Beruflich Dokumente

Kultur Dokumente

Oil Whirl

Hochgeladen von

Jitendra KumarOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Oil Whirl

Hochgeladen von

Jitendra KumarCopyright:

Verfügbare Formate

Oil Whirl

Oil whirl is a problem associated with sleeve type bearings. This vibration occurs only in machines

equipped with pressure lubricated sleeve bearings and operateing at relatively highspeed- normally above

the second critical speed of the rotor. Oil whirl vibration is often quite severe, but easily recognised

because the frequency is slightly less (5 - 8! than one half the rpm of the shaft.

The mechanism of oil whirl can be e"plained by referring to the diagram below.

#nder normal operation, the shaft of the machine will rise up the side of the bearing slightly. $ow far the

shaft will rise depends on shaft %&', rotor weight and oil pressure. The shaft, operating at an eccentric

position from the bearing centre, draws oil into a wedge to produce a pressurised load bearing film. (f the

eccentricity of the shaft within the bearing is increased from this normal operating position, say be

e"ternal shoc) or load transient, additional oil will immediately be pumped in to fill the space vacated by

the shaft thus increaseing the oil film supporting the shaft. This oil film may drive the shaft in a whirling

motion around the bearing. (f damping in the design is sufficient then the system will return to its original

position otherwise the whirling motion will continue.

lternately, a lightly loaded bearing may rise under normal conditions reducing the clearance

above the bearing to a point where an oil wedge forms forcing the shaft bac) down. (n doing so the

clearance is restored at the top of the bearing and the oil wedge fails removing the downward pressure.

*team Turbine bearings are susceptible to oil whirl as they tend to have larger than normal clearances to

allow for high oil flows for cooling

Causes

Normally associated with poor bearing design, . Other problems are

excessive bearing wear

increase in lube oil pressure

Change of oil viscosity

External excitation caused by a transmitted in vibration at the natural oil whirl frequency.

Temporary Remedies

Temporary remedies include

Changing oil temerpature or viscosity

ncrease bearing loading by introducing slight misalignement or imbalance

!crapping the sides of the bearing or grooving the bearing surface to disrupt the lubricant

wedge

Improved Bearing Design

*horter bearings increase the bearing load which can help prevent oil whirl

"emon #ip $esign

This is achieved by machining the two shells whilst shims are fitted between the faces

Tilting #ad%mitchell type

+ thermocouplwe is fitted to the lowest pad

&rooved

,oss of bearing material means reduction in load carrying capacity

Nut Crac'er

Camella

-ormed by boring non-concentric circular bearing surfaces in a bearing allowing th eformation of three

wedges whilst maintaining the correct bearing clearance

Das könnte Ihnen auch gefallen

- Tooth Design: Forces Acting On Spur GearsDokument77 SeitenTooth Design: Forces Acting On Spur GearsJitendra KumarNoch keine Bewertungen

- Oil Whip WhirlDokument3 SeitenOil Whip WhirlPeerasak ArunNoch keine Bewertungen

- Lighting and ShadingDokument44 SeitenLighting and Shadingpalaniappan_pandianNoch keine Bewertungen

- Shaft AlignmentDokument20 SeitenShaft AlignmentmersiumNoch keine Bewertungen

- Problems in Soil Mechanics and Foundation EngineeringDokument172 SeitenProblems in Soil Mechanics and Foundation EngineeringCharilyn Echeverre100% (16)

- Advance VibrationDokument263 SeitenAdvance VibrationSurya Pratap SinghNoch keine Bewertungen

- Api 610Dokument11 SeitenApi 610prakasharmyNoch keine Bewertungen

- Wolfson Eup3 Ch09 Test BankDokument15 SeitenWolfson Eup3 Ch09 Test BankifghelpdeskNoch keine Bewertungen

- Cylinder Liner Gauging 1Dokument5 SeitenCylinder Liner Gauging 1Vinay Kumar Neelam100% (1)

- Pilgrim NutDokument2 SeitenPilgrim NutJitendra KumarNoch keine Bewertungen

- Data Sheet TDD-GD100T PDFDokument2 SeitenData Sheet TDD-GD100T PDFjhon peñaNoch keine Bewertungen

- Resolving Oil Whirl Issues in a Gas Compressor Case StudyDokument42 SeitenResolving Oil Whirl Issues in a Gas Compressor Case StudyChristian Santillan100% (1)

- A Procedure For Lube Oil FlushingDokument9 SeitenA Procedure For Lube Oil FlushingBrosGeeNoch keine Bewertungen

- Plain Bearing FailuresDokument7 SeitenPlain Bearing FailuressourajpatelNoch keine Bewertungen

- Governers FinalDokument52 SeitenGoverners Finaldanish moinNoch keine Bewertungen

- Basic Wear ModesDokument6 SeitenBasic Wear ModesolguinrfNoch keine Bewertungen

- Calculations For IB ChemistryDokument16 SeitenCalculations For IB Chemistryanthor100% (3)

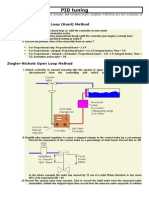

- PID TuningDokument4 SeitenPID TuningJitendra Kumar100% (1)

- Model VS: Instruction ManualDokument52 SeitenModel VS: Instruction ManualAdriano AdrianoNoch keine Bewertungen

- Otc18895 Flow Induced Pulsations in RisersDokument5 SeitenOtc18895 Flow Induced Pulsations in Risershamadani100% (1)

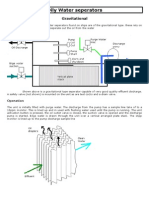

- Oily Water SeperatorsDokument2 SeitenOily Water SeperatorsJitendra KumarNoch keine Bewertungen

- Oil Distribution and Factors in Journal BearingsDokument2 SeitenOil Distribution and Factors in Journal BearingsAnkit DedhiyaNoch keine Bewertungen

- Entrenamiento en ScopometetroDokument36 SeitenEntrenamiento en ScopometetroMauricio Javier DuranNoch keine Bewertungen

- Bombas Multietapa SIHIDokument23 SeitenBombas Multietapa SIHIflorezescobarNoch keine Bewertungen

- CouplingsDokument9 SeitenCouplingssam abusiNoch keine Bewertungen

- Scope: (B) Tank Strapping Includes The Following MeasurementsDokument1 SeiteScope: (B) Tank Strapping Includes The Following MeasurementsEIWAA0% (1)

- Wauk VHP OprDokument209 SeitenWauk VHP Oprmoudar72Noch keine Bewertungen

- HDU - Gear and Bearing Lubrication - SmidthDokument2 SeitenHDU - Gear and Bearing Lubrication - SmidthLuis Orlando Villarroel TorrezNoch keine Bewertungen

- Standards Update Notice (Sun) ISSUED: July 8, 2020: Standard InformationDokument3 SeitenStandards Update Notice (Sun) ISSUED: July 8, 2020: Standard InformationvpjagannaathNoch keine Bewertungen

- WorthingtonCreyssensac Rollair 40-150E Leaflet en 6999010301-LRDokument12 SeitenWorthingtonCreyssensac Rollair 40-150E Leaflet en 6999010301-LRpragnesh prajapati100% (1)

- Steam System Best Practices Ultrasound Testing Steam TrapsDokument12 SeitenSteam System Best Practices Ultrasound Testing Steam TrapsJason Ng Yan FuNoch keine Bewertungen

- Fallas de Rodamientos (Ingles)Dokument44 SeitenFallas de Rodamientos (Ingles)Weimar G. SalazarNoch keine Bewertungen

- Jacket Water SystemDokument2 SeitenJacket Water SystemJitendra KumarNoch keine Bewertungen

- Mech Intro 18.0 WS02.1 Workshop Instructions 2D Gear and RackDokument17 SeitenMech Intro 18.0 WS02.1 Workshop Instructions 2D Gear and RackYrani AlatristaNoch keine Bewertungen

- Increasing Propulsive EfficiencyDokument6 SeitenIncreasing Propulsive EfficiencyJitendra KumarNoch keine Bewertungen

- Altronic V Installation Manual (FORM AV II)Dokument12 SeitenAltronic V Installation Manual (FORM AV II)francis_mouille_iiNoch keine Bewertungen

- Chockfast Orange PDFDokument2 SeitenChockfast Orange PDFKaharul AfandiNoch keine Bewertungen

- BFWT Repair Report 02 Feb 2022Dokument11 SeitenBFWT Repair Report 02 Feb 2022Haitham AbdEl-TawabNoch keine Bewertungen

- Shell Grease Portfolio Conversion Guide Provides Replacement RecommendationsDokument1 SeiteShell Grease Portfolio Conversion Guide Provides Replacement RecommendationsLuis Angel CabreraNoch keine Bewertungen

- HOSS ProductDescriptionDokument6 SeitenHOSS ProductDescriptionmath62210Noch keine Bewertungen

- Brochure o Pumps Deepwell Gas CarriersDokument4 SeitenBrochure o Pumps Deepwell Gas CarriersJohn MarxisNoch keine Bewertungen

- Perforator Drilling ToolsDokument20 SeitenPerforator Drilling ToolsДамир НазиповNoch keine Bewertungen

- Oil Whip and Oil WhirlDokument1 SeiteOil Whip and Oil WhirlkrishnaNoch keine Bewertungen

- Oil Whirl and Whip Instabilities - Within Journal Bearings PDFDokument3 SeitenOil Whirl and Whip Instabilities - Within Journal Bearings PDFNitesh Garg0% (1)

- Floormap3di MFL Tank Floor InspectionDokument6 SeitenFloormap3di MFL Tank Floor InspectionSameh AtiyaNoch keine Bewertungen

- Pyi1701 0000 Pip Et 0001 - 0Dokument18 SeitenPyi1701 0000 Pip Et 0001 - 0Marko QuilahuequeNoch keine Bewertungen

- PDVSA 0602.1.472 Dikes For Storage Tanks 6pDokument6 SeitenPDVSA 0602.1.472 Dikes For Storage Tanks 6pIsmar AdrianNoch keine Bewertungen

- 2016 Vol-2 3 OCTDokument12 Seiten2016 Vol-2 3 OCTsppramNoch keine Bewertungen

- Internormen-Eaton - CCS 2 Contamination Control System - Manual v2.3 PDFDokument80 SeitenInternormen-Eaton - CCS 2 Contamination Control System - Manual v2.3 PDFClarence SmithNoch keine Bewertungen

- En Additin RC 93210Dokument2 SeitenEn Additin RC 93210Dinesh babuNoch keine Bewertungen

- 16 - Manual LST Telefericos PDFDokument36 Seiten16 - Manual LST Telefericos PDFElectricidad IngecablesNoch keine Bewertungen

- (MFL) Arkaline IranDokument12 Seiten(MFL) Arkaline IranFrank MosesNoch keine Bewertungen

- Helical Gear Lubrication RequirementDokument7 SeitenHelical Gear Lubrication RequirementvenkateswaranNoch keine Bewertungen

- Valve Testing & Seat Leakage Comparism PDFDokument6 SeitenValve Testing & Seat Leakage Comparism PDFAnupmaNoch keine Bewertungen

- 1887 125HP Union TD 120 Triplex Sour Pump PackageDokument11 Seiten1887 125HP Union TD 120 Triplex Sour Pump PackageIvan Jojic100% (1)

- Fisher Type 667 Diaphragm ActuatorDokument32 SeitenFisher Type 667 Diaphragm Actuatorimran khanNoch keine Bewertungen

- Maintenance Manual Fontaine Fifth Wheel Maintenance: SAE Standard King PinDokument2 SeitenMaintenance Manual Fontaine Fifth Wheel Maintenance: SAE Standard King PinedilsonNoch keine Bewertungen

- Magnetic Particle Process Guide: Nonfluorescent/Visible Color FluorescentDokument1 SeiteMagnetic Particle Process Guide: Nonfluorescent/Visible Color FluorescentLion A-jNoch keine Bewertungen

- Specification For Bridge Construction (England)Dokument35 SeitenSpecification For Bridge Construction (England)Roy GuoNoch keine Bewertungen

- API-MODIFIED HIGH-PRESSURE THREAD COMPOUNDDokument1 SeiteAPI-MODIFIED HIGH-PRESSURE THREAD COMPOUNDJeremias UtreraNoch keine Bewertungen

- TCPC Running Manual 2019 Rev BDokument10 SeitenTCPC Running Manual 2019 Rev BGouldNoch keine Bewertungen

- 130801512SHA-001 TRDokument17 Seiten130801512SHA-001 TRUsman AliNoch keine Bewertungen

- Aerator PremiumDokument10 SeitenAerator PremiumvijaykumarnNoch keine Bewertungen

- Garlock gasket M & Y values for flange designDokument3 SeitenGarlock gasket M & Y values for flange designGanesh.MahendraNoch keine Bewertungen

- High-Speed Gear Drives Leader Lufkin IndustriesDokument7 SeitenHigh-Speed Gear Drives Leader Lufkin IndustriesAnonymous YmXY1bcNoch keine Bewertungen

- Electric Hoists PDFDokument18 SeitenElectric Hoists PDFedark2009Noch keine Bewertungen

- Ancla Antitorque DTA XBDokument2 SeitenAncla Antitorque DTA XBalfredozavNoch keine Bewertungen

- Dean RA Pump ManualsDokument23 SeitenDean RA Pump ManualscoltonNoch keine Bewertungen

- Flextone User Manual - EnglishDokument66 SeitenFlextone User Manual - EnglishGugu BatungaNoch keine Bewertungen

- Vibration Due to Oil Whirl in Plain or Sleeve BearingsDokument3 SeitenVibration Due to Oil Whirl in Plain or Sleeve BearingsJameel KhanNoch keine Bewertungen

- Experiment 3 - Mechatronic Oil Whirl PDFDokument9 SeitenExperiment 3 - Mechatronic Oil Whirl PDFQee ZackNoch keine Bewertungen

- Oil Whirl and Whip Instabilities - Within Journal BearingsDokument3 SeitenOil Whirl and Whip Instabilities - Within Journal BearingsChristopher GarciaNoch keine Bewertungen

- Oil Whirl and Whip Instabilities - Within Journal BearingsDokument27 SeitenOil Whirl and Whip Instabilities - Within Journal BearingsTalha AamirNoch keine Bewertungen

- Oxygen AnalysersDokument2 SeitenOxygen AnalysersJitendra KumarNoch keine Bewertungen

- Microbes of Microbiological Attac1Dokument3 SeitenMicrobes of Microbiological Attac1Jitendra KumarNoch keine Bewertungen

- Parallel Operation of GeneratorsDokument5 SeitenParallel Operation of GeneratorsJitendra KumarNoch keine Bewertungen

- Overview of Microbiological AttackDokument10 SeitenOverview of Microbiological AttackJitendra KumarNoch keine Bewertungen

- Overall Arrangement: Description of The Salient PartsDokument6 SeitenOverall Arrangement: Description of The Salient PartsJitendra KumarNoch keine Bewertungen

- Operation of A Centrifugal Oil PurifersDokument3 SeitenOperation of A Centrifugal Oil PurifersJitendra KumarNoch keine Bewertungen

- Molybdenum DiSulphideDokument1 SeiteMolybdenum DiSulphideJitendra KumarNoch keine Bewertungen

- Motor Ship Steam Plan1Dokument3 SeitenMotor Ship Steam Plan1Jitendra KumarNoch keine Bewertungen

- Marpol 73Dokument12 SeitenMarpol 73Jitendra KumarNoch keine Bewertungen

- Navigation LightingDokument1 SeiteNavigation LightingJitendra KumarNoch keine Bewertungen

- Motor Ship Steam Plant ControlDokument1 SeiteMotor Ship Steam Plant ControlJitendra KumarNoch keine Bewertungen

- Metallurgical TestingDokument1 SeiteMetallurgical TestingJitendra KumarNoch keine Bewertungen

- Materials Used in Ships Sea Water SystemsDokument1 SeiteMaterials Used in Ships Sea Water SystemsAnkit DedhiyaNoch keine Bewertungen

- LNG Containment DesignsDokument3 SeitenLNG Containment DesignsJitendra KumarNoch keine Bewertungen

- Microbes of Microbiological Attac1Dokument3 SeitenMicrobes of Microbiological Attac1Jitendra KumarNoch keine Bewertungen

- Low Sulphur FuelsDokument1 SeiteLow Sulphur FuelsJitendra KumarNoch keine Bewertungen

- Mechanical GovernorsDokument1 SeiteMechanical GovernorsJitendra KumarNoch keine Bewertungen

- Lube Oil Requirements For Diesel EnginesDokument3 SeitenLube Oil Requirements For Diesel EnginesJitendra KumarNoch keine Bewertungen

- LNG Reliquifactio1Dokument1 SeiteLNG Reliquifactio1Jitendra KumarNoch keine Bewertungen

- Lifting Using Accessories: Calculation of LoadDokument2 SeitenLifting Using Accessories: Calculation of LoadJitendra KumarNoch keine Bewertungen

- Liquified Gas CargoesDokument2 SeitenLiquified Gas CargoesJitendra KumarNoch keine Bewertungen

- ElectricityDokument25 SeitenElectricityWeb BooksNoch keine Bewertungen

- 978 1 4419 5754 2 PDFDokument458 Seiten978 1 4419 5754 2 PDFLUIS ISAAC LEON PARONoch keine Bewertungen

- 1.1 Vector Algebra: 1.1.1 ScalarsDokument7 Seiten1.1 Vector Algebra: 1.1.1 ScalarsreachsudhirNoch keine Bewertungen

- Chemical Bonding II - VSEPR ModelDokument23 SeitenChemical Bonding II - VSEPR ModelYokaris JTNoch keine Bewertungen

- 14 04 08 Referenslista Turbo (SE En)Dokument11 Seiten14 04 08 Referenslista Turbo (SE En)mersiumNoch keine Bewertungen

- Lewis Structures: Molecular Structure and BondingDokument83 SeitenLewis Structures: Molecular Structure and Bondingحني اسفيانيNoch keine Bewertungen

- Classified Examples of Electrical Engineering 1928Dokument103 SeitenClassified Examples of Electrical Engineering 1928dominicrochford3068Noch keine Bewertungen

- BiophysicsandMolecularBiology PDFDokument101 SeitenBiophysicsandMolecularBiology PDFRisikrrishna DasNoch keine Bewertungen

- Torque and Equilibrium (40 charactersDokument2 SeitenTorque and Equilibrium (40 charactersEndai DesuNoch keine Bewertungen

- Sci7 wk10Dokument7 SeitenSci7 wk10Giovanni QuevedoNoch keine Bewertungen

- JEE Test Series ScheduleDokument4 SeitenJEE Test Series ScheduleB.K.Sivaraj rajNoch keine Bewertungen

- Entalglement - Amir D Aczel PDFDokument4 SeitenEntalglement - Amir D Aczel PDFAlejandro LimaNoch keine Bewertungen

- Net Positive Suction HeadDokument16 SeitenNet Positive Suction HeadpandiangvNoch keine Bewertungen

- RDII - Chapter 5 HandoutDokument8 SeitenRDII - Chapter 5 HandoutIlamurianNoch keine Bewertungen

- Energy Transfer in Turbomachines ExplainedDokument4 SeitenEnergy Transfer in Turbomachines Explainedsachintyagi1Noch keine Bewertungen

- The UniverseDokument2 SeitenThe Universeapi-328735767Noch keine Bewertungen

- MicrobiologyDokument82 SeitenMicrobiologyAbhishek SinghNoch keine Bewertungen

- Dynamic of Billboard Thin PlateDokument6 SeitenDynamic of Billboard Thin PlateJoseph Cloyd LamberteNoch keine Bewertungen

- Example For Ch.4Dokument14 SeitenExample For Ch.4Weaven YauNoch keine Bewertungen

- Homework 14 Solutions Spring 2001Dokument2 SeitenHomework 14 Solutions Spring 2001Ikhwan Wf Miscellaneous AveroesNoch keine Bewertungen

- Important Concepts For General Science UPSC IAS PrelimsDokument4 SeitenImportant Concepts For General Science UPSC IAS Prelimshim123verNoch keine Bewertungen

- Classical Mechanics-Pdf by Dr. Rajesh MathpalDokument45 SeitenClassical Mechanics-Pdf by Dr. Rajesh MathpalMunna MunendharNoch keine Bewertungen

- Fundamentals of Statistical Mechanics: EnsemblesDokument10 SeitenFundamentals of Statistical Mechanics: EnsemblesRUIVTOMNoch keine Bewertungen

- Analogous Electrical and Mechanical SystemsDokument9 SeitenAnalogous Electrical and Mechanical SystemsAnuradha ChathurangaNoch keine Bewertungen