Beruflich Dokumente

Kultur Dokumente

(O$p Ec0 Lfi) IENG4

Hochgeladen von

downloadsrkOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

(O$p Ec0 Lfi) IENG4

Hochgeladen von

downloadsrkCopyright:

Verfügbare Formate

IENG440

Project Narrative

Project Requirement: Establishing a Plant for manufacturing Electrical Switches and Plugs

in TRNC.

Dear students, as a requirement in this course, on April 2, 2012, you should submit the first

progressive report and on May 18, 2012, you should submit your final project report. Finally, on

May 21, 2012 you should make presentations of your final project reports.

The first project report must include the information about the following items as related to the

industry you are going to design:

1. Products,

2. Most sold products,

3. Available technologies,

4. Raw materials needed in manufacturing the Products,

5. Market survey,

6. TRNC related rules & regulations.

The final project report must include all items above plus the following items:

7. Design for the Products (at least 3 products) you decide to produce.

8. Process Design (You should provide information on the machinery and operations used

in such industries).

9. Demand forecasts for the products in item 7.

10. Transportation systems to be used by your Plant that you are going to design in IENG442

course.

11. Feasibility study for this Plant you are designing (Including technical and Economic

feasibility).

Useful Information about the Manufacturing Plants for Electrical Switches and Plugs [1]:

1. Products: Electrical switches sockets and plugs are made from electro plated metal and their

thermosetting plastic. They serve mainly in building construction sector for and control of electric

power supply.

2. Justification: The majority of building, mainly dwelling units, are electrically lighted. The

electric power supply needs switches, socket and plug for use of electricity to different purpose.

Presently there is high usage of electricity in urban houses and the spread of rural electrification

has been intensified. New customers of electricity users are increasing. It is necessary to have a

plant that produces the electrical components. TRNC has no single plant that produce electrical

switches socket and plug and it is necessary to establish a factory that serves the potential and

existing demand.

3. Market: The demand for electric switch, socket and plugs in TRNC is currently met entirely

from import. Construction of electrically lighted building/dwelling office and others is rapidly

increasing in all urban towns of the region. The building require large amount of electrical

components. There is also potential demand of the non-dwelling building constructions

(institutional, commercial, industrial etc).

4. Supply of Raw Material:-The major raw materials of such a plant are:

- Plastics

- Metal sheets

- Nickel plating material

- Zinc platting material

- Other chemicals

- Packing materials

The Production Process and Technology Required:

1) The Production Process: The production of the Electrical products basically involves the

process machining (lathing and punching of metal parts and spring making) galvanizing,

molding of plastic parts, assembling, inspection/testing and packing.

2) The Machinery and Equipments required are:

a) Presses - Cleaning (scouring) equipment

b) Trimming machine -Furnace

c) Sheering equipment - Electric planting equipment

d) Milling machine - Injection molding machine

e) Lath (Bench) - Air compressor

f) Drills (Bench) -Other (vise, carriage storage boxes work tables

g) Grinders racks and etc.

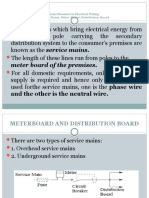

Electrical sockets: Are the small devices which are used to connect electric appliances to the

commercial power supply so that current can flow into them and they can operate. Electrical sockets

are paired with electrical plugs and both of them jointly are responsible for the proper running of

domestic as well as industrial electrical system.

Electrical sockets are also called power sockets are female electrical connectors having holes or

slots inside them. Pins or blades of power plugs are inserted in these slots and then electricity is

supplied to the appliances.

Types / Holes of Electrical Sockets:

Usually there are two or three slots or holes in electrical sockets. The two hole electrical sockets are

used for two pin plugs and three hole sockets for three pin plugs.

Two hole sockets: These electrical sockets carry two wires one of which is the live or hot wire

carrying alternating current from main AC supply to the appliances. The other wire is the neutral wire

that backs the current from the equipment to the mains supply.

Three hole sockets: In three hole electrical sockets, the function of two wires (live and neutral) are

similar to that of two hole sockets but the additional or the third wire is earth or ground wire that

grants electrical safety. In case of any fault in the electrical system, the ground wire ensures that the

exposed conductive surfaces should be at the same electrical potential equal to the earth. This

minimizes the risk of electrical shock if someone accidentally touches electrical device.

Electrical Switches:

An electrical switch is a commonly used device for making, breaking, or changing the course of an

electric circuit. There are different types of electrical switches being manufactured for use in different

applications.

Composition of Electrical Switches

It consists of two or more contacts that are mounted on an insulating structure and is so arranged

that they can be moved into and out of contact with each other with the help of a suitable operating

mechanism.

The two contacts in a switch are made of metal and the metal is chosen keeping in mind the

resistance to corrosion, as most metals are likely to form insulating oxides, which further prevents the

switch from working. Contacts in a switch are often plated with noble metal. The switch also has an

actuator - a moving part that is used for applying operating force to the contacts.

Arrangement of Contacts

All electrical Switches can be classified according to the arrangement of contacts. While few contacts

are normally open until closed by operation of the switch, others are normally closed and opened by

the switch action. An electrical switch having both types of contact is known as a changeover switch.

Two terms are used for describing the switch contacts-pole and throw. While a pole is a set of

contacts belonging to a single circuit. A throw is one of the positions that can be adopted in a switch.

Both the terms have given rise to certain abbreviations that are used for different types of switches in

the electronics industry. In British and American English, the terms two way and three way have

different meanings.

Types of Electrical Switches

There are various types of electrical switches available in the market for use in different applications.

The type of switch will differ for use in industries, residence and various heavy application areas.

Some of the switches being used are:

Centrifugal Switches

DIP Switches

Foot Switches

Mechanical Switches

Rocker Switches

Safety Sensor Switches

Pushwheel Switches

Slide Switches

Specialty Switches

Changeover Switches

Disconnect Switches

Key Lock Switches

Membrane Switches

Rotary Switches

Push Button Switches

Pressure Switches

Snap Action Switches

Note: Information about the Switch Materials can be found in reference [4].

References:

1- https://sites.google.com/site/projectethio/home/electrical-electronics/1-electrical-

switches-socket-and-plug-making-plant

2- http://sourcing.indiamart.com/electrical/electrical-sockets/

3- http://www-materials.eng.cam.ac.uk/mpsite/plug/non_IE/page1.html

4- http://sourcing.indiamart.com/electrical/electrical-switches/switch-materials/

5- http://www.smeda.org/downloads/Cluster_Profile_EFI.pdf

Das könnte Ihnen auch gefallen

- Power Electronics Applied to Industrial Systems and Transports, Volume 1: Synthetic Methodology to Converters and Components TechnologyVon EverandPower Electronics Applied to Industrial Systems and Transports, Volume 1: Synthetic Methodology to Converters and Components TechnologyNoch keine Bewertungen

- A Guide to the Home Electric System: Home Guide Basics Series, #2Von EverandA Guide to the Home Electric System: Home Guide Basics Series, #2Noch keine Bewertungen

- 3RD Eim 10 Module 1 18Dokument22 Seiten3RD Eim 10 Module 1 18bhrayancacheroNoch keine Bewertungen

- Emw Final ReportDokument25 SeitenEmw Final ReportOm BankarNoch keine Bewertungen

- Electrical SystemsDokument5 SeitenElectrical SystemsJames HillNoch keine Bewertungen

- Electrical Accessories. EngDokument14 SeitenElectrical Accessories. EngHI-FINoch keine Bewertungen

- Chapther ThreeDokument3 SeitenChapther ThreeMufutau Kayode LawalNoch keine Bewertungen

- Week 1 EIMDokument61 SeitenWeek 1 EIMKring KringNoch keine Bewertungen

- EE114 1 Homework 2Dokument3 SeitenEE114 1 Homework 2Denver John TejadaNoch keine Bewertungen

- Unit 3 - Introduction To Industrial Arts Part 2 (IEIAT - TLEHE8)Dokument8 SeitenUnit 3 - Introduction To Industrial Arts Part 2 (IEIAT - TLEHE8)Vendivel KristineNoch keine Bewertungen

- Tejada - Homework 2Dokument3 SeitenTejada - Homework 2Denver John TejadaNoch keine Bewertungen

- Parts of An Electric PoleDokument9 SeitenParts of An Electric PoleCATHERINE ROSE ALFEREZNoch keine Bewertungen

- Electronics Fundamentals Research Explains Key ComponentsDokument17 SeitenElectronics Fundamentals Research Explains Key Componentsrowela cristobalNoch keine Bewertungen

- Variable Power Supply ProjectDokument33 SeitenVariable Power Supply ProjectEmmanuelNoch keine Bewertungen

- Design and Construction of A 60a Automatic Power Changeover System With Electronic SwitchingDokument19 SeitenDesign and Construction of A 60a Automatic Power Changeover System With Electronic SwitchingVictor Temitope OwokoleNoch keine Bewertungen

- Electrical WiringDokument11 SeitenElectrical WiringRasydan AliNoch keine Bewertungen

- Junmar Musa ProjectDokument7 SeitenJunmar Musa ProjectMarvin LocionNoch keine Bewertungen

- Quiz 1Dokument3 SeitenQuiz 1Johnmark FormenteraNoch keine Bewertungen

- ILOILO SCIENCE AND TECHNOLOGY UNIVERSITY MIDTERM EXAM COVERS ELECTRICAL SYSTEMSDokument5 SeitenILOILO SCIENCE AND TECHNOLOGY UNIVERSITY MIDTERM EXAM COVERS ELECTRICAL SYSTEMSCrisostomo Andiong BaltazarNoch keine Bewertungen

- Electrical Supplies and MaterialsDokument3 SeitenElectrical Supplies and Materialspartz200477% (39)

- Group 4 ReportDokument5 SeitenGroup 4 ReportMacrey BwaleiNoch keine Bewertungen

- Presentation ElectricalDokument29 SeitenPresentation ElectricalSazid RajaNoch keine Bewertungen

- Electrical House WiringDokument27 SeitenElectrical House WiringMary JennyNoch keine Bewertungen

- ABUTLISDokument10 SeitenABUTLISLorea FalgueraNoch keine Bewertungen

- ElectricDokument5 SeitenElectricPeshwazNoch keine Bewertungen

- Electrical Lesson PlanDokument4 SeitenElectrical Lesson PlanWilson Agustin75% (4)

- Classes of InsulationDokument8 SeitenClasses of InsulationarjunNoch keine Bewertungen

- Information Sheet 1.2-2docxDokument5 SeitenInformation Sheet 1.2-2docxMarc GelacioNoch keine Bewertungen

- IPD and Illumination: Electrical Connectors GuideDokument14 SeitenIPD and Illumination: Electrical Connectors GuideMilan AcharyaNoch keine Bewertungen

- Top Electronic Components Manufacturers GloballyDokument20 SeitenTop Electronic Components Manufacturers GloballyjackNoch keine Bewertungen

- New Electromagnetic ContactorDokument6 SeitenNew Electromagnetic ContactorDavid Felipe BajoneroNoch keine Bewertungen

- Data Center Circuit Breaker GuidelinesDokument7 SeitenData Center Circuit Breaker GuidelinesmksayshiNoch keine Bewertungen

- Exp. - 2 - House Wiring CircuitDokument7 SeitenExp. - 2 - House Wiring CircuitSKMNoch keine Bewertungen

- Elements of ElectricalDokument22 SeitenElements of ElectricalDhruvaNoch keine Bewertungen

- On OC 02 Pranjal RukmangadDokument10 SeitenOn OC 02 Pranjal Rukmangadrukmangadpranjal1902Noch keine Bewertungen

- Commercial and Residential Electrical InstallationDokument15 SeitenCommercial and Residential Electrical InstallationCovid VirusNoch keine Bewertungen

- House Wiring ReportDokument9 SeitenHouse Wiring ReportCovid VirusNoch keine Bewertungen

- Electrical Installation in Building (Politeknik)Dokument24 SeitenElectrical Installation in Building (Politeknik)muhamad syazwan92% (12)

- GROUP 1-Electrical Tools, Supplies, and MaterialsDokument6 SeitenGROUP 1-Electrical Tools, Supplies, and MaterialsshiroyasharyuuNoch keine Bewertungen

- Topic 1 Electrical Installation System in BuildingDokument36 SeitenTopic 1 Electrical Installation System in BuildingArvinthNoch keine Bewertungen

- EIM COMMON UNIT 1 LO 1 2 3 4 Hand Tools - TYpes of WiringDokument71 SeitenEIM COMMON UNIT 1 LO 1 2 3 4 Hand Tools - TYpes of Wiringjunjiecastro88Noch keine Bewertungen

- ILE Report BEMDokument19 SeitenILE Report BEMSardar KamranNoch keine Bewertungen

- Engineering Utilities 1 Module 2: Electrical MaterialsDokument39 SeitenEngineering Utilities 1 Module 2: Electrical MaterialsAndrea Rodriguez MontibonNoch keine Bewertungen

- Engineering - Html#Ixzz2Aykg3Nzc: Mechanical Engineering Is A Discipline ofDokument3 SeitenEngineering - Html#Ixzz2Aykg3Nzc: Mechanical Engineering Is A Discipline ofNiranjan SalunkeNoch keine Bewertungen

- Module 6 - Terminating and ConnectingDokument44 SeitenModule 6 - Terminating and ConnectingMary Jane Blanco FioNoch keine Bewertungen

- BSD - M Odule 5Dokument38 SeitenBSD - M Odule 5M MNoch keine Bewertungen

- TLEDokument4 SeitenTLEAnonymous NcLnsmyEZNoch keine Bewertungen

- Investigating Effects of Process Variables On MRR in EDM by Using Taguchi Parameter Design ApproachDokument6 SeitenInvestigating Effects of Process Variables On MRR in EDM by Using Taguchi Parameter Design ApproachPujara ManishNoch keine Bewertungen

- Electricals Supplies and MaterialsDokument25 SeitenElectricals Supplies and MaterialsROWEL T. REYESNoch keine Bewertungen

- REPAIR MergedDokument178 SeitenREPAIR MergedIra CervoNoch keine Bewertungen

- College of Information Technology Dmmmsu-Mluc City of San FernandoDokument9 SeitenCollege of Information Technology Dmmmsu-Mluc City of San FernandoZoilo BagtangNoch keine Bewertungen

- Refrigeration and Air Conditioning Notes 121129165717 Phpapp01Dokument42 SeitenRefrigeration and Air Conditioning Notes 121129165717 Phpapp01zohaib now engineering easyNoch keine Bewertungen

- Engineering Immersion LabDokument30 SeitenEngineering Immersion LabSudeepNoch keine Bewertungen

- Unit 35 Portfolio Answer 2018Dokument22 SeitenUnit 35 Portfolio Answer 2018Hatem HusseinNoch keine Bewertungen

- Janjan 3rd Year PrintDokument8 SeitenJanjan 3rd Year PrintIVAN JOHN BITONNoch keine Bewertungen

- Power Electronics Devices and Applications GuideDokument12 SeitenPower Electronics Devices and Applications GuideOhanyelu Okeoma DanielNoch keine Bewertungen

- Bài 2,3 Thí Nghiệm Trang Bị ĐiệnDokument37 SeitenBài 2,3 Thí Nghiệm Trang Bị ĐiệnNguyen TrongNoch keine Bewertungen

- Electrical Tools and Equipment CareDokument63 SeitenElectrical Tools and Equipment CareJohn Cedrick JulatonNoch keine Bewertungen

- HandoutsDokument5 SeitenHandoutsJomar MontallanaNoch keine Bewertungen

- IP Security: Henric Johnson Blekinge Institute of Technology, Sweden Henric - Johnson@bth - SeDokument31 SeitenIP Security: Henric Johnson Blekinge Institute of Technology, Sweden Henric - Johnson@bth - Seahmadamminudin89Noch keine Bewertungen

- Electronic Mail Security: Henric Johnson Blekinge Institute of Technology, Sweden Henric - Johnson@bth - SeDokument26 SeitenElectronic Mail Security: Henric Johnson Blekinge Institute of Technology, Sweden Henric - Johnson@bth - SeRishika ChowdaryNoch keine Bewertungen

- Electronic Mail Security: Henric Johnson Blekinge Institute of Technology, Sweden Henric - Johnson@bth - SeDokument26 SeitenElectronic Mail Security: Henric Johnson Blekinge Institute of Technology, Sweden Henric - Johnson@bth - SeRishika ChowdaryNoch keine Bewertungen

- IP Security: Henric Johnson Blekinge Institute of Technology, Sweden Henric - Johnson@bth - SeDokument31 SeitenIP Security: Henric Johnson Blekinge Institute of Technology, Sweden Henric - Johnson@bth - Seahmadamminudin89Noch keine Bewertungen

- How To Hack DatabaseDokument45 SeitenHow To Hack DatabasePrintesh PatelNoch keine Bewertungen

- DLD-1Unit by Ramakrishna PDFDokument69 SeitenDLD-1Unit by Ramakrishna PDFdownloadsrkNoch keine Bewertungen

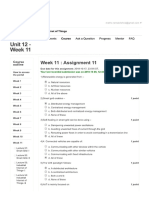

- Introduction To Internet of Things - Unit 12 - Week 11Dokument59 SeitenIntroduction To Internet of Things - Unit 12 - Week 11downloadsrkNoch keine Bewertungen

- Kerio Control Step by Step en 7.0.0Dokument25 SeitenKerio Control Step by Step en 7.0.0-Kashif MirzaNoch keine Bewertungen

- DLD 1unit PDFDokument69 SeitenDLD 1unit PDFdownloadsrkNoch keine Bewertungen

- Unit 4 Secure Electronic TransactionDokument11 SeitenUnit 4 Secure Electronic TransactiondownloadsrkNoch keine Bewertungen

- Introduction To Internet of Things - Unit 12 - Week 11 PDFDokument3 SeitenIntroduction To Internet of Things - Unit 12 - Week 11 PDFdownloadsrkNoch keine Bewertungen

- Introduction To Internet of Things - Unit 12 - Week 11 PDFDokument3 SeitenIntroduction To Internet of Things - Unit 12 - Week 11 PDFdownloadsrkNoch keine Bewertungen

- ECE 0142 Floating Point RepsDokument31 SeitenECE 0142 Floating Point RepsRaaghav SrinivasanNoch keine Bewertungen

- BayometricAPI Developer GuideDokument21 SeitenBayometricAPI Developer Guidedownloadsrk0% (1)

- Irjet V5i2304 PDFDokument5 SeitenIrjet V5i2304 PDFdownloadsrkNoch keine Bewertungen

- Ap Eamcet 2017 Data 12-05-2017Dokument840 SeitenAp Eamcet 2017 Data 12-05-2017downloadsrk0% (1)

- Jntuk Name Guide Lines For Sending Photo GraphsDokument2 SeitenJntuk Name Guide Lines For Sending Photo GraphsdownloadsrkNoch keine Bewertungen

- User GuideDokument23 SeitenUser GuidedownloadsrkNoch keine Bewertungen

- Setting Up A Mikrotik Hotspot With UserManager (Step-By-Step) - Binary HeartbeatDokument16 SeitenSetting Up A Mikrotik Hotspot With UserManager (Step-By-Step) - Binary HeartbeatdownloadsrkNoch keine Bewertungen

- Sample Project DocumentationDokument101 SeitenSample Project DocumentationK Keshava RaoNoch keine Bewertungen

- Project Report ONDokument198 SeitenProject Report ONshantaNoch keine Bewertungen

- (O$p Ec0 Lfi) IENG4Dokument4 Seiten(O$p Ec0 Lfi) IENG4downloadsrkNoch keine Bewertungen

- Data Security and Authentication Using Steganography and Sts ProtocolDokument6 SeitenData Security and Authentication Using Steganography and Sts ProtocoldownloadsrkNoch keine Bewertungen

- Synopsis: 4. Project CategoryDokument3 SeitenSynopsis: 4. Project CategorydownloadsrkNoch keine Bewertungen

- About Wi-Fi HotSpot - Mikrotik RADIUS and User ManagerDokument4 SeitenAbout Wi-Fi HotSpot - Mikrotik RADIUS and User ManagerdownloadsrkNoch keine Bewertungen

- Eamcet2013 LastrankDokument260 SeitenEamcet2013 LastrankdownloadsrkNoch keine Bewertungen

- Low Payment Overhead - Multihop Wlan NetworksDokument35 SeitenLow Payment Overhead - Multihop Wlan NetworksdownloadsrkNoch keine Bewertungen

- SteganographyDokument13 SeitenSteganographynithinvsNoch keine Bewertungen

- Algoritham DescriptionDokument6 SeitenAlgoritham DescriptiondownloadsrkNoch keine Bewertungen