Beruflich Dokumente

Kultur Dokumente

SAL Tender Data Sheets 2013

Hochgeladen von

Danny Durham0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

27 Ansichten7 Seitensal

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldensal

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

27 Ansichten7 SeitenSAL Tender Data Sheets 2013

Hochgeladen von

Danny Durhamsal

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 7

CLIENT: ACSA

PROJECT: PORT ELIZABETH NEW ROAD BRIDGING FACILITY

DATE: AUGUST 2013 BALL VALVE (BV1:8)

Revision: Tender Rev-A

6" - 3 42. Fluid Phase Liquid

4" - 5 43. Flow Rate l/min Various

E

44. Design Max 2000kPa

C

45. Test Pressure

I

46. Set Pressure

L

2. Label BV1:8

V

47. Delta P @ Max Flow

A

3. P&ID 6336GC-800

R

48. Temp Normal -5C to 40C

R

4. Service Product Control

E

49. SP GR 0.76

E

5. Fluid J et A-1

S

50. Viscosity 2.0 cP

N

6. Line Class ANSI 150 51. Vapour Press kPa

E

7. Pipe Schedule 40 52. Upstream Pressure 1400kPa

G

8. Function Product Control

9. Body Size nb Varies

10. Valve Type Ball Valve

11. Calculated Cv

12. Selected Cv

Y

13. Valve Type Manual

D

14. Material Stainless Steel (ASTM A351 CF8M) Note:

O

15. End Connections Flanged (ANSI B16.5 150RF) - No Copper or Brass Permitted

B

16. Plug Form Ball

17. Ball Material Stainless Steel (ASTM A351 CF8M)

18. Body One Piece / Reducing Bore

19. Stem Stainless Steel (ASTM A276) Additional Certification:

20. Elastomers - API607 Tested, Approved and Certified

21. Bearing - ASME B16.10 Dimension

R

22. Pilot

O

23. Type

T

24. Control lines:

A

25. Ball float

U

26. Float rod

T

27.

C

28.

A

29,

30.

S

31. Indicator Yes

E

32. Lockable Yes

I

33. V-Port No

R

34. Strainers No

O

35. Mech Closure No - Manual

S

36. Internal Lining No - Stainless Steel Trim

S

Solenoid, 24d.c. No

E

(energise to open

C

37 OCV.)

C

38 Solenoid valve No

A

39. External coating No - Contractor to Paint Black

40. Stilling well

O

41. Manufacturer

F

42. Model Number

M

Habonim 31P, Inbal or

Equivalent

6336GC-900-A

Quantity 1.

TEL: 011-501-4760

FAX: 011-501-4769

WEB: www.kanteys.co.za

E-MAIL: info@jhb.kanteys.co.za

SERVICE

1 Quantity : 1 No.

2 Equipment tag Nos. :

3 Flow service : Air Elimination for Metering

4 Type & function : Inline strainer and integral gas eliminator for custody transfer

flow metering systems. Vertical low profile unit for horizontal

line mounting.

5 Legal metrology certification : Yes, pattern approval for system. Certificates required

6 Size : 100 NB

7 Strainer : 40 Mesh basket liner - removable

ACCESSORIES

8 Gas release unit isolation : No

9 Drain : Yes - blanked plug

10 Flange nozzle 1" NPT connections : Yes - blanked plugs

11 Differential pressure gauge : Yes - optional price required to be shown for omission

OPERATING CONDITIONS

12 Line class & schedule : ASME B16.5 Class 150

13 Maximum flow rate : 1,500l/min

14 Pressure drop @ 2000 l/min. : 20 kPa

15

Temperature

o

C : Ambient

16 SG : 0.74 - 0.84

MATERIALS

17 Body material : Carbon Steel with Internal Epoxy Lining or Stainless Steel with No Lining

18 Wetted parts : 316 SS

19 Seals : Teflon / VITON

20 Pressure max. working : 1900kPa

21 Flange connections : ASME B16.5 Class 150 - Raised Face

22 Material certificates : Body and Cover Required

MANUFACTURER/MODEL

23 Model : Smith S4-1-ST with RB -Type air release kit (Supplier to confirm

compliance with above data)

Sheet

1 of 1

B.H

B.H

ACSA - PORT ELIZABETH AIRPORT

B.H

Equipment :

Proj. / Title :

NEW ROAD BRIDGING

B.H

Rev:

Date: 07/08/2013

STRAINER GAS ELIMINATOR

07/08/2013

DE

Data Sheet :

A

6336GC-906-A

Engineer :

Checked :

Appr. :

Date :

Date :

Date :

07/08/2013

07/08/2013

By:

TEL: 011-501-4760

FAX: 011-501-4769

WEB: www.kanteys.co.za

E-MAIL: info@jhb.kanteys.co.za

P O BOX 412541, CRAIGHALL, 2024

6453-905-A

Revision : Tender-A

Quantity : 1

Service : Fuel Quantity Measurement for Decanting

Type of meter : 4 - Positive displacement / Double case with mechanical stack

Assize approval : Yes

Compliant with SABS 0259 : Yes

Line Size : NB100 (4)

Maximum flowrate : 1500/min

Operating flowrate : 1200/min

Pressure rating : 1034 kPa

Operating pressure/ temperature : 300 kPa/ ambient

Pressure drop : 10 kPa (at maximum flow)

Products handled : J et-A1

Output : Local display (Litres) (LNC) & Thermal Compensating Output

Flanged connections : ASME 150RF

Materials No zinc, copper or copper alloys to be in contact with the

working fluid

Body : Aluminium alloy

Blades : Aluminium alloy

Seals : Viton or Teflon

(or equivalent approved)

Accessories

Air eliminator/ strainer

No

Preset Counter : Yes

Preset Valve : Yes

Ticket Printer : No

Pulse output device : No

Make & Model : Smith (or equivalent approved)

Tag Number(s) : M

Direction of Flow (Facing Meter) : Left to Right

Other Requirements : Thermal Compensator with Alternate Display

CLIENT: ACSA PROJECT: PORT ELIZABETH NEW ROAD BRIDGING

DATE: AUGUST 2013 DATA SHEET: DECANTING FLOW METER (DFM1)

6336GC-904-A

DATA SHEET FOR: FFB PUMP PROJECT: PORT ELIZABETH NEW ROAD BRIDGING FACILITY

SELF PRIMING CENTRIFUGAL PUMPSET

DATE: AUGUST 2013

PUMP NUMBER: SP-01 Revision: Tender - A

P&I.D. Nos. 6336GC-801 Number required 1

OPERATING DATA

Liquid Water with J et-A1 (Kerosene) Specific gravity, at pumping temperature: 0.74-1.0 @ 20C

Service Pump to Separator Viscosity (Kinematic) @ 40C: 1.5mm/s

Pumping Temperature: Ambient (20C) Vapour press <0.1kPa (abs)

Capacity @ duty point: 200 l/min (3.33l /s) Altitude: 60m

Head @ duty point: 8m (80kPa)

NPSH

A

: 8m

MECHANICAL DATA

Type of Pump: Self priming. (Gorman Rupp 11A3B )* Pump Speed: 2900 rpm *

Direction of rot. (facing drive end): clockwise Mechanical seal: Yes*

Cooling required on: N/a Type of bearing lubrication: Oil/Grease

Cooling water: N/a Pump orientation: Horizontal

Cooling required on: N/a

Position of nozzles (facing driven end) and connections

Suction:

Side

1 RAISED ASA150 FLANGED

Discharge:

Top

1 RAISED ASA150 FLANGED

MATERIALS OF CONSTRUCTION

QUALITY ASSURANCE

Casing: Gray Iron Manufacturer to possess SABS 9001/2 certification

Shaft: Carbon Steel Quality plan to be submitted.

Impeller: Gray Iron TESTS

PUMP DRIVERS

Hydrotest to 1.5 Times

Casing Pressure

Yes

Electric motor: Yes Shop performance tests: No

Type: Direct NPSH tests: No

Speed: 2900 rpm

Voltage/phase/

Frequency

380V/2P/50 Hz ACCESSORIES

Enclosure: Zone 1 (flameproof)

Installed power: 2.2kW * Coupling: Yes (flexible)

Base plate: Yes (galvanised)

NOTES: Coupling guard: Yes

1. * Supplier to advise Pressure gauge: No (by others)

Casing Colour Black

TEL: 011-501-4760

FAX: 011-501-4769

WEB: www.kanteys.co.za

E-MAIL: info@jhb.kanteys.co.za

P O BOX 412541, CRAIGHALL, 2024

6336GC-903-A

DATA SHEET FOR: JET-A1 DECANTING PUMP PROJECT: PORT ELIZABETH NEW ROAD BRIDGING FACILITY

SELF PRIMING CENTRIFUGAL PUMPSET

DATE: AUGUST 2013

PUMP NUMBER: DP-01 Revision: Tender - A

P&I.D. Nos. 6336GC-800 Number required 1

OPERATING DATA

Liquid J et-A1 (Kerosene) Specific gravity, at pumping temperature: 0.74-79 @ 20C

Service Decanting of Truck to Tank Viscosity (Kinematic) @ 40C: 1.5mm/s

Pumping Temperature: Ambient (20C) Vapour press <0.1kPa (abs)

Capacity @ duty point: 1200 l/min (20l /s) Altitude: 60m

Head @ duty point: 62m (450kPa)

NPSH

A

: 8m

MECHANICAL DATA

Type of Pump:

Self priming. (Gorman Rupp RotoPrime

RD4A-B-2)*

Pump Speed: 2900 rpm *

Direction of rot. (facing drive end): clockwise Mechanical seal: Yes*

Cooling required on: N/a Type of bearing lubrication: Oil/Grease

Cooling water: N/a Pump orientation: Horizontal

Cooling required on: N/a

Impeller Size: 9.25 *

Position of nozzles (facing driven end) and connections

Suction:

Side

6 RAISED ANSI150 FLANGED

Discharge:

Top

4 RAISED ANSI150 FLANGED

MATERIALS OF CONSTRUCTION

QUALITY ASSURANCE

Casing: Cast Steel (70-36) Manufacturer to possess SABS 9001/2 certification

Shaft: Carbon Steel Quality plan to be submitted.

Impeller: Steel TESTS

Rotor: Cast Steel (NO COPPER ALLOWED)

PUMP DRIVERS

Hydrotest to 1.5 Times

Casing Pressure

Yes

Electric motor: Yes Shop performance tests: No

Type: Direct NPSH tests: No

Speed: 2900 rpm

Voltage/phase/

Frequency

380V/2P/50 Hz ACCESSORIES

Enclosure: Zone 1 (flameproof)

Installed power: 30kW * Coupling: Yes (flexible)

Base plate: Yes (galvanised)

NOTES: Coupling guard: Yes

1. * Supplier to advise Pressure gauge: No (by others)

2. No Brass or Copper Alloys Allowed in Contact with Fluid Casing Colour Black

Air Eliminator Yes

TEL: 011-501-4760

FAX: 011-501-4769

WEB: www.kanteys.co.za

E-MAIL: info@jhb.kanteys.co.za

P O BOX 412541, CRAIGHALL, 2024

CLIENT: ACSA

PROJECT: PORT ELIZABETH NEW ROAD BRIDGING FACILITY

DATE: AUGUST 2013 DEAD MAN VALVE (DMV1:6)

Revision: Tender Rev-A

1" - 1 42. Fluid Phase Liquid

1" - 5 43. Flow Rate l/min Various

E

44. Design Max 2000kPa

L

2. Label DMV1:6

C

45. Test Pressure

A

3. P&ID 6336GC-800

I

46. Set Pressure

R

4. Service Product Control

V

47. Delta P @ Max Flow

E

5. Fluid J et A-1

R

48. Temp Normal -5C to 40C

N

6. Line Class ANSI 150

E

49. SP GR 0.76-1

E

7. Pipe Schedule 80

S

50. Viscosity 0.89 cP

G

8. Function Product Control 51. Vapour Press kPa

9. Body Size nb Varies 52. Upstream Pressure 1400kPa

10. Valve Type Ball Valve

11. Calculated Cv

12. Selected Cv

Y

13. Valve Type Manual Open / Auto Close

D

14. Material Stainless Steel (ASTM A351 CF8M) Note:

O

15. End Connections Flanged (ANSI B16.5 150RF) - No Brass Permitted

B

16. Plug Form Ball - No Copper Permitted

17. Ball Material Stainless Steel (ASTM A351 CF8M)

18. Body Reducing Bore

19. Stem Stainless Steel (ASTM A276) Additional Certification:

20. Elastomers - API607 Tested, Approved and Certified

21. Bearing - ASME B16.10 Dimension

R

22. Pilot - Material Certificates

O

23. Type

T

24. Control lines:

A

25. Ball float

U

26. Float rod

T

27. Handle Yes - Springloaded Closed

C

28.

A

29,

30.

S

31. Indicator Yes

E

32. Lockable Yes

I

33. V-Port No

R

34. Strainers No

O

35. Mech Closure Yes - Springloaded Closed

S

36. Internal Lining No

S

Solenoid, 24d.c. No

E

(energise to open

C

37 OCV.)

C

38 Solenoid valve No

A

39. External coating No - Contractor to Paint Black

40. Stilling well

O

41. Manufacturer

F

42. Model Number

M

Harbonin 31P, Inball or

Equivalent

6622A-902-A

Quantity 1.

TEL: 011-501-4760

FAX: 011-501-4769

WEB: www.kanteys.co.za

E-MAIL: info@jhb.kanteys.co.za

CLIENT: ACSA

PROJECT: PORT ELIZABETH NEW ROAD BRIDGING FACILITY

DATE: AUGUST 2013 BALL VALVE (BV9:26)

Revision: Tender Rev-A

1" - 1 42. Fluid Phase Liquid

1" - 15 43. Flow Rate l/min Various

" - 2

E

44. Design Max 2000kPa

C

45. Test Pressure

I

46. Set Pressure

L

2. Label BV9:24

V

47. Delta P @ Max Flow

A

3. P&ID 6336GC-800

R

48. Temp Normal -5C to 40C

R

4. Service Product Control

E

49. SP GR 0.76

E

5. Fluid J et A-1

S

50. Viscosity 2.0 cP

N

6. Line Class ANSI 150 51. Vapour Press kPa

E

7. Pipe Schedule 80 52. Upstream Pressure 1400kPa

G

8. Function Product Control

9. Body Size nb Varies

10. Valve Type Ball Valve

11. Calculated Cv

12. Selected Cv

Y

13. Valve Type Manual

D

14. Material Stainless Steel (ASTM A351 CF8M) Note:

O

15. End Connections Flanged (ANSI B16.5 150RF) - No Copper or Brass Permitted

B

16. Plug Form Ball

17. Ball Material Stainless Steel (ASTM A351 CF8M)

18. Body Single Piece / Reducing Bore

19. Stem Stainless Steel (ASTM A276) Additional Certification:

20. Elastomers - API607 Tested, Approved and Certified

21. Bearing - ASME B16.10 Dimension

R

22. Pilot

O

23. Type

T

24. Control lines:

A

25. Ball float

U

26. Float rod

T

27.

C

28.

A

29,

30.

S

31. Indicator Yes

E

32. Lockable Yes

I

33. V-Port No

R

34. Strainers No

O

35. Mech Closure No - Manual

S

36. Internal Lining No - Stainless Steel Trim

S

Solenoid, 24d.c. No

E

(energise to open

C

37 OCV.)

C

38 Solenoid valve No

A

39. External coating No - Contractor to Paint Black

40. Stilling well

O

41. Manufacturer

F

42. Model Number

M

Habonim 31P, Inbal or

Equivalent

6336GC-901-A

Quantity 1.

TEL: 011-501-4760

FAX: 011-501-4769

WEB: www.kanteys.co.za

E-MAIL: info@jhb.kanteys.co.za

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Bondek User GuideDokument0 SeitenBondek User GuidemarioxguzmanNoch keine Bewertungen

- TiniJet Waterjet CuttingDokument1 SeiteTiniJet Waterjet CuttingDanny DurhamNoch keine Bewertungen

- Rev Bai Et Al BHR 2006 Surface Prep DecontaminationDokument9 SeitenRev Bai Et Al BHR 2006 Surface Prep DecontaminationDanny DurhamNoch keine Bewertungen

- Howard JohnsonDokument6 SeitenHoward JohnsonDanny DurhamNoch keine Bewertungen

- Linear Motor For Linear CompressorDokument7 SeitenLinear Motor For Linear CompressorDanny DurhamNoch keine Bewertungen

- A Stirling-Rankine Fuel-Fired Heat PumpDokument9 SeitenA Stirling-Rankine Fuel-Fired Heat PumpDanny DurhamNoch keine Bewertungen

- Performance Characterization of Sunpower Free-Piston Stirling EnginesDokument6 SeitenPerformance Characterization of Sunpower Free-Piston Stirling EnginesDanny DurhamNoch keine Bewertungen

- Qnergy The PCK80 Brochure Spec SheetDokument2 SeitenQnergy The PCK80 Brochure Spec SheetDanny DurhamNoch keine Bewertungen

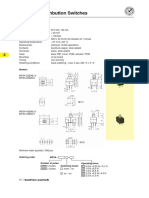

- Miniature Pushbutton Switches: SpecificationsDokument1 SeiteMiniature Pushbutton Switches: SpecificationsDanny DurhamNoch keine Bewertungen

- Photocatalytic Hydrogen Production Using Clinoptilolite-Supported, Eosin Y-Sensitized Tio FOR Water SplittingDokument4 SeitenPhotocatalytic Hydrogen Production Using Clinoptilolite-Supported, Eosin Y-Sensitized Tio FOR Water SplittingDanny DurhamNoch keine Bewertungen

- BK3251 BekenDokument13 SeitenBK3251 BekenDanny DurhamNoch keine Bewertungen

- Series 1846 - Single-Pole Pushbutton Switches: Product Features On RequestDokument3 SeitenSeries 1846 - Single-Pole Pushbutton Switches: Product Features On RequestDanny DurhamNoch keine Bewertungen

- Aluminium: Extruded Sections Square BarDokument1 SeiteAluminium: Extruded Sections Square BarDanny DurhamNoch keine Bewertungen

- CIPCPub201353 01Dokument45 SeitenCIPCPub201353 01Danny DurhamNoch keine Bewertungen

- Mazda cx5Dokument9 SeitenMazda cx5Danny DurhamNoch keine Bewertungen

- FlexiLine PricelistDokument15 SeitenFlexiLine PricelistDanny DurhamNoch keine Bewertungen

- Snaa 123Dokument10 SeitenSnaa 123Danny DurhamNoch keine Bewertungen

- Key Linear Motion Design TaenDokument9 SeitenKey Linear Motion Design TaenDanny DurhamNoch keine Bewertungen

- Rate Book - 2011-NCP Building DPTDokument244 SeitenRate Book - 2011-NCP Building DPTthak_raj84Noch keine Bewertungen

- S2 G 460 - TDS PDFDokument3 SeitenS2 G 460 - TDS PDFWawanDarmawanNoch keine Bewertungen

- Makita Accessories Catalogue 2022 23Dokument234 SeitenMakita Accessories Catalogue 2022 23Hadi Santoso100% (1)

- 1805P ReguladoresDokument8 Seiten1805P ReguladoresALBERTONoch keine Bewertungen

- Pharm. LinimentsDokument38 SeitenPharm. LinimentsDr-Md Abul BarkatNoch keine Bewertungen

- Mini Project in Process Equipment Design & Economics Course at IITBDokument1 SeiteMini Project in Process Equipment Design & Economics Course at IITBAman ShahNoch keine Bewertungen

- Recrystallization NotesDokument9 SeitenRecrystallization NotesanrychoNoch keine Bewertungen

- 200622-Fcu & Refrigerant Pipe & Insulation SizeDokument1 Seite200622-Fcu & Refrigerant Pipe & Insulation Sizegukan rajNoch keine Bewertungen

- Coating QaDokument17 SeitenCoating Qasbmmla100% (9)

- Design of Solar Panel Deployment Mechanism For A 1U CubeSatDokument7 SeitenDesign of Solar Panel Deployment Mechanism For A 1U CubeSatAliMurtazaKothawalaNoch keine Bewertungen

- Troubleshooting-Overhauling of A Centrifugal PumpDokument3 SeitenTroubleshooting-Overhauling of A Centrifugal PumpSrini VasanNoch keine Bewertungen

- General Electric - Inlet Air RecommendationDokument28 SeitenGeneral Electric - Inlet Air Recommendationhussain mominNoch keine Bewertungen

- Commscope Trunk & Distribution Cable ProductsDokument51 SeitenCommscope Trunk & Distribution Cable ProductsMauro Barragan SanchezNoch keine Bewertungen

- Supercharging and TurbochargingDokument23 SeitenSupercharging and TurbochargingTrain Placement CellNoch keine Bewertungen

- DokaDokument23 SeitenDokaKarthik U WCFANoch keine Bewertungen

- Voltaic Cell - Yale UniversityDokument4 SeitenVoltaic Cell - Yale UniversityBelenNoch keine Bewertungen

- TD Operators ManualDokument84 SeitenTD Operators Manualsivan_sg1800Noch keine Bewertungen

- Product Catalogue Camfil FarrDokument61 SeitenProduct Catalogue Camfil FarrTrần Hữu DũngNoch keine Bewertungen

- Project TitleDokument2 SeitenProject TitleDENNIS RAMIREZNoch keine Bewertungen

- Comfort & Harmony: Bouncer Asiento Transat Wiegewippe Balanço-bercinho кресло-качалкаDokument28 SeitenComfort & Harmony: Bouncer Asiento Transat Wiegewippe Balanço-bercinho кресло-качалкаJohn SmithNoch keine Bewertungen

- EE Lab Viva QuestionsDokument3 SeitenEE Lab Viva QuestionsRamaswamy Koodalloor Parasuraman67% (3)

- Supplement 1Dokument11 SeitenSupplement 1Tabish IslamNoch keine Bewertungen

- NBK TA Brochure 2016-EmailDokument11 SeitenNBK TA Brochure 2016-EmailPietrus NimbusNoch keine Bewertungen

- TSP 23 No 1Dokument44 SeitenTSP 23 No 1Primitivo GonzálezNoch keine Bewertungen

- Sheetmetal Design GuidelinesDokument5 SeitenSheetmetal Design GuidelinesVikram Borkhediya0% (1)

- Super End ChipperDokument14 SeitenSuper End ChipperalphatoolsNoch keine Bewertungen

- ST014 Sod - MetasilicateDokument1 SeiteST014 Sod - MetasilicateAreIf Cron BmxStreetNoch keine Bewertungen

- 1600 Wall Sys3 - ADokument24 Seiten1600 Wall Sys3 - ABlack DiscipleNoch keine Bewertungen