Beruflich Dokumente

Kultur Dokumente

Lecture 26

Hochgeladen von

owaisshafiOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Lecture 26

Hochgeladen von

owaisshafiCopyright:

Verfügbare Formate

Geosynt het i c s and y

Rei nf or c ed Soi l St r uc t ur es

Geosynt het i c Rei nf or c ed Pi l e Pl at f or ms

Dr. K. Rajagopal

f f C Professor of Civil Engineering

IIT Madras, Chennai, India

e-mail: gopalkr@iitm.ac.in

Construction on Soft Foundation Soil

Problems

(a) Slope instability

(b) Unacceptable vertical settlements

(From Lawson,2012)

(From Lawson,2012)

2

(c) Localised differential settlements at

embankment surface

(d) Difficulty to move the construction

equipment

( Concept- Lawson,2012)

Methods of Ground Improvement

Soil Replacement

Preloading Preloading

Light Weight Fill

Preloading ith Vertical Drain Preloading with Vertical Drain

Vacuum Preloading

Stone Column-OSC,ESC

Piled Raft

Basal Reinforcement

Piled Embankment

Geosynthetic Reinforced Pile Supported

Embankment

3

Geosynthetic Reinforced y

Piled Embankments

Rail/Road embankment Rail/Road embankment

Soft

clay

Pil I li d Piles Inclined

Piles

Firm stratum

Advantages of Geosynthetic Reinforced Piled g y

Embankments

Faster construction-Loading rate not dependent on the

rate of consolidation of soil

Eliminates differential settlements especially for large

height embankments

Slope stability

Relatively small pile caps and no need for raking piles

Low long term maintenance costs

5

Embankment Piling

CFA (Continuous Flight Auger) piles

Load Transfer Platform at Second Severn Crossing

13

Load Transfer Platform at Second Severn Crossing

(Tensar, UK brochure)

Measured data from Measured data from

Second Severn, UK

(Tensar, UK brochures)

14

( )

Application areas

Bridge abutment approach roads

(Buchanan 1984) (Buchanan,1984)

Airport runways (Hossain and Rao, 2005)

Subgrade improvement (Han, 1975)

Minimize differential settlements under storage

tanks (Alzamora et al. 2000)

Segmental retaining wall (Alzamora et al. 2000)

Widening of the existing roadway embankment

(Han and Gabr 2002)

To construct confined embankment structures

(Lawson 2012)

15

Construction Sequence

Installing piles with certain grid formation in the soft soil up to

a certain depth.

Geosynthetic material is laid on top of a thin layer (0.1 m) of

l t i l granular material.

After placing the geosynthetic p g g y

layer, the embankment fill is

constructed to the required

height in stages.

Fi ll th t ti h Finally the construction such as

railway or road pavement is

built on top of the embankment

16

built on top of the embankment

Geosynthetic Reinforced Piled Embankment System

Plan Layout of the Piles

L t ( ) S d (b) T i l

(a) (b)

Layout (a) Square and (b) Triangular

Geosynthetic Layout

(a) (b)

17

Optimal geosynthetic layout (a) direction of placing the layers and (b) direction of load

(Lawson,2012)

Load Transfer Mechanism

(b) Membrane action of geosynthetic

(a) Soil Arching

(b) Membrane action of geosynthetic

(Russell and Pierpoint,1997)

(a) Soil Arching

( ) C t ti f t d th il d t th (c) Concentration of stresses around the pile due to the

stiffness difference between the soft foundation

soil and the rigid pile

18

soil and the rigid pile

Design Methods

(a) British Standard-BS8006:1995

This is the most widely used method and is very conservative This is the most widely used method and is very conservative.

Based on Marstons (1913) formula for positive projecting ased o a s o s ( 9 3) o u a o pos ve p ojec g

conduits, Jones et al.(1990) developed an empirical relationship

for the ratio of average vertical stress acting on the pile caps to

the average vertical stress acting across the base of the

embankment .

where

c c

v

v

p C a

H

H

o

o

'

'

= =

'

p

c

'=Arched vertical stress on top of the pile

v

'=Average vertical stress on top of the pile

19

C

c

= Arching Coefficient (Marston 1913)

a = size of pile caps

Positive Projecting Conduit

(Marston,1913)

BS8006 adopted Jones et al.(1990) for the design of piled

b k t embankments.

BS8006 gives empirical equations for arching coefficient

as follows

c

C

as follows

c

End bearing piles,C 1.95 0.18

H

a

=

c

Friction piles,C 1.5 0.07

a

H

a

=

a

BS8006 considers two cases

1. Embankment height is below the

critical height of 1.4(s-a):

Arching is not fully

developed

Partial arching

20

Partial arching

Here A= Load acting on the piles due to arching, B= Load taken by the geosynthetic and

C= Load acting on the soft subsoil

( ) ( )

For 0.7 1.4 , s a H s a s s

( )

2 2

2 2

Load on the geosynthetic,

fs q s

c

T

v

s f H f w

p

W s a

s a

o

+ (

| |

=

( |

(

\ .

( ) 1

Geosynthetic Tension T 1

v

T

W s a

(

\ .

= +

r

Geosynthetic Tension, T 1

2 6

where is the geosynthetic strain

f are the partial fact

a

f

c

c

= +

ors used in the design

fs

f , are the partial fact

q

f ors used in the design

b k h i h i b 2. Embankment height is above

the critical height of 1.4(s-a):

Full arching is developed

21

Full arching

Height of embankment above arching height plays no Height of embankment above arching height plays no

role in the tension developed on the geosynthetic.

Same is the case with surcharge

( )

For H>1 4 s a

( )

( )

For H>1.4 ,

1 4

s a

sf s a

(

| | ( )

2 2

2 2

1.4

fs

c

T

v

sf s a

p

W s a

s a

o

(

| |

=

( |

(

\ .

( )

r

1

Geosynthetic Tension, T 1

2 6

T

W s a

= +

2 6 a c

22

Horizontal force at the slope

,| ,|

Horizontal force at the embankment slope after BS8006

(Satibi,2009)

Geosynthetic tensile load needed to resist the horizontal

f f th b k t i T

0.5 ( 2 )

h

rs a fs q

T K f H f q H = +

force of the embankment is T

rs

a

where

K Active lateral earth pressure coefficient

, = partial factors used in the design

fs q

f f

=

23

, p g

fs q

f f

(b) Hewlett and Randolph Method(1988)

This theory is based on limit state of soil in

hemispherical domed region over piles. p g p

The stability of arch at the crown and at the pile top of

h h i h i l d d d i h i the hemispherical dome formed defines the entire

stability.

24

Hemispherical domes (Hewlett & Randolph, 1997)

Stress Reduction Ratio ( S

3D

) defined as the ratio of the Stress Reduction Ratio ( S

3D

) defined as the ratio of the

average vertical stress acting on the reinforcement to

the overburden pressure due to the embankment fill was

1

used to check the stability.

( )

3

1

2

2

1

at the crown of the arch

2

1 1 1 1

1

p

D

k

p

p

S

k

a a a a

k

k

=

(

| |

| |

| | | || |

( + +

|

| | | |

|

\ . \ .\ .

(

\ .

( )

( )

( )

( )

2 1 k

( (

2

1

p

p

k s s s s

| | | |

|

+

\ . \ .\ .

(

\ .

\ .

( )

( )

( )

( )

( )

( )

2 1

3

2 1 2 1

at the pile top 1 1

2 2 3 2 2 3

p

k

p p

D

p p

s k s a k

a

S

s

H k H k

( (

| |

( ( = +

|

\ . ( (

( ) ( )

- Largest value is the critical S

3D

25

(c) The new German Method (EBGEO 2004)

In the old German approach the arching model

developed by Hewlett and Randolph (1988) was used to

calculate the stresses generated due to arching.

EBGEO 2004 adopts the m lti shell arching theor EBGEO 2004 adopts the multi-shell arching theory

based on the work of Zaeske (2001).

26

Multi shell arching theory adopted in New German Method

(Kempfert,2004)

3-dimensional soil element is considered and the

equilibrium of forces about the radial direction is used

to calculate the vertical stress coming onto the soil

, zo k

o

( ) ( )

2

2

2 2

, 1 1 2 1 1 2

4

g

zo k g g g

h

p

h h h h

h

_

_ _

_

k

k

o

| |

| |

| |

| |

|

|

= + + + + +

|

|

|

|

|

\ .

\ .

( ) ( )

,

4

g g g

h

|

|

|

|

\ .

\ .

\ .

\ .

where

( )

( )

2 2

2

2

1 21

2

where

1

1 2 ( )

, K=tan 45 , ,

2 8 8

crit

k

a K

s a s a

s a

s

|

_

'

+

(

= + = =

(

In the second step the vertical stress acting on the top of

, zo k

o

p g p

the subsoil is used to calculate the vertical load F

k

on

the geosynthetic.

27

Load distribution on the geosynthetic for rectangular pile layout

(Kempfert,2004)

( )

2

x,k ,

1

, F

2 2 180

y

Lx x y Lx zo k

x

s

a

A s s atn A

s

t

o

(

= =

(

( )

2

y,k ,

1

, F

2 2 180

x

Ly x y Ly zo k

y

s a

A s s atn A

s

t

o

(

= =

(

(

28

y

The maximum strain c

k

is obtained from the

dimensionless design graphs (EBGEO 2004)

k

J

w

L

Ers

b

dimensionless design graphs (EBGEO, 2004).

Here,

J t il tiff f th J

k

= tensile stiffness of the

geosynthetic (kN/m)

L

w

= (s-a)= pile clear spacing

b

Ers

= width of support

29

(EBGEO,2004)

Horizontal force at the slope

The additional horizontal force in the reinforcement The additional horizontal force in the reinforcement

beneath the embankment slope is given by

( ) ( )

1

E E h k P h k

| |

A

|

( ) ( )

,

ah

2

where K Active earth pressure coefficient

k ah k k k ah

E E h k P h z k

| |

A = = +

|

\ .

=

30

(d) The Dutch Method (CUR 226)

Introduced in 2009.

Adopts major parts of the German EBGEO 2004.

Flat terrain-thin embankments are constructed and

therefore the EBGEO method was modified to suit the therefore the EBGEO method was modified to suit the

requirements. (Eekelen et al.2010)

Main difference from EBGEO-Different set of load-

and-resistance factors were adopted in the Dutch

G id li Guideline.

31

(e) Guido Method

Guido et al. (1987) observed that the inclusion of stiff

biaxial geogrid within a granular fill improved the

bearing capacity of the foundation soil bearing capacity of the foundation soil.

Concluded that the angle of load spread through a Concluded that the angle of load spread through a

granular fill reinforced with geogrid would be at an

angle of 45 degrees.

The approach is mainly for a

single layer of geosynthetic at

the base of the embankment

fill.

( )

3

Stress Reduction Ratio=

D

s a

S

=

32

3

Stress Reduction Ratio

3 2

D

S

H

(f) The Swedish Method

Carlsson (1987) considered a wedge of soil with an

internal angle at the apex of the wedge equal to 30. g p g q

Valid in two-dimensional model.

Carlsson adopted a critical height of 1.87(s-a).

Miriam and George (2003)

presented the expression for p p

S

3D

for this model as per

Hewlett & Randolph (1997)

( ) ( )

( )

3

2

6 tan15

D

s a s a

S

H

+

=

+

33

( )

6 tan15 s a H +

Two dimensional model by Carlsson,1987

Rogbeck et al. (1998) modified this model into a 3D form

which is an inverted truncated pyramid

h di i l d l b b k l 1998

Modified form of this 3D arching model was adopted by

Three dimensional model by Rogbeck et al. ,1998

(Lawson,2012)

g p y

Nordic authorities (Svan et al.2000).

I N di d i th hi l id d t i l d

34

In Nordic design the arching angle was widened to include

an angle of arching between 68-75.

A i i U i C ll (R ll d Pi i 1997 H

Numerical Analyses-Different approaches

Axisymmetric Unit Cell (Russell and Pierpoint 1997, Han

and Gabr 2002, Yoo and Kim 2009)

3D Column (Yoo and Kim 2009, Jenck et al. 2009)

Full three dimensional analyses (Huang et al.2005,Liu et

al.2007)

3DColumn

Pile

Full Embankment

3

5

Axisymmetric unit cell

Major Numerical Work-3D Column

Russell and Pierpoint (1997) carried out a numerical study using Russell and Pierpoint (1997) carried out a numerical study using

FLAC

3D

to compare the different analytical methods.

-Terzaghi (1943), Hewlett and Randolph (1988) and BS 8006 g ( ), p ( )

Two cases were considered-The A13 piled embankment

(heavily reinforced) and the Second Severn Crossing

embankment (minimal reinforcement).

Design methods predicted differently for different embankment

geometries geometries

Tension force calculated by different design methods

Design Methods A13 Embankment

(Reinforcement Tension,

kN/ )

Second Crossing

(Reinforcement Tension,

kN/ ) kN/m) kN/m)

BS8006 73 491

Ter aghi 104 297

36

Terzaghi 104 297

Hewlett & Randolph 104 280

Han and Gabr (2002)

Major Numerical Work-Axisymmetric unit cell

Han and Gabr (2002)

investigated the influence

of the tensile stiffness of

the geosynthetic, the height

of the fill, and the elastic

modulus of the pile

material.

One layer of geosynthetic

was used and a full bond

was assumed between the

geosynthetic and the soil.

Major findings are given

below

Pile Layout and the axisymmetric model considered

for the analysis (Han and Gabr,2002)

37

below.

(a) (b)

Effect of (a) pile modulus and (b) geosynthetic stiffness on the maximum settlements

(Han and Gabr,2002)

The influence of geosynthetic tensile stiffness becomes less

important when the stiffness exceeds 4,000 kN/m.

( , )

For a pile of elastic modulus of 30,000 MPa, the maximum

ttl t f th i f d d d b 20% f

38

settlement for the reinforced case was reduced by 20% from

that for the unreinforced case.

(a) (b)

Effect of geosynthetic (a) Stress Concentration Ratio(b) Tensile force distribution

(Han and Gabr,2002)

(a) (b)

The inclusion of geosynthetic reinforcement enhances the

stress transfer from the soil to the piles.

Tension is not uniform along the geosynthetic and the

maximum tension occurs at the edge of the pile.

39

maximum tension occurs at the edge of the pile.

Major Numerical Work-Full three dimensional

Geogrid Reinforced Pile supported highway embankment Geogrid Reinforced Pile supported highway embankment

located in Shanghai China-Liu et al. (2007)

Case history back analyzed by 3D fully coupled finite-

element analysis.

Instrumented cross section of the embankment

40

Instrumented cross section of the embankment

(Liu et al.,2007)

Full three dimensional model developed

(Li l 2007) (Liu et al.,2007)

Significant load transfer from the soil to the piles due to soil g p

arching-contact pressure acting on the pile was 14 times

higher than that acting on the soil located between the piles.

Lateral displacements considerably reduced- stability of the

embankment increased significantly

41

embankment increased significantly.

Design of Geosynthetic Reinforced Piled Embankment

- Example

Pulverized fly ash filled

embankment

9 m

= 14kN/m

3

Pile caps

(1.1 m square) ( q )

Soft clay

(Without piles

settlement = 700 mm)

4 m

)

Embankment Details

Reinforcement details Reinforcement details

Low creep reinforcement

Tensile safety factor = 3.0

Peak extension at failure = 12%

Geotextiles

Longitudinal

Strength (kN/m)

Transverse

Strength (kN/m) g ( ) g ( )

A 1000 50 A 1000 50

Circular arc Deformation analysis

A

a = 4-1.1 = 2.9 m

A

2u

Geosynthetic

R

G

Assuming

b = 0.2 0.7= 0.14 m

T T

b 0.2 0.7 0.14 m

From the geometry

b

T

T

T

T

2

1

2

b

tan

a

u

=

a

11 03

2

.

a R sin

u

u

=

= 2

7 58

G

G

a R sin

R . m

u =

=

( )

1

2

T

R b

G

Weight of the fill , W =

52 08 W . kN m

T

=

Considering the reaction force as g

0 15 18.9 kN m

B

W . h = =

( )

The tension in the geosynthetic,

( )

251.5 kN/m

Consider a single layer of geosynthetic (Optimal)

T G T B

T R W W = =

Consider a single layer of geosynthetic (Optimal),

total strength = 1050 kN/m

The strain in the ge

G

251 5

otextile, 12 2 87

1050

.

% . % c = =

( )

G

From the geometry 90 0 6

G

R a . % c tu = =

As

G

< the predicted

G

p

Try with b = 0.19 m

u 14 93 u= 14.93

R

G

= 5.63 m

W

T

= 38.08 kN/m

T

T

= 108 kN/m

T

For this the strain

G,

from the load deformation data = 1.23%

F h 1 2% From the geometry,

G

= 1.2%

As these two are compatible the tension in the geosynthetic

T

T

= 108 kN/m.

G

= 1.2 %

G

Catenary Deformation analysis

From the Equation of the catenary, the tension in the

geosynthetic is given by g y g y

( )

2

1

1

a

T WT WB +

( )

( ) ( )

2

2 2

1

1

16 2

1

16 4 16

1 1 1

T

a

T WT WB a

b

b a b b

l

= +

(

( ) ( ) 2 2

1

16 4 16

1 1 1

8

2

G e

b a b b

log

b a

a a

c

(

+ = + + + +

(

1 69

Loading coefficient 0 12

c

c

. h

C .

B

=

c

1DArching: Pressure ratio = C B /h 1D Arching: Pressure ratio = C

c

B

c

/h

2DArching: Pressure ratio = (Cc B /h)

2

2D Arching: Pressure ratio = (Cc B

c

/h)

2

Loading Coefficient,

1 69

0 12 13.71

c

c

. h

C .

B

= =

Pressure ratio (1D) = C

c

B

c

/h = 1.676

Pressure ratio (2D) = (1.676)

2

= 2.809

In any 4 square piles,

o Pile area = 1.21 m

2

T l 16

2

o Total area = 16 m

2

o Soil area = 14.79 m

2

Total load = 16149 = 2016 kN Total load = 16149 = 2016 kN

Load on the pile = 1.211492.809 = 428 kN

Load on soil = 2016 428 = 1588 kN = 107 4 kN/m

2

Load on soil = 2016-428 = 1588 kN = 107.4 kN/m

2

W 107 4 kN/ W

T

= 107.4 kN/m

W

B

= 0.15 h = 18.9 kN/m

As per the equations shown earlier

T = 309 8 kN/m T

T

= 309.8 kN/m

From load-extension data

G

= (309.8/1050)12 = 3.5 %

Using the equation for 1+

G

as shown earlier,

G

= 3.4 %

As the two values are in close agreement further iteration is not As the two values are in close agreement further iteration is not

necessary.

BS 8006-1995 Method

According to BS8006, the minimum height of embankment

required is 0.7 (s-a) and for full arching to develop the height of the

embankment should be greater than 1.4 (s-a)

In the present case, 0.7(4 1.1) = 2.03 m < 9 m and

1.4(4-1.1)=4.06 m < 9 m

- Full arching develops in this case

The Arching coefficient (considering end bearing pile).

1 95

0 18

. H

Cc .

a

=

The vertical stress on the pile cap

= 15.77

2

2

15 77 1 1

C a

(

(

2 15 77 1 1

14 9 468 1 kN/m

9

c

c v

C a

. .

p .

H

o

(

(

= = =

(

(

For H > 1.4(s-a), The distributed load carried by the geosynthetic

reinforcement

( )

1 4s s a

(

| |

( )

2 2

2 2

1 4

176 85 kN/

c

T

v

. s s a

p

W s a

s a

(

| |

=

|

(

\ .

(Serviceability condition, partial factors in the equations are given a value of 1)

= 176.85 kN/m

Tension in the reinforcement (BS8006-Design strain is 5%)

( )

1

1 486 2 kN/m

T

W s a

T

= + =

Tension due to lateral thrust,

1 486.2 kN/m

2 6

r

T

a c

= + =

0 5 170 1 kN/m

L

T . Ka H . = =

Total tension = 656.3 kN/m

7 /

L

Results of Design

By Circular arc method

T

T

= 108 kN/m;

G

= 1.2 %; W

T

= 38.08 kN/m

T

;

G

;

T

By Catenary deformation method y y

T

T

= 310 kN/m;

G

= 3.4 %; W

T

= 107.4 kN/m

By BS 8006 1995 method

T

T

= 656.3 kN/m;

G

= 5 %; W

T

= 176.85 kN/m

T

656.3 N/ ;

G

5 %; W

T

76.85 N/

54

References

1. Alzamora, D., M. H. Wayne and J. Han (2000) Performance of SRW supported by geogrids and jet

grout columns Proc., ASCE Specialty Conf. on Performance Confirmation of Constructed Geotechnical

Facilities, Geotechnical Special Publication, 94, 456466.

2 British Standards BS8006: 1995 Code of practice for strengthened/Reinforced soilsand other fills 2. British Standards BS8006: 1995 Code of practice for strengthened/Reinforced soilsand other fills.

Section 8.3.3 British Standard Institution.

3. Carlsson, B. Reinforced soil, principles for calculation, Terratema AB, Linkping (in Swedish), 1987.

4. CUR 226 2010(2010) Dutch CUR design guideline for piled embankments. ISBN 978 90376-0518-1. ( ) g g f p

5. EBGEO (2004): Bewehrte Erdkrper auf punkt - und linienfrmigen Traggliedern, Entwurf Kapitel

6.9, 05/16/2004 version.

6. Guido, V.A., J.D. Knueppel, and M.A .Sweeny (1987) Plate loading tests on geogrid - reinforced

earth slabs Proceedings of Geosynthetics 87 Conference, New Orleans, 216-225.

7. Han, R. (1975) Piled Embankment Supported by Single Pile Caps. Proceedings of the Conference on

Soil Mechanics and Foundation Engineering, Istanbul, 1,283-290.

8 Han J and MA Gabr (2002) Numerical analysis of geosynthetic reinforced and pile supported earth 8. Han, J. and M.A. Gabr (2002) Numerical analysis of geosynthetic-reinforced and pile-supported earth

platforms over soft soil. Journal of Geotechnical and Geoenvironmental Engineering, ASCE,128(1),

44-53.

9. Hewlett, W.J. and M.F. Randolph (1988) Analysis of piled embankments. Ground Engineering, 21(3),

12-18.

10. Hossain, S. and K.N. Rao (2006) Performance Evaluation and Numerical Modeling of Embankment

over Soft Clayey Soil Improved with Chemico-Pile. Transportation research record, USA, Issue

Number: 1952, 80-89.,267274.

55

Number: 1952, 80 89.,267 274.

References

11. Huang, J., J.G. Collin, and J. Han (2005) 3D Numerical Modelling of a Geosynthetic

Reinforced Pile-Supported Embankment- Stress and Displacement Analysis16

th

International

Conference on Soil Mechanics and Geotechnical Engineering, Osaka, Japan, 12-16. Confe ence on Soil echanics and Geotechnical nginee ing, Osa a, Japa , 6.

12. Kempfert, H.G., C.Gobel,D.Alexiew and C. Heitz (2004) German Recommendations for

Reinforced Embankments on Pile-Similar Elements. Proceedings of the EuroGeo3,Munich

DGGT,279-284

13. Jones, C.J.F.P., C .R. Lawson, and D.J. Ayres Geotextile reinforced piled embankments. , pp 155-

160. In Den Hoed (eds.) International Conf. Geotextiles, Geomembranes and related products,

Balkema, Rotterdam, 1990.

14. Lawson, C.R. (2012) Role of Modelling in the Development of Design Methods for Basal

R i f d Pil d E b k b bli h d i h P di f E F 2012 D lf h Reinforced Piled Embankments, to be published in the Proceedings of EuroFuge 2012, Delft, the

Netherland.

15. Liu, H.L., W. W. Charles, and K. Fei (2007) Performance of a geogrid-reinforced and pile-

supported highway embankment over soft clays-Case study. Journal of Geotechnical and

G i t l E i i ASCE 133(12) 1483 1493 Geoenvironmental Engineering, ASCE, 133(12), 1483-1493.

16. Marston, A. and A.O. Anderson (1913) The theory of loads on pipes in ditches and tests of cement

and clay drain tile and sewer pipe. Engineering experiment station, Bulletin No.31.

17 Miriam E S and MF George (2003) Influence of Clay Compressibility on Geosynthetic Loads 17. Miriam, E.S., and M.F. George (2003) Influence of Clay Compressibility on Geosynthetic Loads

in Bridging Layers for Column-Supported Embankments.Geotechnical Special Publication, no

130-142, 447-460.

56

References

18. Reid, W. M. and N. W. Buchanan(1984)Bridge approach support piling. Piling and Ground

Treatment, Thomas Telford Ltd., London Treatment, Thomas Telford Ltd., London

19. Rogbeck, Y., S. Gustavsson, I. Sodergren and D. Lindquist(1998) Reinforced Piled

Embankments in Sweden-Design Aspects. Proceedings of the Sixth International Conference

on Geosynthetics, 2, 755-762.

20. Russell, D. and N. Pierpoint (1997) An assessment of design methods for piled

embankments. Ground Engineering, 30(11), 39-44.

21. Satibi, S. (2009) Numerical analysis and design criteria of embankments on floating piles. A

h h b d h f S S G PhD thesis submitted to the Universitt of Stuttgart, Stuttgart, Germany.

22. Yoo, C. and S.B. Kim (2009) Numerical modeling of geosynthetic-encased stone column-

reinforced ground. Geosynthetics International, 16(3), 116-126.

23 Z k D (2001) Z Wi k i b h t d 23. Zaeske, D. (2001). ZurWirkungsweise von unbewehrten und

bewehrtenmineralischenTragschichtenu

berpfahlartigenGru

ndungsetementen.

SchriftenreiheGeotechnik,University of Kassel, Germany, Heft 10, February.

57

THANK YOU ! THANK YOU !

58

Das könnte Ihnen auch gefallen

- 2005-07 Ranger 500 EFI 2X4 4X4 Service ManualDokument345 Seiten2005-07 Ranger 500 EFI 2X4 4X4 Service ManualBrian Cook100% (5)

- Chevrolet Captiva Service Manual. MAINTENANCE AND REPAIR.Dokument57 SeitenChevrolet Captiva Service Manual. MAINTENANCE AND REPAIR.krisdiarto@gmail.com96% (23)

- Assign 3Dokument9 SeitenAssign 3Yudha PP0% (1)

- Group 2 (ME 03) - Hoa Phat GroupDokument42 SeitenGroup 2 (ME 03) - Hoa Phat GroupLê Thành DanhNoch keine Bewertungen

- Mononobe OkabeDokument10 SeitenMononobe Okabeardikurniawan100% (1)

- Module 3 Density Altitude ExperimentDokument3 SeitenModule 3 Density Altitude ExperimentIvan100% (1)

- Dji Phantom 4 RTK Book F-2Dokument18 SeitenDji Phantom 4 RTK Book F-2Liu Purnomo100% (1)

- RaithelDokument11 SeitenRaithelJosé Otávio Serrão EleutérioNoch keine Bewertungen

- Example For ExamDokument12 SeitenExample For ExambetongleeNoch keine Bewertungen

- 14 ARC Hong Kong Bearing CapacityDokument6 Seiten14 ARC Hong Kong Bearing CapacityLitan DebnathNoch keine Bewertungen

- Seismic Hazard Analysis of IndiaDokument8 SeitenSeismic Hazard Analysis of IndiaShyam AwalNoch keine Bewertungen

- Formulation of Seismic Passive Resistance of Non-Vertical Retaining Wall Backfilled with c-Φ SoilDokument13 SeitenFormulation of Seismic Passive Resistance of Non-Vertical Retaining Wall Backfilled with c-Φ SoilSergio FlorezgNoch keine Bewertungen

- Visone SantucciDokument14 SeitenVisone SantuccibarouniamineNoch keine Bewertungen

- Lecture26 Ground Response Analysis Part2Dokument35 SeitenLecture26 Ground Response Analysis Part2Arun GoyalNoch keine Bewertungen

- Chapter Three: Bearing Capacity of Soils (Shallow Foundations)Dokument15 SeitenChapter Three: Bearing Capacity of Soils (Shallow Foundations)Wubetie MengistNoch keine Bewertungen

- Bearing CapacityDokument15 SeitenBearing CapacitymohameNoch keine Bewertungen

- Analysis of Laterally Loaded PileDokument16 SeitenAnalysis of Laterally Loaded PileNicola TomasiNoch keine Bewertungen

- Calculation of Passive Earth Pressure of Cohesive Soil Based On Culmann's MethodDokument9 SeitenCalculation of Passive Earth Pressure of Cohesive Soil Based On Culmann's MethodFernando PizarroNoch keine Bewertungen

- Lateral Load Analysis of Single PilesDokument12 SeitenLateral Load Analysis of Single Pilesraphfm33% (3)

- 50CDokument6 Seiten50Cjhacademyhyd89% (9)

- Footings - ExamplesDokument17 SeitenFootings - Examplesssengr12Noch keine Bewertungen

- Soil-Structure Interaction Effects of High Rise BuildingsDokument16 SeitenSoil-Structure Interaction Effects of High Rise Buildingsshubham k mishraNoch keine Bewertungen

- Active Force on Retaining Wall Supporting Φ Backfill Considering Curvilinear Rupture SurfaceDokument10 SeitenActive Force on Retaining Wall Supporting Φ Backfill Considering Curvilinear Rupture SurfaceLawrence CainNoch keine Bewertungen

- Short Pile DesignDokument9 SeitenShort Pile DesignScooby Doo100% (1)

- Active Control For Panel Transmission Loss ImprovementDokument9 SeitenActive Control For Panel Transmission Loss ImprovementVictor CaceresNoch keine Bewertungen

- Chapter 2Dokument15 SeitenChapter 2Yen Ling NgNoch keine Bewertungen

- Geoteknisk Institut: J. Brinch HansenDokument16 SeitenGeoteknisk Institut: J. Brinch HansenErica WalshNoch keine Bewertungen

- Topic 2.3 Ive GeoDokument44 SeitenTopic 2.3 Ive GeoAlex NgNoch keine Bewertungen

- 13 An Experimental Study On Uplift Capacity of Plate AnchorsDokument35 Seiten13 An Experimental Study On Uplift Capacity of Plate AnchorsAna Sofía Arango BermúdezNoch keine Bewertungen

- 10Dokument12 Seiten10rowatersNoch keine Bewertungen

- Leshchinsky&Boedeker JGGE AsceDokument20 SeitenLeshchinsky&Boedeker JGGE AscePedroNoch keine Bewertungen

- Lancellotta Spinta Passiva SismicaDokument3 SeitenLancellotta Spinta Passiva Sismicafermat91Noch keine Bewertungen

- PPR 0882Dokument11 SeitenPPR 0882Nicole CarrilloNoch keine Bewertungen

- Gate 2001Dokument10 SeitenGate 2001tonykalladaNoch keine Bewertungen

- 2017.issue1.paper 03Dokument11 Seiten2017.issue1.paper 03Calin MateiNoch keine Bewertungen

- Influence of Three-Dimensional Soil-Structure Interaction On Structural Responses Induced by Near-Source EarthquakesDokument8 SeitenInfluence of Three-Dimensional Soil-Structure Interaction On Structural Responses Induced by Near-Source EarthquakesroloheNoch keine Bewertungen

- The Bearing Capacity of Footings On Coarse SoilsDokument11 SeitenThe Bearing Capacity of Footings On Coarse SoilsMattNoch keine Bewertungen

- Analysis of Piles Subject To Lateral Soil MovementsDokument7 SeitenAnalysis of Piles Subject To Lateral Soil Movementstangkokhong100% (1)

- Comprehensive Step by Step Calculations For Retaining Wall Analysis Are Provided BelowDokument15 SeitenComprehensive Step by Step Calculations For Retaining Wall Analysis Are Provided BelowLakshmiWijayasiriNoch keine Bewertungen

- Ds Geo3Dokument21 SeitenDs Geo3ramiahyuriNoch keine Bewertungen

- CIV E 354 Geotechnical Engineering Ii: by Giovanni CascanteDokument11 SeitenCIV E 354 Geotechnical Engineering Ii: by Giovanni CascanteVNoch keine Bewertungen

- Bearing Capacity of Shallow FoundationDokument49 SeitenBearing Capacity of Shallow FoundationMuhammad Faisal Habib JanjuaNoch keine Bewertungen

- Geotechnical Analysis: Procedure & CalculationsDokument15 SeitenGeotechnical Analysis: Procedure & CalculationsAndres EscobedoNoch keine Bewertungen

- Baishya 2012 Seismic AEP - HSM - Log SpiralDokument10 SeitenBaishya 2012 Seismic AEP - HSM - Log SpiralsiddalingeshwarahNoch keine Bewertungen

- Modelling Geosynthetic Reinforced Granular Fills Over Soft SoilDokument21 SeitenModelling Geosynthetic Reinforced Granular Fills Over Soft SoilAnonymous q1gBywwNoch keine Bewertungen

- Keynote Speaker 11Dokument9 SeitenKeynote Speaker 11Mangisi Haryanto ParapatNoch keine Bewertungen

- Siol Mechanics 2008JUNDokument12 SeitenSiol Mechanics 2008JUNAnkit AkNoch keine Bewertungen

- Distribution of Seismic Earth Pressures On Rigid Retaining WallsDokument11 SeitenDistribution of Seismic Earth Pressures On Rigid Retaining WallsvijaykumarzNoch keine Bewertungen

- Soil-Structure Interaction For Landslide Stabilizing Piles: C.-Y. Chen, G.R. MartinDokument24 SeitenSoil-Structure Interaction For Landslide Stabilizing Piles: C.-Y. Chen, G.R. Martinramarathnam1989Noch keine Bewertungen

- Geosynthetic-Reinforced Pile-Supported Embankments 3D Discrete Numerical Analyses of The Interaction and Mobilization MechanismsDokument20 SeitenGeosynthetic-Reinforced Pile-Supported Embankments 3D Discrete Numerical Analyses of The Interaction and Mobilization Mechanisms云城择栖Noch keine Bewertungen

- Pile-Supported Embankments On Soft Ground For A High Speed Railway - Load Transfer, Distribution and Concentration by Different Construction MethodsDokument6 SeitenPile-Supported Embankments On Soft Ground For A High Speed Railway - Load Transfer, Distribution and Concentration by Different Construction MethodsJamie MooreNoch keine Bewertungen

- Calculation Models For Dam Foundations With Geotextile Coated Sand ColumnsDokument6 SeitenCalculation Models For Dam Foundations With Geotextile Coated Sand ColumnsEman AhmedNoch keine Bewertungen

- CE306 Shallow and Deep FoundationsDokument34 SeitenCE306 Shallow and Deep FoundationsMustafa LuayNoch keine Bewertungen

- Eccentrically Loaded Strip Foundation On Geogrid-Reinforced SandDokument19 SeitenEccentrically Loaded Strip Foundation On Geogrid-Reinforced SandMohamed MohsenNoch keine Bewertungen

- Impedance-Based Winkler Spring Method For Soil-Pile Group Interaction AnalysisDokument0 SeitenImpedance-Based Winkler Spring Method For Soil-Pile Group Interaction AnalysisHusseinali HusseinNoch keine Bewertungen

- Bearing Capacity - LecturesDokument26 SeitenBearing Capacity - Lecturesprince.rajput8765Noch keine Bewertungen

- Shallow FoundationDokument56 SeitenShallow FoundationAastha Soni50% (2)

- Foundation On LayeredDokument14 SeitenFoundation On LayeredPanxo OrdenesNoch keine Bewertungen

- Tables of Normalized Associated Legendre Polynomials: Mathematical Tables SeriesVon EverandTables of Normalized Associated Legendre Polynomials: Mathematical Tables SeriesNoch keine Bewertungen

- Shallow Foundations: Discussions and Problem SolvingVon EverandShallow Foundations: Discussions and Problem SolvingBewertung: 5 von 5 Sternen5/5 (1)

- Tables of Coulomb Wave Functions: Whittaker FunctionsVon EverandTables of Coulomb Wave Functions: Whittaker FunctionsNoch keine Bewertungen

- Tables of Racah Coefficients: Mathematical Tables SeriesVon EverandTables of Racah Coefficients: Mathematical Tables SeriesNoch keine Bewertungen

- MSC PHD 201509 July LatestDokument2 SeitenMSC PHD 201509 July LatestowaisshafiNoch keine Bewertungen

- DND CompDokument1 SeiteDND CompowaisshafiNoch keine Bewertungen

- CEA WorkshopDokument2 SeitenCEA WorkshopowaisshafiNoch keine Bewertungen

- Application of Laboratory Evaluation To Develop Stiffness Values and Layer Coefficients For DesignDokument54 SeitenApplication of Laboratory Evaluation To Develop Stiffness Values and Layer Coefficients For DesignowaisshafiNoch keine Bewertungen

- Stone Column in PeatDokument21 SeitenStone Column in PeatowaisshafiNoch keine Bewertungen

- Legend:-: General Arrangement ACS550-124A-4 YN3A205086-GAADokument12 SeitenLegend:-: General Arrangement ACS550-124A-4 YN3A205086-GAANeeraj SharmaNoch keine Bewertungen

- Apollo Experience Report Electronic Systems Test Program Accomplishments and ResultsDokument70 SeitenApollo Experience Report Electronic Systems Test Program Accomplishments and ResultsBob AndrepontNoch keine Bewertungen

- Centrifugal PumpDokument56 SeitenCentrifugal Pumpchandraa2208Noch keine Bewertungen

- California Bearing Ratio, Evaluation and Estimation: A Study On ComparisonsDokument4 SeitenCalifornia Bearing Ratio, Evaluation and Estimation: A Study On ComparisonsAmyra MiaNoch keine Bewertungen

- Pravin Yesubon.Y: and Social Responsibility (PSSR) and Personal Survival Techniques (PST)Dokument2 SeitenPravin Yesubon.Y: and Social Responsibility (PSSR) and Personal Survival Techniques (PST)shaNoch keine Bewertungen

- MRT PrjectDokument59 SeitenMRT PrjectFahrul 2394Noch keine Bewertungen

- GAPS Guidelines: Deep Fat FryersDokument4 SeitenGAPS Guidelines: Deep Fat FryersAsad KhanNoch keine Bewertungen

- Electroplating of Silver, Zinc and IronDokument13 SeitenElectroplating of Silver, Zinc and IronTahira AzamNoch keine Bewertungen

- MH16 Series ROOFTOP AC Manual REV 2013Dokument19 SeitenMH16 Series ROOFTOP AC Manual REV 2013caleb perezNoch keine Bewertungen

- 312 Excavators Hydraulic System: Component ListDokument2 Seiten312 Excavators Hydraulic System: Component ListRr hardiyantoNoch keine Bewertungen

- Vector VII 104-561kVA User Manual 6.6.1Dokument165 SeitenVector VII 104-561kVA User Manual 6.6.1juliocanel2009100% (3)

- Guinness Case StudyDokument3 SeitenGuinness Case StudyMunyaradzi T HotoNoch keine Bewertungen

- Datasheet 783Dokument2 SeitenDatasheet 783veertulNoch keine Bewertungen

- AC ResumeDokument2 SeitenAC Resumesampaguita_r7166Noch keine Bewertungen

- 04 Rociador Tyco K11.2 SRDokument6 Seiten04 Rociador Tyco K11.2 SRRuben Saucedo JacomeNoch keine Bewertungen

- American University of Beirut Aub Thesis TemplateDokument12 SeitenAmerican University of Beirut Aub Thesis TemplateHassane EzzeddineNoch keine Bewertungen

- Raman Spectroscopy SetupDokument13 SeitenRaman Spectroscopy SetupRafael RamosNoch keine Bewertungen

- Safety Is Your Top Priority: Explosion-Proof LED LightingDokument62 SeitenSafety Is Your Top Priority: Explosion-Proof LED LightingPhi LongNoch keine Bewertungen

- FMS 2009 Question Paper and Answer KeyDokument6 SeitenFMS 2009 Question Paper and Answer KeyHarish PotterNoch keine Bewertungen

- Dual Draw/Dual Return Fuel System TroubleshootingDokument4 SeitenDual Draw/Dual Return Fuel System Troubleshootinginformer techNoch keine Bewertungen

- Newton Laws of Motion JeopardyDokument19 SeitenNewton Laws of Motion JeopardyJessiel GueribaNoch keine Bewertungen

- Literature ReviewDokument2 SeitenLiterature ReviewkhairulNoch keine Bewertungen

- Body of Knowledge PDFDokument1 SeiteBody of Knowledge PDFAda RamirezNoch keine Bewertungen

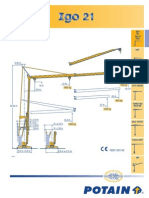

- Potain Igo 21 PDFDokument4 SeitenPotain Igo 21 PDFMarco CruzNoch keine Bewertungen