Beruflich Dokumente

Kultur Dokumente

4JVP44 We 0111

Hochgeladen von

Elkin Martínez SilvaOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

4JVP44 We 0111

Hochgeladen von

Elkin Martínez SilvaCopyright:

Verfügbare Formate

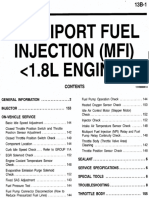

ENGINE DRIVEABILITY AND EMISSIONS 6E1

ENGINE with TF 4JA1-TC/TF

4JH1-TC/NKR 4JH1-TC Bosch VP44 system

CONTENTS

ENGINE DRIVEABILITY AND EMISSIONS

ISUZU Strategy Based Diagnostics .............. 6E-4

Overview .................................................... 6E-4

STRATEGY BASED DIAGNOSTICS

CHART .................................................... 6E-4

Diagnostic Thought Process ...................... 6E-5

1. Verify the Complaint .............................. 6E-5

2. Perform Preliminary Checks .................. 6E-5

3. Check Bulletins and Troubleshooting

Hints ........................................................ 6E-6

4. Perform Service Manual Diagnostic

Checks ..................................................... 6E-6

5a and 5b. Perform Service Manual

Diagnostic Procedures ............................ 6E-6

5c. Technician Self Diagnoses .................. 6E-6

5d. Intermittent Diagnosis .......................... 6E-7

5e. Vehicle Operates as Designed ............ 6E-8

6. Re-examine the complaint ..................... 6E-9

7. Repair and Verify Fix ............................. 6E-9

Specification difference ............................. 6E-10

TF 4JA1-TC with Bosch VP44

System ECM Wiring Scheme

(Manual Transmission) ............................ 6E-11

TF 4JH1-TC with Bosch VP44

System ECM Wiring Scheme

(Automatic Transmission) ........................ 6E-12

TF 4JH1-TC with Bosch VP44

System ECM Wiring Scheme

(Manual Transmission) ............................ 6E-13

N*R 4JH1-TC with Bosch VP44

System ECM Wiring Diagram .................. 6E-14

TF 4JA1-TC/4JH1-TC ECM Pinouts .......... 6E-15

N*R 4JH1-TC ECM Pinouts ....................... 6E-18

TF 4JA1-TC/4JH1-TC, N*R 4JH1-TC,

Specifications ................................................ 6E-21

Tightening Specifications ........................... 6E-21

TF 4JA1-TC with Bosch VP44

System Component Locator .................... 6E-22

TF 4JA1-TC with Bosch VP44

System Component Locator .................... 6E-23

TF 4JA1-TC/4JH1-TC TDC Sensor

Location ................................................... 6E-24

TF 4JA1-TC, 4JH1-TC with Bosch VP44

System Component Locator .................... 6E-25

TF 4JH1-TC with Bosch VP44

System Component Locator .................... 6E-26

TF 4JH1-TC with Bosch VP44

System Component Locator .................... 6E-27

N*R 4JH1-TC with Bosch VP44

System Component Locator .................... 6E-28

N*R 4JH1-TC with Bosch System

Component Locator ................................. 6E-29

N*R 4JH1-TC with Bosch System

Component Locator ................................. 6E-30

N*R 4JH1-TC with Bosch VP44

System Component Locator .................... 6E-31

N*R 4JH1-TC with Bosch VP44

System Component Locator .................... 6E-32

NKR 4JH1-TC with Bosch VP44

System Component Locator .................... 6E-33

TF 4JA1-TC Fuse Box ............................... 6E-34

TF 4JH1-TC Fuse Box ............................... 6E-35

N*R 4JH1-TC Fuse Box ............................. 6E-36

N*R 4JH1-TC Fuse and Relay Panel ........ 6E-37

N*R 4JH1-TC Relay Panel ........................ 6E-38

Abbreviations Charts ................................. 6E-39

Injection pump Control System .................. 6E-40

TDC Sensor ............................................... 6E-41

Engine Coolant Temperature (ECT) Sensor 6E-41

Vehicle Speed Sensor (VSS) ..................... 6E-41

TDC (Engine Speed) Sensor ..................... 6E-41

ECM System Diagram No.1 .................... 6E-42

ECM System Diagram No.2 .................... 6E-43

MAF/IAT Sensor Circuit ............................. 6E-44

ECM System Diagram No.3 .................... 6E-45

ECM System Diagram No.4 .................... 6E-46

ECM System Diagram No.5 .................... 6E-47

General Service Information ...................... 6E-48

Serviceability Issues .................................. 6E-48

Non-OEM Parts ......................................... 6E-48

Poor Vehicle Maintenance ......................... 6E-48

Related System Faults ............................... 6E-48

On-Board Diagnostic (OBD) ...................... 6E-48

On-Board Diagnostic

(Self Diagnosis System) Tests ................. 6E-48

The Diagnostic Executive .......................... 6E-48

Diagnostic Information ............................... 6E-48

Check Engine Lamp .................................. 6E-48

Data Link Connector (DLC) ....................... 6E-48

Reading Flash Diagnostic Trouble Codes . 6E-50

Reading Diagnostic Trouble Codes Using

a TECH 2 ................................................. 6E-50

Clearing Diagnostic Trouble Codes ........... 6E-50

History DTC ............................................... 6E-50

Tech2 ........................................................ 6E-51

Tech2 Features ......................................... 6E-51

Getting Started ........................................... 6E-52

HOME

6E2 ENGINE DRIVEABILITY AND EMISSIONS

Operating Procedure (For Example) ......... 6E-52

DTC ........................................................... 6E-53

DTC Information Mode .............................. 6E-53

Engine ....................................................... 6E-53

History ....................................................... 6E-53

Clear DTC Information ............................... 6E-53

Tech2 Data Display ................................... 6E-53

Plotting Snapshot Graph ........................... 6E-54

Plotting Graph Flow Chart

(Plotting graph after obtaining

vehicle information) ................................. 6E-55

Flow Chart for Snapshot Replay

(Plotting Graph) ....................................... 6E-56

How To Use Breaker Box .......................... 6E-57

Breaker Box Connection Type A for Open

Circuit Check, Short to Ground Check

and Short to Battery Check ..................... 6E-58

Breaker Box Connection Type B for Power,

Signal Voltage Check between ECM

and Sensors ............................................ 6E-59

How To Use TIS2000 Snapshot Analysis .. 6E-60

Snapshot Display ....................................... 6E-60

Typical Scan Data Values ......................... 6E-64

TF 4JA1-TC ............................................... 6E-64

TF 4JH1-TC (MT) ...................................... 6E-65

TF 4JH1-TC (AT) ....................................... 6E-66

NKR 4JH1-TC ............................................ 6E-67

Engine Data Definitions ............................. 6E-69

On-Board Diagnostic (OBD) System Check 6E-80

Circuit Description ..................................... 6E-80

Diagnostic Aids .......................................... 6E-80

Test Description ......................................... 6E-80

On Board Diagnostic (OBD) System Check 6E-81

No Check Engine Lamp ............................. 6E-82

Diagnostic Aids .......................................... 6E-82

Test Description ......................................... 6E-82

No Check Engine Lamp ............................. 6E-83

Check Engine Lamp ON Steady ............. 6E-85

Circuit description ...................................... 6E-85

Diagnostic Aids .......................................... 6E-85

Test Description ......................................... 6E-85

Check Engine Lamp ON Steady ............. 6E-86

DTC P0100

MAF SENSOR MALFUNCTION .............. 6E-87

DTC P0110

IAT Sensor Maifunction ........................... 6E-95

DTC P0115

Engine Coolant Temperature

Sensor Malfunction .................................. 6E-99

DTC P0180 SUB CODE 1011

FUEL TEMPARETURE SENSOR

CIRCUIT RANGE/PERFORMANCE ....... 6E-104

DTC P0215

FUEL CUTOFF SOLENOID VALVE

MALFUNCTION ....................................... 6E-106

DTC P0216

TIMING DEVICE DEVIATION ................. 6E-111

DTC P0216

TIMING DEVICE FLUCTUATION ........... 6E-112

DTC P0251

INJECTION MALFUNCTION ................... 6E-113

DTC P0335

TDC MALFUNCTION .............................. 6E-116

DTC P0380

GLOW DEVICE MALFUNCTION ............ 6E-123

DTC P0381

GLOW TIME TELLTALE CIRCUIT

MALFUNCTION ....................................... 6E-128

DTC P0400

EGR SYSTEM MALFUNCTION .............. 6E-131

DTC P0500

VSS MALFUNCTION ............................... 6E-138

DTC P0560

SYSTEM VOLTAGE MALFUNCTION ..... 6E-141

Circuit Description ...................................... 6E-141

DTC P0561

SWITCHED SYSTEM VOLTAGE

(IGNITION ON) CIRCUIT MALFUNCTION 6E-146

DTC P0606

ECM Malfunction1 ................................... 6E-148

DTC P0606

ECM Malfunction2 ................................... 6E-148

DTC P0645

A/C COMPRESSOR CUTOFF RELAY

MALFUNCTION ....................................... 6E-149

DTC P0703

BRAKE-LIGHT SWITCH CIRCUIT

MAIFUNCTION ........................................ 6E-155

DTC P0704

CLUTCH SWITCH INPUT CIRCUIT

MALFUNCTION ....................................... 6E-158

DTC P1105

BAROMETRIC PRESSURE

SENSOR (BP) MALFUNCTION .............. 6E-160

DTC P1110

INTAKE SHUTTER VSV (DIESEL)

MALFUNCTION (NKR 4JH1-TC only) ..... 6E-161

DTC P1120

AP SENSOR MAIFUNCTION .................. 6E-165

DTC P1173

FUEL REDUCTION CAUSED BY

HIGH COOLANT TEMPERATURE ......... 6E-171

Fuel Reduction adjustment ........................ 6E-171

NKR 4JH1-TC ............................................ 6E-171

TF 4JH1-TC, 4JH1-TC ............................... 6E-171

DTC P1173

FUEL REDUCTION CAUSED BY

HIGH FUEL TEMPERATURE 1 .............. 6E-173

DTC P1173

FUEL REDUCTION CAUSED BY

HIGH FUEL TEMPERATURE 2 .............. 6E-173

DTC P1345

INJECTION PUMP:CAMSHAFT

SPEED MALFUNCTION .......................... 6E-174

DTC P1520

NEUTRAL SWITCH ................................. 6E-175

DTC P1576

EXHAUST BRAKE VALVE1

CIRCUIT MALFUNCTION ....................... 6E-178

DTC P1605

ENGINE DRIVEABILITY AND EMISSIONS 6E3

EEPROM DEFECT .................................. 6E-184

DTC P1610

SEEDS AND KEY FILE DESTROYED .... 6E-185

DTC P1611

WRONG SECURITY CODE ENTERED .. 6E-185

DTC P1612/P1613

IMMOBILIZER NO OR WRONG SIGNAL 6E-185

DTC P1614

Wrong transponder key ........................... 6E-185

DTC P1625

Power supply relay malfunction ............... 6E-186

DTC P1630

FUEL-INJECTION QUANTITY

CIRCUIT MALFUNCTION ....................... 6E-187

DTC P1650

CAN: DEVICE MALFUNCTION ............... 6E-188

DTC P1651 SUB CODE 1010

INJECTION PUMP: CAN MALFUNCTION 6E-190

DTC P1651 SUB CODE 1011

CAN RECEIVEDS ERROR ..................... 6E-191

DTC P1690

MALFUNCTION INDICATION LAMP (MIL)

CIRCUIT MALFUNCTION ....................... 6E-192

Symptom chart & perform procedure ........ 6E-195

1-1. No cranking happens. ........................ 6E-196

1-2. Starter can crank engine, but seems

to be lower than usual. ............................ 6E-196

1-3. Cranking speed seems to be OK,

but no combustion sounds can be heard. 6E-197

1-4. Engine run as idle speed, but can not

raise engine speed to usual engine

speed zone. ............................................. 6E-200

1-5. Engine stall after engine speed reach

more than 2000 rpm. ............................... 6E-203

2. Engine stall ............................................ 6E-205

2-1 Engine stall at idling. ........................... 6E-205

2-2 Engine stall after engine revolution

becomes more than idling speed.

Undershoot stall. ...................................... 6E-209

3. Rough idle ............................................. 6E-211

4. Excessive white smoke. ........................ 6E-214

5. Excessive black smoke ......................... 6E-220

6. Hesitation 7. Surge/Sag ...................... 6E-224

EGR control logic ....................................... 6E-229

8. Lack of power ........................................ 6E-230

9. Poor fuel consumption ........................... 6E-233

SPECIAL SERVICE TOOLS ..................... 6E-237

6E4 ENGINE DRIVEABILITY AND EMISSIONS

ISUZU Strategy Based Diagnostics

Overview

As a retail service technician, you are part of the ISUZU

service team. The team goal is FIX IT RIGHT THE

FIRST TIME for the satisfaction of every customer. You

are a very important member of the team as you

diagnose and repair customer vehicles.

You have maximum efficiency in diagnosis when you

have an effective, organized plan for your work. Strategy

Based Diagnostics (refer to Figure 1) provides you with

guidance as you create and follow a plan of action for

each specific diagnostic situation.

STRATEGY BASED DIAGNOSTICS CHART

ENGINE DRIVEABILITY AND EMISSIONS 6E5

Diagnostic Thought Process

As you follow a diagnostic plan, every box on the

Strategy Based Diagnostics chart requires you to use

the diagnostic thought process. This method of thinking

optimizes your diagnosis in the following ways:

Improves your understanding and definition of the

customer complaint

Saves time by avoiding testing and/or replacing good

parts

Allows you to look at the problem from different

perspectives

Guides you to determine what level of understanding

about system operation is needed:

Owners manual level

Service manual level

In-depth (engineering) level

Owners manual level

Service manual level

In-depth (engineering) level

1. Verify the Complaint

What you should do

To verify the customer complaint, you need to know the

correct (normal) operating behavior of the system and

verify that the customer complaint is a valid failure of the

system.

The following information will help you verify the

complaint:

WHAT the vehicle model/options are

WHAT aftermarket and dealer-installed accessories

exist

WHAT related system(s) operate properly

WHEN the problem occurs

WHERE the problem occurs

HOW the problem occurs

HOW LONG the condition has existed (and if the

system ever worked correctly)

HOW OFTEN the problem occurs

Whether the severity of the problem has increased,

decreased or stayed the same

What resources you should use

Whenever possible, you should use the following

resources to assist you in verifying the complaint:

Service manual Theory or Circuit Description

sections

Service manual System Performance Check

Owner manual operational description

Technician experience

Identical vehicle for comparison

Circuit testing tools

Vehicle road tests

Complaint check sheet

Contact with the customer

2. Perform Preliminary Checks

NOTE: An estimated 10 percent of successful vehicle

repairs are diagnosed with this step!

What you should do

You perform preliminary checks for several reasons:

To detect if the cause of the complaint is VISUALLY

OBVIOUS

To identify parts of the system that work correctly

To accumulate enough data to correctly and

accurately search for a ISUZU Service Bulletin on

ISUZU Web site. http://www.isuzu.co.jp/IDoc/ISB/

2000/

The initial checks may vary depending on the

complexity of the system and may include the following

actions:

Operate the suspect system

Make a visual inspection of harness routing and

accessible/visible power and ground circuits

Check for blown fuses

Make a visual inspection for separated connectors

Make a visual inspection of connectors (includes

checking terminals for damage and tightness)

Check for any DTCs stored by the on-board

computers

Sense unusual noises, smells, vibrations or

movements

Investigate the vehicle service history (call other

dealerships, if appropriate)

What resources you should use

Whenever appropriate, you should use the following

resources for assistance in performing preliminary

checks:

Tech II or other technical equipment for viewing DTCs

Service manual information:

Component locations

Harness routing

Wiring schematics

Procedures for viewing DTCs

Dealership service history file

Vehicle road test

Identical vehicle or system for comparison

6E6 ENGINE DRIVEABILITY AND EMISSIONS

3. Check Bulletins and

Troubleshooting Hints

NOTE: As estimated 30 percent of successful vehicle

repairs are diagnosed with this step!

What you should do

You should have enough information gained from

preliminary checks to accurately search for a bulletin

and other related service information. Some service

manual sections provide troubleshooting hints that

match symptoms with specific complaints.

What resources you should use

You should use the following resources for assistance in

checking for bulletins and troubleshooting hints:

Printed bulletins

Access ISUZU Bulletin Web site, http://www.isuzu.co.jp/

IDoc/ISB/2000/

Videotapes

Service manual

4. Perform Service Manual

Diagnostic Checks

What you should do

The System Checks in most service manual sections

and in most cells of section 8A (electrical) provide you

with:

A systematic approach to narrowing down the

possible causes of a system fault

Direction to specific diagnostic procedures in the

service manual

Assistance to identify what systems work correctly

What resources you should use

Whenever possible, you should use the following

resources to perform service manual checks:

Service manual

Technical equipment (for viewing DTCs and analyzing

data)

Digital multimeter and circuit testing tools

Other tools as needed

5a and 5b. Perform Service Manual

Diagnostic Procedures

NOTE: An estimated 40 percent of successful vehicle

repairs are diagnosed with these steps!

What you should do

When directed by service manual diagnostic checks,

you must then carefully and accurately perform the

steps of diagnostic procedures to locate the fault related

to the customer complaint.

What resources you should use

Whenever appropriate, you should use the following

resources to perform service manual diagnostic

procedures:

Service manual

Technical equipment (for analyzing diagnostic data)

Digital multimeter and circuit testing tools

Essential and special tools

5c. Technician Self Diagnoses

When there is no DTC stored and no matching

symptom for the condition identified in the service

manual, you must begin with a thorough understanding

of how the system(s) operates. Efficient use of the

service manual combined with you experience and a

good process of elimination will result in accurate

diagnosis of the condition.

What you should do

Step 1: Identify and understand the suspect

circuit(s)

Having completed steps 1 through 4 of the Strategy

Based Diagnostics chart, you should have enough

information to identify the system(s) or sub-system(s)

involved. Using the service manual, you should

determine and investigate the following circuit

characteristics:

Electrical:

How is the circuit powered (power distribution

charts and/or fuse block details)?

How is the circuit grounded (ground distribution

charts)?

How is the circuit controlled or sensed (theory of

operation):

If it is a switched circuit, is it normally open or

normally closed?

Is the power switched or is the ground

switched?

Is it a variable resistance circuit (ECT sensor or

TP sensor, for example)?

Is it a signal generating device (MAF sensor of

VSS, for example)?

Does it rely on some mechanical/vacuum

device to operate?

Physical:

Where are the circuit components (component

locators and wire harness routing diagrams):

Are there areas where wires could be chafed

or pinched (brackets or frames)?

Are there areas subjected to extreme

ENGINE DRIVEABILITY AND EMISSIONS 6E7

temperatures?

Are there areas subjected to vibration or

movement (engine, transmission or

suspension)?

Are there areas exposed to moisture, road salt

or other corrosives (battery acid, oil or other

fluids)?

Are there common mounting areas with other

systems/components?

Have previous repairs been performed to wiring,

connectors, components or mounting areas

(causing pinched wires between panels and

drivetrain or suspension components without

causing and immediate problem)?

Does the vehicle have aftermarket or dealer-

installed equipment (radios, telephone, etc.)

Step 2: Isolate the problem

At this point, you should have a good idea of what could

cause the present condition, as well as could not cause

the condition. Actions to take include the following:

Divide (and separate, where possible) the system or

circuit into smaller sections

Confine the problem to a smaller area of the vehicle

(start with main harness connections while removing

panels and trim as necessary in order to eliminate

large vehicle sections from further investigation)

For two or more circuits that do not share a common

power or ground, concentrate on areas where

harnesses are routed together or connectors are

shared (refer to the following hints)

Hints

Though the symptoms may vary, basic electrical failures

are generally caused by:

Loose connections:

Open/high resistance in terminals, splices,

connectors or grounds

Incorrect connector/harness routing (usually in new

vehicles or after a repair has been made):

Open/high resistance in terminals, splices,

connectors of grounds

Corrosion and wire damage:

Open/high resistance in terminals, splices,

connectors of grounds

Component failure:

Opens/short and high resistance in relays,

modules, switches or loads

Aftermarket equipment affecting normal operation of

other systems

You may isolate circuits by:

Unplugging connectors or removing a fuse to

separate one part of the circuit from another part

Operating shared circuits and eliminating those that

function normally from the suspect circuit

If only one component fails to operate, begin testing

at the component

If a number of components do no operate, begin tests

at the area of commonality (such as power sources,

ground circuits, switches or major connectors)

What resources you should use

Whenever appropriate, you should use the following

resources to assist in the diagnostic process:

Service manual

Technical equipment (for data analysis)

Experience

Technical Assistance

Circuit testing tools

5d. Intermittent Diagnosis

By definition, an intermittent problem is one that does

not occur continuously and will occur when certain

conditions are met. All these conditions, however, may

not be obvious or currently known. Generally,

intermittents are caused by:

Faulty electrical connections and wiring

Malfunctioning components (such as sticking relays,

solenoids, etc.)

EMI/RFI (Electromagnetic/radio frequency

interference)

Aftermarket equipment

Intermittent diagnosis requires careful analysis of

suspected systems to help prevent replacing good

parts. This may involve using creativity and ingenuity to

interpret customer complaints and simulating all

external and internal system conditions to duplicate the

problem.

What you should do

Step 1: Acquire information

A thorough and comprehensive customer check sheet is

critical to intermittent problem diagnosis. You should

require this, since it will dictate the diagnostic starting

point. The vehicle service history file is another

source for accumulating information about the

complaint.

Step 2: Analyze the intermittent problem

Analyze the customer check sheet and service history

file to determine conditions relevant to the suspect

system(s).

Using service manual information, you must identify,

trace and locate all electrical circuits related to the

malfunctioning system(s). If there is more than one

system failure, you should identify, trace and locate

areas of commonality shared by the suspect circuits.

6E8 ENGINE DRIVEABILITY AND EMISSIONS

Step 3: Simulate the symptom and isolate the

problem

Simulate the symptom and isolate the system by

reproducing all possible conditions suggested in Step 1

while monitoring suspected circuits/components/

systems to isolate the problem symptom. Begin with the

most logical circuit/component.

Isolate the circuit by dividing the suspect system into

simpler circuits. Next, confine the problem into a smaller

area of the system. Begin at the most logical point (or

point of easiest access) and thoroughly check the

isolated circuit for the fault, using basic circuit tests.

Hints

You can isolate a circuit by:

Unplugging connectors or removing a fuse to

separate one part of the circuit from another

If only component fails to operate, begin testing the

component

If a number of components do not operate, begin test

at areas of commonality (such as power sources,

ground circuits, switches, main connectors or major

components)

Substitute a known good part from the parts

department or the vehicle system

Try the suspect part in a known good vehicle

See Symptom Simulation Tests on the next page for

problem simulation procedures. Refer to service manual

sections 6E and 8A for information about intermittent

diagnosis. Follow procedures for basic circuit testing in

service manual section 8A.

What resources you should use

Whenever appropriate, you should use the following

resources to assist in the diagnostic process:

Service manual

Bulletins

Digital multimeter (with a MIN/MAX feature)

Tech II and Tech II upload function

Circuit testing tools (including connector kits/

harnesses and jumper wires)

Experience

Intermittent problem solving simulation methods

Customer complaint check sheet

Symptom Simulation Tests

1. Vibration

This method is useful when the customer complaint

analysis indicates that the problem occurs when the

vehicle/system undergoes some form of vibration.

For connectors and wire harness, slightly shake

vertically and horizontally. Inspect the connector joint

and body for damage. Also, tapping lightly along a

suspected circuit may be helpful.

For parts and sensors, apply slight vibration to the part

with a light tap of the finger while monitoring the system

for a malfunction.

2. Heat

This method is important when the complaint suggests

that the problem occurs in a heated environment. Apply

moderate heat to the component with a hair drier or

similar tool while monitoring the system for a

malfunction.

CAUTION: Care must be take to avoid overheating

the component.

3. Water and Moisture

This method may be used when the complaint suggests

that the malfunction occurs on a rainy day or under

conditions of high humidity. In this case, apply water in a

light spray on the vehicle to duplicate the problem.

CAUTION: Care must be take to avoid directly

exposing electrical connections to water.

4. Electrical loads

This method involves turning systems ON (such as the

blower, lights or rear window defogger) to create a load

on the vehicle electrical system at the same time you

are monitoring the suspect circuit/component.

5e. Vehicle Operates as Designed

This condition refers to instances where a system

operating as designed is perceived to be unsatisfactory

or undesirable. In general, this is due to:

A lack of understanding by the customer

A conflict between customer expectations and vehicle

design intent

A system performance that is unacceptable to the

customer

What you should do

You can verify that a system is operating as designed

by:

Reviewing service manual functional/diagnostic

checks

Examining bulletins and other service information for

supplementary information

Compare system operation to an identical vehicle

If the condition is due to a customer misunderstanding

or a conflict between customer expectation and system

operation, you should explain the system operation to

the customer.

If the complaint is due to a case of unsatisfactory

system performance, you should contact Technical

Assistance for the latest information.

What resources you should use

Whenever possible, you should use the following

resources to facilitate the diagnostic process:

ENGINE DRIVEABILITY AND EMISSIONS 6E9

Vehicle service information (service manual, etc.)

ISUZU field support

Experience

Identical vehicle or system for comparison

6. Re-examine the complaint

When you do not successfully find/isolate the problem

after executing a diagnostic path, you should re-

examine the complaint.

What you should do

In this case, you will need to backtrack and review

information accumulated from step 1 through 4 of

Strategy Based Diagnostics. You also should repeat any

procedures that require additional attention.

A previous path may be eliminated from consideration

only if you are certain that all steps were executed as

directed. You must then select another diagnostic path

(step 5a, 5b, 5c or 5d). If all possible options have been

explored, you may call or seek ISUZU field support.

What resources you should use

Whenever possible, you should use the following

resources to facilitate the diagnostic process:

Service manual

Accumulated information form a previous diagnostic

path

Service information and publications

ISUZU field support

7. Repair and Verify Fix

What you should do

After you have located the cause of the problem, you

must execute a repair by following recommended

service manual procedures.

When the repair is completed, you should verify the fix

by performing the system checks under the conditions

listed in the customer complaint.

If applicable, you should carry out preventive measures

to avoid a repeat complaint.

What resources you should use

Whenever possible, you should use the following

resources to facilitate the repair process:

Electrical repair procedures

Service manual information and publications

6E10 ENGINE DRIVEABILITY AND EMISSIONS

Specification difference

Vehicle Model TF NKR

Engine 4JA1-TC 4JH1-TC 4JH1-TC

Engine desplacemert 2.5L 3.0L 3.0L

Intake shutter N/A N/A standard

Exhaust Brake N/A N/A standard

Idle 730rpm

25rpm

at 80C

700rpm

25rpm

MT, AT

at 80C

700rpm

25rpm

at 80C

Transmission MT MT AT MT

Immobilizer standard standard standard not available

EGR EGR with EGR cooler no EGR no EGR EGR with

EGR cooler

Catalitic

converter

Floor type catatic converter not available not available assembled in silencer

QWS option not available not available EC HK Taiwan

stand-

ard

not

available

not

available

ABS not available not available not available EC HK Taiwan

option not

available

not

available

ENGINE DRIVEABILITY AND EMISSIONS 6E11

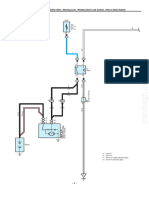

TF 4JA1-TC with Bosch VP44 System ECM Wiring Scheme (Manual Transmission)

060RY00393

A

C

C

B

2

B

1

O

F

F

I

G

2

S

T

I

G

1

S

W

;

I

G

N

I

T

I

O

N

B

A

T

T

M

A

I

N

8

0

A

I

G

.

1

5

0

A

G

L

O

W

5

0

A

I

G

2

4

0

A

8

B

/

R

P

A

0

1

3

W

P

A

0

3

3

W

P

A

1

3

3

W

P

A

1

6

0

.

5

G

C

A

0

1

0

.

5

G

I

C

4

8

0

.

5

R

C

A

0

2

0

.

8

5

W

K

A

0

1

0

.

8

5

Y

M

A

0

1

0

.

5

B

/

R

I

C

5

0

J

/

C

;

B

A

C

G

(

B

)

8

W

P

A

2

8

3

W

/

B

P

A

0

2

0

.

5

L

/

R

I

C

1

1

5

R

/

W

H

B

0

1

3

B

/

R

3

B

/

R

P

A

1

7

3

B

P

A

2

8

2

B

/

Y

I

C

0

1

2L/R

IC05

0

.

5

I

Z

0

3

0

.

5

I

Z

0

4

I

N

J

.

P

U

M

P

T

.

P

.

S

.

&

S

W

;

I

D

L

E

(

T

H

R

O

T

T

L

E

V

A

L

V

E

)

E

C

T

s

e

n

s

o

r

2L/R

IC02

2L/R

IC02

0.5L/B

IC04

I

Z

0

6

0.5B/Y

IC03

0.5L/R

IC17

0.5W/B

IC22

0.5Y

IC31

A37(40)

A56(58)

A41(3)

E

C

M

2

5

A

B

A

C

K

1

5

A

E

N

G

I

N

E

1

0

A

M

E

T

E

R

1

5

A

RELAY ; ECM MAIN

VSV ; EXT 1

RELAY ; A/C COMPRESSOR

R

E

L

A

Y

;

G

L

O

W

S

W

;

T

H

E

R

M

O

SW ; BRAKE

RESISTER ; CLUTCH SW

(YZK NO ; 7321-9900)

RESISTER ; IDLE UP

R

E

S

I

S

T

E

R

;

N

E

U

T

R

A

L

S

W

(

I

D

L

E

S

W

)

B

A

C

K

U

P

L

A

M

P

B

R

A

K

E

L

A

M

P

SW ; CLUTCH

SW ; NEUTRAL

SW ; BACK UP

SW ; OIL

0.5L/R

IC18

0.5W/R

IC23

A59(61)

VSV ; EXT 2

0.5L/R

IC16

0.5L/R

IC15

0.5B/O

IC26

B19(97)

0.5W/R IC27

4 B2(83)

0.5G/R IC28

5 2 B7(88)

0.5B/R IC30

3 B14(92)

0.5B/L IC39

0.5B/L HB06

0.5BR/R

IC14

0.5B

BX16

0.5G/R

BA26

0.5B

HY05

1 B3(84)

A44(46)

B24(100)

A63(63)

B23(99)

B29(105)

B13(91)

A69(69)

A47(49)

A35(38)

A55(57)

B15(93)

B8(89)

B16(94)

0.5L/Y IC06

A36(39)

0.5R IC12

A27(30)

0.5W/B IC13

(ON)

(OFF)

(OFF)

A65(65)

0.5Y IC08

0.5L/R

IC09

0.5B

IZ05

5B/R

HB03

0.85Y

KA01

0.85R/Y

KA02

0.85Y

MA02

0.5L/B

MA03

0.5Y/B

MA06

0.5Y/G

MA09

0.5W/R

MA11

0.5L

MA10

GLOW PULG x4

0.5G

IC07

0.5B

IZ08

0.5B/W

IC10

0

.

5

B

/

W

I

C

5

8

0

.

5

B

I

Z

1

0

0

.

5

B

/

L

E

X

0

2

0

.

5

O

/

B

M

B

0

4

0.85B

MX05

0.5B

IZ06

THERMO UNIT

0.5Y

IC57

A28(31)

B6(87)

0.5O/L

MA28

A40(43)

0.5BR/Y

IC29

0.5BR/W HA20

A39(42)

0.5B/R

MA05

A24(27)

0.5L/W

IC21

0.5G

HA18

0.5G

HA22

0.5BR

HA23

0.5BR HA19

0.5BR HA17

A68(68)

A38(41)

A30(33)

EVRV ; EGR

SW ; ENG WARMING

JOINT

TO MX01

J

O

I

N

T

T

O

E

X

1

2

JOINT

TO BA15

JOINT

TO SX01

2

M

A

F

E

B

S

T

O

P

1

0

A

0.5B

HX03

0.5B

EX03

0.5L

IC47

0.5G

HA24

B-10

A-16

A-15

A-2

0.5R

IC32

3

A-3

0.5O

IC33

4

A-4

0.5P

IC34

1

1

3

2

A-5

0.5G/B

IC35

A-6

0.5R/G

IC36

A-7

0.5G/O

IC37

A-8

0.5B/G

IC38

A-9

A-1

B-11

VEHICLE SPEED

SENSOR

A-11

A-12

B-6

B-5

B-14

OIL PSESSURE UNIT

4WD SW

FUEL

HEATER

MAG.CLUTCH

(COMPRESSOR)

SPEED METER

METER

TACHO METER

OIL GAGE

ENG COOLANT

B6

B15

A10

B8

A6

4WD

OIL

GLOW

CHECK ENG

B3

A8

B2

A9

0

.

5

O

/

L

M

B

0

1

CONT ; IMMOBILIZER(B1)

1

2 4

RELAY ; A/C THERMO

0.5G HA21

0.5G

IC30

ECM

REV

0.5G/R

HA13

0.5L/W HA14

0.5G/W HA16

FUSE ; BLOOR

1

2 4

ELEC.THERMO

0.5B/P

IC43

B-7

0.5GR

IC44

B-1

I

Z

0

7

IZ05

T

D

C

A61(2)

2B

IZ01

B22(98)

B12(90)

B25(101)

0.5W

IC45

B-2

0.5G/R

IC46

B-3

B-10

A62(1)

2B

IZ02

A32(35)

ECM

A43(45)

0.5R/L

MB11

CONT ;

IMMOBILIZER(B8)

C

O

N

T

;

I

M

M

O

B

I

L

I

Z

E

R

(

B

5

)

1 9

2

1

0

3

1

1

4

1

2

5

1

3

6

1

4

7

1

5

8

1

6

B-5

;

E

N

G

I

N

E

;

E

N

G

.

H

A

R

N

.

-

E

N

G

R

O

O

M

H

A

R

N

.

C

O

N

N

E

C

T

I

O

N

SW ; PRESSURE

270

510

6E12 ENGINE DRIVEABILITY AND EMISSIONS

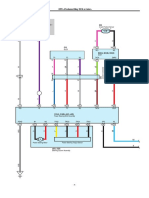

TF 4JH1-TC with Bosch VP44 System ECM Wiring Scheme (Automatic Transmission)

060RY00394

5

R

/

W

H

B

0

1

0

.

5

L

/

W

H

B

0

4

0

.

5

L

/

R

I

C

1

1

0

.

5

B

R

H

A

1

5

0

.

5

B

R

H

A

1

9

A

C

C

B

2

B

1

O

F

F

I

G

2

S

T

I

G

1

S

W

;

I

G

N

I

T

I

O

N

B

A

T

T

M

A

I

N

8

0

A

I

G

.

1

5

0

A

G

L

O

W

5

0

A

I

G

2

4

0

A

8

B

/

R

P

A

0

1

3

W

P

A

0

3

3

W

P

A

1

3

3

W

P

A

1

6

0

.

5

G

C

A

0

1

0

.

5

G

I

C

4

8

0

.

5

R

C

A

0

2

0

.

8

5

R

/

Y

K

A

0

2

0

.

8

5

W

K

A

0

1

0

.

8

5

Y

M

A

0

1

J

/

C

;

B

A

C

G

(

B

)

8

W

P

A

2

8

3

W

/

B

P

A

0

2

3

B

/

R

3

B

/

R

P

A

1

7

3

B

P

A

2

8

2

B

/

Y

I

C

0

1

2L/R IC05

0

.

5

I

Z

0

3

0

.

5

I

Z

0

4

E

B

I

N

J

.

P

U

M

P

T

.

P

.

S

.

&

S

W

;

I

D

L

E

(

T

H

R

O

T

T

L

E

V

A

L

V

E

)

E

C

T

s

e

n

s

o

r

2L/R

IC02

2L/R

IC02

0

.

5

L

/

R

I

C

6

2

0.5L/B IC04

0.5B/Y

IC03

0.5Y

IC31

A56(58)

A41(3)

E

C

M

2

5

A

B

A

C

K

1

5

A

E

N

G

I

N

E

1

0

A

M

E

T

E

R

1

5

A

RELAY ; ECM MAIN

R

E

L

A

Y

;

G

L

O

W

S

W

;

T

H

E

R

M

O

SW ; BRAKE

B

A

C

K

U

P

L

A

M

P

B

R

A

K

E

L

A

M

P

SW ; OIL

0.5L/R

IC15

0.5W/R IC27

0.5L/R IC11

0.5L/W HB04

0.5L/R HA15

0.5L/R IC15

0.5L/R HA19

4 B2(83)

0.5G/R IC28

5 2 B7(88)

0.5B/R IC30

3 B14(92)

0.5B/L IC39

1 B3(84)

0.5BR/W HA20

A38(41)

B24(100)

A63(63)

B23(99)

B29(105)

B13(91)

A69(69)

A47(49)

A35(38)

A55(57)

B15(93)

B8(89)

B16(94)

A30(33)

0.5L/Y IC06

0.5B/L HB06

A36(39)

0.5R

IC12

A27(30)

0.5W/B

IC13

(ON)

ELEC.THERMO

(OFF)

A65(65)

0.5R/B

IC60

B6(87)

5B/R

HB03

0.85Y

MA02

0.5L/B

MA03

0.5Y/B

MA06

0.5Y/G

MA09

0.5W/R

MA11(W/SOF)

TB07(W/O SOF)

0.5L

MA10

0.5O/L

MB01

GLOW PULG x4

0

.

5

B

/

L

E

X

0

2

0

.

5

O

/

B

M

B

0

4

0.85B

MX05

0.5B

IZ06

THERMO UNIT

0.5O/L

MA18

A40(43)

0.5BR/R

IC29

A39(42)

0.5B/R

MA05

A24(27)

0.5L/W

IC21

A68(68)

J

O

I

N

T

T

O

E

X

1

2

2

MAF

OA05

O

A

2

5

0.5R/Y

OA60

37

A46(48)

5

25

0.5B/R

OA06

6

A26(28)

0.5B

OX01

ENG

EARTH

TCM

E

B

S

T

O

P

1

0

A

0.5B

EX03

0.5L

IC47

A-16

A-15

A-2

0.5R

IC32

3

A-3

0.5O

IC33

4

A-4

0.5P

IC34

1

1

3

2

A-5

0.5G/B

IC35

0.5R/G

IC36

0.5G/O

IC37

0.5B/G

IC38

A

F

C

B

VEHICLE SPEED

SENSOR

A-11

A-12

B-2

A-6

B-3

OIL PSESSURE UNIT

4WD SW

SPEED METER

METER

TACHO METER

OIL GAGE

TCM

ENG COOLANT

B6

10

11

31

32

47

48

B15

A10

B8

A6

4WD

OIL

GLOW

CHECK ENG

B3

A8

B2

A9

CONT ; IMMOBILIZER(B1)

0.5G

IC48

0.5B/P

IC43

B-5

0.5O

IC44

B-6

I

Z

0

7

IZ05

T

D

C

A61(2)

2B

IZ01

B22(98)

B12(90)

B25(101)

0.5W

IC45

A-7

0.5G/R

IC46

A-8

A-9

A62(1)

2B

IZ02

A32(35)

ECM

A43(45)

0.5R/L

MB11

CONT ;

IMMOBILIZER(B8)

C

O

N

T

;

I

M

M

O

B

I

L

I

Z

E

R

(

B

5

)

1 9

2

1

0

3

1

1

4

1

2

5

1

3

6

1

4

7

1

5

8

1

6

A-1

0.5B/G

LA09

C-14

0.5B/W

LA06

B-4

0.5Y/V

OA59

C-2

0.5Y/L

OA58

C-4

0.5Y/R

OA32

C-3

0.5W/R

OA57

C-10

0.85R/Y

KA02

A-10

0.5R/G

OA10

0.5R/Y

OA11

0.5W/R

OA31

0.5R/B

IC61

C-15

;

E

N

G

I

N

E

;

E

N

G

.

H

A

R

N

.

-

E

N

G

R

O

O

M

H

A

R

N

.

C

O

N

N

E

C

T

I

O

N

RELAY ;

A/C COMPRESSOR

1

2 4 0.5G

HA18

FUSE ;

A/C

FUSE ;

BLOOR

0.5B

HX22

0.5G

HA23

MAG.CLUTCH

(COMPRESSOR)

B-1

0.5G/R

HA13

0.5L/W

HA14

0.5BR

HA17

RELAY ;

A/C THERMO

1

2 4 0.5G HA21

0.5G/W HA16

0.5B

HX03

0.5G

HA24

RESISTER ; IDLE UP

(YZK NO ; 7321-9430)

P

R

N

D

2

1

N B

SW ; MODE

RELAY ; STARTER

FUSE ; STARTER

270

ENGINE DRIVEABILITY AND EMISSIONS 6E13

TF 4JH1-TC with Bosch VP44 System ECM Wiring Scheme (Manual Transmission)

5

R

/

W

H

B

0

1

0

.

5

L

/

R

H

B

0

4

0

.

5

L

/

R

I

C

1

1

0

.

5

L

/

R

H

A

1

5

A

C

C

B

2

B

1

O

F

F

I

G

2

S

T

I

G

1

S

W

;

I

G

N

I

T

I

O

N

B

A

T

T

M

A

I

N

8

0

A

I

G

.

1

5

0

A

G

L

O

W

5

0

A

I

G

2

4

0

A

8

B

/

R

P

A

0

1

3

W

P

A

0

3

3

W

P

A

1

3

3

W

P

A

1

6

0

.

5

G

C

A

0

1

0

.

5

G

I

C

4

8

0

.

5

R

C

A

0

2

0

.

8

5

W

K

A

0

1

0

.

8

5

Y

M

A

0

1

J

/

C

;

B

A

C

G

(

B

)

8

W

P

A

2

8

3

W

/

B

P

A

0

2

3

B

/

R

3

B

/

R

P

A

1

7

3

B

P

A

2

8

2

B

/

Y

I

C

0

1

2L/R

IC05

2L/R

IC05

0

.

5

I

Z

0

3

0

.

5

I

Z

0

4

E

B

I

N

J

.

P

U

M

P

T

.

P

.

S

.

&

S

W

;

I

D

L

E

(

T

H

R

O

T

T

L

E

V

A

L

V

E

)

E

C

T

s

e

n

s

o

r

2L/R

IC02

2L/R

IC02

2L/B

IC04

0.5B/Y

IC03

0.5Y

IC31

A56(58)

A41(3)

E

C

M

2

5

A

B

A

C

K

1

5

A

E

N

G

I

N

E

1

0

A

M

E

T

E

R

1

5

A

RELAY ; ECM MAIN

R

E

L

A

Y

;

G

L

O

W

S

W

;

T

H

E

R

M

O

SW ; BRAKE

RESISTER ; CLUTCH SW

(YZK NO ; 7321-9900)

(IDLE SW)

B

A

C

K

U

P

L

A

M

P

B

R

A

K

E

L

A

M

P

SW ; CLUTCH

SW ; BACK UP

SW ; OIL

0.5L/R

IC15

0.5W/R IC27

0.5L/R IC11

0.5L/R HB04

0.5L/R HA15

0.5G IC07

0.5L/R IC15

0.5L/R HA19

4 B2(83)

0.5G/R IC28

5 2 B7(88)

0.5B/R IC30

3 B14(92)

0.5B/L IC39

1 B3(84)

0.5BR/W HA20

A38(41)

B24(100)

A41(63)

B23(99)

B29(105)

B13(91)

A69(69)

A47(49)

A35(38)

A55(57)

B15(93)

B8(89)

B16(94)

A30(33)

0.5L/Y

IC06

0.5B/L

HB06

A36(39)

0.5R

IC12

A27(30)

0.5W/B

IC13

(ON)

ELEC.THERMO

(OFF)

(OFF)

A65(65)

0.5Y IC08

5B/R

HB03

0.85Y

KA01

0.85R/Y

KA02

0.85Y

MA02

0.5L/B

MA03

0.5Y/B

MA06

0.5Y/G

MA09

0.5W/R

MA11(W/SOF)

TB07(W/O SOF)

0.5L

MA10

0.5O/L

MB01

GLOW PULG x4

0.5G

IC07

0.5B

IZ08

0

.

5

B

/

L

E

X

0

2

0

.

5

O

/

B

M

B

0

4

0.85B

MX05

0.5B

IZ06

THERMO UNIT

0.5Y

IC57

A28(31)

0.5O/L

MA18

A40(43)

0.5BR/R

IC29

A39(42)

0.5B/R

MA05

A24(27)

0.5L/W

IC21

A68(68)

J

O

I

N

T

T

O

E

X

1

2

2

MAF

E

B

S

T

O

P

1

0

A

RESISTER ; NEWTRAL SW

0.5B

IZ10

0.5B/W

IC58

0.5B

EX03

0.5L

IC47

A-16

A-15

A-2

0.5R

IC32

3

A-3

0.5O

IC33

4

A-4

0.5P

IC34

1

1

3

2

A-5

0.5G/B

IC35

0.5R/G

IC36

0.5G/O

IC37

0.5B/G

IC38

A

F

C

B

A-1

A-10

VEHICLE SPEED

SENSOR

A-11

A-12

B-2

A-6

B-3

OIL PSESSURE UNIT

4WD SW

SPEED METER

METER

TACHO METER

OIL GAGE

ENG COOLANT

B6

B15

A10

B8

A6

4WD

OIL

GLOW

CHECK ENG

B3

A8

B2

A9

CONT ; IMMOBILIZER(B1)

0.5G

IC48

0.5B/P

IC43

B-5

0.5O

IC44

B-6

I

Z

0

7

IZ05

SW ; NEWTRAL

T

D

C

A61(2)

2B

IZ01

B22(98)

B12(90)

B25(101)

0.5W

IC45

A-7

0.5G/R

IC46

0.5B/W

IC10

0.5L/R

IC09

A-8

A-9

A62(1)

2B

IZ02

A32(35)

ECM

A43(45)

0.5R/L

MB11

CONT ;

IMMOBILIZER(B8)

C

O

N

T

;

I

M

M

O

B

I

L

I

Z

E

R

(

B

5

)

1 9

2

1

0

3

1

1

4

1

2

5

1

3

6

1

4

7

1

5

8

1

6

A-9

;

E

N

G

I

N

E

;

E

N

G

.

H

A

R

N

.

-

E

N

G

R

O

O

M

H

A

R

N

.

C

O

N

N

E

C

T

I

O

N

RELAY ;

A/C COMPRESSOR

1

2 4 0.5G

HA18

FUSE ;

A/C

FUSE ;

BLOOR

0.5B

HX22

0.5G

HA23

MAG.CLUTCH

(COMPRESSOR)

B-1

0.5G/R

HA13

0.5L/W

HA14

0.5BR

HA17

RELAY ;

A/C THERMO

1

2 4 0.5G

HA21 0.5G/W HA16

0.5B

HX03

0.5G

HA24

RESISTER ; IDLE UP

270

510

270

6E14 ENGINE DRIVEABILITY AND EMISSIONS

N*R 4JH1-TC with Bosch VP44 System ECM Wiring Diagram

060RY00363

060RY00329

A

C

C

B

O

F

F

S

T

O

N

K

E

Y

S

W

5

W

P

A

0

7

0

.

5

B

R

H

A

0

9

0

.

8

5

G

/

O

H

A

1

1

0

.

5

G

/

O

I

C

4

8

0

.

5

L

/

R

I

C

3

9

0

.

5

L

/

R

I

C

3

3

3L/R IC34

M

A

G

N

E

T

C

L

U

T

C

H

(

C

O

M

P

R

E

S

S

O

R

)

P

D

S

0.85G/W

HA10

0.85Y/G

HA19

0.5B

IZ12

5

B

/

L

H

B

0

1

0

.

8

5

W

P

A

1

0

3

B

/

Y

I

C

0

1

1

.

2

5

B

/

Y

I

C

0

5

0

.

5

G

/

Y

C

A

0

1

0

.

5

L

G

/

R

I

C

2

1

0

.

3

B

I

Z

0

9

0

.

5

B

R

/

R

I

C

2

0

1

35

2

4

M

A

F

1

4

V

,

6

0

m

A

0

.

5

B

R

/

R

I

C

1

9

0

.

5

L

/

R

I

C

2

2

0

.

5

B

R

I

C

6

5

0

.

5

B

/

O

I

C

2

7

0

.

5

L

G

I

C

1

6

0

.

5

L

G

/

W

I

C

2

9

0

.

5

B

/

W

I

C

3

1

1

.

2

5

L

/

R

I

C

5

9

0

.

5

B

/

Y

M

A

0

1

0

.

5

L

/

R

I

C

2

6

0

.

5

B

I

C

1

5

0

.

5

L

/

R

I

C

2

8

2

L

/

R

I

C

3

0

0

.

5

G

/

Y

I

C

4

1

0

.

5

W

/

G

I

C

4

0

1

.

2

5

B

/

Y

I

C

6

3

0

.

5

L

/

R

I

C

0

9

2

L

/

R

I

C

0

2

0

.

5

L

/

B

I

C

0

3

0

.

5

G

C

A

0

2

0

.

5

G

I

C

1

0

0

.

5

W

I

C

0

4

A

-

5

6

C

O

N

T

U

N

I

T

;

E

N

G

I

N

E

A

-

4

1

A

-

3

6

A

-

2

7

A

-

6

5

A

-

2

8

A

-

6

4

A

-

5

8

A

-

3

9

A

-

4

0

A

-

4

4

A

-

5

7

B

-

2

B

-

7

B

-

1

4

B

-

1

9

B

-

3

A

-

3

7

B

-

1

7

B

-

6

B

-

2

4

B

-

2

3

B

-

2

9

B

-

1

3

A

-

3

0

A

-

3

8

D

I

A

G

(

4

5

)

M

A

I

N

R

E

L

A

Y

(

5

8

)

B

A

T

(

+

)

(

3

)

I

G

(

3

9

)

B

A

R

A

K

E

O

N

(

3

0

)

B

A

R

A

K

E

O

F

F

(

6

5

)

C

L

U

T

C

H

(

3

1

)

S

W

;

E

X

H

.

B

R

A

K

E

(

6

4

)

M

E

T

E

R

I

N

D

(

E

X

H

.

B

R

A

K

E

)

(

6

0

)

(

K

E

Y

O

N

;

E

N

A

B

L

E

)

M

E

T

E

R

I

N

D

(

C

H

E

C

K

E

N

G

.

)

(

4

2

)

M

E

T

E

R

I

N

D

(

G

L

O

W

)

(

4

3

)

Q

W

S

S

W

(

4

6

)

M

E

T

E

R

I

N

D

(

Q

W

S

)

(

5

9

)

(

K

E

Y

O

N

;

E

N

A

B

L

E

)

M

A

F

+

5

V

(

8

3

)

M

A

F

S

I

G

.

(

8

8

)

M

A

F

G

N

D

(

9

2

)

E

G

R

(

9

7

)

M

A

T

S

I

G

.

(

8

4

)

M

A

G

.

V

A

L

V

E

(

E

X

H

.

B

R

A

K

E

)

(

4

0

)

I

N

T

.

S

L

O

T

T

L

E

(

9

5

)

S

W

;

N

E

U

T

R

A

L

(

8

7

)

I

N

J

.

P

U

M

P

(

C

A

N

-

H

)

(

1

0

0

)

I

N

J

.

P

U

M

P

(

C

A

N

-

L

)

(

9

9

)

I

N

J

.

P

U

M

P

(

M

A

B

)

(

1

0

5

)

I

N

J

.

P

U

M

P

(

D

Z

G

)

(

9

1

)

A

/

C

S

W

(

3

3

)

A

/

C

R

E

L

A

Y

(

4

1

)

0

.

5

W

/

B

I

C

1

1

0

.

5

Y

I

C

1

2

0

.

5

L

G

/

L

I

C

1

3

0

.

5

G

/

R

I

C

6

4

0

.

5

G

/

Y

I

C

1

7

0

.

5

O

/

L

I

C

1

8

0

.

5

W

/

R

I

C

2

3

0

.

5

G

/

R

I

C

2

4

0

.

5

B

/

R

I

C

2

5

0

.

5

B

/

L

I

C

5

6

0

.

5

W

I

C

6

0

0

.

5

G

B

B

0

9

S

T

O

P

L

A

M

P

0.5L/R IC06

0.5L/R IC07

0.5L/R IC08

S

W

;

C

L

U

T

C

H (

C

L

U

T

C

H

P

E

D

A

L

;

O

F

F

)

(

B

R

A

K

E

P

E

D

A

L

;

O

F

F

)

(

B

R

A

K

E

P

E

D

A

L

;

O

N

)

S

W

;

E

X

H

.

B

R

A

K

E

S

W

;

E

N

G

.

W

A

R

M

1

6

8

1

5

7

1

4

6

1

3

5

1

2

4

1

1

3

1

0

2

9 1

0.5B

IZ08

0.5Y/G

IC47

0

.

3

B

I

Z

0

6

F

R

A

M

E

E

A

R

T

H

P

O

I

N

T

F

R

A

M

E

E

A

R

T

H

P

O

I

N

T

2B

IZ04

0.5B

ZZ05

0.5B

ZZ06

0.5B/W

IC32

M

A

I

N

8

0

A

K

E

Y

S

W

5

0

A

#12

GAUGE,

BACK

10A

#11

WIPER,

WASHER

15A

#2

AIR CON

10A

#1

HEATER

25A #15

H/L

LEVELINGA

10A

#18

GENERATOR

15A

#

2

0

E

C

U

2

5

A

#

1

7

S

T

O

P

L

A

M

P

1

0

A

#19

TURN

10A

G

L

O

W

6

0

A

B

A

T

T

F

T

X

2

L

TO RELAY ; CORNEING

T

O

B

L

O

W

E

R

M

O

T

O

R

TO RELAY ; TAIL

TO ELECTRO THERMO

T

O

R

E

L

A

Y

;

C

H

A

R

G

E

R

E

L

A

Y

;

T

H

E

R

M

O

A

/

C

R

E

L

A

Y

;

H

E

A

T

E

R

&

A

/

C

R

E

L

A

Y

;

G

/

P

U

L

G

R

E

L

A

Y

;

A

/

C

C

O

M

P

.

RELAY ;

A/C ON SIGNAL

TO SW ; BACK UP LAMP

(

)

T

O

C

O

N

T

U

N

I

T

;

A

B

S

S

T

O

P

L

A

M

P

S

I

G

N

A

L

T

O

R

E

L

A

Y

;

C

H

A

R

G

E

R

E

L

A

Y

;

E

C

U

J/C

S

W

;

S

T

O

P

L

A

M

P

E

V

R

V

;

E

G

R

M

A

G

.

V

A

L

V

E

;

E

X

H

.

B

R

A

K

E

V

S

V

;

I

N

T

.

T

H

R

O

T

T

L

E

S

W

;

N

E

U

T

R

A

L

(

N

E

U

T

R

A

L

;

O

N

)

S

W

;

I

D

E

L

0

.

5

L

G

/

L

I

C

1

4

1

4

V

,

2

.

0

W

1

4

V

,

1

.

4

W

1

4

V

,

1

.

4

W

M

E

T

E

R

E

X

H

.

B

R

A

K

E

C

H

E

C

K

E

N

G

.

G

L

O

W

85

67

1

I

N

J

.

P

U

M

P

T

W

I

S

T

L

I

N

E

0

.

5

R

I

C

3

6

0

.

5

O

I

C

3

7

0

.

5

P

I

C

3

8

0

.

5

L

I

C

5

8

2

0

.

5

Y

I

C

3

5

A

-

4

3

I

S

O

-

K

(

3

5

)

0

.

5

Y

I

C

5

7

A

-

3

2

G

N

D

.

(

9

3

)

0

.

5

B

/

P

I

C

5

2

B

-

1

5

132

87

42

9

F

R

A

S

H

J

1

8

5

0

E

X

H

.

B

/

C

U

T

O

U

T

E

X

H

.

B

/

C

U

T

I

N

W

A

T

E

R

T

E

M

P

(

E

C

U

)

(

8

9

)

0

.

5

G

R

I

C

5

1

B

-

8

A

L

D

L

C

O

N

N

E

C

T

O

R

T

D

C

(

S

H

I

E

L

D

E

D

)

(

1

0

1

)

0

.

5

B

I

Z

0

7

B

-

2

5

T

D

C

(

-

)

(

9

8

)

0

.

5

W

I

C

5

0

I

Z

1

0

(

S

H

I

E

L

D

) E

C

T

s

e

n

s

o

r

T

D

C

C

O

N

T

.

U

N

I

T

;

A

B

S

W

I

T

H

;

A

B

S

V

E

H

I

C

L

E

S

P

E

E

D

B

-

2

2

T

D

C

(

+

)

(

9

0

)

0

.

5

R

I

C

4

9

B

-

1

2

G

N

D

.

(

1

)

A

-

6

2

G

N

D

.

(

2

)

A

-

6

1

A

C

C

E

L

S

E

N

S

O

R

(

I

D

E

L

)

(

6

9

)

A

-

6

9

A

C

C

E

L

S

E

N

S

O

R

(

G

N

D

.

)

(

4

9

)

A

-

4

7

A

C

C

E

L

S

E

N

S

O

R

(

S

I

G

.

)

(

3

8

)

A

-

3

5

A

C

C

E

L

S

E

N

S

O

R

(

+

5

V

)

(

5

7

)

A

-

5

5

G

L

O

W

R

E

L

A

Y

(

9

4

)

B

-

1

6

A

B

S

(

I

N

)

(

3

2

)

0

.

5

L

G

/

W

B

B

0

6

A

-

2

9

A

B

S

(

O

U

T

)

(

6

2

)

0

.

5

L

G

/

B

B

B

0

7

0

.

3

W

/

G

B

B

2

0

0

.

3

W

/

B

B

B

2

1

0

.

8

5

B

M

X

0

1

0.85B

MX06

0

.

3

V

M

X

0

4

0

.

5

B

/

Y

M

A

3

2

0

.

5

Y

/

G

M

A

3

3

0

.

5

B

M

X

1

1

0

.

5

Y

/

B

M

A

0

8

0

.

5

B

I

Z

1

1

A

-

6

0

V

E

H

I

C

L

E

S

P

E

E

D

(

6

8

)

0

.

5

Y

/

G

I

C

4

6

A

-

6

8

E

N

G

.

S

P

E

E

D

(

O

U

T

P

U

T

-

1

)

(

2

7

)

0

.

5

L

G

M

A

0

7

2

B

I

Z

0

1

2