverandAgricultural Implements World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- Cut Stone & Stone Products World Summary: Market Values & Financials by CountryVon EverandCut Stone & Stone Products World Summary: Market Values & Financials by CountryNoch keine Bewertungen

- A Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessVon EverandA Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessNoch keine Bewertungen

- Personality Development of StudentsDokument4 SeitenPersonality Development of Studentsமுஹம்மது உவைஸ்Noch keine Bewertungen

- Artificial IntelligenceDokument1 SeiteArtificial Intelligenceமுஹம்மது உவைஸ்Noch keine Bewertungen

- Sudoku KidsDokument1 SeiteSudoku Kidsமுஹம்மது உவைஸ்Noch keine Bewertungen

- Singapore Now...Dokument124 SeitenSingapore Now...முஹம்மது உவைஸ்Noch keine Bewertungen

- Lady JC & JCRT Week Celebration: April 2 - 8Dokument4 SeitenLady JC & JCRT Week Celebration: April 2 - 8முஹம்மது உவைஸ்Noch keine Bewertungen

- Comparative Analysis of Financial Statement of Two CompaniesDokument24 SeitenComparative Analysis of Financial Statement of Two Companiesrexieace75% (4)

- Cartwright Lumber Company Paper EXAMPLEDokument5 SeitenCartwright Lumber Company Paper EXAMPLEJose SermenoNoch keine Bewertungen

- Taco Bout ItDokument14 SeitenTaco Bout Itapi-248790355Noch keine Bewertungen

- Fixed-Income NotesDokument3 SeitenFixed-Income Notesalexa ubaldoNoch keine Bewertungen

- World Bank Finance Details For TanescoDokument115 SeitenWorld Bank Finance Details For TanescoAmani KeenjaNoch keine Bewertungen

- Belay Getachew PDFDokument119 SeitenBelay Getachew PDFeyaNoch keine Bewertungen

- Credit Appraisal at PNBDokument76 SeitenCredit Appraisal at PNBpankhu_0686% (7)

- Audi 101 and 102 Auditing NotesDokument126 SeitenAudi 101 and 102 Auditing Notesgavin henningNoch keine Bewertungen

- Role and Importance of Agriculture in The CaribbeanDokument13 SeitenRole and Importance of Agriculture in The CaribbeanJagdeesh Gosine33% (3)

- Icici Group Code of Business Conduct and Ethics 2017Dokument31 SeitenIcici Group Code of Business Conduct and Ethics 2017shreyas patil67% (6)

- Property Case DigestsDokument16 SeitenProperty Case DigestsAli Sinsuat MusurNoch keine Bewertungen

- SMIC Series C and D Bonds Final Prospectus Dated June 21 2012Dokument427 SeitenSMIC Series C and D Bonds Final Prospectus Dated June 21 2012dendenliberoNoch keine Bewertungen

- SIGTAS & New IRC Forms - AmDokument24 SeitenSIGTAS & New IRC Forms - AmAnnahMaso100% (2)

- WBW Deed - Compare Version (3).pdf WBWC Settlement Deed Allan Family Wide Bay Water Lenthalls Dam Gate Failures Peter Care CEO Fraser Coast Regional Council Hervey Bay Burrum River Torbanlea Howard Crest Gate Failure Dam Failure Tops Gates FailureDokument23 SeitenWBW Deed - Compare Version (3).pdf WBWC Settlement Deed Allan Family Wide Bay Water Lenthalls Dam Gate Failures Peter Care CEO Fraser Coast Regional Council Hervey Bay Burrum River Torbanlea Howard Crest Gate Failure Dam Failure Tops Gates FailureLenthallsdamgatefailNoch keine Bewertungen

- Lease Legalese Made EasyDokument4 SeitenLease Legalese Made EasyfizzyshadowNoch keine Bewertungen

- 1CENEO1 - Cameroon Coffee Supply Chain Risk AssessmentDokument34 Seiten1CENEO1 - Cameroon Coffee Supply Chain Risk AssessmentRomir ChatterjeeNoch keine Bewertungen

- Integrated Payments APIDokument41 SeitenIntegrated Payments APIsebichondoNoch keine Bewertungen

- A Summer Internship Report On: Master of Business AdministrationDokument47 SeitenA Summer Internship Report On: Master of Business AdministrationLove GumberNoch keine Bewertungen

- Money Placed in A BankDokument3 SeitenMoney Placed in A BankZacharie GarciaNoch keine Bewertungen

- CH 7 IntermediateDokument21 SeitenCH 7 IntermediateArely ChapaNoch keine Bewertungen

- Assignment 2 IbmDokument27 SeitenAssignment 2 IbmneemNoch keine Bewertungen

- alservlet/StatementPDFServlet?account PDFDokument1 Seitealservlet/StatementPDFServlet?account PDFJACKSON NATIONALNoch keine Bewertungen

- 9706 Y10 SM 2 PDFDokument6 Seiten9706 Y10 SM 2 PDFTinyiko BandaNoch keine Bewertungen

- Leasing and Asset Finance: Fourth EditionDokument1 SeiteLeasing and Asset Finance: Fourth Editionahong100Noch keine Bewertungen

- Types of LeasingDokument22 SeitenTypes of LeasingRavish Chitgope100% (2)

- 20160921-Director & Shareholder AgreementDokument4 Seiten20160921-Director & Shareholder AgreementLeesbourne MatthewNoch keine Bewertungen

- 2203 Week 5 TemplateDokument39 Seiten2203 Week 5 TemplateHORTENSENoch keine Bewertungen

- Assr Bdo Knows Cecl FinalDokument48 SeitenAssr Bdo Knows Cecl FinalMark FesencoNoch keine Bewertungen

- Estafa, BP 22Dokument68 SeitenEstafa, BP 22Marry SuanNoch keine Bewertungen

- Finance HW 2Dokument3 SeitenFinance HW 2ValeriaRiosNoch keine Bewertungen