Beruflich Dokumente

Kultur Dokumente

New - Reinforcement of Nozzle

Hochgeladen von

hardik5818Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

New - Reinforcement of Nozzle

Hochgeladen von

hardik5818Copyright:

Verfügbare Formate

P kgf/cm2 5.

8

D mm 5700

t

r,int

mm 9.92

t

r,ext

mm 0

S

v

kgf/cm2 1670.295

c.a.

,shell

mm 0

t

'

mm 11

d' mm 132

t

n

'

mm 14.87

L

pr1

mm 40

S

n

kgf/cm2 1172.67

Off mm 0

t

r n,ext

mm 0

D

p

mm 0

t

e

mm 0

h mm 40

L' mm 3

X mm 14.87

leg

1

mm 0

leg

2

mm 10

c.a.

,nozzle

mm 0

S

p

kgf/cm2 1670.295

t mm 11

t

n

mm 14.87

d mm 102.26

W mm 0

radian 0

t

r n mm 0.32579

t

r

mm 9.92

height of beveled transition

Internal pressure

Internal diameter of the shell

SHELL INPUTS

hub height of integral nozzle

thickness of reinforcing pad

type of nozzle

is it split type padding

Nozzle O.D.

Doc. No. Revision

Page No

DESIGN CALCULATION FOR SET IN, SET ON NOZZLE WITH

AND WITHOUT PAD AND SELF REINFORCED NOZZLE

Reqd. thickness of shell (corresponding to external pressure)

self reinforcing nozzle

Allowable stress in shell at given temp

outside diameter of reinforcing pad

Corrosion allowance of shell

NO

Nozzle wall thickness provided

nozzle projection outside the vessel wall

Offset distance

USE ASME CODE SECTION-8 DIVISION I (UG-37)

allowable stress in reinforcing pad at given temp

width of reinforcing pad

layout angle

NOZZLE INPUTS

REINFORCING PAD INPUTS

Reqd. thickness of shell (governing the case)

corrosion allowance of nozzle (internal only)

hub thickness of integral nozzle

reqd. nozzle thk

INTEGRAL NOZZLE INPUTS

weld leg between pad and shell

CERTAIN DERIVED PARAMETERS

Nozzle wall thickness after corrosion

Shell thickness after corrosion

Shell thickness provided

WELD LEGS INPUTS

reqd. nozzle thickness(corresponding to external pressure)

inside diameter of nozzle

Reqd. thickness of shell (corresponding to internal pressure)

weld leg between nozzle and pad/shell

allowable stress in nozzle

SELECT FROM DROP DOWN LIST

SELECT FROM DROP DOWN LIST

WITHOUT CORROSION ALLOWANCE

WITHOUT CORROSION ALLOWANCE

CONSIDER LIQUID HEAD

CALCULATIONS BY ASME CODE SECTION-8 DIVISION I (UG-37)

CALCULATION OF CERTAIN FACTORS

PROVIDED NOZZLE WALL THICKNESS IS SUFFICIENT

2*max(d,R

n

+t

n

+t)

limit normal to vessel wall (t

lnp

)

204.52

0.702074

min(2.5t,2.5t

n

+t

e

)

0.702074

27.5

-

tlnp mm

-

LIMITS OF REINFORCEMENT

limit parallel to vessel wall (D

1

)

D1 mm

-

-

min(Sn,Sp)/Sv

Sn/Sv

t

ext

+c.a.

,nozzle

t

b3

from table +c.a.

,nozzle

mm 5.73

fr1,fr2

min nozzle thickness(t

ug45

)

fr3

mm 5.73

MIN NOZZLE THICKNESS (ACCORDING TO UG-45)

t

a

(P(d')/(2(S

n

+(0.4*P)))+c.a.

,nozzle

t

b1

t

int

+c.a.

,nozzle

max(t

a

,.min(t

b3

,max(t

b2

,t

b1

)))

t

b2

mm 0.32579

mm 9.92

mm 0

0

A

62

0

mm

2

mm

2

mm

2

-

-

Area required

mm

2

-

A

r

OPENING IS NOT ADEQUATELY REINFORCED, INCREASE THICKNESS OF

REINFORCING ELEMENTS

A

61

+A

62

mm

2

mm

2

A

2

A

4

A

5

A

1

+A

2

+A

41

+A

42

+A

5

+A

61

+A

62

Area available in pad

Area available in hub

A

T

A

6

0

1102.314

100.8716

561.6108

100

Area available in shell

Area available in welds

(min(D

p

,2*d,2*(R

n

+t

n

+t))-d-2t

n

)t

e

f

r4

2*min(h,t

lnp

,L

pr1

)*(X-t

n

')*f

r2

fr4

Sp/Sv

force correlation factor

min(5f

r2

t(t

n

-t

r n

),2f

r2

t

n

(t

n

-t

r n

)(2.5t

n

+t

e

)

(leg

1

)

2

f

r1

Area available in nozzle

mm

2

A

61

-

if integral type(0.75+0.25cos2),else 1

1

1

mm

2

A

1

max(d[E

1

t-Ft

r

]-2t

n

(E

1

t-Ft

r

)(1-f

r1

) , 2(t+t

n

)(E

1

t-Ft

r

)-2t

n

(E

1

t-Ft

r

)(1-f

r1

))

total area available

Area available in bevel

Area available in hub plus bevel

mm

2

0

762.4825

max(t

lnp

-h,0)*((max(t

lnp

-h,0)/L')*(X-t

n

))+(X-t

n

-((max(t

lnp

-h,0)/L'))*(X-tn))*max(t

lnp

-h,0)*2

[if fr<1] dt

r

F + 2t

n

t

r

F(1-f

r1

), else dt

r

F

AREA CALCULATION

CALCULATION BY APPENDIX 1-10

R

n

mm 51.13

5.73

t

ext

+c.a.

,nozzle

t

b1

LIMITS OF REINFORCEMENT

PROVIDED NOZZLE WALL THICKNESS IS SUFFICIENT

R

eff

2850

CERTAIN PARAMETERS

mm

(d'-2t

n

)/2

inside radius of nozzle

0

mm

max(t

a

,.min(t

b3

,max(t

b2

,t

b1

)))

effective vessel wall length

effective pressure radius

D/2+c.a

,shell

.

8t,10t,8(t+t

e

)(acc to diff condtns.)

t

b3

mm 5.73

from table +c.a.

,nozzle

min nozzle thickness(t

ug45

)

t

b2

mm

mm L

R

88

MIN NOZZLE THICKNESS (ACCORDING TO UG-45)

t

a

mm 0.32579

(P(d')/(2(S

n

+(0.4*P)))+c.a.

,nozzle

mm

t

int

+c.a.

,nozzle

9.92

L

H

mm 32.5074

t

eff

L

H3

L

H4

L

H2

51

A

5

A

T

S

allow

R

nc

for calculating A

1

min(10, (2R

n

+t

n

)/((D+t

eff

)t

eff

)

0.5

area contributed by nozzle

17004.41

-

if(L

H

<h+t)t

n

L

H

else(X(h+t)+0.78(t

n

2

/(X-c.a.))(R

n

t

n

)

0.5

)

total area available

A

1

+A

2

+A

41

+A

42

+A

5

allowable local primary membrane stress

for calculating L

H

for calculating L

H

X(h+t)+0.78(t

n

/(X-c.a.))(R

n

t

n

)

0.5

0

1501.385

1759.005

FORCE CALCULATION

R

n

/cos

mm

mm

mm

88

72.5074

f

S

kgf

11

63.78107

51.13

kgf

8(t+t

e

)

for calculating LH

mm

effective nozzel wall length

if(h=0),min(L

H1

,L

H2

,L

H3

) else min(L

H1

,L

H2

,L

H4

)

nozzle radius opening in vessel along long chord

if t

e

>0.5tand w>8(t+t

e

),t+t

e

else t

mm

mm

50

effective thickness used in calc. of pressure stress

968

483.3851

1.5*S

n

A

1

mm

2

mm

2

area contributed by reinforcing pad

min(A

5a

,A

5b

)

A

4

CALCULATION OF AREAS

mm

2

A

2

area contributed by welds

0.467321

ALLOWABLE STRESS

kgf/cm

2

mm

2

f

N

internal pressure force on nozzle

32.5074

L

pr1

+ t

0.5Leg

1

2

+ 0.5leg

2

2

for calculating L

H

t+0.78(R

n

t

n

)0.5

L

H1

PR

n

(L

H

-t)

internal pressure force on shell

PR

eff

(L

R

+t

n

)

area contributed by vessel

tL

R

max(1,/4)

mm

2

max. local primary membrane stress at nozzle intersection

min(P

max1

,P

max2

)

nozzle maximum allowable pressure

used in calculation of P

max

average primary membrane stress

discontinuity force from internal pressure

PR

eff

R

nc

used in calculation of P

max1

used in calculation of P

max

kgf/cm

2

kgf/cm

2

A

P mm

2

kgf

P

L

kgf/cm

2

kgf/cm

2

kgf/cm

2

kgf/cm

2

R

n

(L

H

-t)+R

eff

(L

R

+t

n

+R

nc

)

439999.7

8451.789

P

max1

f

Y

1896.798

1699.763

MAXIMUM ALLOWABLE PRESSURE CALCULATION

5.378659

4.526095

4.526095

STRESS CALCULATION

general primary membrane stress

S

n

*(t/R

eff

)

P

max2

P

max

avg

circ

1502.727

max[2

avg

-

circ

,

circ

]

(f

N

+f

S

+f

Y

)/A

T

Pr

eff

/t

eff

S

allow

/(2(A

p

/A

T

)-(R

eff

/t

eff

))

OPENING IS NOT ADEQUATELY REINFORCED, INCREASE THICKNESS OF

REINFORCING ELEMENTS

CALCULATION BY APPENDIX 1-7

CONDITION ON LIMIT OF REINFORCEMENT

(A

T,l

>A

R

)

LIMITS OF REINFORCEMENT

area required for reinforcement

required for reinforcement remains the same and thus we will directly use it

two third of area required

max(t

a

,.min(t

b3

,max(t

b2

,t

b1

)))

0.6666666*A

T

PROVIDED NOZZLE WALL THICKNESS IS SUFFICIENT

from ug-37

area contributed by welds

area contributed by pad

mm

2

100

A

5

same as in ug-37

2*max(0.75*d,R

n

+t+t

n)

min(2.5*t,2.5t

n

+t

e

)

limit normal to vessel wall

limit parallel to vessel wall

mm 154 d

1

A

2 mm

2

561.6108

A

4

mm

2

0

A

T mm

2

1102.314

A

R mm

2

734.8758

min nozzle thickness(t

ug45

)

mm 5.73

t

b3

mm 5.73

from table +c.a.

,nozzle

t

b2

mm 0

t

ext

+c.a.

,nozzle

area contributed by shell

AREA CALCULATION

t

b1

mm 9.92

t

int

+c.a.

,nozzle

MIN NOZZLE THICKNESS (ACCORDING TO UG-45)

t

a

mm 0.32579

(P(d')/(2(S

n

+(0.4*P)))+c.a.

,nozzle

(d

1

-2*R

n

)*[E

1

t-Ft

r

]-2t

n

(E

1

t-Ft

r

)(1-f

r1

)

mm 27.5

A

1

same as in ug-37

d

2

area contributed by nozzle

some additional conditions are imposed on ug-37 when we use appendix 1-7 but area

min((d

1

-d-2t

n

)t

e

f

r4

,(D

p

-d-2t

n

)t

e

f

r4

)

mm

2

46.31004

and 3.4 (Rt)

0.5

and and vessel I.D. is greater than 1500mm

0 A

61 mm

2

0

A

T,l mm

2

707.9209

FOR GIVEN INPUTS IT NEED NOT BE CHECKED

area contributed by bevel

mm

2

CONDITION ON STRESSES

(S

m

<S

m,allow

and S

m+b

<S

m+b,allow

)

check following condition on stresses only if nozzle I.D. is greater than 1000mm

area contributed by hub

total area within limits

LIMIT OF REINFORCEMENT IS NOT SATISFIED

same as in ug-37

A

q

+A

2

+A

41

+A

42

+A

5

+A

61

+A

62

same as in ug-37

A

62

CALCULATION OF SHADED AREAS FOR MEMBRANE STRESS

758.37

0

shaded area in fig 1-7-1 A

s mm

2

2551.92

R

m

mm

R

eff

+ t/2

mean radius of shell

mean radius of nozzle

distance between neutral axis and shell bottom

STRESS CALCULATION

33.31573

11661906

mm

4

moment of inertia

t*max(16t,(R

m

t)

0.5

)

t

e

*min(16t,W,(R

m

t)

0.5

)

area of reinforcing pad

R

n

+ t

n

/2

CALCULATION OF AREAS FOR BENDING STRESS

R

nm

mm 58.565

S

m+b kgf/cm

2

A

2

area of shell

combined membrane and bending stress

max bending stress

bending moment

P(R

n

3

/6 +RR

n

e)

Ma/I

S

m

+S

b

A

1

t

n

*min(L

pr1

+t,max(t+t

e

+(R

nm

t

n

)

0.5

,t+t

e

+16t

n

))

area of nozzle

mm

2

1949.531

mm

2

0

area of bevel

A

3 mm

2

a mm

e mm

(X-t

n

')*(k

1

+t)

CALCULATION OF MOMENT OF INERTIA

2855.5

e+t/2

P(R(R

n

+t

n

+(R

m

t)

0.5

)+R(t+(R

nm

t

n

)

0.5

))/A

s

kgf/cm

2

S

m

1580.225

28286.97

max. membrane stress

1674.376

M

S

b kgf/cm

2

94.15092

38.81573

I

kgfcm

mm

2

A

4

A

5 mm

2

0

distance between neutral axis &shell midwell

area of hub

0.5*(X-tn')*k

2

STRESS CONDITION IS NOT SATISFIED,INCREASE REINFORCEMENTS

allowable membrane stress

S

m,allow kgf/cm

2

1172.67

S

m+b,allow kgf/cm

2

1759.005

1.5*Sn

allowable combined membrane and bending stress

S

n

0.5*(X-t

n

')*min(L',(t+t

n

+(R

nm

t

n

)

0.5

-h))+(X-t

n

')*(t+min(t+t

e

+(R

nm

t

n

)

0.5

,h))+t

n

(t+t

e

+(R

nm

t

n)

0.5

)+ t*(R

m

t)

0.5

+ t

e

(min(16t,W)

0.5*(X-t

n

')*min(L',(t+t

n

+(R

nm

t

n

)

0.5

-h))+(X-t

n

')*(t+min(t+t

e

+(R

nm

t

n

)

0.5

,h))+t

n

(t+t

e

+(R

nm

t

n)

0.5

)+ t*(R

m

t)

0.5

+ t

e

(min(16t,W)

P Kgf/cm2 5.8

E - 1

Di mm 5700

Do mm 132

Rn mm 51.13

D mm 102.26

t mm 70

tn2 mm 14.87

tn mm 14.87

Lx3 mm 40

C mm 0

S Kgf/cm2 1670.295

SN Kgf/cm2 1172.67

Leg mm 10

Lx4-Lx3 mm 0

Lpr1 mm 62.305

DO THK.

323.8 8.34

273 8.11

219.1 7.16

168.3 6.22

141.3 5.73

114.3 5.27

101.6 5.02

88.9 4.8

73 4.52

60.3 3.42

48.3 3.22

42.2 3.12

33.4 2.96

26.7 2.51

21.3 2.42

17.1 2.02

13.7 1.96

10.3 1.51

132 5.73

NOZZLE MATERIAL FACTOR

frn - 0.702074

MIN(Sn/S,1)

THIS IS MINIMUM REQUIRED THICKNESS OF NOZZLE AS PER TABLE 4.5.2 .

BUT WE HAVE TO CHECK MINIMUM THICKNESS OF NOZZLE BY INTERNAL

PRESSURE & EXTERNAL PRESSURE CALCULATION ALSO

HENCE MIN REQIRED THK OF NOZZLE MAX(tnX,tnY) 5.73

THICKNESS OF NOZZLE IS ADEQUATE

THICKNESS OF NOZZLE IS NOT ADEQUATE

NOZZLEALLOWBLE

OUTSIDE NOZZLE FILLET WELD

BEVEL HEIGHT

GIVEN PERPENDICULAR LIMIT OF REINFORCEMENT

COMPUTED MINIMUM REQUIRED THICKNESS

0.5*D*(EXP(P/(S*E))-1)+C tn2 mm 0.253514

HEAD THICKNESS

NOZZLE THICKNESS

HUB THICKNESS

HUB HEIGHT

CORROSION ALLOWANCE

SHELL ALLOWBLE

INTERNAL PRESSURE

JOINT EFFICIENCY

INSIDE DIA OF SHELL

OUTSIDE DIA OF NOZZLE

INSIDE RADIUS OF NOZZLE

INSIDE DIA OF NOZZLE

DESIGN CALCULATION FOR VARIBLE THICKNESS NOZZLE TO

HEMI HEAD

Page No

Doc. No. Revision

(DI+2C)/t - 81.42857

Reff mm 2850

Fp - 1

LH1 mm 27.57359

LH2 mm 62

- 0.184302

A2 cm

2

14.50919

A2a cm

2

5.948

A2b cm

1

-8.0124

A2C cm

2

8.561193

A2 cm

2

14.50919

A4 cm

2

0.5

At cm

2

82.26852

AREA PROVIDE BY NOZZLE-SHELL FILLET WELD

TOTAL AREA

AREA REINFORCEMENT & MAWP CALCULATION

NOZZLE RADIUS FOR FORCE CALCULATION

Rxn mm 58.24725

tn/ In(1+tn/Rn)

A2 (IF PERPENDICULAR LIMIT IF LESS THAN HUB HEIGHT)

A2a ( REINFORCEMENT BY HUB)

A2b ( REINFORCEMENT BY BEVEL)

A2c ( REINFORCEMENT BY BEVEL+ NOZZLE WALL)

TOTAL AREA PROVIDED BY NOZZLE

AREA CALCULATION

AREA PROVIDED BY VESSEL WALL

A1 cm2 71.582 t x LR x max(/5^0.85),1)

EFFECTIVE NOZZLE WALL LENGTH OUTSIDE THE VESSEL

LH mm 97.57359

MIN(LH1,LH2) + t

NON LINERATITY PARAMETER

NOZZLE ATTACHMENT FACTOR

LH1 ( Fp x SQRT(Rn,tn) )

LH2 (Equal to Lpr1)

MIN(SQRT(Reff x t),2 x Rn)

PERPENDICULAR LIMIT OF REINFORCEMENT

FEA DERIVED FACTOR TO MODIFY NOZZLE LENGTH

Cn - 1

MIN((t/tn)^0.35,1)

SHELL DIA TO THICKNESS RATIO

EFFECTIVE RADIUS OF SHELL

PARALLEL LIMIT OF REINFORCEMENT

EFFECTIVE LENGTH OF VESSEL WALL

LR mm 102

EFFECTIVE NOZZLE THICKNESS

tn2eff mm 14.87

tn2-c

EFFECTIVE HUB THICKNESS

tneff mm 14.87

tn-c

PL Kgf/cm2 230.7069

Sallow Kgf/cm2 2505.443

WELD LENGTH OF NOZZLE

L

- 103.62

STRENGTH OF NOZZLE ATTACHMENT WELDS

DICONTINUITY FORCE FACTOR

Ky - 1.290827

(Rn+tn) / Rnc

SUMMARY OS STRESS RESULT

LOCAL PRIMARY MEMBRANE STRESS

ALLOWED LOCAL PRIMARY MEMBRANE STRESS

STRESSES ARE UNDER PERMISIBLE LIMIT

LOCAL PRIMARY MEMBRANE STRESS

PL Kgf/cm2 230.7069

MAX(2 x avg -circ , circ)

GENERAL PRIMARY MEMBRANE STRESS

circ Kgf/cm2 119.512

P x Rxs / (2 X teff)

NOZZLE PASS

STRESS CALCULATION

AVERAGE PRIMARY MEMBRANE STRESS

avg Kgf/cm2 175.1094

( fs + fy + fn )/ At

MAXIMUM ALLOWABLE WORKING PRESSURE CANDIDATE

Pmax1 Kgf/cm2 62.98713

MIN(Pmax1,Pmax2)

MAXIMUM ALLOWABLE WORKING PRESSURE CANDIDATE 1

Pmax1 Kgf/cm2 81.06059

2 X S/ (t / Rxs)

MAXIMUM ALLOWABLE WORKING PRESSURE CANDIDATE 1

Pmax1 Kgf/cm2 62.98713

Sallow/ ( 2 x Ap/At - Rxs/2 X teff )

AREA RESISTING INTERNAL PRESSURE

Ap cm2 2483.792

( fs + fy + fn )/ P

DISCONTINUITY FORCE FROM INTERNAL PRESSURE

fy kgf 4277.453

P x Rxs x Rnc/2

FORCE ACTING ON THE SHELL

fs kgf 9798.906

P x Rxs (LR + tn)

FORCE ACTING ON THE NOZZLE

fn kgf 329.6368

P x Rxn x LH

ALLOWABLE LOCAL PRIMARY MEMBRANE STRESS

Sallow Kgf/cm2 2505.443

1.5 x S x E

SHELL RADIUS FOR FORCE CALCULATION

Rxs mm 2884.772

teff/ In(1+teff/Reff)

- mm 7.071

DATE

WELD STRENGTH IS OK

PREPARED BY

VERIFIED BY

5521.453

MIN(fy x ky , 1.5 x Sn x A2) , x P x Rn^2 x ky^2)

WELD STRESS VALUE

Kgf/cm2 1.172019

WELD THROAT DIMENSION

WELD LOAD VALUE

fwelds kgf

L

- 103.62

/2 x (Rn/tn)

1.09962 8577.037

0.092082

Das könnte Ihnen auch gefallen

- ASME UG 37 Nozzles PDFDokument6 SeitenASME UG 37 Nozzles PDFlatif.deNoch keine Bewertungen

- Calculation of Pipe Reinforcement ASME B31 3Dokument3 SeitenCalculation of Pipe Reinforcement ASME B31 3Brant AkkanNoch keine Bewertungen

- New - Reinforcement of NozzleDokument24 SeitenNew - Reinforcement of NozzleVaniya GoelNoch keine Bewertungen

- Cs & Las Impact Req - Asme Sec Viii Div 2Dokument16 SeitenCs & Las Impact Req - Asme Sec Viii Div 2AmitNarayanNitnawareNoch keine Bewertungen

- Nozzle Reinforcement Calculations: HH1&HH2 (Hand Hole) : Description Regulation Formula Symbol Value UnitDokument1 SeiteNozzle Reinforcement Calculations: HH1&HH2 (Hand Hole) : Description Regulation Formula Symbol Value Unitmiteshpatel191Noch keine Bewertungen

- Asme - Shell External Pressure REV ADokument1 SeiteAsme - Shell External Pressure REV APohn Myint HanNoch keine Bewertungen

- AD 2000 Shell Under External PressureDokument3 SeitenAD 2000 Shell Under External Pressuremechengg01100% (1)

- Tailing LugDokument2 SeitenTailing Lugjagannadha varmaNoch keine Bewertungen

- Ref: Procedure No. 2-10 Pg. No. 59, Pressure Vessel Design Manual by Dennis Moss, 3rd EditionDokument5 SeitenRef: Procedure No. 2-10 Pg. No. 59, Pressure Vessel Design Manual by Dennis Moss, 3rd EditionSivi NallamothuNoch keine Bewertungen

- Base Ring Fillet Size CalculationDokument4 SeitenBase Ring Fillet Size Calculationmiteshpatel191Noch keine Bewertungen

- External Pressure Calculation Results SummaryDokument8 SeitenExternal Pressure Calculation Results SummaryAndika DearsonNoch keine Bewertungen

- Pipe Thickness Calculations - : ClassDokument1 SeitePipe Thickness Calculations - : ClassOluwachidiNoch keine Bewertungen

- Design Procedure For Aes He PDFDokument30 SeitenDesign Procedure For Aes He PDFRyan Goh Chuang HongNoch keine Bewertungen

- Flat Ends With A Relief GrooveDokument11 SeitenFlat Ends With A Relief GrooveEng-CalculationsNoch keine Bewertungen

- Trunnion AnalysisDokument45 SeitenTrunnion AnalysisChiragJansariNoch keine Bewertungen

- Sight Glass Flange AnalysisDokument4 SeitenSight Glass Flange AnalysisOmil Rastogi0% (2)

- Cylindrical ShellsDokument3 SeitenCylindrical ShellsEng-CalculationsNoch keine Bewertungen

- Project of Pressure VesselDokument25 SeitenProject of Pressure VesselKalkidan DanielNoch keine Bewertungen

- Stress RelievingDokument1 SeiteStress RelievingCruz Gabriel Rosetti100% (1)

- Toriconical Head Ver 1.1Dokument4 SeitenToriconical Head Ver 1.1Iqbal AhmadsNoch keine Bewertungen

- Finglowv2Dokument16 SeitenFinglowv2RobinReyndersNoch keine Bewertungen

- Bolt TorqueDokument3 SeitenBolt TorqueHeri KurniawanNoch keine Bewertungen

- Welding Calculation ModulDokument5 SeitenWelding Calculation ModulricardoNoch keine Bewertungen

- Determine Shell ThicknessDokument53 SeitenDetermine Shell ThicknessRajul MuraliNoch keine Bewertungen

- Blind Flange (10 Bar)Dokument7 SeitenBlind Flange (10 Bar)SyedZainAliNoch keine Bewertungen

- U-V-673 - Manual Flange and GussetDokument8 SeitenU-V-673 - Manual Flange and GussetDarshan PanchalNoch keine Bewertungen

- PCC1 - Addendum - 31210130 (Feb 2013) - GM1-001-G0000-MS-7880-00003Dokument2 SeitenPCC1 - Addendum - 31210130 (Feb 2013) - GM1-001-G0000-MS-7880-00003Abhay UpadhyayNoch keine Bewertungen

- Reinforcement Pad DesignDokument3 SeitenReinforcement Pad DesignAkshat JainNoch keine Bewertungen

- 0.0bolt Torque Calculation - R0Dokument9 Seiten0.0bolt Torque Calculation - R0Darshan PanchalNoch keine Bewertungen

- Design of Pressure Vessel NewDokument442 SeitenDesign of Pressure Vessel NewkhanfaqihNoch keine Bewertungen

- Final Weld Strength CalnsDokument5 SeitenFinal Weld Strength CalnsamachmouchiNoch keine Bewertungen

- BREVIA DE CALCUL PENTRU SEPARATORUL ORIZONTAL TRIFAZIC 80MCDokument223 SeitenBREVIA DE CALCUL PENTRU SEPARATORUL ORIZONTAL TRIFAZIC 80MCakın ersözNoch keine Bewertungen

- E4.5.1 6 PTB 4 2015 PDFDokument50 SeitenE4.5.1 6 PTB 4 2015 PDFKingston RivingtonNoch keine Bewertungen

- ASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound GasketsDokument5 SeitenASME B16.47!75!300# Series B Flanges With FLEXSEAL Spiral Wound Gasketserik aranaNoch keine Bewertungen

- Sample FLG CalcDokument6 SeitenSample FLG CalcameyyammaiNoch keine Bewertungen

- PV Elite Vessel Analysis Program HorizontalDokument55 SeitenPV Elite Vessel Analysis Program HorizontalMarizta Perdani PutriNoch keine Bewertungen

- Compress EvaluateDokument23 SeitenCompress EvaluateVishalDhiman100% (1)

- Stress at Junction of Shell & HeadDokument13 SeitenStress at Junction of Shell & HeadRey Fiedacan100% (1)

- SADDLE SUPPORT DESIGNDokument6 SeitenSADDLE SUPPORT DESIGNSISIR KR BARMAN0% (1)

- Narrow Face Flange - Slip On Hub TypeDokument17 SeitenNarrow Face Flange - Slip On Hub TypeEng-CalculationsNoch keine Bewertungen

- Pressure Design Straight Pipe (Run Pipe)Dokument6 SeitenPressure Design Straight Pipe (Run Pipe)gembirasekaliNoch keine Bewertungen

- New - Reinforcement of NozzleDokument31 SeitenNew - Reinforcement of NozzleChagar HarshpalNoch keine Bewertungen

- Shell Inputs: Use Asme Code Section-8 Division I (Ug-37)Dokument34 SeitenShell Inputs: Use Asme Code Section-8 Division I (Ug-37)Bashu PoudelNoch keine Bewertungen

- New - Reinforcement of NozzleDokument31 SeitenNew - Reinforcement of NozzleNithin ZsNoch keine Bewertungen

- Sudyrah, Station Design Calculation of Existing Steel Tank Inlet Connection N-1 Doc. No.96-QC20-J-414Dokument7 SeitenSudyrah, Station Design Calculation of Existing Steel Tank Inlet Connection N-1 Doc. No.96-QC20-J-414Hgagselim SelimNoch keine Bewertungen

- Section VIII CalDokument19 SeitenSection VIII CalPradeep Kothapalli100% (1)

- Section VIII CalDokument21 SeitenSection VIII CalRuben Samoel Barros RochaNoch keine Bewertungen

- Ibr Calc GSRDokument4 SeitenIbr Calc GSRAniket GaikwadNoch keine Bewertungen

- Calculation of Nozzle Thickness and Pressure LimitsDokument6 SeitenCalculation of Nozzle Thickness and Pressure LimitsSACHIN PATELNoch keine Bewertungen

- UEPL THICKNESS CALCULATION FOR SBA AND SAC VESSELS ROSA TPPDokument8 SeitenUEPL THICKNESS CALCULATION FOR SBA AND SAC VESSELS ROSA TPPmkchy12100% (1)

- 6 Inch NB Nozzle Calculation Appendex 1-7Dokument11 Seiten6 Inch NB Nozzle Calculation Appendex 1-7SACHIN PATELNoch keine Bewertungen

- 26 Pressure Vessel.Dokument21 Seiten26 Pressure Vessel.mishtinil93% (14)

- Asme Viii Shell & Se HeadDokument5 SeitenAsme Viii Shell & Se HeadSnr George RaczNoch keine Bewertungen

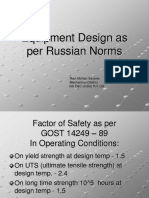

- Equipment Design As Per Russian Norms - 20090218Dokument45 SeitenEquipment Design As Per Russian Norms - 20090218vikasNoch keine Bewertungen

- Thickness Calculation of Pressure Vessel ShellDokument22 SeitenThickness Calculation of Pressure Vessel ShellAkshat Jain88% (26)

- Super CalculationsDokument9 SeitenSuper CalculationsNoé MarínNoch keine Bewertungen

- Nozzle and ReinforcementDokument23 SeitenNozzle and ReinforcementAzharyanto Fadhli100% (1)

- Ibr CalcDokument4 SeitenIbr CalcUmesh Kondkar100% (7)

- Page No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced NozzleDokument24 SeitenPage No Doc. No. Revision Design Calculation For Set In, Set On Nozzle With and Without Pad and Self Reinforced NozzleAboMuhmadSr.Noch keine Bewertungen

- Baffle Cut Diagrams and ExplanationsDokument2 SeitenBaffle Cut Diagrams and ExplanationsPravin KhilariNoch keine Bewertungen

- Tema ReqDokument21 SeitenTema Reqhardik5818Noch keine Bewertungen

- Ngineers India Limited: Allowable Nozzle Loads Standard NoDokument4 SeitenNgineers India Limited: Allowable Nozzle Loads Standard Nohardik5818Noch keine Bewertungen

- Mechanical Design Basics of Tall ColumnsDokument45 SeitenMechanical Design Basics of Tall Columnshardik5818Noch keine Bewertungen

- PV Elite Heat Exchanger CalculationsDokument99 SeitenPV Elite Heat Exchanger CalculationscbousmuNoch keine Bewertungen

- Collar Type BoltDokument1 SeiteCollar Type Bolthardik5818Noch keine Bewertungen

- Bending Moment and Shear Force Diagrams ExplainedDokument11 SeitenBending Moment and Shear Force Diagrams Explainedhardik5818100% (1)

- EIL Nozzle LoadsDokument5 SeitenEIL Nozzle LoadsAniket GaikwadNoch keine Bewertungen

- ASME VIII A13 - Vessels of Noncircular Cross Section (Type 13-2 (A) (6) )Dokument14 SeitenASME VIII A13 - Vessels of Noncircular Cross Section (Type 13-2 (A) (6) )hardik5818100% (1)

- PH - Acidity H2S Level Temperature Duration of Exposure Nature of The MaterialDokument9 SeitenPH - Acidity H2S Level Temperature Duration of Exposure Nature of The Materialhardik5818Noch keine Bewertungen

- Base Ring AnalysisDokument9 SeitenBase Ring Analysisasirul_meNoch keine Bewertungen

- Section Properties03Dokument20 SeitenSection Properties03xavierlthNoch keine Bewertungen

- PH - Acidity H2S Level Temperature Duration of Exposure Nature of The MaterialDokument9 SeitenPH - Acidity H2S Level Temperature Duration of Exposure Nature of The Materialhardik5818Noch keine Bewertungen

- Asme - PVP2005-71728Dokument11 SeitenAsme - PVP2005-71728ash1968Noch keine Bewertungen

- Stainless Steel Pressure RatingsDokument7 SeitenStainless Steel Pressure RatingsNauman KhanNoch keine Bewertungen

- Torque-Tension Chart For B7Dokument1 SeiteTorque-Tension Chart For B7Ramón C. Silva H.Noch keine Bewertungen

- Asme - PVP2005-71728Dokument11 SeitenAsme - PVP2005-71728ash1968Noch keine Bewertungen

- 2 - Pipe Schedule & Inner Dia DimensionsDokument1 Seite2 - Pipe Schedule & Inner Dia DimensionsHazairin As-Shiddiq RahmanNoch keine Bewertungen

- EJMA Bellows - CalculatorDokument5 SeitenEJMA Bellows - Calculatorhardik5818Noch keine Bewertungen

- Pressure Vessel Design CalculationsDokument127 SeitenPressure Vessel Design Calculationsajayghosh314086% (22)

- Stainless Steel Pressure RatingsDokument7 SeitenStainless Steel Pressure RatingsNauman KhanNoch keine Bewertungen

- Nozzle Table 27.9.2017Dokument1 SeiteNozzle Table 27.9.2017hardik5818Noch keine Bewertungen

- Strain Hardening, Cold Working, and Annealing EffectsDokument7 SeitenStrain Hardening, Cold Working, and Annealing EffectsPawan Kumar SapraNoch keine Bewertungen

- Strengthening Mechanism3 PDFDokument78 SeitenStrengthening Mechanism3 PDFAmber WilliamsNoch keine Bewertungen

- Pressure Drop Calc - STDDokument25 SeitenPressure Drop Calc - STDhardik5818Noch keine Bewertungen

- Appendix 2) : Optional Type Flange (Fig. 2-4 (8) )Dokument18 SeitenAppendix 2) : Optional Type Flange (Fig. 2-4 (8) )hardik5818Noch keine Bewertungen

- 2 - Pipe Schedule & Inner Dia DimensionsDokument1 Seite2 - Pipe Schedule & Inner Dia DimensionsHazairin As-Shiddiq RahmanNoch keine Bewertungen

- Wood Thermal ConductivityDokument8 SeitenWood Thermal Conductivityhardik5818Noch keine Bewertungen

- PV Elite Heat Exchanger CalculationsDokument99 SeitenPV Elite Heat Exchanger CalculationscbousmuNoch keine Bewertungen

- 2 - Pipe Schedule & Inner Dia DimensionsDokument1 Seite2 - Pipe Schedule & Inner Dia DimensionsHazairin As-Shiddiq RahmanNoch keine Bewertungen

- Workshop 01.1: Shell Disk: ANSYS Mechanical Basic Structural NonlinearitiesDokument13 SeitenWorkshop 01.1: Shell Disk: ANSYS Mechanical Basic Structural NonlinearitiesSahil JawaNoch keine Bewertungen

- Strip Deflection Compatibility Method ...Dokument9 SeitenStrip Deflection Compatibility Method ...Umed ADA-ALSATARNoch keine Bewertungen

- TNPSC TopicDokument11 SeitenTNPSC TopicM PraveenNoch keine Bewertungen

- Sayyad 2015Dokument25 SeitenSayyad 2015Hichem SofNoch keine Bewertungen

- Meever India Brochure FinalDokument44 SeitenMeever India Brochure FinalSrinu NaikNoch keine Bewertungen

- Chapter 4 - Part 2Dokument13 SeitenChapter 4 - Part 2Dhea Meirina SariNoch keine Bewertungen

- Design Lab Report 1Dokument7 SeitenDesign Lab Report 1Faris ShabuddinNoch keine Bewertungen

- AnsysDokument15 SeitenAnsysginupaulNoch keine Bewertungen

- Car Park DesignDokument5 SeitenCar Park DesignAhamedKh100% (2)

- Final Year Building Project PresentationDokument48 SeitenFinal Year Building Project PresentationSudeen ShresthaNoch keine Bewertungen

- Arch BridgeDokument133 SeitenArch BridgeLau Kim Hwa100% (2)

- Restrepo Rodriguez ACI Journal 110-s56Dokument18 SeitenRestrepo Rodriguez ACI Journal 110-s56CONSTHURAG2012Noch keine Bewertungen

- Applied Solid Mechanics Peter Howel PDFDokument13 SeitenApplied Solid Mechanics Peter Howel PDFanon_558118723Noch keine Bewertungen

- Ss Designprestressedconcrete enDokument8 SeitenSs Designprestressedconcrete enMarko ŠimićNoch keine Bewertungen

- Structural Calculation EOTDokument9 SeitenStructural Calculation EOTswatantar17100% (6)

- AISC (2005) SpecificationsDokument19 SeitenAISC (2005) SpecificationsAndrew BlackNoch keine Bewertungen

- Farm StructuresDokument3 SeitenFarm StructuresErika HonorioNoch keine Bewertungen

- SHEAR CONNECTION (Plate Washer and Tab Checks)Dokument5 SeitenSHEAR CONNECTION (Plate Washer and Tab Checks)katar kumarNoch keine Bewertungen

- Detail Project Boq of 25kld STPDokument13 SeitenDetail Project Boq of 25kld STPAminur RahmanNoch keine Bewertungen

- ISOLATED FOOTING DESIGNDokument6 SeitenISOLATED FOOTING DESIGNGani AnosaNoch keine Bewertungen

- SF BM TheoryDokument4 SeitenSF BM TheoryRAMAKANT RANANoch keine Bewertungen

- Lab Manual for Strength of Materials ExperimentsDokument54 SeitenLab Manual for Strength of Materials ExperimentsAli ShehryarNoch keine Bewertungen

- Problem Sheet - 1 (Theories of Failure & Factor of Safety)Dokument2 SeitenProblem Sheet - 1 (Theories of Failure & Factor of Safety)S D100% (1)

- Livro - Desgin of Steel To Concrete Joints - Design ManuaL I - ECCS PDFDokument130 SeitenLivro - Desgin of Steel To Concrete Joints - Design ManuaL I - ECCS PDFLuís Ferreira100% (1)

- The Journal of Strain Analysis For Engineering Design-2004-Fantilli-447-57Dokument12 SeitenThe Journal of Strain Analysis For Engineering Design-2004-Fantilli-447-57Marimuthu KaliyamoorthyNoch keine Bewertungen

- Intrvw 1Dokument6 SeitenIntrvw 1shrihari naikNoch keine Bewertungen

- Ur s10 Rev3 Corr1 pdf2566Dokument18 SeitenUr s10 Rev3 Corr1 pdf2566SreekanthNoch keine Bewertungen

- Bamboo Reinforced Concrete PDFDokument24 SeitenBamboo Reinforced Concrete PDFshahbaghi100% (1)

- Thickness Cal. Fo DM Water Storage Tank-API 650Dokument15 SeitenThickness Cal. Fo DM Water Storage Tank-API 650Jose Rodriguez50% (2)