Beruflich Dokumente

Kultur Dokumente

Piling Project Quality Plan

Hochgeladen von

6984Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Piling Project Quality Plan

Hochgeladen von

6984Copyright:

Verfügbare Formate

GS ENGINEERING & CONSTRUCTION CORP

JOB NO.

PBS RFCCPQP 01 - 012

REV.

A

PILING PROJECT QUALITY PLAN

SHEET : 1 OF 74

RESID FLUIT CATALYTIC CRACKING

PT. PERTAMINA UP-IV CILACAP

PILING PROJECT QUALITY PLAN

AT RFCC PT. PERTAMINA

PT. PAKUBUMI SEMESTA

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 2 of 74

TABLE OF CONTENT

INTRODUCTION..3

OBJECTIVES...........................3

REFERENCES.....4

DEFINITION..4

ORGANIZATION AND RESPONSIBILITIES...4

PROJECT QUALITY EXECUTION PLAN....5

ATTACHMENT

ATTACHMENT 1. QC ORGANIZATION CHART

ATTACHMENT 2. INSPECTION AND TEST PLAN ( ITP ) AND FORM

ATTACHMENT 3. EQUIPMENT AND MATERIAL SPESIFICATION

ATTACHMENT 4. WPS

ATTACHMENT 5. CRANE AND OPERATOR CERTIFICATE

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 3 of 74

1. INTRODUCTION

Purpose

The Purpose of this Project Quality Plan (PQP) is to define the project quality

system, activities, procedures, practices, resources and responsibilities for achieving

quality and the quality assurance and quality control activities to be performed by the

Subcontractor for the Project. This Quality Plan is basis for executing the quality

activities to be performed during the project stage including the continuous quality

improvement.

Scope

The Project Quality Program that will be described in this Project Quality Plan

comprised

of quality activities to be performed and document to be produced during the project

from the initial stage to the completion of project.

Also this Project Quality Plan (PQP) shall govern the following:

a) QC Organization (see Attachment-1) and Responsibilities (See Point 2.0

Organization & Responsibilities)

b) Coordination between the construction group and quality group within

Subcontractor organization, and Client / Owners Inspectors.

c) Quality Control including test and inspection reporting and recording /

Inspection Test Plan. d) Inspection tools

Control of Quality Plan

This Project Quality Plan (PQP) will be controlled by the Project Manager and

distributed in accordance with the standard project distribution procedure in which

all personnel are aware of their duties with respect to the plan.

The Project Control will assist the Project Manager in making periodic

documented reviews to ensure current quality requirements have been

considered and incorporated where applicable. The Project Manager or his

designated, to identify the recipients and to indicate the latest revision status, and

maintains a master distribution list.

Control is also implemented for the mechanism and implementation stage of the

Quality Program for these Project activities which is depicted in the relevant

quality system element, activity addressed procedure, responsible personnel, of

activity and evidenced document for the activity.

2. OBJECTIVES

Principle objectives of this Project Quality Plan are:

a. To ensure engineering design, procurement and construction activities are

planned, organized, implemented controlled and effectively discharged so

that information provided is consistent with project needs and design output

meets the Client/ Owner requirements and complies with regulatory (MIGAS /

Indonesian Regulatory) and with safety & environment requirements.

b. To monitor and review all project activities by preventing nonconformities

during all phases of the work (Engineering, Procurement and Construction)

and ensuring that the product and /or service conform to Client/Owner

requirement.

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 4 of 74

3. REFERENCES

The following documents shall be referred and part of this PQP (Project Quality Plan):

AWS D1. 1 American Welding Society - Structural Welding

Code - Steel.

ASTM D 4945 - 89 Test Method for High-Strain Dynamic Testing of

Pile

ASTM D 1143 - 81 Method of Testing Pile under Static Axial

Compressive Load

ASTM D 3966-90 Method of Testing Pile under Lateral Load

PBS RFCCGS 01 012 Work Prosedure of piling Work & Loading Test

4. DEFINITION

The following words shall have the meaning indicated when used herein:

Project : RESID FLUIT CATALYTIC CRACKING

PT. PERTAMINA UP IV CILACAP

Company : PT. PERTAMINA UP - IV

Contractor : GS ENGINEERING AND CONSTRUCTION Corp.

Sub Contractor : PT.PAKUBUMI SEMESTA

5. ORGANIZATION AND RESPONSIBILITIES

5.1. Organization

Contractor Overall QC project organization is shown in the Organization Chart

Attachment 1 shows the reporting relationship of the Project Quality personnel

who manage, perform and verify work affecting quality.

5.2. Responsibilities

5.2.1.Project Manager

The Project Manager is responsible for the quality of the project

management process. This includes the implementation, execution and

maintaining effectiveness of the project quality system. The Project

Manager has overall responsibility for ensuring that the project will meet

the clients requirements. He approves the Project Quality Plan and

ensures that all members of the Project Team fully understand the

principles of the quality process.

5.2.2. Site Manager

The Site Managerreports to the Project Manager for all site and

construction activities including the selection of Subcontractors that

perform the work at the site and assessment of Subcontractor capabilities.

He shall assume the responsibility for the quality of the construction or

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 5 of 74

services as stipulated in the requirement and to meet legal government

regulation.

The Site Managerand his Construction Superintendent/ Supervisors are

responsible to support and cooperate with the QA/QC team to ensure

smooth implementation of this PQP.

The Site Managershall conduct Inspection Meeting with related member

(Sub- Contractor, Client and Owner) if there are any large work problems

5.2.3.QC Supervisors

QC Supervisors shall be responsible to run all QC activities within the

project in accordance with this plan (PQP)

QC Supervisors shall carry out all inspection tasks (within Sub-contractors

scope of work) as specified in its PQP and all relevant QA procedures.

Site Managerwith the assistance of QC Supervisors will be responsible for

technique of communicating and handing over all original inspection

records to Client/Owner upon particularly completion of the Project.

6. PROJECT QUALITY EXECUTION PLAN

6.1. Coordination and Communication

6.1.1. The QC Supervisors shall prepare overall Inspection and test

schedule for each job of the project.

This schedule shall be based on and synchronized with field construction

schedule. Close communication and coordination between construction

groups and quality group is required for this schedule preparation, revision

and progress updating. The Site Manager shall review this inspection

schedule for concurrence. The inspection schedule once approved by the

Site Manager shall also be distributed to Clients quality control

representative for reference.

6.1.2. The QC Supervisors shall consult with his counterpart Clients

quality control representative pertinent to any complain or nonconformance

findings, and propose for the acceptable resolution.

The QC Supervisors shall maintain close communication with their

counterpart of Clients inspectors pertinent to daily inspection activities and

the planned nextone or two days inspection.

The daily inspection activities for the next coming week shall be prepared

on the Weekly Inspection Schedule (based on the overall QC Schedule)

andsubmitted to the Clients relevant inspector for information. Application

for inspection witness by Client shall be forwarded at least one daybefore

the test / inspection date as reference.Copy of approved inspection

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 6 of 74

records shall be submitted to the Clients.

Inspectors for their file at the latest one-day after the test/inspection

completiondate. All original records shall be logged properly for later

transmission by the Site Manager to Client upon or after completion of the

project; one complete set copy shall be handled over to Contractors

Quality Assurance Department.

6.3. Inspection Equipment/Tools

6.3.1. Subcontractor will make available all inspection equipment and tools

needed to ensure proper implementation of QC activities, i.e.:

- Piling crane,Hydraulic Hammer, Welding Engine

6.3.2. Control and maintenance of the inspection tools as follows:

- Ensure the inspection tools are properly calibrated,

monitor status of calibration and maintain re-calibration

as required

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 7 of 74

ATTACHMENT - 1

QC ORGANIZATION CHART

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 8 of 74

QC ORGANIZATION CHART

Office ( Jakarta )

Site ( Cilacap )

Project Manager

T. Bintang S

Site Manager

Victor Saputra

QC Supervisors

Agus Purwanto

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 9 of 74

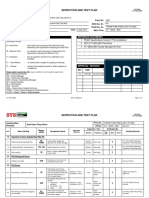

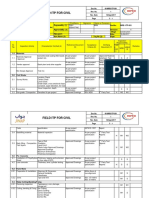

ATTACHMENT - 2

INSPECTION TEST PLAN ( ITP ) AND FORM

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 10 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 11 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 12 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 13 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 14 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 15 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 16 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 17 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 18 of 74

ATTACHMENT - 3

EQUIPMENT AND MATERIAL SPECIFICATION

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 19 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 20 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 21 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 22 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 23 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 24 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 25 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 26 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 27 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 28 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 29 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 30 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 31 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 32 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 33 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 34 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 35 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 36 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 37 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 38 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 39 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 40 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 41 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 42 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 43 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 44 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 45 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 46 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 47 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 48 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 49 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 50 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 51 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 52 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 53 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 54 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 55 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 56 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 57 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 58 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 59 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 60 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 61 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 62 of 74

ATTACHMENT - 4

WPS

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 63 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 64 of 74

ATTACHMENT - 5

CRANE AND OPERATOR CERTIFICATE

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 65 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 66 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 67 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 68 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 69 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 70 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 71 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 72 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 73 of 74

RFCC PT. PERTAMINA Project

PROJ ECT QUALI TY PLAN

Page 74 of 74

Das könnte Ihnen auch gefallen

- Road Construction Essentials QA/QC PlanDokument10 SeitenRoad Construction Essentials QA/QC Planrafiullah amireeNoch keine Bewertungen

- Itp PilingDokument3 SeitenItp PilingMikiRoniWijaya50% (6)

- ITP Piling WorksDokument4 SeitenITP Piling WorksMohammad Hadoumi Saldan100% (1)

- PROJECT QUALITY PLAN Rev-00Dokument33 SeitenPROJECT QUALITY PLAN Rev-00shahhassa989% (18)

- 027-ITP For Pre - Cast Concrete PDFDokument11 Seiten027-ITP For Pre - Cast Concrete PDFKöksal Patan75% (4)

- K 3 Project Quality PlanDokument23 SeitenK 3 Project Quality PlanJonathan JoeNoch keine Bewertungen

- Method Statement & ITP For Construction of Tunnel Retaining Wall at S10 Part 3-5 and 5-5 PDFDokument10 SeitenMethod Statement & ITP For Construction of Tunnel Retaining Wall at S10 Part 3-5 and 5-5 PDFrayNoch keine Bewertungen

- General Earthwork Procedures: PT Aurecon Indonesia ProcedureDokument16 SeitenGeneral Earthwork Procedures: PT Aurecon Indonesia ProcedureMohamed Amine Zemouri0% (1)

- Preparation of Inspection & Test Plans For Civil & Steelworks, Rev.0 Foster Wheeler Energy LTD Work Practice Construction OperationsDokument5 SeitenPreparation of Inspection & Test Plans For Civil & Steelworks, Rev.0 Foster Wheeler Energy LTD Work Practice Construction Operationssateeshsingh100% (2)

- Method Statement For Piling WorksDokument2 SeitenMethod Statement For Piling Worksshahul_hamid_277% (22)

- Construction Quality Management. 1Dokument6 SeitenConstruction Quality Management. 1XDXDXDNoch keine Bewertungen

- Inspection and Test Plan Fro RoadDokument81 SeitenInspection and Test Plan Fro RoadJay Alvin Dagpin Denoyo87% (30)

- Construction Project Quality Plan (PQP)Dokument15 SeitenConstruction Project Quality Plan (PQP)MohamedNoch keine Bewertungen

- PQPDokument16 SeitenPQPMuhammad ShazwanuddinNoch keine Bewertungen

- ITP & Ceklis Bored PileDokument5 SeitenITP & Ceklis Bored Pilefari_civil06Noch keine Bewertungen

- Sheet Pile Driving Record 2Dokument2 SeitenSheet Pile Driving Record 2orode franklynNoch keine Bewertungen

- Method Statement For Casting Blinding ConcreteDokument2 SeitenMethod Statement For Casting Blinding ConcreteCrazyBookWorm100% (2)

- Method Statement For Earth WorkDokument8 SeitenMethod Statement For Earth WorkOsama Abdulkafi100% (1)

- Qcs 2010 Part 1.08 Quality AssuranceDokument179 SeitenQcs 2010 Part 1.08 Quality AssuranceRotsapNayrbNoch keine Bewertungen

- Method Statement of Driven PileDokument5 SeitenMethod Statement of Driven Pilenght794233% (3)

- Construction Project Quality Plan BLANKDokument21 SeitenConstruction Project Quality Plan BLANKLa Tonya IbekilliNem Williams100% (2)

- 7 - Request For InspectionDokument1 Seite7 - Request For InspectionfreannNoch keine Bewertungen

- 3009 - Method Statement For Administration Building Construction PDFDokument38 Seiten3009 - Method Statement For Administration Building Construction PDFNjilou LagaticNoch keine Bewertungen

- Project Quality Plan (04.09.2008)Dokument43 SeitenProject Quality Plan (04.09.2008)Chu Yee Sheng100% (10)

- Method Statement For GeotextileDokument17 SeitenMethod Statement For GeotextileGökhan Gökçe0% (1)

- Method Statement For Piling Work (Edited)Dokument18 SeitenMethod Statement For Piling Work (Edited)Faeez Zain100% (6)

- ITP CIVIL WORK-Rev-1Dokument6 SeitenITP CIVIL WORK-Rev-1Ateeq Rahman100% (1)

- ITP Clearing and GrubbingDokument12 SeitenITP Clearing and GrubbingAntonio Tomas Gonzalez LosaNoch keine Bewertungen

- PQP EpldtDokument8 SeitenPQP Epldtmartin leeNoch keine Bewertungen

- Project Quality PlanDokument55 SeitenProject Quality Plansamer8saif75% (4)

- Method Statement For Construction of Pile CAP: DATE: 24-OCT-15 REV: 01Dokument8 SeitenMethod Statement For Construction of Pile CAP: DATE: 24-OCT-15 REV: 01Joe PSNoch keine Bewertungen

- Bored Pile - Method StatementDokument13 SeitenBored Pile - Method Statementbtcong93100% (2)

- QA QC PLAN For CNG..Dokument21 SeitenQA QC PLAN For CNG..Pugel Yeremias100% (1)

- Piling ProcedureDokument20 SeitenPiling ProcedurePaulusjonfreser80% (10)

- Batching Plant ChecklistDokument4 SeitenBatching Plant ChecklistSubramanian BalakrishnanNoch keine Bewertungen

- Inspection Test PlanDokument6 SeitenInspection Test PlanMOST PASON100% (1)

- 01 Method Statement For Pile Cap Foundations (Findal)Dokument8 Seiten01 Method Statement For Pile Cap Foundations (Findal)Joe PS83% (6)

- Inspection Test Plan For Civil Works Rev 01Dokument22 SeitenInspection Test Plan For Civil Works Rev 01Eze Nonso50% (2)

- Method Statement For Piling Works PDFDokument2 SeitenMethod Statement For Piling Works PDFrozaidiabdulrahim100% (1)

- Concrete Method Statement PDF FreeDokument14 SeitenConcrete Method Statement PDF FreeAli Kaya100% (2)

- ITP - Concrete Works PDFDokument2 SeitenITP - Concrete Works PDFntah8483% (35)

- QA-QC PlanDokument228 SeitenQA-QC PlanZameer Ahmed100% (4)

- 17 Kerb MethodologyDokument2 Seiten17 Kerb MethodologyAnish Panchal100% (2)

- Project Quality Plan RevDokument81 SeitenProject Quality Plan Revzampacaanas89% (9)

- Project Quality Plan (PQP) Submittal Checklist: Available Y / N Adequate Y / NDokument3 SeitenProject Quality Plan (PQP) Submittal Checklist: Available Y / N Adequate Y / NMylean Monterola100% (3)

- Method Statement For Embankment and SubgradeDokument19 SeitenMethod Statement For Embankment and SubgradeBiswajit BarikNoch keine Bewertungen

- Method Statement Bored PileDokument9 SeitenMethod Statement Bored PileAsma Farah100% (3)

- Method Stament PDA TestDokument14 SeitenMethod Stament PDA TestTonni KurniawanNoch keine Bewertungen

- Method Statement For Pile BreakingDokument3 SeitenMethod Statement For Pile BreakingAnonymous YxBTH8lhZ100% (4)

- Overall Project Quality Management PlanDokument62 SeitenOverall Project Quality Management Planlee100% (9)

- ITP-FW For Civil & Building WorksDokument17 SeitenITP-FW For Civil & Building WorksRajnath Rajbhar Pancham86% (7)

- ITP For PilingDokument9 SeitenITP For PilingAntonio Tomas Gonzalez Losa100% (2)

- Piling Project Quality Plan 1 PDFDokument74 SeitenPiling Project Quality Plan 1 PDFNazirul Naim Zamri100% (1)

- Number Three Wind Farm Lewis County, New York Case 16-F-0328 May 2018 1 Project InformationDokument6 SeitenNumber Three Wind Farm Lewis County, New York Case 16-F-0328 May 2018 1 Project Informationblackberry7130gNoch keine Bewertungen

- Project Quality PlanDokument72 SeitenProject Quality PlanMuhammad zeshan javed100% (2)

- Quality Assurance and Quality Control PlanDokument6 SeitenQuality Assurance and Quality Control PlanTia KurniawatiNoch keine Bewertungen

- Sample Quality PlanDokument17 SeitenSample Quality PlanKhaled Abdelbaki100% (1)

- Phase Three - G5-Quality Management PlanDokument5 SeitenPhase Three - G5-Quality Management PlanjigsawibNoch keine Bewertungen

- Project Quality Plan RequirementDokument14 SeitenProject Quality Plan Requirementimran_amamiNoch keine Bewertungen

- Quality Management PlanDokument9 SeitenQuality Management Planmurtada kamilNoch keine Bewertungen

- JSAloading Test Works ContohDokument2 SeitenJSAloading Test Works Contoh6984Noch keine Bewertungen

- Astm-D3966 07 PDFDokument18 SeitenAstm-D3966 07 PDFJaouad Id Boubker100% (1)

- Astm-D3966 07 PDFDokument18 SeitenAstm-D3966 07 PDFJaouad Id Boubker100% (1)

- Driving Pile Prebore (New Hammer)Dokument14 SeitenDriving Pile Prebore (New Hammer)6984Noch keine Bewertungen

- Bro CPD SikaWrap UsDokument4 SeitenBro CPD SikaWrap Us6984Noch keine Bewertungen

- Barack ObamaDokument3 SeitenBarack ObamaVijay KumarNoch keine Bewertungen

- 3.1 MuazuDokument8 Seiten3.1 MuazuMon CastrNoch keine Bewertungen

- Riveted JointsDokument28 SeitenRiveted Jointsgnbabuiitg0% (1)

- Test Report: Tested By-Checked byDokument12 SeitenTest Report: Tested By-Checked byjamilNoch keine Bewertungen

- Practical Research 2.9Dokument22 SeitenPractical Research 2.9Michael GabertanNoch keine Bewertungen

- Surge Arrester PresentationDokument63 SeitenSurge Arrester PresentationRamiro FelicianoNoch keine Bewertungen

- 3.15.E.V25 Pneumatic Control Valves DN125-150-EnDokument3 Seiten3.15.E.V25 Pneumatic Control Valves DN125-150-EnlesonspkNoch keine Bewertungen

- Sta404 07Dokument71 SeitenSta404 07Ibnu Iyar0% (1)

- Planning Theory Syllabus - 2016Dokument24 SeitenPlanning Theory Syllabus - 2016LakshmiRaviChanduKolusuNoch keine Bewertungen

- The Genius of Marie Curie Shohini GhoseDokument4 SeitenThe Genius of Marie Curie Shohini GhoseMarta HrynyovskaNoch keine Bewertungen

- Sap EwmDokument2 SeitenSap EwmsirivirishiNoch keine Bewertungen

- Risk Assessment For Harmonic Measurement Study ProcedureDokument13 SeitenRisk Assessment For Harmonic Measurement Study ProcedureAnandu AshokanNoch keine Bewertungen

- Column Buckling TestDokument8 SeitenColumn Buckling TestWiy GuomNoch keine Bewertungen

- Classroom Debate Rubric Criteria 5 Points 4 Points 3 Points 2 Points 1 Point Total PointsDokument1 SeiteClassroom Debate Rubric Criteria 5 Points 4 Points 3 Points 2 Points 1 Point Total PointsKael PenalesNoch keine Bewertungen

- ZH210LC 5BDokument24 SeitenZH210LC 5BPHÁT NGUYỄN THẾ0% (1)

- Gilbert Cell Design PDFDokument22 SeitenGilbert Cell Design PDFvysNoch keine Bewertungen

- History Homework Help Ks3Dokument8 SeitenHistory Homework Help Ks3afetnjvog100% (1)

- Lifecycle of A Butterfly Unit Lesson PlanDokument11 SeitenLifecycle of A Butterfly Unit Lesson Planapi-645067057Noch keine Bewertungen

- Concrete Lab ManualDokument20 SeitenConcrete Lab ManualkelmazodroNoch keine Bewertungen

- Group 2 - BSCE1 3 - Formal Lab Report#6 - CET 0122.1 11 2Dokument5 SeitenGroup 2 - BSCE1 3 - Formal Lab Report#6 - CET 0122.1 11 2John Eazer FranciscoNoch keine Bewertungen

- Lab Final SolutionDokument18 SeitenLab Final SolutionZeeNoch keine Bewertungen

- Introduction To SCRDokument19 SeitenIntroduction To SCRAlbin RobinNoch keine Bewertungen

- The Neuroscience of Helmholtz and The Theories of Johannes Muèller Part 2: Sensation and PerceptionDokument22 SeitenThe Neuroscience of Helmholtz and The Theories of Johannes Muèller Part 2: Sensation and PerceptionCrystal JenningsNoch keine Bewertungen

- Three Revolutionary Architects - Boullee, Ledoux, and Lequeu PDFDokument135 SeitenThree Revolutionary Architects - Boullee, Ledoux, and Lequeu PDFTran LeNoch keine Bewertungen

- Validación Española ADHD-RSDokument7 SeitenValidación Española ADHD-RSCristina Andreu NicuesaNoch keine Bewertungen

- Sai Deepa Rock Drills: Unless Otherwise Specified ToleranceDokument1 SeiteSai Deepa Rock Drills: Unless Otherwise Specified ToleranceRavi BabaladiNoch keine Bewertungen

- Electromechani Cal System: Chapter 2: Motor Control ComponentsDokument35 SeitenElectromechani Cal System: Chapter 2: Motor Control ComponentsReynalene PanaliganNoch keine Bewertungen

- Time Table & Instruction For Candidate - Faculty of Sci & TechDokument3 SeitenTime Table & Instruction For Candidate - Faculty of Sci & TechDeepshikha Mehta joshiNoch keine Bewertungen

- High Performance Vector Control SE2 Series InverterDokument9 SeitenHigh Performance Vector Control SE2 Series InverterhanazahrNoch keine Bewertungen

- Placa 9 - SHUTTLE A14RV08 - 71R-A14RV4-T840 - REV A0 10ABR2012Dokument39 SeitenPlaca 9 - SHUTTLE A14RV08 - 71R-A14RV4-T840 - REV A0 10ABR2012Sergio GalliNoch keine Bewertungen