Beruflich Dokumente

Kultur Dokumente

Magnetic Particle Testing

Hochgeladen von

Ganapathy VigneshOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Magnetic Particle Testing

Hochgeladen von

Ganapathy VigneshCopyright:

Verfügbare Formate

BY

GANAPATHY (13ME007)

ME(CAD/CAM)

This module is intended to present information on

the widely used method of magnetic particle

inspection.

Magnetic particle inspection can detect both

production discontinuities (seams, laps, grinding

cracks and quenching cracks) and in-service damage

(fatigue and overload cracks).

Magnetic lines of force

around a bar magnet

Opposite poles attracting Similar poles repelling

Introduction to Magnetism

Magnetism is the ability of matter to

attract other matter to itself. Objects

that possess the property of

magnetism are said to be magnetic or

magnetized and magnetic lines of

force can be found in and around the

objects. A magnetic pole is a point

where the a magnetic line of force

exits or enters a material.

Magnetic field lines:

Form complete loops.

Do not cross.

Follow the path of least

resistance.

All have the same strength.

Have a direction such that

they cause poles to attract

or repel.

A ferromagnetic test specimen is magnetized with a strong

magnetic field created by a magnet or special equipment. If

the specimen has a discontinuity, the discontinuity will

interrupt the magnetic field flowing through the specimen

and a leakage field will occur.

Finely milled iron particles coated with a dye pigment are

applied to the test specimen. These particles are attracted to

leakage fields and will cluster to form an indication directly

over the discontinuity. This indication can be visually detected

under proper lighting conditions.

Basic steps involved:

1. Component pre-cleaning

2. Introduction of magnetic field

3. Application of magnetic media

4. Interpretation of magnetic particle indications

When inspecting a test part with the magnetic particle

method it is essential for the particles to have an unimpeded

path for migration to both strong and weak leakage fields

alike. The parts surface should be clean and dry before

inspection.

Contaminants such as oil,

grease, or scale may not

only prevent particles from

being attracted to leakage

fields, they may also

interfere with interpretation

of indications.

The required magnetic field can be introduced into a component in a

number of different ways.

1.Using a permanent magnet or an electromagnet that contacts the

test piece

2.Flowing an electrical current through the specimen

3.Flowing an electrical current through a coil of wire around the part

or through a central conductor running near the part.

Two general types of magnetic fields (longitudinal and

circular) may be established within the specimen. The type of

magnetic field established is determined by the method used

to magnetize the specimen.

A longitudinal magnetic field has

magnetic lines of force that run

parallel to the long axis of the

part.

A circular magnetic field has

magnetic lines of force that run

circumferentially around the

perimeter of a part.

Being able to magnetize the part in two

directions is important because the best

detection of defects occurs when the lines of

magnetic force are established at right angles to

the longest dimension of the defect. This

orientation creates the largest disruption of the

magnetic field within the part and the greatest

flux leakage at the surface of the part. An

orientation of 45 to 90 degrees between the

magnetic field and the defect is necessary to

form an indication.

Since defects may

occur in various and

unknown directions,

each part is normally

magnetized in two

directions at right

angles to each other.

Flux Leakage

No Flux Leakage

Application of Magnetic

Media (Wet Versus Dry)

MPI can be performed using either

dry particles, or particles

suspended in a liquid. With the

dry method, the particles are

lightly dusted on to the surface.

With the wet method, the part is

flooded with a solution carrying

the particles.

The dry method is more portable.

The wet method is generally more

sensitive since the liquid carrier

gives the magnetic particles

additional mobility.

Wet particles are typically supplied

as visible or fluorescent. Visible

particles are viewed under normal

white light and fluorescent particles

are viewed under black light.

After applying the magnetic field, indications that form

must interpreted. This process requires that the inspector

distinguish between relevant and non-relevant indications.

The following series of images depict

relevant indications produced from a

variety of components inspected

with the magnetic particle method.

Fluorescent, Wet Particle Method

Fluorescent, Wet Particle Method

Fluorescent, Wet Particle Method

Fluorescent, Wet Particle Method

Fluorescent, Wet Particle Method

Fluorescent, Wet Particle Method

Fluorescent, Wet Particle Method

Visible, Dry Powder Method

Indication

Visible, Dry Powder Method (SHEILD

METAL ARC WELDING)

Visible, Dry Powder Method

Parts inspected by the magnetic particle method may

sometimes have an objectionable residual magnetic field

that may interfere with subsequent manufacturing

operations or service of the component.

Possible reasons for demagnetization include:

May interfere with welding and/or machining operations

Can effect gauges that are sensitive to magnetic fields if

placed in close proximity.

Abrasive particles may adhere to components surface and

cause and increase in wear to engines components, gears,

bearings etc.

Demagnetization requires that the residual magnetic field is

reversed and reduced by the inspector.

This process will scramble the magnetic domains and

reduce the strength of the residual field to an acceptable

level.

Demagnetized

Magnetized

Can detect both surface and near sub-surface defects.

Can inspect parts with irregular shapes easily.

Precleaning of components is not as critical as it is for some other

inspection methods. Most contaminants within a flaw will not

hinder flaw detectability.

Fast method of inspection and indications are visible directly on

the specimen surface.

Considered low cost compared to many other NDT methods.

Is a very portable inspection method especially when used with

battery powered equipment.

Cannot inspect non-ferrous materials such as aluminum,

magnesium or most stainless steels.

Inspection of large parts may require use of equipment

with special power requirements.

Some parts may require removal of coating or plating to

achieve desired inspection sensitivity.

Limited subsurface discontinuity detection capabilities.

Maximum depth sensitivity is approximately 0.6 (under ideal

conditions).

Post cleaning, and post demagnetization is often necessary.

Alignment between magnetic flux and defect is important

Das könnte Ihnen auch gefallen

- Magnetic Particle Inspection - PresentationDokument37 SeitenMagnetic Particle Inspection - PresentationzdenmanNoch keine Bewertungen

- 11 - Data Obtained During WTDokument18 Seiten11 - Data Obtained During WTAmin Amin100% (1)

- Hooke's Law and PressureDokument12 SeitenHooke's Law and Pressurevivaan100% (1)

- Flow Meter TypesDokument11 SeitenFlow Meter TypesFaisal RafiqueNoch keine Bewertungen

- ERR Power Station Project BookletDokument18 SeitenERR Power Station Project BookletAnonymous C0KBah6TEqNoch keine Bewertungen

- Haemolytic Anemia: DR Dumitha Govindapala MBBS, MD (Col), MRCP (London), FRCPDokument53 SeitenHaemolytic Anemia: DR Dumitha Govindapala MBBS, MD (Col), MRCP (London), FRCPLilaksha Hasaranga100% (1)

- Bourdon TubeDokument13 SeitenBourdon TubeJamer Ian Mustapha100% (2)

- Production Engineering TechnologyDokument28 SeitenProduction Engineering TechnologyReband AzadNoch keine Bewertungen

- Physics Quick Notes by MDCATDokument23 SeitenPhysics Quick Notes by MDCATZaryab Khan100% (1)

- Level Measurement and Control Systems ExplainedDokument14 SeitenLevel Measurement and Control Systems ExplainedVarsha Praburam100% (1)

- Flammability Characteristics of Combustible Gases and VaporsDokument216 SeitenFlammability Characteristics of Combustible Gases and Vaporsrohl55Noch keine Bewertungen

- Wli 00Dokument0 SeitenWli 00Adriana RezendeNoch keine Bewertungen

- Fluid Detection in Carbonate ReservoirsDokument17 SeitenFluid Detection in Carbonate Reservoirslucian_lovNoch keine Bewertungen

- Biophysical EnergyDokument27 SeitenBiophysical Energyphanimitra@gmail.com100% (1)

- Magnetic Particle InspectionDokument34 SeitenMagnetic Particle InspectionSyed Tanveer100% (2)

- Magnetic Particle TestingDokument37 SeitenMagnetic Particle Testingjiten100% (1)

- Magnetic PropertiesDokument29 SeitenMagnetic PropertiesSiyan ShivaNoch keine Bewertungen

- Chapter 2 - Eddy Current PrinciplesDokument57 SeitenChapter 2 - Eddy Current Principlesvibinkumars@gmail.com100% (1)

- Field Measurement Handbook PDFDokument63 SeitenField Measurement Handbook PDFMin JiangNoch keine Bewertungen

- Modeling A SolenoidDokument6 SeitenModeling A Solenoidjrl5432Noch keine Bewertungen

- 1.3 Coriollis PDFDokument12 Seiten1.3 Coriollis PDFAsahel NuñezNoch keine Bewertungen

- Formation Testing: Supercharge, Pressure Testing, and Contamination ModelsVon EverandFormation Testing: Supercharge, Pressure Testing, and Contamination ModelsNoch keine Bewertungen

- Understanding PH MeasurementDokument10 SeitenUnderstanding PH MeasurementAnnisa Novita Putri SiregarNoch keine Bewertungen

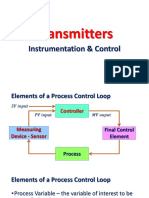

- TransmittersDokument40 SeitenTransmittersSka dooshNoch keine Bewertungen

- Automatic Control System CompressDokument116 SeitenAutomatic Control System Compressswapnil28.08 k100% (1)

- Astm D790-03Dokument11 SeitenAstm D790-03breynnero100% (2)

- Leak Detection Sales PresentationDokument20 SeitenLeak Detection Sales PresentationsamehhaboubiNoch keine Bewertungen

- ABB-733-WPO Understanding Coriolis Mass FlowmeterDokument3 SeitenABB-733-WPO Understanding Coriolis Mass FlowmetercarlosmandopintoNoch keine Bewertungen

- Basics of Instrumentation & ControlDokument29 SeitenBasics of Instrumentation & ControlprathmeshNoch keine Bewertungen

- OBN Acquisition: Complex Imaging with Full Azimuth Broadband DataDokument57 SeitenOBN Acquisition: Complex Imaging with Full Azimuth Broadband DataFasih KazainullahNoch keine Bewertungen

- PH Measurement BasicsDokument8 SeitenPH Measurement Basicsviralshukla85Noch keine Bewertungen

- Coriolis White PaperDokument17 SeitenCoriolis White PaperOscar Yazit Salah GarcíaNoch keine Bewertungen

- Non Destructive TestingDokument118 SeitenNon Destructive Testingandini dini100% (1)

- Coriolis PDFDokument11 SeitenCoriolis PDFdanielaNoch keine Bewertungen

- HE MMC 9 Manual 05 May 08Dokument64 SeitenHE MMC 9 Manual 05 May 08Javierfox9850% (2)

- Intro To Muph and Wet GasDokument54 SeitenIntro To Muph and Wet GasPritesh PatelNoch keine Bewertungen

- Acoustic Modem IntroductionDokument13 SeitenAcoustic Modem Introductionlsaty123Noch keine Bewertungen

- 2011 XXDokument15 Seiten2011 XXMauro CostaNoch keine Bewertungen

- Optical Fiber LecturesDokument161 SeitenOptical Fiber LecturesZakareya FathallaNoch keine Bewertungen

- Verifying Flowmeter Accuracy PDFDokument8 SeitenVerifying Flowmeter Accuracy PDFAyman TermaniniNoch keine Bewertungen

- Doppler Ultrasonic Flow Meters Measure FlowseditDokument15 SeitenDoppler Ultrasonic Flow Meters Measure FlowseditHonesto Raff IvanNoch keine Bewertungen

- Product Data Sheet MPFM 2600 M Roxar en Us 170810 PDFDokument10 SeitenProduct Data Sheet MPFM 2600 M Roxar en Us 170810 PDFglopessNoch keine Bewertungen

- Downhole LoggingDokument54 SeitenDownhole LoggingMohammadFaisalQureshiNoch keine Bewertungen

- Data Reduction Strategies for Reducing Costs and RisksDokument13 SeitenData Reduction Strategies for Reducing Costs and RisksguillogpsNoch keine Bewertungen

- Design of spiral resistance heating elementsDokument6 SeitenDesign of spiral resistance heating elementsarg0nautNoch keine Bewertungen

- RPDIR-L06 Xray Production WEBDokument46 SeitenRPDIR-L06 Xray Production WEBfahimabidNoch keine Bewertungen

- Level Measurement Using Gauge Glass TechniqueDokument3 SeitenLevel Measurement Using Gauge Glass TechniqueYeabsira WorkagegnehuNoch keine Bewertungen

- Customer Flow Computer Work SheetDokument2 SeitenCustomer Flow Computer Work SheetBilly Isea DenaroNoch keine Bewertungen

- A Comprehensive Approach To The Design of Advanced Well Completions PDFDokument174 SeitenA Comprehensive Approach To The Design of Advanced Well Completions PDFanon_450586282Noch keine Bewertungen

- High-Pressure Union Pressure Transducer Performance Verification Procedu...Dokument11 SeitenHigh-Pressure Union Pressure Transducer Performance Verification Procedu...LudwinNoch keine Bewertungen

- Production Logging Tools, Principles, Limitations and ApplicationsDokument14 SeitenProduction Logging Tools, Principles, Limitations and ApplicationsAP04 MAHI YTNoch keine Bewertungen

- Society of Petroleum GeophysicistsDokument57 SeitenSociety of Petroleum Geophysicistsdinesh_hsenidNoch keine Bewertungen

- History of InstrumentationDokument18 SeitenHistory of InstrumentationRaphael CuencaNoch keine Bewertungen

- Introduction to Magnetic Particle Inspection (MPIDokument82 SeitenIntroduction to Magnetic Particle Inspection (MPIMarcel BurlacuNoch keine Bewertungen

- 015 Emat Slofec TechniqueDokument9 Seiten015 Emat Slofec TechniquejasminneeNoch keine Bewertungen

- Temperature Transmitter TR45Dokument16 SeitenTemperature Transmitter TR45cysautsNoch keine Bewertungen

- Chemical AutosavedDokument20 SeitenChemical AutosavedZhaye AnnNoch keine Bewertungen

- Gas Ratio Analysis in Hovsan Oil FieldDokument7 SeitenGas Ratio Analysis in Hovsan Oil FieldRidwan ChandraNoch keine Bewertungen

- Ultrasonic Liquid Level SensorDokument24 SeitenUltrasonic Liquid Level Sensormadhuri12345678Noch keine Bewertungen

- ValvesDokument108 SeitenValvesShakerMahmood100% (1)

- Welding Eng Lab GuidenceDokument15 SeitenWelding Eng Lab Guidencewan yusufNoch keine Bewertungen

- SPE 149602 Distributed Acoustic Sensing - A New Way of Listening To Your Well/ReservoirDokument9 SeitenSPE 149602 Distributed Acoustic Sensing - A New Way of Listening To Your Well/ReservoirBolsec14Noch keine Bewertungen

- Advanced Techniques For Acoustic Liquid Level DeterminationDokument14 SeitenAdvanced Techniques For Acoustic Liquid Level Determinationmáté_galambosiNoch keine Bewertungen

- 097r68855 SynopsisDokument5 Seiten097r68855 SynopsisGanapathy VigneshNoch keine Bewertungen

- Weldability of Materials - Copper and Copper Alloys - Job Knowledge 23Dokument3 SeitenWeldability of Materials - Copper and Copper Alloys - Job Knowledge 23Ganapathy VigneshNoch keine Bewertungen

- Nmims Mba Distance DetailsDokument9 SeitenNmims Mba Distance DetailsGanapathy VigneshNoch keine Bewertungen

- Ans ExDokument19 SeitenAns ExGanapathy VigneshNoch keine Bewertungen

- Resume PreparationDokument1 SeiteResume PreparationGanapathy VigneshNoch keine Bewertungen

- Flexible Manufacturing SystemDokument19 SeitenFlexible Manufacturing SystemGanapathy VigneshNoch keine Bewertungen

- 10 Best Ways To Destroy The EarthDokument8 Seiten10 Best Ways To Destroy The EarthGanapathy VigneshNoch keine Bewertungen

- Robotic Friction Stir Welding: Submitted by S.SATHISH (13MEO16) M.SIVAGANESAN (13ME017) M.Suriya Prakash (13me018)Dokument1 SeiteRobotic Friction Stir Welding: Submitted by S.SATHISH (13MEO16) M.SIVAGANESAN (13ME017) M.Suriya Prakash (13me018)Ganapathy VigneshNoch keine Bewertungen

- Holistic MarketingDokument1 SeiteHolistic MarketingGanapathy VigneshNoch keine Bewertungen

- CH 34Dokument40 SeitenCH 34Ganapathy VigneshNoch keine Bewertungen

- Quiz (Lecture 5) : Date: 14/3/2018 (Wednesday) Time: 2.15 PM VenueDokument50 SeitenQuiz (Lecture 5) : Date: 14/3/2018 (Wednesday) Time: 2.15 PM VenueKoh Jiun AnNoch keine Bewertungen

- Low Voltage MeasurementDokument2 SeitenLow Voltage Measurementsina123Noch keine Bewertungen

- 9702 w05 QP 4Dokument16 Seiten9702 w05 QP 4api-3706826Noch keine Bewertungen

- Generalized definition of cross polarization for antennasDokument5 SeitenGeneralized definition of cross polarization for antennashomeiraNoch keine Bewertungen

- Lecture - 13 and 14 Notes (1) - 1Dokument8 SeitenLecture - 13 and 14 Notes (1) - 1Irene NziluNoch keine Bewertungen

- 10 Ind Topic 4Dokument36 Seiten10 Ind Topic 4Buriro HayatNoch keine Bewertungen

- Electricity and Magnetism Problems Concepts and PrinciplesDokument12 SeitenElectricity and Magnetism Problems Concepts and Principlessalman suhailNoch keine Bewertungen

- Magnetic Proximity SwitchDokument9 SeitenMagnetic Proximity SwitchSagar ChachondiaNoch keine Bewertungen

- Evaluación Trimesral Nivel Alto Grado11Dokument15 SeitenEvaluación Trimesral Nivel Alto Grado11Jadir Ferney Rico IbañezNoch keine Bewertungen

- PHY118 OpenStax Notes ExplainedDokument88 SeitenPHY118 OpenStax Notes ExplainedPeter NardiNoch keine Bewertungen

- Determination of The Earth's Magnetic Field: (Item No.: P2430100)Dokument6 SeitenDetermination of The Earth's Magnetic Field: (Item No.: P2430100)Sebastian M.Noch keine Bewertungen

- Magnetic MaterialDokument6 SeitenMagnetic MaterialGthulasi78Noch keine Bewertungen

- Physics 2 PDFDokument22 SeitenPhysics 2 PDFSipra PaulNoch keine Bewertungen

- Analytical Modeling of Magnetic Field in Surface Mounted Permanent Magnet Tubular Linear MachinesDokument17 SeitenAnalytical Modeling of Magnetic Field in Surface Mounted Permanent Magnet Tubular Linear Machinessandeepsandy07Noch keine Bewertungen

- Set-I Kendriya Vidyalaya Sangathan Bhopal Region Pre Broad 2020Dokument10 SeitenSet-I Kendriya Vidyalaya Sangathan Bhopal Region Pre Broad 2020Vikram SinghNoch keine Bewertungen

- Faraday Laws of Induction: ProblemsDokument9 SeitenFaraday Laws of Induction: ProblemsSyed Mustafa MunirNoch keine Bewertungen

- Magnetism and Matter Class 12: Chapter 5: A Story of MagnetsDokument14 SeitenMagnetism and Matter Class 12: Chapter 5: A Story of MagnetsMahak pooniaNoch keine Bewertungen

- CBSE Class 10 Science Magnetic Effects NotesDokument12 SeitenCBSE Class 10 Science Magnetic Effects NotesAkshithNoch keine Bewertungen

- Section 16.4 Force On Current-Carrying Conductor in Magnetic FieldDokument18 SeitenSection 16.4 Force On Current-Carrying Conductor in Magnetic Fieldtwy113Noch keine Bewertungen

- Lecture 3Dokument97 SeitenLecture 3Akagbulem RuthNoch keine Bewertungen

- TAP 411 - 5: Flux and Flux DensityDokument4 SeitenTAP 411 - 5: Flux and Flux Densitypritzel_13Noch keine Bewertungen

- Electric Forces and ChargesDokument6 SeitenElectric Forces and ChargesJing Joel Jem Faith AlponsoNoch keine Bewertungen

- Engineering Science and Technology, An International JournalDokument9 SeitenEngineering Science and Technology, An International JournalAli EmamiNoch keine Bewertungen

- Phy Mock p1BDokument22 SeitenPhy Mock p1BA PersonNoch keine Bewertungen

- Assignment 1690189094Dokument257 SeitenAssignment 1690189094saanvi.sethi0812Noch keine Bewertungen