Beruflich Dokumente

Kultur Dokumente

Easy Compressed Directions For PVC Stretcher

Hochgeladen von

api-255328761Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Easy Compressed Directions For PVC Stretcher

Hochgeladen von

api-255328761Copyright:

Verfügbare Formate

How to Make a Silk Scarf Stretcher from PVC Pipe

If you are going to paint dye onto a silk scarf, as versus just

bunching one up on a plastic plate and dropping dye on it willy-nilly

(which oddly enough can come out pretty well), you will want to

stretch it with some tension on a frame

!he tension keeps the scarf taut and prevents sagging, which would

allow any dye applied to run directly downhill into the hollows rather

than spreading evenly by capillary action !his is particularly

important if you plan on using a resist material painted on to corral

dyes so they don"t run amok # no point spending all that time outlining a design if sagging material lets

the dye run over a resist line on its gleeful way downhill

$ere is a picture of my finished %&' stretcher, which cost me about ()* to make # the construction was

a little more fiddly than originally planned, as the store didn"t carry the e+act plumbing fittings I wanted,

so I made do with what they had which entailed buying some e+tra fittings to convert between si,es If

you plan ahead better than I did here (especially if you can find left over parts from a friend"s

construction site-), you will probably be able to do a more streamlined job for less money $owever, I

am documenting the process as I stumbled through it, so it may serve someone as a bit of a guide and

help them save time through their own project $ave at it-

Step 1 Figure out what size you want

I wanted to be able to stretch scarves of various si,es, from say . to /) wide, and up to 0 1" long (23)

I planned on putting stainless steel safety pins along the edges of the scarves and using rubber bands

stretching from the pins to the %&' pipe frame, using a trampoline effect to keep the scarf taut I figured

I should add at least * on each side of my largest scarf to allow room for the rubber bands, which meant

I needed to add 0 to both the length and the width of my largest scarf /) + 23 scarf plus 0 e+tra on

each side means I need a /3 + 3. frame

Step 2 Sketch design to determine supplies needed

4ketch out your design showing dimensions so you will know how many pieces of pipe to buy (generally

found in /5 foot sections) &isit a plumbing supply website (I used $ome 6epot) so you will be familiar

with the various kinds of fittings available and their si,es !hink about how fittings will join the pipes I

decided to use / pipe as the 1 pipe looked like it might bend too easily $ence I needed / fittings

7elow is a copy of my plan - for the si,e I wanted, I determined

I would need two pieces of /5" pipe, . 4ide 8utlet 9lbows, .

4lip ! couplings and . :educing ;emale <dapters or whatever

else looked like it would make good feet

I set out to the store with my list

/

Slip Coupling

If I used just two long sections of pipe for the sides, they would

bow in when under tension # I wanted a brace in the middle

I will add a ! in the middle of the long sides, adding a short section

of pipe below for a leg, then add another ! that will hold a brace

running between the sides

Four!way Cross Coupling

=hen I got to the store they only had * 4lip ! couplings left in the

/ si,e !hese ;our-way 'ross 'ouplings will work fine, and the

bottom of the coupling looks like it would make a sturdy foot

I will need to add a three inch section of pipe between the ! junction and the four-way cross coupling

so the scarf will not inadvertently touch the cross bar (which would allow dye a place to pool)

Side "utlet #l$ows

!his side outlet elbow would be perfect for my . corners, joining the

pipes in a s>uare frame and allowing easy addition of a piece of the

leftover / pipe for the legs ?nfortunately they didn"t have any of

these at all-

I did find these Socket %educing couplings, which looked like they

would work !hey will make a corner for the / pipe I want for the

frame, but the reduction to 1 inch means I will have to use 1 pipe for

the legs, not left-over / sections as planned $owever, the legs don"t

really need to be heavy duty, since I will only be using the frame for

silk scarves # not e+actly a heavy load I decide to soldier on

4ome @ale &dapters (shown) are needed which will attach to the

small port to securely hold the smaller 1 inch pipe for the legs Aou

will save money by not having to do this-

%educing Female &dapters

!he end of the 1 pipe used for the legs will need some kind of foot

!hese reducing female adapters will accept the 1 pipe and provide a

steady base

Step ' %ound up your tools

)

Aou will needB

- $acksaw (buy yourself a nice new blade)

- !ape measure or yardstick

- 4andpaper ( 1 sheet of medium C fine)

- %encil and magic marker, *+D card

- 9lectrical or vinyl tape

- =6.5 or other lubricant for joints

- 4mall can %&' cement # see note below

I decided not to use the cement, as I want to be able to take my stretcher apart for storage between

projects If you are using cement, put some gloves on and ensure good ventilation

!he wine glass is for after I am done of courseE

Step ( )ayout the pieces and dou$le check the plan

7efore cutting any pipe, double check your figures on your sketch I had to re-draw some sections

and change the leg arrangement due to the change in fittings I also neglected to allow for the

diameter of the pipe itself in my line drawing, so the finished framework was about an inch bigger

than I had originally planned, which didn"t matter for this project, but it is something to remember

Step * Measuring and cutting the pipes

@easure out the longest pipe section you will need @ake a clear mark and write keep on the

correct side of the line =rapping a *+D card around the pipe will help you draw an even mark all the

way around the pipe

=rap a piece of electrical or vinyl tape around the pipe at the mark, but don"t cover up the mark

entirely (if you do you might cut on the wrong side of the tape-)

6on"t screw that up- 6on"t drink any wine-

!he hacksaw blade will want to jump around a little 4lowly draw it across the pipe, supporting the

blade so it touches the edge of the black tape (much easier to see than a dinky pencil mark, plus the

tape cuts down on the blade jittering around)

<fter a few light passes, the pipe will be scored and the blade will settle in 4core the pipe carefully

all the way around before getting aggressive with the blade If you try to cut all the way through

without scoring, invariably the cut will be crooked If you have a band saw, lucky you

*

Fote the ragged edge of the pipe that the hacksaw left (top pipe)

!ake your medium grit sandpaper and smooth the burrs off the edges (this will be easier if the paper is

wrapped around a wood block)

!hen take the fine grit paper and finish smoothing the edge, plus the last inch or so of the outside of

the pipe =hen the pipe is smooth it will easily slide into a coupling, and will allow a good bond with

the cement, if you will be using it

Step + &ssem$ling the upper frame

'ut the four pieces of pipe that will form the top of the frame <fter

each cut, double check the length of each matching piece to ensure

uniformity

4lide the *-way elbow pieces on the ends of the long side pieces of

pipe 4crew the male adapters into the bottoms of the elbows

(remember I have a few e+tra steps here as I had to get additional

fittings to go with the couplings I could get)

Aou should adapt these steps to match whatever fittings you have

9ven if you plan on using cement, do not apply any until the entire frame is assembled and you have

checked for mistakes Aou won"t get those pieces apart again after you glue them- ;or now they will

fit >uite snuggly all on their own If you don"t plan on using cement later, spray the ends with

lubricant to make insertion easier

?se a 4lip ! coupling to connect the side pieces of the upper

frame !hen slide the other end of the side pieces into their

respective corner couplings

Fow slide the cross pieces for the ends into the corner couplings

Aou may have to tor>ue the pipes around a bit to get the frame to

s>uare up

If the frame appears >uite a bit off, check to see if you have slid

each pipe all the way into the couplings # there are stop guides

inside each coupling

.

Step , &dding cross $race and legs

;lip the frame over and insert the three inch sections of pipe into the bottom of the 4lip ! coupling !hen

add the other ! (or here, the ;our-way 'ross) coupling to the pipe 4lip the center brace into place

!he center couplingGbrace assembly will serve as the center legs of the frame < measurement of these

legs compared to the bit of leg already present on the frame corners (due to whatever couplings are being

used there) will indicate how long a leg to cut for the corners

!ake a !-s>uare or a ruler and carefully measure the perpendicular

distance between the top of the frame and the bottom of the ;our-way

'ross coupling (which is serving as the center leg)

If this measurement is not the same on both sides, you will have to remove

the longer leg section and sand it down until it matches 8therwise you

will have a wobbly frame

@ark the dimension down on a clean piece of paper ;or an e+ample, this

measurement was 3 H

Fow measure the distance between the top of the frame and the bottom of

the male adapter screwed into the corner elbows

:ecord this on the piece of paper mentioned in the last step ;or this

e+ample it was * I Juckily I remembered to allow for the depth inside

the coupling that the pipe would slip into (remember those stop guides

inside the couplingsKK) It was 1

I wanted a foot on the bottom of the leg # a ;emale :educing coupling

which will add a 1 to the length # since the two numbers will cancel each

other out I can ignore them

D

6oing the math, 3 H minus * I indicates the leg segment needed for the corners would be . 1

!o be sure this was going to work I marked the lines on the piece of paper which gave me a nice visual

representation of where I needed to cut the 1 pipe with the foot already on it

Step - Finish

;lip frame over and adjust # you may have to grasp both sides of

the frame and apply a little tor>ue (carefully-) here and there to

settle it down on all its legs, and to s>uare up the sides to each

other < t-s>uare is useful for this step too

If you want to cement the pieces, disassemble the entire frame

(but mark those pieces first so you can put it back easily-) and

repeat the steps following the directions on the can

$ere is a snapshot showing a scarf stretched on my frame # note

the rubber band (short) on the left, and a much larger one on the

right of the picture !his is an 3 inch scarf # rather than suspend

it in the middle of my /3 frame, I prefer it closer to one end so I

can apply my brush without reaching over Leep a bo+ of

rubber bands of various si,es handy

If you are working with a shorter scarf, simply tape a leftover

section of pipe (or a yardstick or whatever) across the frame at

the desired point and use that as the end

4ince I did not glue my stretcher, I can also re-configure it by taking out two of the side pieces and the

center legs, making it just .) long

I hope this tutorial is useful for you # if my directions are unclear or you have a comment, feel free to

send me a note $ave yourself a happy dye-

@ary 9 $ogencamp mary.hogencamp@gmail.com

0

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Belt Manual 3.2Dokument119 SeitenBelt Manual 3.2Bjorn FejerNoch keine Bewertungen

- Aa4vg Series 32 Size 71 PDFDokument44 SeitenAa4vg Series 32 Size 71 PDFHidroil Neuquen SrlNoch keine Bewertungen

- Parts SN 568203 RS446Dokument244 SeitenParts SN 568203 RS446มนต์ชัย บุญธนลาภ100% (1)

- Présentation de La Norme CEMA ConvoyeursDokument36 SeitenPrésentation de La Norme CEMA ConvoyeursahmedNoch keine Bewertungen

- 13-3. Principles of Selection: A. Manufacturer RecommendationsDokument24 Seiten13-3. Principles of Selection: A. Manufacturer RecommendationsAshkan AbbasiNoch keine Bewertungen

- Descargar PDF W-XDokument2 SeitenDescargar PDF W-XEDWIN VACANoch keine Bewertungen

- SPS/D BH3000Dokument2 SeitenSPS/D BH3000Dinh NguyenNoch keine Bewertungen

- British Standard Steel ConduitDokument1 SeiteBritish Standard Steel Conduitap00Noch keine Bewertungen

- t14 Tilt Up BracesDokument1 Seitet14 Tilt Up BracesDavid A. ArandaNoch keine Bewertungen

- Technical Information: General Gear Pumps and Gear MotorsDokument68 SeitenTechnical Information: General Gear Pumps and Gear MotorsNguyen TrungNoch keine Bewertungen

- Cement Mill ChainsDokument8 SeitenCement Mill ChainsJulioCNuñezNoch keine Bewertungen

- Genuine Cummins Parts - LF6068 - 09Dokument3 SeitenGenuine Cummins Parts - LF6068 - 09EPESANoch keine Bewertungen

- SANY STC800S Load Charts ManualDokument18 SeitenSANY STC800S Load Charts ManualLautaroNoch keine Bewertungen

- Euro Klim AteDokument5 SeitenEuro Klim Atewesam allabadiNoch keine Bewertungen

- Piping Material SpecificationDokument69 SeitenPiping Material SpecificationGautam Ghoshal50% (2)

- Aluminium Rail Roof Top (R1)Dokument2 SeitenAluminium Rail Roof Top (R1)krishna kumarNoch keine Bewertungen

- Tech Tip #51: Everyday Helpful Facts and FormulaeDokument1 SeiteTech Tip #51: Everyday Helpful Facts and FormulaeMohamed MeeranNoch keine Bewertungen

- Reparacion Deutsch HD y DT Sehs9615Dokument17 SeitenReparacion Deutsch HD y DT Sehs9615polish22Noch keine Bewertungen

- Design of Machine Elements - Ii: Course Code:13ME1126 L TPC 4 1 0 3Dokument3 SeitenDesign of Machine Elements - Ii: Course Code:13ME1126 L TPC 4 1 0 3Krypton 2000Noch keine Bewertungen

- Design of I-Shape Column Base Plate With Moment and Axial CompressionDokument2 SeitenDesign of I-Shape Column Base Plate With Moment and Axial CompressionAndro RebuyasNoch keine Bewertungen

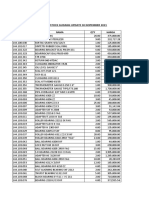

- Stock Gudang Update 30 Nopember 2021Dokument32 SeitenStock Gudang Update 30 Nopember 2021Alif AlifNoch keine Bewertungen

- Manual SBIIIDokument120 SeitenManual SBIIIRama Krishna88% (8)

- Lecture 1 - Construction of Synchronous GeneratorDokument11 SeitenLecture 1 - Construction of Synchronous GeneratorNdapewelao MbwaleNoch keine Bewertungen

- Hoja de Datos PSVDokument6 SeitenHoja de Datos PSVMarc MarNoch keine Bewertungen

- Esp. VirabrequimDokument4 SeitenEsp. VirabrequimflavioNoch keine Bewertungen

- Parts Catalogue For Professional Embroidery Machine PR600 PR600 CDokument43 SeitenParts Catalogue For Professional Embroidery Machine PR600 PR600 CcinthiaNoch keine Bewertungen

- Unit 1 Power Transmission DevicesDokument69 SeitenUnit 1 Power Transmission DevicesAbhijeet somawarNoch keine Bewertungen

- HTL Low Profile Hydraulic Torque Wrench 1.2Dokument4 SeitenHTL Low Profile Hydraulic Torque Wrench 1.2TaimoorNoch keine Bewertungen

- QPQPJQ: Block Junction Tee Code 61 or 62 Block Pads / Block Flange or PadDokument4 SeitenQPQPJQ: Block Junction Tee Code 61 or 62 Block Pads / Block Flange or PadHuy NguyễnNoch keine Bewertungen

- Thermo King Parts Manual CF-II M53 (uPA+) - P PDFDokument93 SeitenThermo King Parts Manual CF-II M53 (uPA+) - P PDFSerhiiNoch keine Bewertungen