Beruflich Dokumente

Kultur Dokumente

Intake and Exhaust System Optimization of Internal Combustion Engines

Hochgeladen von

bobmeonly1Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Intake and Exhaust System Optimization of Internal Combustion Engines

Hochgeladen von

bobmeonly1Copyright:

Verfügbare Formate

Reporte Tcnico

RT-ID- 012/2003

Intake and exhaust system optimization of

internal combustion engines

Juan Pablo Alianak y Norberto Nigro

Departamento de Ingeniera

Escuela de Ingeniera Mecnica

Facultad de Ciencias Exactas, Ingeniera y Agrimensura

Universidad Nacional de Rosario

Secretara de Ciencia y Tcnica

Facultad de Ciencias Exactas, Ingeniera y Agrimensura

Universidad Nacional de Rosario

Av. Pellegrini 250 - 2000 Rosario Argentina

http://www.fceia.unr.edu.ar/secyt

Enviado 10 de Octubre de 2003

Revisado

Disciplina: Ingeniera Mecnica

2

Este documento es publicado por la FCEIA para su consulta externa. El mismo se publica como

Reporte de Investigacin para divulgacin de las tareas cientficas que se desarrollan en la FCEIA,

Universidad Nacional de Rosario. Los autores conservan los derechos de autora y copia de la totalidad

de su trabajo aqu publicado. Luego de su posterior eventual publicacin externa a la FCEIA, los

requerimientos debern dirigirse a los autores respectivos. El contenido de este reporte refleja la visin

de los autores, quienes se responsabilizan por los datos presentados, los cuales no necesariamente

reflejan la visin de la SeCyT-FCEIA. Tanto la SeCyT-FCEIA como los autores del presente reporte

no se responsabilizan por el uso que pudiera hacerse de la informacin y/o metodologas publicadas.

Cualquier sugerencia dirigirla a: rtsecyt@fceia.unr.edu.ar

Un trabajo basado en este pero resumido ha sido enviado recientemente a la Revista International

Journal of Engine Research y hasta el momento no hemos recibido respuesta de parte de ellos acerca de

su recepcin

3

Optimizacin del sistema de admisin y escape de un

motor de combustin interna

Juan Pablo Alianak* y Norberto Nigro**

Departamento de Ingeniera

Escuela de Ingeniera Mecnica

Facultad de Ciencias Exactas, Ingeniera y Agrimensura

Universidad Nacional de Rosario

El diseo de motores es uno de los proyectos mas desafiantes de la Ingeniera Mecnica. Esto es principalmente

debido a la gran cantidad de variables involucradas. Mas an, los motores de alta performance aplicados a

vehculos de competicin necesitan un estudio detallado y una muy profunda tarea de optimizacin con el fin de

alcanzar los ms altos ndices de potencia especfica. Entre los diferentes factores que influencia el rendimiento

de un motor la eficiencia volumtrica parece ser uno de los mas importantes. Este ndice mide la capacidad de

aspirar de un motor asociado a las carreras de carga de mezcla fresca y barrido de gases quemados a travs de los

sistemas de admisin y escape. Siguiendo los ltimos avances cientficos en cuanto a las capacidades

computacionales, los mtodos numricos basados en la teora de a dinmica de gases aparecen como muy

atractivos para resolver este tipo de problemas. En general estas ecuaciones son acopladas con otras de ndole

termodinmica aplicadas a los principales componentes del motor tal como cilindros, tomas de aire, tanques o

recipientes de volumen fijo, silenciadores, etc. Debido a los simples modelos fenomenolgicos incluidos en el

sistema del motor, un gran nmero de coeficientes empricos necesitan ser estimados. Esta tarea involucra

mediciones experimentales combinadas con una buena estrategia para vincularlos con los principales parmetros

incgnitas. No obstante, no solo la dinmica de fluidos y la termodinmica juegan un rol crucial sino tambin la

respuesta mecnica del tren de vlvulas completo es muy importante para optimizar la eficiencia volumtrica de

un motor. En este sentido la teora de sistemas multi cuerpos puede asistir en el entendimiento de cmo las no

linealidades influencian el comportamiento dinmico del tren de vlvulas completo. Este trabajo presenta una

nueva estrategia para calibrar el software de un motor y una metodologa de diseo ptimo de levas para trenes

de vlvulas de motores de combustin interna basada en un anlisis combinado de la termodinmica, la dinmica

de gases y la mecnica.

Palabras claves: : Dinmica de gases, motores de combustin interna, admisin y escape, tren de vlvulas

Intake and exhaust system optimization of internal

combustion engines

Engine design is one of the most challenging mechanical engineering projects. This is mainly due to the huge amount

of variables involved. Moreover, high performance engines applied to a racing car need a detailed study and a very

good optimization task in order to achieve the highest indices of specific power. Among the different factors that

influence the engine performance, volumetric efficiency seems to be one of the most important ones. This index

measures the breathing capacity of an engine associated with the gas charge process through the intake and exhaust

systems. following

Following the latest advances in computers capability, numerical methods whose principal equations come from the

gas-dynamic theory have been applied to solve this problem. In general, these equations are coupled with

thermodynamic equations applied to the principal devices of an engine, such as cylinders, air intake, tanks, mufflers,

etc. Due to the very simple phenomenological models included in the engine system, a number of empirical

coefficients need to be estimated. This task involves experimental measurements combined with a good strategy to

link them with the main numerical unknown parameters. However, not only fluid dynamics and thermodynamics

play a crucial role, but also the mechanical response of the whole valve train is very important to optimize the

volumetric efficiency of an engine. In this sense, the multibody system theory can be of assistance in order to

understand how the nonlinearities influence the dynamic behavior of the whole valve train.

This paper presents a new strategy to calibrate an engine system software, plus a methodology to design optimal

cams for valve trains of internal combustion engines based on thermodynamics, gas dynamics and mechanical

analysis.

Keywords: Gas dynamics, internal combustion engines, optimization, intake and exhaust, valve train.

* jpalianak@hotmail.com

**nnigro@intec.unl.edu.ar

4

Introduction

Today, the fast advances in computer hardware make it possible to reproduce an engine test

virtually and with high accuracy before going to the laboratory for fine-tuning. In this way,

an important amount of development lead-time in trials and errors is saved. The strong

influence of the intake and exhaust system dynamics on the volumetric efficiency and

eventually on the engine performance is well known. A strong effort was developed since

the publication of two of the pioneer papers in this area [1, 2] written with an analytical and

graphical point of view.Earlier contributions were based on characteristic method [3, 4]. In

the last decade a great number of robust and accurate algorithms was developed for the gas

dynamics and wave propagation in multi-dimensional configurations. One of the main

research lines has got robust and fast algorithms for unstructured grids in very complex and

variable geometries. On the other hand, numerous scientific papers have been published with

the aim of attaining high resolution schemes in very simple geometries like a one

dimensional domain. The results obtained by the CFD community along this research line

have been very fruitful and they can be used in the simulation of more complex dynamic

systems in which the assumption of one dimensional flow is valid. This is just the case in an

internal combustion engine where the flow in manifolds can be approximated through this

assumption without losing much accuracy, the main goal of the analysis being the tuning

effects. Joining CFD schemes for the manifolds with some thermodynamic models for

cylinders, tanks, junctions and valves, it is possible to build a computational tool for the

whole engine system that is able to predict its performance before going through more

expensive laboratory experiments. Finally, the actual observation in the laboratory

determines the degree of accuracy in the simulation, which allows us to do finer adjustments

to reach the target. This project began some years ago with the development of a single-

cylinder four stroke spark ignition engine simulator. The mathematical model is based on a

thermodynamic and a one dimensional gas dynamics description of the intake and exhaust

system published earlier [5]. Later, multi cylinder configurations were added to this

development in order to enhance this predictive tool. The Euler equations arising from the

gas dynamics model were solved using two different numerical approximations, a streamline

upwind Petrov-Galerkin finite element method (SUPG-FEM) [6, 7], and also a high

resolution finite volume scheme called total variation diminishing (TVD) [8], with no

significant differences in the results obtained with them. For the coupling of tanks and

cylinders with pipes, a model based on a nozzle analogy is used [9], allowing for the

possibility of subsonic or sonic flow condition through the intake and the exhaust valves.

The coupling of pipes and the junctions is solved using a model based on a pressure

equalizer coupled with mass and energy balance equations, characteristic propagation

equations, and an entropy equalizer for the outgoing branches at the junction [10]. Much

work is currently being done along this research line since the code validation is a very

intricate subject. The inherent difficulties in getting detailed measurements in engine

configurations compel us to take indirect and global measures in order to estimate some

engine operation parameters. The selection of this strategy is crucial for the software

reliability, and good predictions are necessary for design improvements. Nowadays this

open problem is subject of debate; how to combine in an optimal way the theory and the

available measurements to get good software calibration is the question to be answered. This

is one of the main topics that this papers covers, and a novel strategy is proposed as an

answer to the scientific community.

Besides, there is a real need to combine gas dynamics, thermodynamics and mechanical

analysis in order to optimize the volumetric efficiency of an internal combustion engine.

While thermodynamics is mainly necessary to solve the power cycle of the engine operation,

5

the flow pattern is crucial to understand how the pressure waves interact with the valves

timings, drastically influencing the pumping work in the engine cycle. But these two

phenomena are not enough to predict the engine performance. The mechanical behavior of

the involved mechanism is also responsible for the normal operation of the engine. The

valves timings, the mechanical reliability and the durability will be warranted only if the

mechanical response is under control. This kind of analysis is not frequently reported in the

literature, probably because there is a standard division between fluid dynamics and solid

mechanics for researchers on computational mechanics. This paper also presents an

optimization task linking these three great areas in order to improve the valve train design.

This methodology can easily supplement our daily work so as to get better control on the

whole engine behavior.

The first section of this paper is a brief description of the mathematical and numerical

modeling of the gas dynamics and thermodynamics equations used for the engine system.

The following section presents the code calibration with a few new available basic

measurements in order to link them with the main unknown parameters in the model in order

to reproduce accurately the engine power recorded in the laboratory. The next sections deal

with the intake and exhaust timings optimization task, the optimal cam profile generation

and finally the mechanical response verification. The final section is for conclusions.

Numerical models for the gas dynamics and

thermodynamics in an internal combustion engine

Historically, researchers and engine designers following Heywood [11] and Ramos [12]

have been using four different categories of internal combustion engine models:

1. air standard cycle simulation,

2. zero and quasi-dimensional thermodynamic models,

3. a combination of zero dimensional and one dimensional models,

4. multidimensional models

The first approach was used in the past when only human work was available and there were

no computer capabilities. The limitation of this kind of model was in the prediction of the

pumping cycle, when the influence of the gas dynamics in the manifolds is crucial.

Following in complexity, the zero dimensional thermodynamic models offer the possibility

of including the unsteady behavior of the system and the variable thermo physical properties

along the whole cycle. Because of its simplicity, the emptying and

filling models [13] may result an attractive technique for the intake and the exhaust system.

It consists of assuming a fixed volume for each manifold and follow their time evolution

with a spatial average for the thermodynamic variables. In this sense, this strategy represents

a significant improvement in relation to the earlier models because the gas charging process

can be added to the whole computation and tuning may be predicted.

However, the traveling waves in the manifolds are not represented at all because of the

spatial averaging. In order to include this effect that has a significant influence on the

volumetric efficiency, the following model includes a one dimensional representation of the

gas flow inside the manifolds solving the mass, momentum and energy balance in each tube

of the whole engine network [5, 9, 14, 15, 16, 17]. A simple spatial discretization is adopted

using a robust numerical scheme to solve it. It is possible to solve the entire engine

configuration including a number of devices like cylinders, mufflers, manifolds, tanks,

6

junctions, carburetors, air cleaners, catalytic converters, and so on, with an accuracy level

that depends strongly on experimental measurements to

calibrate the whole model. The last kind of model deals with multidimensional or CFD

models that includes the whole three dimensional domain with the added complexity of

treating moving boundaries, turbulent flows, and reactive flows. This kind of model requires

powerful computer resources like parallel processing on cluster of personal computers or

workstations and they are only used for special purposes. As mentioned above, the goal of

the engine simulator is to predict the engine performance allowing for some modifications in

order to improve it. Generally, the engine software of thermodynamic based models solving

the flow in the manifolds by a one dimensional CFD scheme is composed by:

a set of cylinders,

the intake and exhaust ports and valves,

the intake and exhaust manifolds

air intake or tanks

junctions

A brief description the devices mentioned above is included below; readers interested in

these topics can refer to the papers published in the related literature [5, 9, 14, 15, 16, 17, 18,

19]

Cylinder model

This model assumes the cylinder to be a variable volume reactor. In general, it is an open

thermodynamic system with the inlet and outlet represented by the intake and exhaust

valves. The model is composed by the mass and energy conservation equations and the ideal

gas law assumption.

T R

p

Q V p h

dt

dE

m

dt

dm

gas

j

j

j

j

=

+ =

=

where m is the cylinder trapped mass, E is the internal energy of the cylinder contents, h is

for the entalphy, ,p and T are the density, pressure and temperature inside the cylinder, V

is the cylinder volume, Q the heat flux through the system and R is the gas constant

employed in the ideal law.

To close this model the following models are added:

the crank rod mechanism model

a combustion heat release model

a heat transfer model

a model for the flow through ports and valves

The first model establishes the piston position at each time step solving the motion of the

crank rod mechanism analitically. Using the expression for the piston position in time,

7

the heat transfer surface area, the combustion chamber volume and its time variation are

computed straightforwardly using one of the following expressions:

) (

4

) (

) sin( ) cos(

2

2 2 2

s a l

D

V V

s a l D A A A

a l a s

c

c

c p ch

+ + =

+ + + =

+ =

where is the crank angle, V

c

is the clearance volume, D

c

is the cylinder bore, l is the

connecting rod length, a is the crankshaft radius, A

ch

is the head cylinder surface area and A

p

is the crown piston surface area.

The combustion is solved using a single zone model in which the burned fraction of fuel is

computed by the Wiebe function [11], an empirical based formula that expresses the burning

rate as a function of the combustion duration.

The well known Woschni or Annand heat release models may be used for the heat losses

estimation from the hot gases inside the cylinder through the combustion chamber walls to

the cooling system [20, 21]. Mathematically these models are written as:

) (

wall ht

T T h A Q =

This model consists of a simple analogy with flow over a flat plate [22] adjusted by

experimental measurements to estimate the heat losses to the engine cooling system. The

main feature of this model is the correlation between the Nusselt, the Reynolds number and

the Prandtl number, which allows us to compute a convective film coefficient (h in the

above expression). A and T

wall

are the heat transfer surface area and the cylinder wall

temperature respectively.

For the flow through poppet valves, the treatment is split according to the flow direction

following a model extracted from the earlier Benson papers[9]. In both cases a simple

analogy with flow through nozzles is done, and sonic condition is only possible for the

exhaust valve. For inflow condition the process is treated as subsonic and isentropic. This

condition is generally found for normal intake or for exhaust with backflow at the end of its

stroke.

For outflow from cylinder to the pipe through the exhaust valve, a simple analogy with a

convergent nozzle that may be chocked or not depending on the pressure jump between the

cylinder and the exhaust manifold is used [9]. The same model is also used for backflow at

the intake valve where normally chocked condition is not established.

Manifolds

Manifolds are three dimensional curved ducts with variable cross section in which the flow

inside has a very complex behavior. Because performance prediction of an internal

combustion engine is the main target and due to the computer resources available a one

dimensional approach is adopted for such a device. This approximation allows us to

represent the pressure waves developed inside the manifolds, which makes it possible to

8

gain an insight into the gas dynamics inside the engine. The gas motion affects the tuning

and therefore the global performance through the volumetric efficiency. In order to include

effects like variable cross section, viscous friction, and wall heat transfer in a one

dimensional description, some source terms are defined. Then, an inviscid gas dynamic

model represented by the Euler equations enhanced with extra sources terms to account for

these effects is used to predict the gas motion during the charge and discharge processes.

The numerical computations are carried out by an upwinding finite element scheme using

the well known SUPG method [6, 7] or a finite volume high resolution scheme like a second

order accurate TVD scheme [8] with similar results. For more details see [5, 11, 15, 17, 19].

Tanks

It is a particular case of a cylinder (chamber) with a fixed volume. Therefore, its model is

similar to the cylinder model with neither piston work nor combustion heat generation. In

this work the tank is also considered as adiabatic. The links between each tank and the set of

manifolds connected to them is solved using the same valve model used for the cylinders but

now considering the flow area to be the same as the cross section of each tube connected to

the tank.

Junctions

Branch junctions are frequently found in the intake and exhaust systems of multi-cylinder

internal combustion engines. They are one of the most complex boundary conditions for

wave action models. The one employed in this work [10] is based on the following

equations:

mass balance at the junction

energy balance at the junction

the conservation of the incoming Mach lines characteristic corresponding to each

pipe end

the conservation of the incoming path lines characteristic

the pressure is uniform in all the N branch junctions

the equalizing of the outgoing entropy or enthalpy

Let the junction be defined as the intersection of p incoming tubes and q outgoing tubes,

with N q p = + the total number of tubes at the junction. Mathematically this model can be

written as:

1. mass conservation

j j j j j

N

j

j

n u F m with m = =

=

1

0

2. energy conservation

)

2

1

) 1 (

( 0

2

2

1

j

j

j

j

N

j

j

u

c

m h with h +

= =

=

3. conservation of the incoming Mach lines

, ,

( ) ( )

j j j in j in j

dp du

c j

dx dx

+

4. conservation of the incoming path lines

9

2

,

( ) ( )

j j in j

dp dp

c j p

dx dx

5. equal pressure at all branches

i j

p p i j =

6. equal entropy at all the outgoing branches

2

2

2 2

1 1

( ) ( ) , ,

( 1) 2 ( 1) 2

j

i

i j

c

c

u u i q i j j q

+ = +

All the models above are solved in a time marching procedure using an explicit scheme; the

nonlinearities are solved by a Newton method that proves to be very robust.

Code calibration

This section starts with a preliminary numerical example in which the results achieved with

the 1D engine simulator serve as rough calibration of the code for future design purposes.

Other numerical results and also experimental measurements are available for this example

[19].

This example is a good starting point to detect differences in the code implementation prior

to moving to real engine tests in which the differences in the results come from several

factors very difficult to identify, specially those concerning data uncertainties. Many other

academic examples not included in this paper have been tested showing in general a good

agreement.

An academic example

The table below shows the main parameters of the engine used for this preliminary example.

The rest of the data set is described in the related literature [19].

Engine Model FIAT, 4 cylinder GDI

Displacement volume 1.60E-03 m

3

Bore x Stroke 0.08051 x 0.0784 m

Rod connected length 0.1285 m

Compression ratio 11.5

IVO IVC (lift = 0.0001 m) 7 BTDC 47 ABDC

EVO EVC (lift = 0.0001 m) 45 BBDC 5 ATDC

Table 1: Engine data Example 1

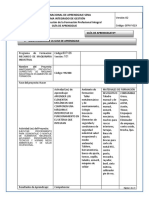

The engine configuration is sketched in figure, 1 which shows an EGR valve recycling

burned gases from the exhaust to the admission. The main goal of this example is the tuning

of the EGR and throttle valve openings for a preset value of the residual gases trapped in the

cylinder charge to have an idea about the control of this kind of system.

One of the main changes relative to the original problem definition is the usage of a different

valve lift profile where only the maximum lift and the timings were kept. Another difference

10

is the absence of a swirl valve placed at the intake port. In this example, only a straight tube

was placed with only one valve having the same geometric area as the two valves of the

original configuration.

The original work includes simulation with and without EGR system and for three engine

speeds. In this work we only include results with the EGR system.

Figures 2 to 4 show the pressure at the intake plenum for 1000 rpm, 2000 rpm and 4000 rpm

respectively. Increasing the engine speed produces an increment in the amplitude of the

pressure waves located at the intake plenum and also a change in the shape of the pressure

wave. Figures 5 to 7 show the intake plenum temperature where the mean value ncreases

drastically with the engine speed, as well as the amplitude of the temperature variation

inside this tank.

Intake

Plenum

EGR

valve

Intake

manifolds

Exhaust

manifolds

Cylinders

Catalytic

converter

Muffler

Throttle

valve

Air

Cleaner

Figure 1: Engine configuration Example 1

11

Figure 2 Plenum pressure 1000 rpm with EGR

Figure 3 Plenum pressure 2000 rpm with EGR

Figures 8 to 10 show the cylinder trapped mass. There is more trapped mass for 2000 rpm

than for 1000 rpm, but increasing to 4000 rpm produces a drop of the mass trapped probably

due to a lack of intake and exhaust tuning.

12

Figure 4 Plenum pressure 4000 rpm with EGR

Figure 5 Plenum temperature 1000 rpm with EGR

13

Figure 6 Plenum temperature 2000 rpm with EGR

Figure 7 Plenum temperature 4000 rpm with EGR

14

Figure 8 cylinder trapped mass 1000 rpm with EGR

Figure 9 cylinder trapped mass 2000 rpm with EGR

15

Figure 10 cylinder trapped mass 4000 rpm with EGR

16

Experimental data and results

The following tables show some experimental data and results.

Regime (rpm) Plenum

pressure

(Pa)

Plenum

temperature

(Kelvin)

Exhaust

temperature

(Kelvin)

1008 8.38E+04 335 493

2005 9.01E+04 334 657

3999 6.75E+04 355 998

Table 2(a): Experimental results Example 1

Regime

(rpm)

Trapped Mass

(Kg)

% EGR

1008 0.302E-03 29.2

2005 0.330 E-03 18.5

3999 0.259 E-03 11.2

Table 2(b): Experimental results Example 1

The diameters of the throttle and EGR valves are included in the following table:

Throttle valve EGR valve

1000 rpm

EGR

0.010 m 0.006 m

2000 rpm

EGR

0.014 m 0.0073 m

4000 rpm

EGR

0.016 m 0.007 m

Table 2(c): Experimental data Example 1

In this example the strategy was based on fixing the throttle and EGR valve diameters

according to table 2 (c), and the trend of the results obtained was in agreement with a similar

analysis over the available measurements, specially with EGR, trapped mass and the average

values of pressure and temperature at the intake plenum.

Real engine test

This methodology was used on two types of engines: a Mitsubishi Lancer with a direct

acting overhead cam-valve gear configuration and an overhead valve cam in block valve

gear Chevrolet engine. For the sake of brevity, only results on the latter are included here.

17

As mentioned above, the ultimate goal of this test is the manufacturing of a new and more

promising camshaft that will improve engine power performance.

The numerical strategy adopted for this task is below:

1. Finding a new valve timing capable of enhancing the power curve in a wide range of

engine speeds using the engine simulator. No fuel consumption and emissions were

taken into account.

2. An optimal valve profile [23] based on kinematics arguments is obtained with this

new valve timing.

3. With this valve profile the corresponding cam profile is generated by an inverse

method using Mecano software.

4. A computational prediction of the new cam profile dynamic response inserted in the

valve train is done using Mecano software. Geometric interferences, mechanical

stresses and valve floating are the main topics to be analyzed.

The first step is purely a thermodynamics and gas dynamics analysis, the second and the

third are based on geometric arguments and the last is a mechanical verification of the

design.

Six cylinder engine test Stage 1

The first item above consists in optimizing the engine performance mainly by changing the

valve timings. Changes in the maximum valve lift were avoided because the piston and the

valve are closely mounted to allow for changes in this value in the current operation of this

engine.

This first task was performed using the engine simulator presented in this paper.

The engine configuration of the six cylinder Chevrolet engine is shown in figure 11, and

details about it are included in the next paragraphs.

Sensor 1

Intake

manifold

Cylinder

Exhaust

manifold

Sensor 2

Sensor 3

Sensor 4

Figure 11: six cylinder engine configuration

18

Intake manifolds: formed by ten tubes and four junctions connecting them. The carburetor is

considered to be at wide open throttle, and due to this operation condition the pressure drop

through it is neglected. The wall temperature of these tubes is considered uniform at a value

of 293 Kelvin degrees.

Cylinder head: formed by a piece of manifold modeled as a tube and a valve modeled as a

nozzle for each side, the intake and the exhaust ports.

Cylinder: with 0.097m of bore, 0.0675m of stroke, connecting rod length of 0.163m and a

compression ratio of 9.5:1. The wall temperature was taken in relation to data available from

the experimental data set, mainly the oil and water temperature.

Exhaust manifold: formed by nine tubes and three junctions

Calibration of six cylinder engine

In order to make the predictions more accurate, a calibration of the engine simulator with

experimental measurements obtained from a real engine test is needed. After this process, it

is possible to propose some modifications in order to improve the engine design. The

mathematical model of the engine contains some uncertain parameters that introduce errors

in the computation. Supplementing the model with information from the real test minimized

those errors. The following data coming from the real test were used:

a) Flowmeter: The flow rate of air through the cylinder head as a function of the lift of

the valve is measured. This test is performed in a static way, modifying the position

of the valve step by step and forcing the air through the gap between the valve and

the seat through a vacuum of ten inches water column. Thus it is possible to get an

idea of the influence of the three dimensional effects present in the cylinder head,

which was not considered with the engine simulator. On the other hand, the dynamic

behavior coupled with the three dimensional flow pattern is not reproduced by this

type of test. However, this kind of information is useful in order to adjust the flow

rate of fresh mixture through the cylinder head. By comparing these measurements

with those obtained doing the same test in a virtual way it is possible to compute the

discharge coefficient, which is one of the parameters to be adjusted.

b) Air consumption : the information of the air consumed by the engine in the real test

is also available. It is very useful information when it comes to doing extra

adjustment of the discharge coefficient with the engine speed.

19

DISCHARGE COEFFICIENT

0,00

0,05

0,10

0,15

0,20

0,25

0,30

0,35

0 5 10 15 20

Valve lift [mm]

C

D

Figure 12: Discharge coefficient from flowmeter measurments

Figure 12 shows a typical discharge flow coefficient curve obtained through a port

flowmeter test

c) Exhaust temperature: One of the main drawbacks of most engine simulators oriented

to race applications is the need to introduce estimations of the combustion duration.

As the combustion is modeled with a single zone model, it is one of the main

unknown parameters that should be input in the computation. As far as the authors

know, the novel methodology proposed in this paper, which is able to estimate the

combustion duration through measurements of the exhaust temperature, has never

been published before in the related bibliography. In the real test some thermocouples

were placed at a distance of 0.300 m from the cylinder head. By working out

averages with these temperature values over the six cylinders and repeating these

measurements for the whole range of engine speeds used in its normal operation, it is

possible to get an idea of how long the combustion lasts as a function of the engine

speed. When plotting the temperature curve versus. rpm and approximating this

behavior with a curve, the following two features should be remarked:

1- The slope of the approximate curve represents the sensitivity of the

combustion duration with the engine speed, i.e. the ratio between the time

consumed for the combustion of the whole fresh mixture at high engine speed in

relation to that at low engine speed. This argument is based on the assumption

that the increasing in the exhaust temperature may be caused by a delayed

quenching of the flame front.

2- The value of the exhaust temperature represents how long the combustion

takes for an specific engine speed.

This assumption was checked on the engine simulator using different combustion durations

and keeping the ignition angle fixed until the exhaust temperature away from the cylinder

agrees with the experimental measurement. These computational results allow us to quantify

this lack of information about the combustion duration. On the other hand, looking at the

20

torque and fuel consumption plots of the real engine it is possible to enforce the combustion

duration results obtained with the above mentioned procedure.

d) Torque and power curve: This information is used to scale the convective heat

transfer film coefficient in the Woschni or Anand model. This parameter mainly

change the level of engine power keeping the curve shape unaltered.

150

170

190

210

230

250

270

5500 6500 7500 8500 9500 10500

Curve 1 Curve 2

Figure 13: Power for different convective film coefficient

Curve number two in figure 13 was obtained using a convective film coefficient smaller than

that of curve number one producing a larger power.

e) Fuel and air consumption. Fuel and air flow rate allows us to adjust the

equivalence ratio of the fresh mixture going into the engine. This information is

necessary due to the fact that the engine tested uses carburetor for fuel metering.

The table below summarizes the strategy adopted :

Real Data Adjusted variable

Head cylinder flowmeter Discharge coefficient

Exhaust temperature Combustion duration approximated

by a straight line

Torque and power Convective heat transfer coefficient

Fuel and air consumption Equivalence ratio of fresh mixture

Table 3: Real data and adjusted variables used for calibration

Results after calibration

In the pictures below both the simulation results and the experimental ones obtained in the

laboratory can be plotted.

Figure 14 shows the torque and power curve, figures 15,16 and 17 show the temperature of

the exhaust gases, the air flow rate and the fuel consumption respectively.

21

The difference between the simulated and the real fuel consumption is mainly related to the

fuel metering of the engine; the carburetor in the real engine does not keep the equivalence

ratio fixed with the engine speed (rpm), and the engine simulator was used with a fixed

value obtained by an average of the real ones.

After the calibration the curves achieved by the engine simulator agree quite well with the

real ones.

Remarks

1. the simulator has the necessary calibration to be used as a good diagnostic tool for

this engine,

2. after the calibration, improvement of the engine is feasible. In order to achieve this,

one of the main variables to optimize are the valve timings.

3. Regarding the assumption of the variable combustion duration in relation to the

engine speed, the fuel consumption (figure 17) does not show a significant variation

at different engine speeds while the torque (figure 14) drops drastically at high rpms.

Assuming that the fuel is completely burned, the fact that the combustion duration at

high rpm is longer than that at low rpm can be inferred.

150

170

190

210

230

250

270

290

5500 6500 7500 8500 9500

rpm

[

H

P

]

[

N

m

]

Torque_Sim Power_Sim Torque_exp Power_exp

Figure 14: Experimental versus simulation torque and power

22

800

900

1000

1100

1200

1300

1400

1500

5500 6500 7500 8500 9500 10500

rpm

[

F

]

Temp_Sim Temp_exp

Figure 15: Exhaust temperature

800

900

1000

1100

1200

1300

1400

1500

5500 6500 7500 8500 9500 10500

rpm

[Lbs/Hr]

Mass air sim Mass air exp

Figure 16: Air mass flow rate

23

70

75

80

85

90

95

100

105

110

115

5500 6500 7500 8500 9500

rpm

[Lbs/hr]

Mass fuel sim Mass fuel exp

Figure 17: Fuel mass flow rate

Intake and exhaust optimization

The optimization of the engine is defined in terms of the description of the objective

function, the constraints and the variables to be modified.

With regard to the objective function, the main goal is the improvement of the power curve

at a specified engine speed range. At first sight there is no constraint in this problem; only

lower and upper bound for the variables are desirable.

The variables chosen for the optimization task are the angles where the intake and the

exhaust valves open and close.

The modification of the valve timings achieved during the engine optimization may require

changes in the camshaft design depending on how this changes are selected.

Before making the decision of building a new camshaft, some simple modifications were

explored. The computational analysis was divided in three stages:

1. keeping the original camshaft, only the position of both cams in relation to the

crankshaft were modified.

2. modifying the position of the two cams independently

3. building a new cam profile

Stage 1:

Figure 18 shows the original configuration and two modifications, one with an advance of

three degrees and the other with a retard of three degrees in relation to the original one.

These curves show that while the engine power is improved at high engine speeds, with a

retarded timing at low engine speeds the timings needs to be advanced.

24

Stage 2:

This stage was divided in two parts, the first with the exhaust valve timing being fixed in the

original position and moving the intake valve timing, and the second with the intake valve

fixed and changing the exhaust valve timing forward and backward from the original

position. Both results can be seen in figures 19 and 20. Gains and losses should be seen as a

percentage relative to the original configuration.

Stage 3:

Finally, a completely new profile was adopted in which the timings were moved separately.

Figure 21 shows the behavior when modifying the intake valve and keeping the exhaust

valve fixed to the original timings and figure 22 shows the behavior when the exhaust valve

is modified keeping the intake timings fixed to the original values. For example, AAA+5

means an advance of 5 degrees in the intake valve opening in relation to the original value,

the intake valve close and the two exhaust timing being fixed to the original values.

98,5

99,0

99,5

100,0

100,5

101,0

101,5

102,0

102,5

5800 6800 7800 8800

RPM

[

%

]

3 delay Original 3 advance

Figure 18: Stage 1- comparison of curves with different camshaft positions

25

98,5

99,0

99,5

100,0

100,5

101,0

101,5

5800 6800 7800 8800

RPM

Adv 6 Adv 3

%

Delay 3 Delay 6

Figure 19: Stage 2- comparison of curves with different intake camshaft positions

97,0

98,0

99,0

100,0

101,0

102,0

103,0

5800 6300 6800 7300 7800 8300 8800 9300

RPM

[

%

]

Adv 6 Adv 3 Orig

Delay 3 Delay 6 Delay 9

Delay 12 Delay 15

Figure 20: Stage 2- comparison of curves with different exhaust camshaft positions.

26

98,5

99,0

99,5

100,0

100,5

101,0

101,5

102,0

102,5

5500 6000 6500 7000 7500 8000 8500 9000 9500 10000

RPM

[

%

]

IVC+5 IVC+10 IVO-5 IVO-10

Figure 21: Stage 3- comparison of curves with different intake camshaft positions

99,0

100,0

101,0

102,0

103,0

104,0

105,0

106,0

107,0

5500 6000 6500 7000 7500 8000 8500 9000 9500 10000

R P M

[

%

]

EVO-5 EVO-10 EVC+5 EVC+10 Serie3 IVO-10 and EVC+10

Figure 22: Stage 3- comparison of curves with different exhaust camshaft positions

27

The most relevant conclusion about this optimization task is shown in figure 22, where the

power improvement at almost all engine speeds is obtained modifying only the exhaust

valve close timing. Figures 23, 24 and 25 help clarify the reason of this behavior. The

higher the gas flow rate at the overlapping angles, the lower the pressure inside the cylinder,

which helps get more fresh mixture during the intake stroke. These figures were obtained at

8500 rpm close to the rated speed.

-300 -200 -100 0 100 200 300

0

50

100

150

200

250

VELOCITIES THROUGH VALVES

[m/s]

Figure 23: original configuration (blue) and EVC+10 (red)

-300 -200 -100 0 100 200 300

-0.1

-0.05

0

0.05

0.1

0.15

0.2

MASS FLOW RATE THROUGH VALVES

[Kg/s]

Figure 24: Original configuration (blue) and EVC+10 (red)

28

-300 -200 -100 0 100 200 300

0.6

0.8

1

1.2

1.4

1.6

1.8

2

CYLINDER PRESSURE

[atm]

Figure: 25: Original configuration (blue) EVC+10 (red)

Further remarks

From the optimization point of view, it can be concluded that the power improvement of this

engine is exhaust valve timings- sensitive, specially at the closing phase, while the intake

timings do not produce significant changes.

An introduction to mechanical analysis

A number of factors should be considered in the design of motor engine valve trains and

cams, which may be briefly classified into thermodynamics, gas dynamics and mechanical

ones.

The maximum valve lift and the valve timings are determined according to thermodynamics

and gas dynamics considerations as presented in the above sections. After finding the best

valve timings from the engine power optimization point of view, the mechanical analysis is

used to build a feasible camshaft whose computed timings and optimal valve lift profile

warrant a safe mechanical behavior. The main goal is to find a way to reproduce the above

defined timings in an optimal way from the mechanical point of view. This task is split in

the following three parts:

1. an ad-hoc novel software is employed to produce an optimal valve lift profile with

several constraints. [23]

2. the next step transforms the valve profile in a cam profile through an inverse

kinematics synthesis.

3. Finally this cam profile is placed inside the whole valve train mechanisms and it is

verified through a dynamical analysis.

29

For the last two steps Mecano multibody software was used [24].

Structural considerations are taken into account both to satisfy thermodynamics, gas

dynamics and mechanical factors, and to keep the structural integrity of the mechanism and

optimize its performance.

To this aim, efforts should be minimized to work within the allowable stress

levels, and jumping between cam and follower should be avoided.

Further complexity appears because of nonlinearities introduced by the kinematical chain

usually interposed between cam and valve. Last but not least, the feasible solution space is

restricted to avoid mechanical interferences.

In [23] a systematic procedure for optimal cam design was presented and this code is applied

in the first step of this work.

After properly defining an optimization problem and solving it, a valve lift profile is

computed as input data to a mechanical synthesis phase of analysis in which the cam profile

required to reach the desired valve motion is the output result, i.e. the second step.

Finally, in the third step, the whole mechanical system is dynamically analyzed in order to

validate the operation conditions.

Optimal Cam profile

Among the various mechanical design factors that influence the design of cams for motor

engine valve trains, we take into consideration geometrical interferences and dynamic

forces. Even though the considerations below were used for overhead cam end pivot rocker

arm valve train configuration, their applications to pushroad type are similar.

Interferences

The intake valve opening and exhaust valve closing are carried out in the area of the piston

top dead centre (TDC). Since the distances between valves-piston and also between valves

themselves are very small, it is necessary to detect and avoid any possible geometrical

interference during the design of valve motion. This factor is very critical especially in

engines with large valves overlapping.

Dynamical forces

In order to reach the maximum valve lift L in the time interval when the valve remains open,

it is necessary to specify a motion profile that satisfies not only the above mentioned

interference constraints but also the following dynamic restrictions [25]:

no jumping between cam and follower,

no impact in the valve seating,

maximum stresses bounded for reliability and minimal wear.

Spring dynamics also plays a fundamental role in high speed cam follower systems. At high-

speeds, springs may lose force due to an internal resonance. This resonance may be excited

by high-order harmonics of the cam lift at any speed. Distributed-parameter models of the

spring have been proposed to simulate the spring dynamics [26, 27, 28, 29, 30, 31].

Modelling of coil clash phenomena has been taken into account using a moving boundary

technique [32]. Furthermore, spring designs with variable cross section have also been

proposed to minimize amplitude of spring resonance [33]. Nested springs are used to

introduce dissipation by Coulomb friction between inner and outer spring coils and damp

30

internal resonance. The estimation of friction values is a difficult task, so various forms of

predicting them

have been proposed [27, 34].

Constrained Optimization Strategy

In this section we present some brief details about the optimization problem

fully explained in the original paper [23] Motion in time of motor valves may follow the

general description in figure 26.

rise

dwell

return

u

a

a

low

a

high

Figure 26: Valve acceleration profile shape function

Five zones can be distinguished: initial ramp, acceleration, spring-control, deceleration, and

final ramp. Ramps are designed to strike the cam-follower at a given velocity and to allow

some amount of clearance between cam and follower at the closed position. At the end of

the ramp, the valve is accelerated by a curve of increasing slope. The curve should be such

that transmitted load does not suffer sudden changes and the valve effectively follows the

cam. While moving under spring control, the valve decelerates up to reaching zero velocity

and then accelerates downward until closing, passing through a deceleration zone and final

ramp [25].

The maximum values of positive acceleration are limited by the maximum efforts the system

can sustain. On the other hand, in the spring-controlled zone, the negative acceleration

imposed by the cam profile should be lower than a given limit in order to make the inertia

load a fraction of the available spring force and avoid jumping. As mentioned before,

31

thermodynamics and gas dynamics factors are used to select both the maximum valve lift L

and the valve timings

VO

(valve opening angle) and

Vc

(valve closing angle) are assumed

as input data for the mechanical analysis. represents the crank angle. Valve motion is

induced through an imposed smooth profile of acceleration as follows:

( ) ( )

=

=

N

j

j

a a

1

where

( )

( )

| |

( )

| |

>

<

=

j

j j

j j

j

j

j

j

e a

e a

a

0

1

1

0

5 . 0

5 . 0 1

1

1

with

2

1

5 . 0

j j

j

+

= =

where

j

is the length of the interval | |

j j

,

1

Function ( )

j

a can be seen as a smoothed

rectangular profile, with support | |

j j

,

1

and height

j

a . Parameter controls smoothness

(and thus, jerk): for large values of accelerations are closer to a rectangular profile. In

practice a value of 7 = is generally adopted, which gives a smooth enough accelerations

profile. Velocities and displacements can be obtained by time integration. Looking at figure

26 three zones can be distinguished in the valve motion: rise, upper dwell and return.

Moreover, the valve motion is parameterized in terms of the set of angles 11 , 1 , , =

j

.

These parameters are not independent, and it is possible to extract a subset of only six free

parameters using the following considerations: The initial and final angular displacements

0

and

11

are equal to the valve opening and closing angles

VO

and

VC

. During the rise

phase, the motion profile should verify the conditions~:

( ) ( )

( ) ( ) 0

5 5

0 0

= =

= =

v L u

v v h u

ramp ramp

During the return phase, the motion profile should verify the conditions:

( ) ( )

( ) ( )

ramp ramp

v v h u

v L u

= =

= =

11 11

6 6

0

Here,

ramp

h and

ramp

v are the height and velocity of the quietening ramps (at the design

speed). Ramps are added to ensure that the valve contacts the valve seat at a maximum

speed equal to

ramp

v , low enough to minimize impact forces and avoid jumps, regardless of

the actual value of clearance [35]. Typical values of valve velocity are approximately 0.4 to

32

0.6 m/sec, and clearance of about 0.0001 to 0.0002 m is used between cam and follower.

From the conditions mentioned for the rise phase some angles can be eliminated from the set

of independent parameters. Doing the same for the return phase and after some algebra we

finally get the selected values for parameterization of motion that are the three first intervals

lengths plus the last three intervals lengths, i.e.:

{ }

11 10 9 3 2 1

*

=

Optimization

The objective of the design is to maximize the area below the lift curve in order to maximize

the net flow income. Defining the flow area as:

( )

d u

VC

VO

This integral can be evaluated as

=

=

11

1 j

j

A A with

( )

d u A

j

j

j j

=

1

The definition of the optimization problem is completed with the set of constraints:

No interference between valve and piston: the piston displacement in relation to the

closed position of the valve, projected along the valve axis, can be written as:

( ) ( ) ( ) ( ) ( ) cos sin cos 1

2 2 2

|

.

|

\

|

+ + =

c b b c

a l l a x

where

c

a is the crank radius,

b

l is the connecting-rod length, is the free displacement of

the valve when the piston is at the TDC

0

, and is the angle between the valve axis and

the piston axis. Then, the condition of non-interference can be expressed in the form:

( ) ( ) 0 x u

No interference between the valves: in order to avoid interference between valves,

the valves displacements

int

u ,

exh

u for which each valve touches the other are first

determined. Then the intake valve displacement profile without this particular

constraint is computed.

Afterwards, the exhaust valve displacement profile is calculated which verifies

( )

int

> <

exh

u u

where

int

is the crank angular displacement from which ( )

int

u u > at the intake valve.

33

Positive interval lengths: the interval lengths should be greater than or equal to zero

11 , 1 , 0 = j

j

Positive valve displacement: the computed valve displacement should be greater than

zero, i.e.

( ) 0 u

The objective function and restrictions are scaled so that the optimization problem is well

defined. An optimization problem is therefore defined, whose solution

( ) ( )

* *

max arg A

opt

=

is computed using standard routines for constrained optimization.

Remarks:

As mentioned before, the valve train configuration used for this development was an

overhead cam end pivot rocker arm. As in this work the engine has a pushroad type

configuration, two minor modifications are implemented: there is no interference between

valves and the acceleration shape functions normally have not a dwell zone. For the latter

an overlapping between points 5 and 6 in figure 26 is imposed with a negative acceleration,

a zero velocity condition and maximum lift.

Mechanisms analysis

The valve train configuration is shown in figure 27. It is composed by several mechanical

elements modeled by a multibody system approach and solved by finite elements. The main

elements are described in the following paragraphs. This model is fully parametric and the

configuration is mounted from a set of geometric data.

Figure 27: Valve train configuration

34

Cam and follower : In the kinematics synthesis or inverse problem we input the valve

movement and we replace the unknown cam profile and its follower by a distance captor

that measures the distance between the end of the hydraulic valve lifter and the center of the

camshaft. The result is the temporal variation of this distance that allows us to draw the cam

profile. In the dynamic or direct analysis, the cam and follower pair are linked by contact

forces, the cam profile input from the inverse synthesis being the medium by which the

whole valve train movement is entered. The follower may be plane or curved with a user

specified radius. In order to avoid numerical drawbacks associated with the contact between

cam and follower, the cam profile is smoothed through a spline curve approximation and its

profile is composed by approximately 180 points written in polar coordinates.

Hydraulic valve lifter: in the multibody system this mechanical element is modeled as a

rigid body and its mass is the main parameter to be input.

Hydraulic valve lifter and pushrod coupling: this is solved using a spring which works only

in compression with a stiffness coefficient similar to that of steel.

Pushrod: the flexibility was considered only for this mechanical element, and the pushrod

was split in N parts. In this work N=4 was used, but this value can be modified by the user.

Rocker arm: this was modeled as a rigid body with a specified mass and mass moment of

inertia about its pivot. The coupling between the rocker arm and the pushrod is solved by

another spring that works only in compression load with no reaction in traction load. This

gross representation of the real linkage is enough for our goals because the latter is evidence

of a mechanical failure in the valve train in which case the simulation should not continue.

On the other hand, the coupling between the rocker arm and the valve stem is modeled by

another cam and follower element solving the contact forces in detail for the verification of a

valve floating condition.

Valve spring: The force exerted by the valve spring in a running engine deviates

substantially from its static values. The reason for these deviations is that the spring has

internal oscillation modes, the so called spring surge modes. The lowest surge

eigenfrequency lies below the first valve train eigenfrequency, and both are strongly excited

at high engine speeds. The valve spring is a very elastic medium compared to the other valve

train components in which disturbances are transmitted longitudinally and relatively slowly

in the form of waves. The motion of individual elements is governed by the wave equation,

and one way of obtaining the spring force under dynamic conditions is to discretize the

spring into a large number of small spring elements. The external spring and internal springs

are split in N parts choosing N as the number of spring coils, eight in this work.

Valve: This element is considered as a rigid body The interaction between the valve and the

port seat has not been taken into account.

Mechanical simulation results

Taking into account the dynamical behavior at different engine speeds and considering that

the more interesting regime is above 8000 rpm, the engine speed has been swept between

8000 to 10000 each 150 rpm. Five cycles are done at each speed in order to stabilize the

35

engine operation which leads to a clear understanding of how the cam profile and the spring

dynamics interact with the rest of the valve train.

A comparison between the operation of the original configuration in relation to the modified

one allows us to check if the behavior of the new valve train configuration satisfies

mechanical criteria.

Some interesting results with this model are shown in the figures below. They are obtained

for one of the most representative engine speeds.

Figure 28 shows the contact force acting at the linkage between the main cam and its

follower Here the force never crosses through the horizontal axis and it is always of the

same sign. Therefore, it is never at a critical situation of valve floating. Next, figure 29

shows the external spring force evidencing the dynamic behavior of the spring. Even though

the valve is closed and remains at rest, the spring continues moving, and when the valve

starts to open at the next cycle the spring is not generally at rest. In this way, it is possible to

include the residual vibration caused by the spring internal modes in the analysis. Figure 30

plots the lateral displacement of the pushrod, which shows the flexural behavior of this

element and its own dynamic response caused by the inclusion of the flexibility component.

Finally, figure 31 shows the contact force acting at the linkage between the rocker arm and

the valve stem where once more the curve does not cross over the horizontal axis,

evidencing that contact is always warranted.

SAMCEF APR 2 2003 08:52:00

Stress (ORD.)

Time (ABS.)

0.6500 0.6550 0.6600 0.6650 0.6700 0.6750 0.6800 0.6850 0.6900

Time

100.

Str.(EL=401 C=1)

-100.

-200.

-300.

-400.

-500.

-600.

-700.

-800.

-900.

-1000.

Figure 28: Cam follower contact force

36

SAMCEF APR 2 2003 08:56:16

Stress (ORD.)

Time (ABS.)

0.7300 0.7350 0.7400 0.7450 0.7500 0.7550 0.7600 0.7650 0.7700 0.7750 0.7800 0.7850

Time

-60.

Str.(EL=1005 C=1)

-80.

-100.

-120.

-140.

-160.

-180.

-200.

-220.

-240.

-260.

Figure 29: external spring forces

SAMCEF APR 2 2003 08:54:14

Displacement (ORD.)

Time (ABS.)

0.6850 0.6900 0.6950 0.7000 0.7050 0.7100 0.7150 0.7200 0.7250 0.7300 0.7350 0.7400

Time

0.2000

Displ.(N=605 C=1)

-0.2000

-0.4000

-0.6000

-0.8000

-1.

-1.2000

Figure 30: Lateral displacement of the pushrod

37

SAMCEF APR 2 2003 08:52:58

Stress (ORD.)

Time (ABS.)

0.7600 0.7650 0.7700 0.7750 0.7800 0.7850 0.7900 0.7950 0.8000 0.8050 0.8100 0.8150 0.8200

Time

-50.

Str.(EL=301 C=1)

-100.

-150.

-200.

-250.

-300.

-350.

Figure31: contact forces at the rocker arm and valve stem coupling

Conclusions

A valve train optimization procedure was presented in which gas dynamics, thermodynamics

and mechanical effects are included. This strategy allows us to have better control of some

design variables that prove to have a great influence over the volumetric efficiency of an

internal combustion engine. Besides, a new calibration methodology is proposed, which is

based on the linking of some uncertain critical parameters in the engine simulator data set

and some basic laboratory measurements. This procedure proves to be very efficient,

showing high agreement between numerical predictions and real observations. The whole

procedure finishes with the design description of the cam profile to be manufactured.

Acknowledgements

To Juan Tofoni for his work in part of this project, to Professor Alberto Cardona for his

guidance in topics related with multibody systems, to CONICET and UNR for their

financial support.

References

1. De Haller R.,.The application of a graphic method to some dynamic problems in

gases. Sulzer Technical Review, 1(6) (1945)

2. Jenny E., Unidimensional transient flow with consideration of friction, heat transfer

and change of section. Brown Boveri Review, 47(11) (1950)

3. Benson R., Annand W. & Baruah P., A simulation model including intake and

exhaust systems for a single cylinder four-stroke cycle spark ignition engine. Int. J.

38

Mech. Science, 17:97-124 (1975)

4. Takizawa M., Uno T., Oue T. & Yura T. ,. A study of gas exchange process

simulation of an automotive multi-cylinder internal combustion engine. SAE

Technical Papers Series 0410: 1-14 (1982)

5. Nigro N., Storti M. & Ambroggi L., Modelizacion numerica de un motor de

combustion interna monocilindrico, Revista Internacional de Metodos Numericos

para calculo y disegno en Ingenieria. 15(1): 21-54, (1999)

6. Hughes T. and Mallet M., A new finite element method for CFD: The generalized

streamline operator for multidimensional advection-diffusion systems, Comp. Meth.

Applied Mech. Eng, 58:305-328 (1986)

7. Tezduyar T. and Hughes T., Finite Element formulations for convection dominated

flows with particular emphasis on the compressible Euler equations, AIAA, 83-0125

(1983)

8. Harten A., A high resolution scheme for the computation weak solutions of

hyperbolic conservation laws. J. Comp. Physics, 49: 357-393 (1983)

9. Benson R., The Thermodynamics and Gas Dynamics of Internal Combustion

Engines. Clarendon Press, Oxford, I. (1982)

10. Corberan J., A new constant pressure model for N-branch junctions, Proc. Instn

Mech Engrs, 206:117-123 (1992)

11. Heywood J., Internal Combustion Engine. Fundamentals. Mc Graw Hill. (1988)

12. Ramos J., Internal Combustion Engine Modeling. Hemisphere Publ. Corp (1989)

13. Horlock J. & Winterbone D., The Thermodynamics and Gas Dynamics of Internal

Combustion Engines. Clarendon Press, Oxford, II. (1986)

14. Blair G., Design and Simulation of Four Stroke Engines. SAE Bookstore. (1999)

15. Engl G. & Rentrop P., Gas flow in a single cylinder internal combustion engine: A

model and its numerical treatment. Int. J. Num. Meth. Heat Fluid Flow, 2:.63-78

(1992)

16. Engl G., A fast solver for gas flow network. Proc. of tenth GAMM SEM,Kiel,

Numerical Fluid Mechanics (1994)

17. Corberan J.& Gascon M., TVD schemes for the calculation of flow in pipes of

variable cross-section. Math. Comput. Modelling 21:85-92 (1995)

18. Yacoub Y.& Bata R., Development and validation of a thermodynamic model for an

SI single-cylinder engine, Journal of Engineering for Gas Turbines and Power. 120:

209-216 (1998)

19. Alessandri M., Simulazione della fase di recambio della carica in un motore benzina

ad iniezione diretta, Tesi di Laurea, Univerita Degli Studi di Roma Tor Vergata,

Facolta di Ingegneria, Dipartimento di Ingegneria Mecanica (1999)

20. Annand W., Heat transfer in the cylinders of reciprocating internal combustion

engines. Proc. Instn. Mech. Engrs. 177: 973-980 (1963)

21. Borman G.& Nishiwaki K., Internal combustion engine heat transfer, Prog. in

Energy and combustion Science. 13: 1-46 (1987)

22. Chow A.& Wyszynski M., Thermodynamic modelling of complete engine systems-

a review. Proc. Instn Mech Engrs. 213-D: 403-415 (1999)

23. Cardona A., Lens L.& Nigro N., Optimal Design of Cams. Journal of Multibody

System Dynamics. 7: 285-305 (2002)

24. Samtech S.A., Samcef-Mecano, User Manual, Lige, Belgium (1996)

25. Taylor, C., The Internal Combustion Engine in Theory and Practice. MIT Press.

(1984)

26. Pisano, A. & Freudenstein F., An Experimental and Analytical Investigation of the

Dynamic Response of a High-Speed Cam-Follower System.- Part 2: A Combined,

39

Lumper/Distributed Parameter Dynamic Model. ASME Journal of Mechanisms,

Transmissions, and Automation in Design. 105: 699-704 (1983)

27. Hanachi, S. & Freudenstein F., The Development of a Predictive Model for the

Optimization of High-Speed Cam-Follower Systems with Coulomb Damping

Internal Friction and Elastic and Fluidic Elements. Journal of Mechanisms,

Transmissions, and Automation in Design, 108: 506-515. (1986)

28. Lin, Y. & Pisano A., General Dynamic Equations of Helical Springs with Static

Solution and Experimental Verification. Journal of Applied Mechanics. 54: 910-917.

(1987)

29. Unlusoy, Y. & Tumer S., Analytical Dynamic Response of Elastic Cam-Follower

Systems with Distributed Parameter Return Spring. Journal of Mechanical Design.

115: 612--620. (1993)

30. Schamel, A., Hammacher J. & Utsch D., Modeling and Measurement Techniques for

Valve Spring Dynamics in High Revving Internal Combustion Engines (1995.)

31. J. Harralson (ed.): Design of Racing and High Performance Engines, PT-53. SAE:

83-99. (1995)

32. Lin, Y. & Pisano A., Three-Dimensional Dynamic Simulation of Helical

Compression Springs. Journal of Mechanical Design. 112: 529-537 (1990)

33. Lin, Y., Hodges P. & Pisano A., Optimal Design of Resonance Suppression Helical

Springs. Journal of Mechanical Design 115: 380-384. (1993)

34. Unlusoy, Y. & Tumer S., Nonlinear Dynamic Model and its Solution for a High

Speed Cam Mechanism with Coulomb Friction. Journal of Sound and Vibration.

169: 395-407. (1994)

35. Heizler, H., Advanced Engine Technology. SAE International. (1995)

Das könnte Ihnen auch gefallen

- Modelado fenomenológico del proceso de combustión por difusión diéselVon EverandModelado fenomenológico del proceso de combustión por difusión diéselNoch keine Bewertungen

- TC Magazine 202Dokument48 SeitenTC Magazine 202Anonymous CuwlwJNoch keine Bewertungen

- Análisis del proceso de barrido en motores de dos tiempos pequeña cilindradaVon EverandAnálisis del proceso de barrido en motores de dos tiempos pequeña cilindradaNoch keine Bewertungen

- Diseno Del Sistema de Suspension de Un Vehiculo Monoplaza Tipo Formula SenaDokument73 SeitenDiseno Del Sistema de Suspension de Un Vehiculo Monoplaza Tipo Formula SenaBesller ZunigaNoch keine Bewertungen

- Cálculo termofluidodinámico de filtros de partículas de flujo de paredVon EverandCálculo termofluidodinámico de filtros de partículas de flujo de paredBewertung: 5 von 5 Sternen5/5 (1)

- 2012-8 Rendimiento Volumetrico PDFDokument18 Seiten2012-8 Rendimiento Volumetrico PDFRicardo Rioja RochaNoch keine Bewertungen

- Modelado Euleriano de flujo bifásico para el cálculo CFD de chorros diéselVon EverandModelado Euleriano de flujo bifásico para el cálculo CFD de chorros diéselNoch keine Bewertungen

- Configuración de SuspensionesDokument23 SeitenConfiguración de SuspensionesPablo CanelosNoch keine Bewertungen

- Estudio de los efectos de la post inyección sobre el proceso de combustión y la formación de hollín en motores diéselVon EverandEstudio de los efectos de la post inyección sobre el proceso de combustión y la formación de hollín en motores diéselBewertung: 5 von 5 Sternen5/5 (1)

- Comportamiento Dinámico Del AutomóvilDokument12 SeitenComportamiento Dinámico Del AutomóvilNyh CompeticionNoch keine Bewertungen

- Motor De Vórtice: Crear un tornado de fuego en turbinas para obtener más energíaVon EverandMotor De Vórtice: Crear un tornado de fuego en turbinas para obtener más energíaNoch keine Bewertungen

- Osciloscopio - Inyección A GasolinaDokument29 SeitenOsciloscopio - Inyección A GasolinaEDISON PUSAYNoch keine Bewertungen

- Sistemas de dirección electrohidráulicas y eléctricas asistidas HEPS y EPSDokument119 SeitenSistemas de dirección electrohidráulicas y eléctricas asistidas HEPS y EPSGilbertoNoch keine Bewertungen

- La Aerodinámica en La F1Dokument12 SeitenLa Aerodinámica en La F1javi_1_9_9_4_0Noch keine Bewertungen

- Suspensión PDFDokument17 SeitenSuspensión PDFdanielbrenlla100% (1)

- Tesis Freno Regenerativo Raul PDFDokument90 SeitenTesis Freno Regenerativo Raul PDFJanii ArandaNoch keine Bewertungen

- AleronesDokument5 SeitenAleronesLePadroteJefedeJefes0% (1)

- Susp - Clase - 1 - 2 SDokument19 SeitenSusp - Clase - 1 - 2 SRodrigo Barceló0% (1)

- Calculos y Terminos Mas Utilizados para Conocer El MotorDokument6 SeitenCalculos y Terminos Mas Utilizados para Conocer El MotorAlejandro González GaiteroNoch keine Bewertungen

- Ruville Juntas Homocineticas Cat PCDokument98 SeitenRuville Juntas Homocineticas Cat PCartemisa kemnisNoch keine Bewertungen

- Implementación de Intercooler FrontalDokument140 SeitenImplementación de Intercooler FrontalRobert Cuevas Poma100% (2)

- Formula para Fabricar HeaderDokument21 SeitenFormula para Fabricar HeaderBRAYAN MARQUEZ MORALESNoch keine Bewertungen

- ALERONDokument103 SeitenALERONGeorge GuerreroNoch keine Bewertungen

- Libro de Diseño y Fabricacion de TubularesDokument109 SeitenLibro de Diseño y Fabricacion de TubularesNALLELY THAMARA MOSCOSO DELGADONoch keine Bewertungen

- Ingeniero de PistaDokument54 SeitenIngeniero de PistaBimbo223344Noch keine Bewertungen

- Kit MetanolDokument7 SeitenKit MetanolGabrielNoch keine Bewertungen

- Circulacion CurvaDokument12 SeitenCirculacion CurvaAndres ArbitoNoch keine Bewertungen

- Diseño Aerodinámico y Simulación Computacional de Auto Eléctrico Solar Mediante CFD y Modelo de Turbulencia RansDokument92 SeitenDiseño Aerodinámico y Simulación Computacional de Auto Eléctrico Solar Mediante CFD y Modelo de Turbulencia RansFuad Mauad80% (5)

- Tecnica de Gases de Escape. Fund Del Motor de Gasolina 1 A 21 PDFDokument19 SeitenTecnica de Gases de Escape. Fund Del Motor de Gasolina 1 A 21 PDFJesusfdo Copa100% (1)

- Motores de émbolo y turbo: componentes y ciclo de operaciónDokument6 SeitenMotores de émbolo y turbo: componentes y ciclo de operaciónAbdiel NolascoNoch keine Bewertungen

- Gua de Setups en 21 PasosDokument3 SeitenGua de Setups en 21 Pasosjulian_ginesNoch keine Bewertungen

- Manual de Modificaciones de Motores Diesel para CompeticiónDokument6 SeitenManual de Modificaciones de Motores Diesel para CompeticiónSteve da Rivia100% (1)

- Sistema de Emisones de Gases Del Vehiculo LivianoDokument44 SeitenSistema de Emisones de Gases Del Vehiculo LivianoFrancisco AguirreNoch keine Bewertungen

- Ensayos Coast Down 1Dokument167 SeitenEnsayos Coast Down 1Daniel FredianiNoch keine Bewertungen

- Race Car Technology 24Dokument39 SeitenRace Car Technology 24Luis Tamayo100% (1)

- Múltiple de Admisión y Escape, TiposDokument63 SeitenMúltiple de Admisión y Escape, TiposBilly KingNoch keine Bewertungen

- Proyecto Aleron Coche CompeticionDokument69 SeitenProyecto Aleron Coche CompeticionLuis Tamayo100% (1)

- Calculo Diseño Colector EscapeDokument129 SeitenCalculo Diseño Colector EscapeCharlee Zozo75% (4)

- 03 Cap 1 Origen de Los Lubricantes OkDokument15 Seiten03 Cap 1 Origen de Los Lubricantes OkGamaliel Castro MontorNoch keine Bewertungen

- Electronica y Electricidad de CompeticionDokument30 SeitenElectronica y Electricidad de Competicionkris310Noch keine Bewertungen

- Motores Hemi Chrysler y DodgeDokument9 SeitenMotores Hemi Chrysler y Dodgedeviljin 979Noch keine Bewertungen

- Historia de La Aerodinámica en Los Autos de CarreraDokument11 SeitenHistoria de La Aerodinámica en Los Autos de CarreraAngela VazquezNoch keine Bewertungen

- Diseno y Simulacion de Motores de 2 Tiempos EspanolDokument599 SeitenDiseno y Simulacion de Motores de 2 Tiempos EspanolWilmer Salinas100% (1)

- Guia Practica F1 2002Dokument22 SeitenGuia Practica F1 2002Horacio MalpassiNoch keine Bewertungen

- Master Presencial 2019web 0Dokument28 SeitenMaster Presencial 2019web 0Mario LogachoNoch keine Bewertungen

- Chasis tubular para autos de competiciónDokument17 SeitenChasis tubular para autos de competiciónGerar Jalid GonzálezNoch keine Bewertungen

- Todo Sobre Los HeadersDokument17 SeitenTodo Sobre Los HeadersJulio Morales CuevaNoch keine Bewertungen

- Reparacion y Trucaje de MotoresDokument67 SeitenReparacion y Trucaje de Motoresxavier100% (3)

- Trabajo de Aerodinamica f1Dokument65 SeitenTrabajo de Aerodinamica f1Ricardo Hulett100% (1)

- Karting PDFDokument92 SeitenKarting PDFAnthony ToledoNoch keine Bewertungen

- Todo Lo Que Necesitas Saber Sobre El EscapeDokument13 SeitenTodo Lo Que Necesitas Saber Sobre El EscapeJesus BCNoch keine Bewertungen

- Aumenta la potencia de tu motor: Modificaciones sencillas y de tallerDokument35 SeitenAumenta la potencia de tu motor: Modificaciones sencillas y de tallerdiegopikadjNoch keine Bewertungen

- ESTUDIO DE DISEÑO Y FABRICACIÓN DE UNA MOTOCICLETA DE COMPETICION DE 125cc.Dokument169 SeitenESTUDIO DE DISEÑO Y FABRICACIÓN DE UNA MOTOCICLETA DE COMPETICION DE 125cc.Daniel León100% (3)