Beruflich Dokumente

Kultur Dokumente

A4954 Datasheet

Hochgeladen von

Angly1959Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

A4954 Datasheet

Hochgeladen von

Angly1959Copyright:

Verfügbare Formate

Description

Designed for pulse width modulated (PWM) control of two

DC motors, the A4954 is capable of peak output currents to

2 A and operating voltages to 40 V.

Input terminals are provided for use in controlling the speed and

direction of a DC motor with externally applied PWM control

signals. Internal synchronous rectification control circuitry is

provided to lower power dissipation during PWM operation.

Internal circuit protection includes overcurrent protection,

motor lead short to ground or supply, thermal shutdown with

hysteresis, undervoltage monitoring of V

BB

, and crossover-

current protection.

The A4954 is provided in a low-profile 16-pin TSSOP package

with exposed thermal pad (suffix LP) that is lead (Pb) free,

with 100% matte tin leadframe plating.

A4954-DS, Rev. 4

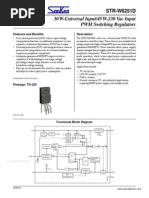

Features and Benefits

Low R

DS(on)

outputs

Overcurrent protection (OCP)

Motor short protection

Motor lead short to ground protection

Motor lead short to battery protection

Low Power Standby mode

Adjustable PWM current limit

Synchronous rectification

Internal undervoltage lockout (UVLO)

Crossover-current protection

Dual Full-Bridge

DMOS PWM Motor Driver

Package: 16-pin TSSOP with exposed

thermal pad (suffix LP)

Functional Block Diagram

Not to scale

A4954

Control

Logic

LSS34

OUT3

VBB

IN3

IN4

Charge

Pump

OSC

Disable

UVLO

VREF34

7V

GND

TSD

10

Control

Logic

LSS12

OUT1

OUT2

VBB

IN1

IN2

Charge

Pump

OSC

Disable

Load Supply

UVLO

VREF12

7V

GND

(Optional)

(Optional)

TSD

10

OUT4

Dual Full-Bridge DMOS

PWM Motor Driver

A4954

2

Allegro MicroSystems, LLC

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

Terminal List Table

Number Name Function

1 GND Ground

2 VREF34 Analog input for bridge 3-4

3 IN3 Logic input 3

4 IN4 Logic input 4

5 IN2 Logic input 2

6 IN1 Logic input 1

7 VREF12 Analog input for bridge 1-2

8 GND Ground

9 VBB Load supply voltage

10 OUT1 DMOS full bridge output 1

11 LSS12 Power return sense resistor connection for bridge 1-2

12 OUT2 DMOS full bridge output 2

13 OUT3 DMOS full bridge output 3

14 LSS34 Power return sense resistor connection for bridge 3-4

15 OUT4 DMOS full bridge output 4

16 VBB Load supply voltage

PAD Exposed pad for enhanced thermal dissipation

Pin-out Diagram

Absolute Maximum Ratings

Characteristic Symbol Notes Rating Unit

Load Supply Voltage V

BB

40 V

Logic Input Voltage Range V

IN

0.3 to 6 V

V

REF

Input Voltage Range V

REF

0.3 to 6 V

Sense Voltage (LSSx pin) V

S

0.5 to 0.5 V

Motor Outputs Voltage V

OUT

2 to 42 V

Output Current I

OUT

Duty cycle = 100% 2 A

Transient Output Current i

OUT

T

W

< 500 ns 5 A

Operating Temperature Range T

A

Temperature Range E 40 to 85 C

Maximum Junction Temperature T

J

(max) 150 C

Storage Temperature Range T

stg

55 to 150 C

Selection Guide

Part Number Packing

A4954ELPTR-T 4000 pieces per 13-in. reel

A4954ELP-T 96 pieces per tube

Thermal Characteristics may require derating at maximum conditions, see application information

Characteristic Symbol Test Conditions* Value Unit

Package Thermal Resistance R

JA

On 2-layer PCB with 3.8 in

2

. exposed 2-oz. copper each side 43 C/W

On 4-layer PCB based on JEDEC standard 34 C/W

*Additional thermal information available on the Allegro website.

GND

VREF34

IN3

IN4

IN2

IN1

VREF12

GND

VBB

OUT4

LSS34

OUT3

OUT2

LSS12

OUT1

VBB

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

PAD

Dual Full-Bridge DMOS

PWM Motor Driver

A4954

3

Allegro MicroSystems, LLC

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

ELECTRICAL CHARACTERISTICS Valid at T

J

= 25C, unless otherwise specified

Characteristics Symbol Test Conditions Min. Typ. Max. Unit

General

Load Supply Voltage Range V

BB

8 40 V

R

DS(on)

Sink + Source Total R

DS(on)

I

OUT

= |1.5 A|, T

J

= 25C 0.8 1.12

I

OUT

= |1.5 A|, T

J

= 125C 1.28 1.8

Load Supply Current I

BB

f

PWM

< 30 kHz 10 mA

Low Power Standby mode 10 A

Body Diode Forward Voltage V

f

Source diode, I

f

= 1.5 A 1.5 V

Sink diode, I

f

= 1.5 A 1.5 V

Logic Inputs

Logic Input Voltage Range

V

IN(1)

2.0 V

V

IN(0)

0.8 V

V

IN(STANDBY)

Low Power Standby mode 0.4 V

Logic Input Current

I

IN(1)

V

IN

= 2.0 V 40 100 A

I

IN(0

) V

IN

= 0.8 V 16 40 A

Logic Input Pull-Down Resistance RRR

LOGIC(PD)

V

IN

= 0 V = IN1 = IN2 = IN3 = IN4 50 k

Input Hysteresis V

HYS

250 550 mV

Timing

Crossover Delay t

COD

50 500 ns

V

REF

Input Voltage Range V

REF

0 5 V

Current Gain A

V

V

REF

/ I

SS

, V

REF

= 5 V 9.5 10.5 V/V

V

REF

/ I

SS

, V

REF

= 2.5 V 9.0 10.0 V/V

V

REF

/ I

SS

, V

REF

= 1 V 8.0 10.0 V/V

Blank Time t

BLANK

2 3 4 s

Constant Off-time t

off

16 25 34 s

Standby Timer t

st

IN1 = IN2 = IN3 = IN4 < V

IN(STANDBY)

1 1.5 ms

Power-Up Delay t

pu

30 s

Protection Circuits

UVLO Enable Threshold V

BBUVLO

V

BB

increasing 7 7.5 7.95 V

UVLO Hysteresis V

BBUVLOhys

500 mV

Thermal Shutdown Temperature T

JTSD

Temperature increasing 160 C

Thermal Shutdown Hysteresis T

TSDhys

Recovery = T

JTSD

T

TSDhys

15 C

Dual Full-Bridge DMOS

PWM Motor Driver

A4954

4

Allegro MicroSystems, LLC

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

Characteristic Performance

PWM Control Timing Diagram

PWM Control Truth Table

IN1, IN3 IN2, IN4 10V

S

> V

REF

OUT1, OUT3 OUT2, OUT4 Function

0 1 False L H Reverse

1 0 False H L Forward

0 1 True H/L L Chop (mixed decay), reverse

1 0 True L H/L Chop (mixed decay), forward

1 1 False L L Brake (slow decay)

0 0 False Z Z Coast, enters Low Power Standby mode after 1 ms

Note: Z indicates high impedance.

Reverse/

Fast Decay

Reverse/

Slow Decay

Forward/

Fast Decay

Forward/

Slow Decay

GND

GND

+I

REG

0 A

-I

REG

IN1,

IN3

IN2,

IN4

I

OUTx

V

IN(1)

V

IN(1)

Dual Full-Bridge DMOS

PWM Motor Driver

A4954

5

Allegro MicroSystems, LLC

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

Functional Description

Device Operation

The A4954 is designed to operate two DC motors. The output

drivers are all low-R

DS(on)

, N-channel DMOS drivers that feature

internal synchronous rectification to reduce power dissipation.

The current in each of the two output full bridges is regulated

with fixed off-time pulse width modulated (PWM) control cir-

cuitry. The IN1-IN2 and IN3-IN4 inputs allow two-wire control

for each bridge.

Protection circuitry includes internal thermal shutdown, and pro-

tection against shorted loads, or against output shorts to ground

or supply. Undervoltage lockout prevents damage by keeping the

outputs off until the driver has enough voltage to operate nor-

mally.

Standby Mode

Low Power Standby mode is activated when all four input (INx)

pins are low for longer than 1 ms. Low Power Standby mode

disables most of the internal circuitry, including the charge pump

and the regulator. When the A4954 is coming out of standby

mode, the charge pump should be allowed to reach its regulated

voltage (a maximum delay of 200 s) before any PWM com-

mands are issued to the device.

Internal PWM Current Control

Initially, a diagonal pair of source and sink FET outputs are

enabled and current flows through the motor winding and the

optional external current sense resistor, R

Sx

. When the voltage

across R

Sx

equals the comparator trip value, then the current

sense comparator resets the PWM latch. The latch then turns off

the sink and source FETs (Mixed Decay mode).

V

REF

The maximum value of current limiting is set by the selection

of R

Sx

and the voltage at the VREFx pin in each channel. The

transconductance function is approximated by the maximum

value of current limiting, I

TripMAX

(A), which is set by:

I

TripMAX

=

A

V

R

S

V

REF

where V

REF

is the input voltage on the VREFx pin (V) and R

S

is

the resistance of the sense resistor () on the corresponding LSSx

terminal.

Overcurrent Protection

A current monitor will protect the IC from damage due to output

shorts. If a short is detected, the IC will latch the fault and dis-

able the outputs. Each channel has independent OCP protection.

The fault latch can only be cleared by coming out of Low Power

Standby mode or by cycling the power to VBB. During OCP

events, Absolute Maximum Ratings may be exceeded for a short

period of time before the device latches.

Shutdown

If the die temperature increases to approximately 160C, the full

bridge outputs will be disabled until the internal temperature falls

below a hysteresis, T

TSDhys

, of 15C. Internal UVLO is present

on VBB to prevent the output drivers from turning-on below the

UVLO threshold.

Braking

The braking function is implemented by driving the device in

Slow Decay mode, which is done by applying a logic high to both

inputs of both channels, after a bridge-enable Chop command

(see PWM Control Truth Table). Because it is possible to drive

current in both directions through the DMOS switches, this con-

figuration effectively shorts-out the motor-generated BEMF, as

long as the Chop command is asserted. The maximum current can

be approximated by V

BEMF

/ R

L

. Care should be taken to ensure

that the maximum ratings of the device are not exceeded in worse

case braking situations: high speed and high-inertia loads.

Dual Full-Bridge DMOS

PWM Motor Driver

A4954

6

Allegro MicroSystems, LLC

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

Synchronous Rectification

When a PWM off-cycle is triggered by an internal fixed off-time

cycle, load current will recirculate. The A4954 synchronous rec-

tification feature turns-on the appropriate DMOSFETs during the

current decay, and effectively shorts out the body diodes with the

low R

DS(on)

driver. This significantly lowers power dissipation.

When a zero current level is detected, synchronous rectification is

turned off to prevent reversal of the load current.

Mixed Decay Operation

The bridges operate in Mixed Decay mode. Referring to the

lower panel of the figure below, as the trip point is reached, the

device goes into fast decay mode for 50% of the fixed off-time

period. After this fast decay portion the device switches to slow

decay mode for the remainder of the off-time. During transitions

from fast decay to slow decay, the drivers are forced off for the

Crossover Delay, t

COD

. This feature is added to prevent shoot-

through in the bridge. During this dead time portion, synchro-

nous rectification is not active, and the device operates in fast

decay and slow decay only.

Mixed Decay Mode Operation

V

PHASE

I

OUT

I

OUT

+

0

See Enlargement A

Enlargement A

t

COD

t

COD

t

COD

Fixed Off-Time, t

off

= 25 s

Fast Decay Slow Decay

I

Trip

0.50 t

off

0.50 t

off

Dual Full-Bridge DMOS

PWM Motor Driver

A4954

7

Allegro MicroSystems, LLC

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

Application Information

Sense Pins (LSSx)

In order to use PWM current control, a low-value resistor is

placed between the LSSx pin and ground for current sensing pur-

poses. To minimize ground-trace IR drops in sensing the output

current level, the current sensing resistor should have an indepen-

dent ground return to the star ground point. This trace should be

as short as possible. For low-value sense resistors, the IR drops in

the PCB can be significant, and should be taken into account.

When selecting a value for the sense resistor be sure not to

exceed the maximum voltage on the LSSx pin of 500 mV at

maximum load. During overcurrent events, this rating may be

exceeded for short durations.

Ground

A star ground should be located as close to the A4954 as possible.

The copper ground plane directly under the exposed thermal pad

of the device makes a good location for the star ground point. The

exposed pad can be connected to ground for this purpose.

Layout

The PCB should have a thick ground plane. For optimum

electrical and thermal performance, the A4954 must be soldered

directly onto the board. On the underside of the A4954 package is

an exposed pad, which provides a path for enhanced thermal dis-

sipation. The thermal pad must be soldered directly to an exposed

surface on the PCB in order to achieve optimal thermal conduc-

tion. Thermal vias are used to transfer heat to other layers of the

PCB.

The load supply pin, VBB, should be decoupled with an electro-

lytic capacitor (typically 100 F) in parallel with a lower valued

ceramic capacitor placed as close as practicable to the device.

OUT3

OUT2

RS12

GND

GND

GND

C1

BULK

C2

CAPACITANCE

VBB

OUT4

OUT1

RS34

GND

VBB

1

PAD

A4954

R

S12

C1 C2

VBB

OUT4

LSS34

OUT3

OUT2

LSS12

OUT1

VBB

VREF34

IN3

IN4

IN2

IN1

VREF12

GND

GND

R

S34

Bill of Materials

Item Reference Value Units Description

1 RS12, RS34

0.25

(for V

REF

= 5 V, I

OUT

= 2 A)

2512, 1 W, 1% or better,

carbon film chip resistor

2 C1 0.22 F X5R minimum, 50 V or greater

3 C2 100 F Electrolytic, 50 V or greater

Dual Full-Bridge DMOS

PWM Motor Driver

A4954

8

Allegro MicroSystems, LLC

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

Package LP, 16-Pin TSSOP

with exposed thermal pad

A

1.20 MAX

0.15

0.00

0.30

0.19

0.20

0.09

8

0

0.60 0.15

1.00 REF

C

SEATING

PLANE

C 0.10

16X

0.65 BSC

0.25 BSC

2 1

16

5.000.10

4.400.10 6.400.20

GAUGEPLANE

SEATINGPLANE

A Terminal #1 mark area

B

For Reference Only; not for tooling use (reference MO-153 ABT)

Dimensions in millimeters

Dimensions exclusive of mold flash, gate burrs, and dambar protrusions

Exact case and lead configuration at supplier discretion within limits shown

B

C

Exposed thermal pad (bottomsurface); dimensions may vary with device

6.10

0.65

0.45

1.70

3.00

3.00

16

2 1

Reference land pattern layout (reference IPC7351

SOP65P640X110-17M);

All pads a minimumof 0.20 mmfromall adjacent pads; adjust as

necessary to meet application process requirements and PCBlayout

tolerances; when mounting on a multilayer PCB, thermal vias at the

exposed thermal pad land can improve thermal dissipation (reference

EIA/JEDECStandard JESD51-5)

PCBLayout Reference View C

Branded Face

3 NOM

3 NOM

Dual Full-Bridge DMOS

PWM Motor Driver

A4954

9

Allegro MicroSystems, LLC

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

Copyright 2010-2013, Allegro MicroSystems, LLC

Allegro MicroSystems, LLC reserves the right to make, from time to time, such de par tures from the detail spec i fi ca tions as may be required to

permit improvements in the per for mance, reliability, or manufacturability of its products. Before placing an order, the user is cautioned to verify that

the information being relied upon is current.

Allegros products are not to be used in life support devices or systems, if a failure of an Allegro product can reasonably be expected to cause the

failure of that life support device or system, or to affect the safety or effectiveness of that device or system.

The in for ma tion in clud ed herein is believed to be ac cu rate and reliable. How ev er, Allegro MicroSystems, LLC assumes no re spon si bil i ty for its

use; nor for any in fringe ment of patents or other rights of third parties which may result from its use.

For the latest version of this document, visit our website:

www.allegromicro.com

Revision History

Revision Revision Date Description of Revision

Rev. 4 August 6, 2012 Update PWM table

Das könnte Ihnen auch gefallen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Bewertung: 2.5 von 5 Sternen2.5/5 (3)

- Motor Driver - Full-Bridge PWM - A3953-N5Dokument14 SeitenMotor Driver - Full-Bridge PWM - A3953-N5Ludwig Schmidt100% (1)

- STRW6252Dokument15 SeitenSTRW6252miltoncgNoch keine Bewertungen

- A3953 DatasheetDokument12 SeitenA3953 DatasheetMohan RajNoch keine Bewertungen

- Datasheet PDFDokument15 SeitenDatasheet PDFperro sNoch keine Bewertungen

- Microstepping DMOS Driver With Translator: Description Features and BenefitsDokument18 SeitenMicrostepping DMOS Driver With Translator: Description Features and BenefitsSaid BoubkerNoch keine Bewertungen

- Ltc1629/Ltc1629-Pg Polyphase, High Efficiency, Synchronous Step-Down Switching RegulatorsDokument28 SeitenLtc1629/Ltc1629-Pg Polyphase, High Efficiency, Synchronous Step-Down Switching Regulatorscatsoithahuong84Noch keine Bewertungen

- STCC05-B: Home Appliance Control CircuitDokument13 SeitenSTCC05-B: Home Appliance Control Circuitsvhanu4010Noch keine Bewertungen

- Mach Cong Suat Cau H - Lmd18200Dokument14 SeitenMach Cong Suat Cau H - Lmd18200hieuhuech1Noch keine Bewertungen

- 3000W Single Output Power Supply Spec SheetDokument6 Seiten3000W Single Output Power Supply Spec SheetGrigoriu CodrutaNoch keine Bewertungen

- LMD18201 3A, 55V H-Bridge: Literature Number: SNVS092CDokument14 SeitenLMD18201 3A, 55V H-Bridge: Literature Number: SNVS092CIrfan AbbasiNoch keine Bewertungen

- CA3140Dokument20 SeitenCA3140Brzata PticaNoch keine Bewertungen

- Quasi-Resonant Topology Primary Switching Regulators: STR-W6756Dokument8 SeitenQuasi-Resonant Topology Primary Switching Regulators: STR-W6756perro sNoch keine Bewertungen

- Ca3140, Ca3140A: 4.5Mhz, Bimos Operational Amplifier With Mosfet Input/Bipolar Output FeaturesDokument19 SeitenCa3140, Ca3140A: 4.5Mhz, Bimos Operational Amplifier With Mosfet Input/Bipolar Output FeaturesRicardo Teixeira de AbreuNoch keine Bewertungen

- High Voltage Resonant Controller: DescriptionDokument17 SeitenHigh Voltage Resonant Controller: DescriptionJesus SilvaNoch keine Bewertungen

- L4972ADokument23 SeitenL4972ARICHIHOTS2Noch keine Bewertungen

- 3000W Single Output Power Supply: SeriesDokument7 Seiten3000W Single Output Power Supply: SeriesAlexander PekarovskiyNoch keine Bewertungen

- Ca3140, Ca3140A: 4.5Mhz, Bimos Operational Amplifier With Mosfet Input/Bipolar Output FeaturesDokument22 SeitenCa3140, Ca3140A: 4.5Mhz, Bimos Operational Amplifier With Mosfet Input/Bipolar Output FeaturesfcabreraibanezNoch keine Bewertungen

- A4989 DatasheetDokument17 SeitenA4989 DatasheetGopalkrishnan Nadar100% (1)

- Tle6220gp DatasheetDokument18 SeitenTle6220gp Datasheetmaelo99999Noch keine Bewertungen

- STR W6753 DatasheetDokument8 SeitenSTR W6753 DatasheetjgerabmNoch keine Bewertungen

- Anp013 1509Dokument9 SeitenAnp013 1509camorra1923Noch keine Bewertungen

- A 2918 SW Data SheetDokument8 SeitenA 2918 SW Data SheetGustavo LunaNoch keine Bewertungen

- Tps 40057 PWPDokument33 SeitenTps 40057 PWPcatsoithahuong84Noch keine Bewertungen

- Ic 3843Dokument4 SeitenIc 3843nishatiwari82Noch keine Bewertungen

- High Efficiency Low-Side N-Channel Controller For Switching RegulatorsDokument33 SeitenHigh Efficiency Low-Side N-Channel Controller For Switching Regulatorssoft4gsmNoch keine Bewertungen

- LMD 18200Dokument14 SeitenLMD 18200Itzamary Romero SosaNoch keine Bewertungen

- 60 W-Universal Input/90 W-230 Vac Input PWM Switching RegulatorsDokument14 Seiten60 W-Universal Input/90 W-230 Vac Input PWM Switching RegulatorsIBSDIALLO0% (1)

- MC 1496Dokument12 SeitenMC 1496Alejandro GarciaNoch keine Bewertungen

- Tle 6220 PDFDokument17 SeitenTle 6220 PDFFabio JuniorNoch keine Bewertungen

- 1/2/3-Phase Quick-PWM IMVP-6.5 VID Controllers: General Description FeaturesDokument39 Seiten1/2/3-Phase Quick-PWM IMVP-6.5 VID Controllers: General Description FeaturesSunil SuwarnkarNoch keine Bewertungen

- 161 20551 0 FS7M0880Dokument16 Seiten161 20551 0 FS7M0880Edwin Vitovis TorresNoch keine Bewertungen

- MITSUBISHI PS21245-E 4th Gen IGBT Inverter ModuleDokument9 SeitenMITSUBISHI PS21245-E 4th Gen IGBT Inverter ModulepukymottoNoch keine Bewertungen

- Ca3130, Ca3130aDokument17 SeitenCa3130, Ca3130aproctepNoch keine Bewertungen

- Off-Line Quasi-Resonant Switching Regulators: STR-X6769Dokument9 SeitenOff-Line Quasi-Resonant Switching Regulators: STR-X6769Alfredo Valencia RodriguezNoch keine Bewertungen

- A3979 DatasheetDokument15 SeitenA3979 DatasheetИван КосмонавтNoch keine Bewertungen

- Iramx 16 Up 60 ADokument17 SeitenIramx 16 Up 60 AJandfor Tansfg ErrottNoch keine Bewertungen

- En CD00000085Dokument16 SeitenEn CD00000085amijoski6051Noch keine Bewertungen

- 5V-0.5A Very Low Drop Regulator With Reset: DescriptionDokument6 Seiten5V-0.5A Very Low Drop Regulator With Reset: DescriptionDan EsentherNoch keine Bewertungen

- Tb62206Fg: Bicd PWM 2 Phase Bipolar Stepping Motor DriverDokument28 SeitenTb62206Fg: Bicd PWM 2 Phase Bipolar Stepping Motor DriverLuis Alejandro Blanco CalvoNoch keine Bewertungen

- A3953 Datasheet PDFDokument12 SeitenA3953 Datasheet PDFfelres87Noch keine Bewertungen

- Fully Integrated H-Bridge Motor Driver: VNH3SP30Dokument26 SeitenFully Integrated H-Bridge Motor Driver: VNH3SP30Dan EsentherNoch keine Bewertungen

- Quasi-Resonant Topology Primary Switching Regulators: STR-W6735Dokument13 SeitenQuasi-Resonant Topology Primary Switching Regulators: STR-W6735perro sNoch keine Bewertungen

- Two-Phase Stepper Motor Driver: DescriptionDokument19 SeitenTwo-Phase Stepper Motor Driver: DescriptionDan EsentherNoch keine Bewertungen

- L6208D To L6208PDDokument16 SeitenL6208D To L6208PDwtn2013Noch keine Bewertungen

- Transition-Mode PFC Controller: 1 FeaturesDokument17 SeitenTransition-Mode PFC Controller: 1 Featuresadriancho66Noch keine Bewertungen

- Sla7024 26 29mDokument12 SeitenSla7024 26 29mbashtavNoch keine Bewertungen

- IRAMX16UP60ADokument18 SeitenIRAMX16UP60Atheylor1990Noch keine Bewertungen

- Green Mode PWM Controller Ap384XgDokument13 SeitenGreen Mode PWM Controller Ap384XgbaphometabaddonNoch keine Bewertungen

- 000 1 Ca3109Dokument20 Seiten000 1 Ca3109moongaboongaNoch keine Bewertungen

- Fan 7314Dokument14 SeitenFan 7314Kamal NonekNoch keine Bewertungen

- VNH2SP30-E: Automotive Fully Integrated H-Bridge Motor DriverDokument26 SeitenVNH2SP30-E: Automotive Fully Integrated H-Bridge Motor DriverIan LuksNoch keine Bewertungen

- Ap5002 - PWM Control 2a Step-Down ConverterDokument10 SeitenAp5002 - PWM Control 2a Step-Down ConverterAmador Garcia IIINoch keine Bewertungen

- TC120 PWM/PFM Step-Down Combination Regulator/Controller: Features General DescriptionDokument12 SeitenTC120 PWM/PFM Step-Down Combination Regulator/Controller: Features General DescriptionRijal SaifurNoch keine Bewertungen

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsVon EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsBewertung: 3.5 von 5 Sternen3.5/5 (6)

- Roboticsv2 2Dokument360 SeitenRoboticsv2 2Angly1959Noch keine Bewertungen

- Roboticsv2 2Dokument360 SeitenRoboticsv2 2Angly1959Noch keine Bewertungen

- PIC16 (L) F1938/9 Data SheetDokument485 SeitenPIC16 (L) F1938/9 Data SheetAngly1959Noch keine Bewertungen

- PIC16 (L) F1938/9 Data SheetDokument485 SeitenPIC16 (L) F1938/9 Data SheetAngly1959Noch keine Bewertungen

- Probleme Rezolvate QMDokument3 SeitenProbleme Rezolvate QMStefan IstratescuNoch keine Bewertungen

- Requirement-Supply of Line Materials To TUMKUR Circle For FY 11-12 Till 24.02.2012Dokument27 SeitenRequirement-Supply of Line Materials To TUMKUR Circle For FY 11-12 Till 24.02.2012Bescom GmprocurementNoch keine Bewertungen

- Phocos ManualDokument53 SeitenPhocos ManualTafadzwa Kudzie BootrosNoch keine Bewertungen

- 11 000 Measuring Equipment SummaryDokument38 Seiten11 000 Measuring Equipment SummaryAdrian GarciaNoch keine Bewertungen

- Lighting Lighting: Essential Smartbright Led Downlight G2Dokument3 SeitenLighting Lighting: Essential Smartbright Led Downlight G2richard sinagaNoch keine Bewertungen

- Liebert GXT MT+LB 6kva Ups User Manual: Single Phase Online UPSDokument31 SeitenLiebert GXT MT+LB 6kva Ups User Manual: Single Phase Online UPSVedant DesaiNoch keine Bewertungen

- MK RepairsDokument141 SeitenMK RepairsAnonymous SJyuwb0DNoch keine Bewertungen

- 2nd Assignment For First TermDokument10 Seiten2nd Assignment For First TermRaj ChauhanNoch keine Bewertungen

- Physics For Scientists and Engineers, 6e: Chapter 28 - Direct Current CircuitsDokument29 SeitenPhysics For Scientists and Engineers, 6e: Chapter 28 - Direct Current CircuitsFaiza AliNoch keine Bewertungen

- CD4016Dokument8 SeitenCD4016api-3708997100% (1)

- Utc Ta7343apDokument5 SeitenUtc Ta7343apClaudiuMaxmiucNoch keine Bewertungen

- Thesis On Ohmic HeatingDokument171 SeitenThesis On Ohmic HeatingDr-Paras PorwalNoch keine Bewertungen

- Fundamentals of Electromagnetic Wave PropagationDokument26 SeitenFundamentals of Electromagnetic Wave PropagationUMEESSNoch keine Bewertungen

- Portable X Ray Machine SpecificationDokument3 SeitenPortable X Ray Machine Specificationwalter sandoNoch keine Bewertungen

- ABB Motors and Technical Data Sheet - DOL Generators: No. Data Unit RemarksDokument4 SeitenABB Motors and Technical Data Sheet - DOL Generators: No. Data Unit RemarksDayner Roque CaballeroNoch keine Bewertungen

- How To Interface An LED With 8051 MicrocontrollerDokument7 SeitenHow To Interface An LED With 8051 MicrocontrollerPramillaNoch keine Bewertungen

- MCQ in Est by S Cuervo of ExcelDokument10 SeitenMCQ in Est by S Cuervo of ExcelCatherine TaubNoch keine Bewertungen

- Isc 2SD998: Silicon NPN Power TransistorDokument2 SeitenIsc 2SD998: Silicon NPN Power TransistorDjoNoch keine Bewertungen

- Fundamentals of Electric Machines A Primer With MatlabDokument411 SeitenFundamentals of Electric Machines A Primer With MatlabKONANNoch keine Bewertungen

- NJYW1 Floatless Relay Technical OverviewDokument2 SeitenNJYW1 Floatless Relay Technical OverviewPrince NeroNoch keine Bewertungen

- 11 VSD& Harmonics PDFDokument100 Seiten11 VSD& Harmonics PDFsiruslara6491Noch keine Bewertungen

- HP236ADokument49 SeitenHP236Agandalfg8Noch keine Bewertungen

- Stepper Motor Technical Note: Microstepping Myths and RealitiesDokument4 SeitenStepper Motor Technical Note: Microstepping Myths and Realitiesmixarim100% (1)

- Wave Optics Animation - PpsDokument20 SeitenWave Optics Animation - Ppsaleena'Noch keine Bewertungen

- Features: Slls115E - October 1980 - Revised October 2007Dokument27 SeitenFeatures: Slls115E - October 1980 - Revised October 2007Iván GissiNoch keine Bewertungen

- Collins 20170425 SolidStateBatteryDokument28 SeitenCollins 20170425 SolidStateBatteryJames RowsellNoch keine Bewertungen

- Ba Msf220vu e PDFDokument8 SeitenBa Msf220vu e PDFSyariefNoch keine Bewertungen

- EVTV Pierburg CWA-50 Coolant Pump Specs and TestingDokument3 SeitenEVTV Pierburg CWA-50 Coolant Pump Specs and TestingHarold TheHelicopter100% (4)

- Sony VX550 PDFDokument59 SeitenSony VX550 PDFcrm102bNoch keine Bewertungen