Beruflich Dokumente

Kultur Dokumente

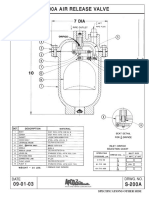

APCO Air Valve 613

Hochgeladen von

jones0055Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

APCO Air Valve 613

Hochgeladen von

jones0055Copyright:

Verfügbare Formate

S

L

O

W

C

L

O

S

I

N

G

A

I

R

/

V

A

C

U

U

M

V

A

L

V

E

S

A

I

R

V

A

L

V

E

S

VALVE & PRIMER CORPORATION

1420 S. WRIGHT BLVD. SCHAUMBURG, IL 60193-4599

847.524.9000 FAX:847.524.9007 800.323.6969

website: www.apcovalves.com e-mail: factory@apcovalves.com

1420 S. WRIGHT BLVD. SCHAUMBURG, IL 60193-4599

847.524.9000 FAX:847.524.9007 800.323.6969

website: www.apcovalves.com e-mail: factory@apcovalves.com

2 0 0 0

M i l l e n n i u m

E d i t i o n

6

1

3

B

U

L

L

E

T

I

N

SERIES 1900

ISO FLANGE CONNECTIONS

AVAILABLE

101

MANUFACTURED TO AWWA C-512

STANDARD

Return to Previous Menu

MAXIMUM AIR FLOW VELOCITY IN GOOD PIPELINE DESIGN

The Air/Vacuum Valve operates in the normal fashion allowing air to escape freely at

any velocity (maximum discharge velocity is approximately 300 feet per second at 6.7

PSI; however, good pipeline design restricts velocity flows of air to 100 feet per second

which occurs at approximately 1 PSI).

The APCO Slow Closing Air/Vacuum Valve actually consists of a standard

Air/Vacuum Valve mounted on top of a Surge Check Unit.

The Surge Check Unit operates on the interphase between the kinetic energy in the

relative velocity flows of air and water. The Surge Check is a normally open valve,

spring loaded, so that air passes through unrestricted. Then when water rushes into

the Surge Check Unit, the disc begins to close against the spring tension and reduces

the rate of flow of water into the air valve by means of throttling holes in the disc.

This ensures normal gentle closing of the Air/Vacuum Valve regardless of the initial

velocity flows involved and minimizes pressure surges when the valve closes.

As soon as the Air/Vacuum Valve is closed, the pressure on both sides of the Surge

Valve disc equalizes and the disc automatically returns to its open position. This means

the Air/Vacuum Valve does not need an incipient vacuum to open, but can open at any

time the water level drops and line pressure approaches atmospheric and immediately

have full re-entry flow of air into the pipeline before a vacuum can form.

it does!

The APCO Slow Closing Air/Vacuum Valve is designed expressly to eliminate critical

shock conditions occurring in those installations where the operating conditions cause

a regular air valve to slam open and/or closed.

This Slow Closing feature protects the Air/Vacuum Valve itself and at the same time

prevents the Air/Vacuum Valve from creating a surge in the pipeline by slamming shut.

This type Slow Closing Air/Vacuum Valve should not be considered as relief for

*shock conditions which develop elsewhere in the system. However, actual field tests

prove the Surge Check Unit may protect the Air/Vacuum Valve in cases where the

Air/Vacuum Valve can be destroyed by severe shut-off shock.

This protection far outweighs the small cost of the Surge Check Unit when you consider

the tremendous field damage that can result from an Air/Vacuum Valve failure.

* For pipeline shock protection see Bulletin 7000 for details of Hydraulically Controlled Air/Vacuum Valves, or Bulletin 3000 for Surge

Relief Valves.

to use it!

1. High points in pipelines where the hydraulic gradient and flow conditions are such

that a negative pressure can possibly form.

2. High points on sections of pipeline having water velocities in excess of 10 F.P.S.

3. Adjacent to any quick closing valve in a pipeline such as a check or gate valve

where a vacuum can be formed upon closure.

4. On the discharge of larger deep well turbine pumps between the pump and the

check valve.

to engineer

If an Air/Vacuum Valve is to be installed inside the pump house, use threaded or flanged outlet connection

and pipe back into the well or to outside. This will greatly muffle the high noise level caused by the air being

discharged and provide for drainage of any small amount of water or water vapor that may discharge.

102

WHAT

HOW IT

WORKS

WHERE

NOTE NOTE

SLOW CLOSING AIR/VACUUM VALVES

SLOW CLOSING AIR/VACUUM VALVES

HOW IT

WORKS

WHAT

WHERE

Return to Previous Menu

6

1

3

S

L

O

W

C

L

O

S

I

N

G

A

I

R

/

V

A

C

U

U

M

V

A

L

V

E

S

A

I

R

V

A

L

V

E

S

B

U

L

L

E

T

I

N

HOW TO SELECT

STEP ONE:

CHECK PUMP CURVE FOR G.P.M. CAPACITY AT NO HEAD CONDITION.

STEP TWO:

ENTER CHART WITH G.P.M. TO DETERMINE SIZE.

STEP THREE:

IF VALVE IS TO BE INSTALLED INSIDE PUMP HOUSE SPECIFY DIS-

CHARGE CONNECTION. SIZES 4 AND 6 AVAILABLE WITH SCREWED

OR FLANGED CONNECTIONS. SIZE 8 AND LARGER FLANGED ONLY.

* STEP FOUR:

IF THE PUMP IS SCHEDULED TO RUN FOR PROLONGED PERIODS

(6 - 8 HOURS) WITHOUT STOPPING, AUTOMATIC AIR RELEASE

VALVES SHOULD BE ADDED.

PUMP

CAPACITY

G.P.M.

(OPTIONAL)

AIR RELEASE

VALVE NO.

VALVE

SIZE

MODEL NO.

*

BELOW 6,300 See Bulletin No. 586

6,301 - 13,500 4 1904 200A

13,501 - 32,000 6 1906 200A

32,001 - 60,000 8 1908 200A

60,001 - 90,000 10 1910 200

90,001 - 140,000 12 1912 200

140,001 - 180,000 14 1914 200

180,001 - 250,000 16 1916 200

The following method of selection will satisfy normal installations.

For further information, check with our engineering department.

SLOW CLOSING AIR/VACUUM VALVES

APCO EXCLUSIVE FEATURES

Because the Air/Vacuum Valve and Surge Check Unit are each self-contained

items, the Surge Check Unit can be added to any Air/Vacuum Valve already in

service making it into a Slow Closing Air/Vacuum Valve.

4 1904 11

1

8 25

3

4 25

3

4

6 1906 13

5

8 30

1

4 30

1

2

8 1908 17

1

4 34

7

8 35

3

8

10 1910 20 38

7

8 39

1

2

12 1912 29 45

1

8 45

1

8

14 1914 29 46

7

8 46

7

8

16 1916 32 49

1

4 49

1

4

VALVE

SIZE

MODEL

NO.

MODEL

NO.

MODEL

NO.

MAX.

DIAM.

HEIGHT HEIGHT HEIGHT

WIDTH WIDTH

125 LB 125 LB 125 LB

250 LB 250 LB 250 LB

1304 15

1

2 28

5

8 29

7

8

1306 18

3

4 34

3

8 34

1

2

1308 23

1

4 40

7

8 41

3

8

1310 25

1

2 45

1

4 45

7

8

1312 28

1

2 54

3

8 54

3

8

1314 31

1

4 55

1

8 55

1

8

1316 33

3

4 60

3

4 60

3

4

1204 19

7

16 30

1

2 30

7

8

1206 22

11

16 35

3

8 36

1208 25

1

2 41

7

8 42

3

8

1210 27

7

8 45

3

4 46

1

2

1212 32

7

8 50

7

8 50

7

8

1214 41

7

8 52

1

4 52

1

4

1216 45

1

2 55

3

8 55

3

8

SERIES 1900

AIR/VACUUM VALVE &

SURGE CHECK VALVE

SERIES 1700

AIR/VACUUM VALVE,

SURGE CHECK VALVE & AIR RELEASE VALVE

SERIES 1300

AIR/VACUUM VALVE,

SURGE CHECK VALVE & BUTTERFLY VALVE

SERIES 1200

AIR/VACUUM VALVE, SURGE CHECK VALVE

AIR RELEASE & BUTTERFLY VALVE

APCO AIR/VACUUM VALVE

Stainless Steel float and trim, synthetic, non-destructible

seat. Positively will not blow shut even at maximum dis-

charge velocities. Regular 125 lb. or 250 lb. flange mates

with similar flange on Surge Check Unit.

APCO SURGE CHECK VALVE

Bronze or stainless trim and Stainless Steel spring for

ultimate in protection.

APCO AIR RELEASE VALVE

Will open while line is in operation against pressures

up to 300 PSI to exhaust small pockets of entrained air.

Stainless Steel Concave Float. (Higher pressure valves

available.)

Simplicity of design no delicate needle valves to fail or

need adjustment. Positively will not blow shut.

REPLACE SHUT-OFF VALVE WITH

APCO BUTTERFLY VALVE

Costs to excavate pipeline trenches can be greatly

reduced by using APCO Butterfly Valves for isolation

instead of gate valves. APCO Butterfly Valves are

economical, reliable and much shorter, permitting a

reduction in depth of the trench.

103

SIZES 3 & SMALLER, SEE BULLETIN 586 LARGER SIZES READILY AVAILABLE CONTACT FACTORY.

AIR/VACUUM

VALVE

SURGE CHECK

VALVE

RETAINER PLATE

BUTTERFLY

VALVE

200A

AIR

RELEASE

VALVE

SEAT DETAIL

AIR AND VACUUM

VALVE

125 LB: 14 & LARGER

250 LB: ALL SIZES

GATE

VALVE

AIR RELEASE VALVE

AND

BUTTERFLY VALVE

OPTIONAL

(SEE CHARTS BELOW)

GUARANTEED ASTM QUALITY

MATERIALS USED THROUGHOUT

1704 19

1

2 27

1

2 28

1706 22

3

4 31

7

8 32

1

4

1708 25

1

2 34

5

8 35

1

2

1710 27

7

8 38

7

8 39

1

2

1712 32

7

8 45

7

8 45

7

8

1714 41

7

8 45

5

8 45

5

8

1716 45

1

2 49

3

4 49

3

4

MODEL

NO.

HEIGHT

WIDTH

125 LB 250 LB

Return to Previous Menu

VALVE & PRIMER CORPORATION

1420 S. WRIGHT BLVD. SCHAUMBURG, IL 60193-4599

847.524.9000 FAX:847.524.9007 800.323.6969

website: www.apcovalves.com e-mail: factory@apcovalves.com

FOR AIR/VACUUM VALVE

AIR INFLOW/OUTFLOW THRU VALVE IN STANDARD CUBIC FEET OF FREE AIR PER SECOND, (SCFS)

WITH SURGE CHECK UNITS

HUNDREDTHS OF A SECOND

HUNDREDTHS OF A SECOND

0

1

100

2

100

3

100

4

100

5

100

6

100

7

100

8

100

9

100

10

100

11

100

12

100

750 P.S.I.

600 P.S.I.

450 P.S.I.

300 P.S.I.

150 P.S.I.

0 P.S.I.

WITHOUT SURGE CHECK UNITS

0

1

100

2

100

3

100

4

100

5

100

6

100

7

100

8

100

9

100

10

100

11

100

12

100

750 P.S.I.

600 P.S.I.

450 P.S.I.

300 P.S.I.

150 P.S.I.

0 P.S.I.

24 2018161412 10 8 6 4 3 2 1

1

2 VALVE SIZE

1

2

3

4

5

6

V

A

C

U

U

M

A

C

R

O

S

S

V

A

L

V

E

I

N

P

S

I

2000 1000 500 300 200 100 50 40 30 20 10 8 7 6 5 4 3 2 1 0.8 0.6 0.4 0.3 0.2

INFLOW

VALVE SIZE

1

2 1 2 3 4 6 8 10 121416182024

6

5

4

3

2

1

P

R

E

S

S

.

D

I

F

F

.

A

C

R

O

S

S

V

A

L

V

E

I

N

P

S

I

0.2 0.3 0.4 0.60.8 1 2 3 4 5 6 7 810 20 30 40 50 100 200 300 500 1000 2000

OUTFLOW

CURVES SHOWN ARE ACTUAL FLOW CAPACITIES AT 14.7 PSI BAROMETRIC PRESSURE

AT 70 F TEMPERATURE BASED ON ACTUAL TEST.

THESE FIGURES ARE NOT MERELY FLOW CAPACITIES ACROSS THE ORIFICE,

BUT FLOW CAPACITIES ACROSS THE ENTIRE VALVE.

IN THE TEST SET-UP AIR APPROACH VELOCITY IS NEGLIGIBLE, THEREFORE, ACTUAL

FLOW CAPACITY EXCEEDS THE VALUES SHOWN ON CHART.

TESTS CONDUCTED BY:

PHILLIP PETROLEUM COMPANY

ENGINEERING DEPARTMENT TEST DIVISION

EDMOND PLANT PLANT FEB. 2, 1961

SOUTHERN RESEARCH RESEARCH INSTITUTE

BIRMINGHAM, ALABAMA MAY 8, 1959

SURGE PRESSURE COMPARISON

The graph shows actual surge pressures experienced closing a standard Air/Vacuum Valve under identical conditions with and without the

APCO Surge Check Unit when filling a 150 PSI line. Note that without the Surge Check Unit the maximum surge pressure exceeds line pressure by

550 PSI, or approximately five times line pressure, whereas with the Surge Check Unit the maximum surge pressure only exceeded the line pressure

by 150 PSI, or twice line pressure.

On especially critical installations further surge dampening can be effected by using two Surge Check Units under the Air/Vacuum Valve.

These pressure recordings were taken on a Minneapolis Honeywell No. 906 visicorder high speed oscillograph with a maximum frequency response of

5000 C.P.S. and a linograph travel of 10 inches per sec.

SPECIFICATIONS

The Slow Closing Air/Vacuum Valve shall be four valves furnished assembled and tested as a single unit. The Air/Vacuum Valve must have a stainless steel float guided at

each end with stainless stems. The stems shall be guided through stainless steel bushings inside the body and cover. The seat* must be Buna-N fastened to the cover with

stainless shoulder screws without distortion to allow drop tight closure.

The cover shall have a male lip to fit the female body register for positive float guide direction into the seat. Cover outlets may be threaded, flanged, or hooded. (Engineer to

specify one.)

The Surge Check Valve shall be a normally open spring loaded valve consisting of a body, seat and plug bolted to the inlet of the Air/Vacuum Valve. The surge check shall

operate on the interphase between the kinetic energy and relative velocity flows of air and water, allowing air to pass through, but water shall close the surge check, reducing

the rate of water flow by means of throttling orifices in the plug to prevent shock closure of the Air/Vacuum Valve. The surge check orifices must be adjustable type to suite

operating conditions in the field.

The inlet Isolation Butterfly Valve shall be Wafer (Compact) Style constructed to AWWA Standards with hand lever and variable position locking device. The seat to be freely

interchangeable from the body without need for special tools or skill. The seat must be Buna-N, molded with a steel flanged insert for high strength and tight seating. The disc

must pivot eccentrically from closed position to clear center valve area.

The Air Release Valve shall be side connected to the upper valve, but separated with an isolation shut-off valve. The internal mechanism shall be the compound lever type to

permit the valve to open under pressure to vent pockets of entrapped air as they accumulate. The compound mechanism shall be activated by a stainless steel concave float

to lift the Buna-N needle to shut-off the Air Release orifice.

The Slow Closing Air/Vacuum Valve shall have been flow tested in the field, substantiated by test data to show reduction of surge pressure in the valve.

Materials shall be certified to A.S.T.M. specifications:

Air/Vacuum Valve/Air Release Valve covers, bodies

Surge Check Body and Butterfly Valve Body Cast Iron ASTM A126 GR.B

Floats & Spring Stainless Steel ASTM A240

Surge Check Seat & Disc Bronze ASTM B584

Air Release Valve Needle Buna-N

*Air/Vacuum Valve Seat Buna-N (4 through 12)

(14 & up; & 250# class) Stainless Steel with Buna-N molded seal ASTM A240

ARV Leverage assembly Delrin ASTM D2133

Butterfly Valve Shaft Stainless Steel ASTM A270

Exterior Paint Universal Metal Primer FDA Approved For Potable Water Contact

Valve to be APCO Series 1200 Slow Closing Air & Vacuum Valves as manufactured by Valve & Primer Corporation, Schaumburg, Illinois, U.S.A.

104

PERFORMANCE GRAPH

PERFORMANCE GRAPH

VALVE & PRIMER CORPORATION HEREBY RESERVES THE RIGHT TO CHANGE ANY

COMPONENT PARTS WHICH, IN THE OPINION OF ITS ENGINEERING DEPARTMENT,

WILL IMPROVE THE PRODUCT OR INCREASE ITS SERVICEABILITY.

DIMENSIONS ARE FOR ILLUSTRATIVE PURPOSES ONLY. PLEASE CONFIRM ALL DIMENSIONAL

INFORMATION WITH VALVE & PRIMER CORPORATION ENGINEERING DEPARTMENT.

Return to Previous Menu

Das könnte Ihnen auch gefallen

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsVon EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNoch keine Bewertungen

- Air Vacuum ValvesDokument4 SeitenAir Vacuum ValvesmariuspiNoch keine Bewertungen

- Air Release 2014Dokument4 SeitenAir Release 2014Aly AnisNoch keine Bewertungen

- Combination Air ValvesDokument4 SeitenCombination Air ValvesFelipe OliverosNoch keine Bewertungen

- Apco Air Release Valves Arv Arv Air Release Valves Sales 600Dokument4 SeitenApco Air Release Valves Arv Arv Air Release Valves Sales 600RashedNoch keine Bewertungen

- Air Eliminators 13WS WHS-Technical InformationDokument2 SeitenAir Eliminators 13WS WHS-Technical Informationsugandaraj522Noch keine Bewertungen

- APCO. S-200a Air Release ValveDokument2 SeitenAPCO. S-200a Air Release ValveAlberto Diaz100% (2)

- Control ValvesDokument26 SeitenControl ValvesSandi Aslan100% (1)

- Apco Air Valve GuideDokument12 SeitenApco Air Valve Guideanon_711152122Noch keine Bewertungen

- De Super HeaterDokument2 SeitenDe Super HeatergateauxboyNoch keine Bewertungen

- Design Input - Pressure Reducing ValveDokument8 SeitenDesign Input - Pressure Reducing ValvekausikrNoch keine Bewertungen

- Pressure Seal Valves-GateDokument24 SeitenPressure Seal Valves-GateHieu NguyenNoch keine Bewertungen

- Pressure RegulatorDokument4 SeitenPressure RegulatorRICHIHOTS2Noch keine Bewertungen

- Butterfly ValveDokument25 SeitenButterfly ValveRahul JadhavNoch keine Bewertungen

- Horizontal Split CasingDokument6 SeitenHorizontal Split Casingvivekpec100% (1)

- Honeywell Mp953 Pneumatic PositionerDokument4 SeitenHoneywell Mp953 Pneumatic PositionerMartin BourgonNoch keine Bewertungen

- Products Valves Sanitary PBM Series 9, 2 WayDokument40 SeitenProducts Valves Sanitary PBM Series 9, 2 Waydingobk1Noch keine Bewertungen

- PBM Sanitary Ball ValvesDokument40 SeitenPBM Sanitary Ball ValvesAnonymous bTvqZMftNoch keine Bewertungen

- BALON Floating Valve - Installation and Repair Manual 2Dokument13 SeitenBALON Floating Valve - Installation and Repair Manual 2Rudi Syarif Hidayat HarahapNoch keine Bewertungen

- Pilot Float Valve 45fwrDokument5 SeitenPilot Float Valve 45fwrripcurlzNoch keine Bewertungen

- Texsteam-Ñ Bomba QuímicaDokument8 SeitenTexsteam-Ñ Bomba QuímicarivomarNoch keine Bewertungen

- Fisher 630 Series PDFDokument10 SeitenFisher 630 Series PDFClemente Rafael Marval EscalonaNoch keine Bewertungen

- Differential Pressure GaugeDokument2 SeitenDifferential Pressure GaugeManikandan SenthilNoch keine Bewertungen

- Deluge Valve ADokument14 SeitenDeluge Valve APatel MehulkumarNoch keine Bewertungen

- SST Series Engineering Manual 413a-Sem 0Dokument52 SeitenSST Series Engineering Manual 413a-Sem 0Gerber GarciaNoch keine Bewertungen

- Grove g4n Gate Valve BrochureDokument24 SeitenGrove g4n Gate Valve BrochureFrancis Almia100% (1)

- Shell MESC Number 774133.010.1 (NEAREST)Dokument2 SeitenShell MESC Number 774133.010.1 (NEAREST)Ehsan Ur Rehman100% (1)

- Bv421 Pressure Reducing ValveDokument4 SeitenBv421 Pressure Reducing ValveFAIYAZ AHMEDNoch keine Bewertungen

- Persta Gate Valves PDFDokument52 SeitenPersta Gate Valves PDFSalah InhgaruoNoch keine Bewertungen

- Mar Win SteamDokument33 SeitenMar Win SteamChristopher RequintoNoch keine Bewertungen

- Deluge Valve - SD-DVH3Dokument16 SeitenDeluge Valve - SD-DVH3Nata 1986Noch keine Bewertungen

- Sullair Stationary Pocket GuideDokument27 SeitenSullair Stationary Pocket GuideMiguel Angel Jiménez CarpioNoch keine Bewertungen

- Deluge Valve - SD-DVH2Dokument16 SeitenDeluge Valve - SD-DVH2Vijay Gaikwad0% (1)

- Handbook Valve Technology 03.04.2020Dokument132 SeitenHandbook Valve Technology 03.04.2020Ramazan YaşarNoch keine Bewertungen

- AIRTORQUEDokument20 SeitenAIRTORQUEPaula MendesNoch keine Bewertungen

- What Pump Designed ForDokument4 SeitenWhat Pump Designed Forjuwie86Noch keine Bewertungen

- CatalogueDokument429 SeitenCatalogueHarkamal SinghNoch keine Bewertungen

- GMCDokument122 SeitenGMCramudo ZNoch keine Bewertungen

- HeliCoil NPT Inserts 8UNDokument4 SeitenHeliCoil NPT Inserts 8UNAce Industrial SuppliesNoch keine Bewertungen

- Helical Oil SeparatorsDokument6 SeitenHelical Oil SeparatorsGauravNoch keine Bewertungen

- Regulator's Swegelok (High PressuDokument64 SeitenRegulator's Swegelok (High PressuhoangcokhiNoch keine Bewertungen

- 290 08 PDFDokument4 Seiten290 08 PDFmlevNoch keine Bewertungen

- Bourdon's Tube Pressure GaugeDokument32 SeitenBourdon's Tube Pressure GaugeRajanikantJadhav100% (1)

- Piston & Ball Check ValvesDokument8 SeitenPiston & Ball Check Valveswilasn1Noch keine Bewertungen

- Camisas Refrigeracion Flowsleeves Pi-058 GB 2013-06-12Dokument38 SeitenCamisas Refrigeracion Flowsleeves Pi-058 GB 2013-06-12daniel2rialNoch keine Bewertungen

- Enflow Floating BallvalvesDokument8 SeitenEnflow Floating Ballvalvesa100acomNoch keine Bewertungen

- Elmar Pannel - BP ColombiaDokument6 SeitenElmar Pannel - BP ColombiaFelipe Augusto Diaz SuazaNoch keine Bewertungen

- Presentation CVM Zwick PDFDokument19 SeitenPresentation CVM Zwick PDFteacgNoch keine Bewertungen

- Jet Pump Technical DataDokument11 SeitenJet Pump Technical DataIdelia Cutipa Yauri100% (1)

- Complation Check ListDokument1 SeiteComplation Check ListAhmed OusamaNoch keine Bewertungen

- Liquid Pump 1.5 HP 2 HP 2.2 HP Series Models A H XH S PDFDokument30 SeitenLiquid Pump 1.5 HP 2 HP 2.2 HP Series Models A H XH S PDFHidroil Neuquen SrlNoch keine Bewertungen

- Ro-Flo Parts Book ENGDokument86 SeitenRo-Flo Parts Book ENGedI_restrepo_1Noch keine Bewertungen

- Haskel Liquid Pumps v16Dokument24 SeitenHaskel Liquid Pumps v16Carl Moritz50% (2)

- Hydo Test ProcedureDokument2 SeitenHydo Test ProcedureAbdulMajidYousoffNoch keine Bewertungen

- 01 - Transfer Pumps & TexsteamDokument26 Seiten01 - Transfer Pumps & TexsteamMarsyaNoch keine Bewertungen

- Best Practices For Steam Control Valve InstallationDokument4 SeitenBest Practices For Steam Control Valve InstallationBen MusimaneNoch keine Bewertungen

- 4216 Mud Balance ManualDokument2 Seiten4216 Mud Balance ManualAli AliievNoch keine Bewertungen

- Apco Airvacuum Valves Avv Sales 601Dokument8 SeitenApco Airvacuum Valves Avv Sales 601Jhony MedranoNoch keine Bewertungen

- Series 600: Globe Style Sizes 3 Through 42 InchesDokument8 SeitenSeries 600: Globe Style Sizes 3 Through 42 Inchesrizviabbas2012Noch keine Bewertungen

- Cav - Valvulas. Mariposa - CavitacionDokument6 SeitenCav - Valvulas. Mariposa - CavitacionzmudioNoch keine Bewertungen

- DEWRANCE Tyco Welded in SeatDokument4 SeitenDEWRANCE Tyco Welded in Seatjones0055Noch keine Bewertungen

- Pub002 003 00 - 1011Dokument88 SeitenPub002 003 00 - 1011jones0055Noch keine Bewertungen

- ISO 8501 Photo ReferDokument5 SeitenISO 8501 Photo Referapi-386436191% (11)

- แบบมาตรฐานสถานีสุบน้ำแบบโรงสูบDokument15 Seitenแบบมาตรฐานสถานีสุบน้ำแบบโรงสูบjones0055Noch keine Bewertungen

- How To Control SurgeDokument22 SeitenHow To Control SurgeGlishna Peushan WidanapathiranaNoch keine Bewertungen

- NT3BB-4PWN Quick Installation GuideDokument14 SeitenNT3BB-4PWN Quick Installation Guidejones0055Noch keine Bewertungen

- Transient Article On Energy Savings With Air ValvesDokument2 SeitenTransient Article On Energy Savings With Air Valvesjones0055Noch keine Bewertungen

- Numerical Methods For Modeling Transient Flow: in Distribution SystemsDokument0 SeitenNumerical Methods For Modeling Transient Flow: in Distribution Systemsjones0055Noch keine Bewertungen

- Pressure Surges and Air Valve Specification PDFDokument22 SeitenPressure Surges and Air Valve Specification PDFTONNoch keine Bewertungen

- Characteristic Curve PDFDokument1 SeiteCharacteristic Curve PDFjones0055Noch keine Bewertungen

- A4 Water Treatment ProcessDokument22 SeitenA4 Water Treatment Processjones0055Noch keine Bewertungen

- Waterman Telescoping ValvesDokument4 SeitenWaterman Telescoping Valvesjones0055Noch keine Bewertungen

- An Introduction To Total Productive Maintenance (TPM) - VenkateshDokument22 SeitenAn Introduction To Total Productive Maintenance (TPM) - Venkateshtehky63Noch keine Bewertungen

- Green Tea ExtractDokument28 SeitenGreen Tea ExtractNikhil TribhuwanNoch keine Bewertungen

- Bodas Service FullDokument21 SeitenBodas Service Fullvivs100% (1)

- Design 8 ConsheetDokument7 SeitenDesign 8 ConsheetEryl David BañezNoch keine Bewertungen

- Basics of ProtectionDokument183 SeitenBasics of Protectionsushmitha100% (1)

- of Gatorade..Dokument29 Seitenof Gatorade..Jay ThakkarNoch keine Bewertungen

- ChemiTek SOLARWASHPROTECT DATASHEETDokument2 SeitenChemiTek SOLARWASHPROTECT DATASHEETPhani ArvapalliNoch keine Bewertungen

- ThermAsset 2 Low ResDokument2 SeitenThermAsset 2 Low ResThonny Barrera QuispeNoch keine Bewertungen

- RippleTankSE Key PDFDokument10 SeitenRippleTankSE Key PDFYesi Setyo Ningrum100% (1)

- X2 / 275 and 300 Vac: B 32 92 EMI Suppression CapacitorsDokument6 SeitenX2 / 275 and 300 Vac: B 32 92 EMI Suppression CapacitorsDimas ScrewNoch keine Bewertungen

- St. Louis Regional Economic Adjustment Strategic Plan 2011 - AECOMDokument242 SeitenSt. Louis Regional Economic Adjustment Strategic Plan 2011 - AECOMnextSTL.comNoch keine Bewertungen

- Unit 4 Photosynthesis-1Dokument7 SeitenUnit 4 Photosynthesis-1Abraham BanjoNoch keine Bewertungen

- Chapter 11 - Valves and Actuators With The NAMUR-InterfaceDokument13 SeitenChapter 11 - Valves and Actuators With The NAMUR-InterfaceJoseph MagonduNoch keine Bewertungen

- Harris - AN-PRC150 HF-VHF Combat Radio - Instruction ManualDokument49 SeitenHarris - AN-PRC150 HF-VHF Combat Radio - Instruction ManualAbhinav Ashok ChandelNoch keine Bewertungen

- Hazardous Area Classification: Codes of Practice and StandardsDokument13 SeitenHazardous Area Classification: Codes of Practice and StandardsborrowmanaNoch keine Bewertungen

- Force and Types of Forces Muscular Mechanical Gravitational Magnetic Frictional Static Electric ForceDokument3 SeitenForce and Types of Forces Muscular Mechanical Gravitational Magnetic Frictional Static Electric ForceJasvinder Singh67% (3)

- Vibrating Level Switches: For Bulk GoodsDokument2 SeitenVibrating Level Switches: For Bulk GoodsGiorgiana RosuNoch keine Bewertungen

- TechnetiumDokument3 SeitenTechnetiumDavid JonesNoch keine Bewertungen

- Chapter 3 Gases Lesson1 - 12Dokument97 SeitenChapter 3 Gases Lesson1 - 12Julius Salas100% (1)

- k1 S11ea0 PDFDokument147 Seitenk1 S11ea0 PDFErroz RosadiNoch keine Bewertungen

- 5 - Tank Itp - Inspection & Test Plan For TanksDokument10 Seiten5 - Tank Itp - Inspection & Test Plan For TanksAhmed Hassan100% (2)

- Form 1 AWS D1.1Dokument2 SeitenForm 1 AWS D1.1Bui Chi TamNoch keine Bewertungen

- Aquarea Split Systems Installation Handbook 2013 (A2W-SPX-130305-012)Dokument80 SeitenAquarea Split Systems Installation Handbook 2013 (A2W-SPX-130305-012)Anonymous ec2P0F5iKXNoch keine Bewertungen

- ICD Brookfield Place Brochure 05.05.2021Dokument24 SeitenICD Brookfield Place Brochure 05.05.2021Febin ShakibNoch keine Bewertungen

- .0 .0 Pelton - WheelDokument4 Seiten.0 .0 Pelton - WheelRabei RomulusNoch keine Bewertungen

- 10 Science TP 11 1Dokument5 Seiten10 Science TP 11 1Ananaya BansalNoch keine Bewertungen

- Manual - Ew-Combi Mk2Dokument8 SeitenManual - Ew-Combi Mk2Trần Thùy LinhNoch keine Bewertungen

- CTO 550 115 Current TransformerDokument3 SeitenCTO 550 115 Current Transformersagar ramaniNoch keine Bewertungen

- KAT0815-0001-E Single Pole Insulated Conductor RailDokument36 SeitenKAT0815-0001-E Single Pole Insulated Conductor RailirinaNoch keine Bewertungen

- Eg430ndt BrochureDokument2 SeitenEg430ndt BrochurePrabha KaranNoch keine Bewertungen

- Lecture 1. Introduction To Farm Power and EnergyDokument30 SeitenLecture 1. Introduction To Farm Power and EnergyMaureen Joy Cascayan EspirituNoch keine Bewertungen