Beruflich Dokumente

Kultur Dokumente

Blind Fasteners

Hochgeladen von

aiyubi2Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Blind Fasteners

Hochgeladen von

aiyubi2Copyright:

Verfügbare Formate

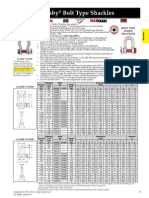

PRODUCT

BLIND FASTENERS

EDITION

2002

PRODUCT#

FASTENING SYSTEMS

COMMENTS

Fairchild Fasteners offers a variety of Blind Fasteners

LOCATION

www.fairchildfasteners.com

B lind Fa s t e ne r s B lind Fa s t e ne r s

For more than 50 years,Fairchild Fastenershas set industry standards in the

design and manufacture of precision fasteners,fastening systems and support

tooling. Offering a variety of blind fasteners,Fairchild Fasteners serves the

needs of aerospace,industrial,and automotive markets with proven excellence

and innovation.

Today,Fairchild Fasteners meets the challenges of an expanded arena.

Our totally integrated company provides global industry support through

worldwide sales and services.

The Fairchild philosophy helps explain our ongoing leadership. We are

committed to constant improvement of every product,system and service.

To maintain our cutting edge engineering and manufacturing expertise,

we select teams of highly skilled personnel who use the latest computer

applications to provide total,custom solutions. Our commitment is broad yet

highly specific,with experienced specialists assigned to each product line.

Our success in achieving and maintaining quality is well documented.

Fairchild Fasteners has distinguished itself by achieving ISO 9001/AS9000

Registration,FAA Certifications and NADCAP Third Party Accreditation,in

addition to an extensive set of customer approvals. Since 1991,Fairchild

Fasteners has been dedicated to Continuous Improvement programs. At each

facility,Lean Manufacturing and Service Workshops have become a way of life.

For high technology fastener solutions,look to Fairchild Fasteners.

Our dedication to excellence is the template for success.

The Accu-LokBlind Fastening

System,which consists of Accu-Lok I,

Accu-Lok II and Accu-Lok IIa,

is designed specifically for use in

composite structures where access

is limited to one side of the structure.

It combines high joint preload with

a large diameter footprint on the

blind side. The large footprint enables

distribution of the joint preload over

a larger area,thus virtually eliminating

the possibility of delaminating the

composite structure.

The Accu-Lok family includes the

Accu-Lok II and Accu-Lok IIa,which

are available with the Dryv-Cap

non-threaded installation system.

The Dryv-Cap is essentially a disposable

driver,which positively engages the

driving recess in the fastener and is

captivated to each fastener. The

Dryv-Cap eliminates the wear

associated with conventional drivers.

The interface between the Dryv-Cap

and the installation tool is a standard

hex. Only two installation nosepieces

are required for installation of all

fastener sizes. The Dryv-Cap positively

engages the fastener and installation

tooling,avoiding rotation of the

fastener during installation. This

eliminates marring of the parent

material surface.

The Accu-Lok family of blind fasteners

is easily installed using common,widely

available tooling. All of the necessary

toolsare specified in the detail catalogs

and individual customer drawings.

Fairchild Fasteners Assembly Tool

Systems offers a wide selection of both

hand and power installation tools.

A

c

c

u

-

L

o

k

The Accu-Lok Fastening System is

designed to be galvanically compati-

ble with carbon fiber reinforced

composite structures. The main nut

body is most commonly made from

6Al-4V Titanium. Alternate materials

are available upon request. The

sleeve component is made from 300

series Corrosion Resistant Steel. Each

assembly also contains a small Acetal

insert. Various finishes are available

for these fasteners.

Both unified and metric products

are available. Accu-Lok fasteners are

covered by NASstandards.

Typical Accu-Lok applications include

fixed and rotary-wing,commercial

and military aircraft.

1

Pat ent pendi ng on Dr yv- Cap.

No Accu- Lok sal es per mi t t ed i nt o Spai n unt i l 2004.

2

V

i

s

u

-

L

o

k

The Visu-Loksystem is a blind

fastener that provides high shear,

tensile,fatigue,and self-locking

capabilities. Unlike conventional nut

and bolt combinations,the Visu-Lok

blind bolt can be completely installed,

and fully verified,from one side of

the structure. When installed,the

Visu-Lok forms a solid,blind side

head,with minimum preload levels

guaranteed. Manufactured in 1/16

increments,Visu-Loks have an

operational grip range of .062.

The Visu-Lok family includes the

Visu-Lok II, which utilizes a disposable

drive nut. This drive nut allows

for the use of only two installation

nosepieces for installation of all

fastener sizes.

A tapered version of the Visu-Lok

is ideally suited for extreme or severe

fatigue applications. It combines

one-sided installation with the

advantages of tapered,interference

fit. The tapered Visu-Lok also offers

the highest possible fatigue life and

uniform high preload values,as well

as positive self-locking characteristics.

Since it distributes the overall load

more evenly,fewer fasteners may be

required. Tapered Visu-Loks are also

used for aircraft modifications or

repairs.

The Visu-Lok system uses common

installation toolsat standard air

pressure levels. Fairchild Fasteners

Assembly Tool Systems offers a wide

selection of both hand and power

installation tools.

Visu-Lok fasteners are available in

a wide range of materials, including

Aluminum,Alloy Steel,H-11,Corrosion

Resistant Steels,Inconel Nickel-

Chromium Alloy,and Titanium.

Visu-Loks are produced in flush and

protruding head styles for shear and

tension applications. Various finishes

are available.

Other variationsof the Visu-Loks

are oversize and close-tolerance

(interference fit) configurations.

Both unified and metric products are

available. Visu-Lok blind fasteners are

covered by NASstandards.

Typical Visu-Lok applications

include fixed and rotary-wing,

commercial and military aircraft.

The EM (electrical-mechanical)

Studis a blind fastening system

designed for grounding terminal pur-

poses and lightweight structural

attachments. The fastener is placed

into a pre-drilled,loose tolerance hole

from one side of the work. Standard

pull-toolsare used to exert an axial

load until the stem separates. Once

installed,the grounding stud is imme-

diately ready for the attachment of

one or more grounding straps. The

grounding stud makes full contact

with and expands the cylindrical

hole surface to achieve a positive

electrical contact and firm mechanical

attachment.

Compared with the traditional

method of providing grounding

terminals for electrical equipment,

this system offers a significantly lower

total installed cost due to the ease

of installation and reduction in the

number of components.

A variationof the EM Stud includes a

double-ended configuration featuring

a threaded shank on both sides of the

work surface. It has all of the advan-

tages of the standard EM Stud with

the additional benefit of being able to

provide a grounding terminal on both

sides of the structure,eliminating up

to 50% of the weight,fastener cost,

and labor. Oversize replacements are

also available.

Installation of the EM Stud is simple,

convenient,and fast. Rivet type pull-

toolsthat seat the stud and expand

the sleeve are available from Fairchild

Fasteners Assembly Tool Systems.

EM Studs are available in several

material combinations. Typical stud

materials are Alloy Steel and A286

Corrosion Resistant Steel. Sleeve

materials include Aluminum and 300

series Corrosion Resistant Steel.

Both unified and metric products

are available. EM Studs are covered

by various customer standards.

Typical EM Stud applicationsinclude

wire bundle attachment and terminal

grounding.

E

M

S

t

u

d

3

Fairchild Fasteners is a total

solutions provider for fasteners and

installation tools to the aerospace,

industrial and automotive markets.

Our Assembly Tool Systems (ATS)

Division has over forty years of experi-

ence in providing answers for all of

our customersassembly needs.Tools

are available for installation of our

complete line of blind fasteners.

ATS also offers Design & Engineering

Services,Tool Lease Programs,

Tool Rental Programs,Service and

Maintenance Programs,and

Calibration Services. In addition,ATS

is a full line Atlas CopcoDistributor.

For installing one part or thousands,

ATS has the right tool for any

application.

Fairchild Fasteners / Assembly Tool Systems

801 S.Placentia Avenue Fullerton,CA 92831 U.S.A.

714/278-8908 Fax:714/871-4821

4

T

o

o

l

i

n

g

S

u

p

p

o

r

t

2002 Fai rchi l d Fast ener s / BFB1.0 5M 7/ 02

Fa i r chi l d Fa st ener s

South Bay Operations

3000West LomitaBoulevard

Torrance,California 90505

U.S.A.

310/784-2600

www.fairchildfasteners.com

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Repair Manual JSK 38Dokument38 SeitenRepair Manual JSK 38aiyubi2Noch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Fifthwheel - JOST JSK 38CDokument2 SeitenFifthwheel - JOST JSK 38Caiyubi2100% (2)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Crosby Mckissick Sheaves CatalogDokument29 SeitenCrosby Mckissick Sheaves Catalogaiyubi2Noch keine Bewertungen

- Vendor Qualification ProcessDokument11 SeitenVendor Qualification ProcessGautam Kumar100% (4)

- Typical Project Quality Plan & ITP CPCDokument14 SeitenTypical Project Quality Plan & ITP CPCPadmanabhan Venkatesh100% (1)

- SN 200Dokument100 SeitenSN 200T Mathew Tholoor100% (2)

- CROSBY Master Link & Shackles - MetricDokument2 SeitenCROSBY Master Link & Shackles - Metricaiyubi2Noch keine Bewertungen

- CROSBY Master Link & Shackles - MetricDokument2 SeitenCROSBY Master Link & Shackles - Metricaiyubi2Noch keine Bewertungen

- Total Quality Management Six SigmaDokument304 SeitenTotal Quality Management Six Sigmajuancgr77Noch keine Bewertungen

- Acf Fastener HandbookDokument84 SeitenAcf Fastener Handbookninjanear2012100% (2)

- MS Projects Day 2 FinalDokument183 SeitenMS Projects Day 2 FinalDushan SenarathneNoch keine Bewertungen

- ISO 3834 Check ListDokument2 SeitenISO 3834 Check Listsheikmoin100% (1)

- Coel Catalogue 2006 1Dokument58 SeitenCoel Catalogue 2006 1Danilo MontesanoNoch keine Bewertungen

- BSBMGT608 Assessment InstructionDokument32 SeitenBSBMGT608 Assessment Instructionsarah chepwogenNoch keine Bewertungen

- Tube ToolsDokument120 SeitenTube ToolsMr. S.L. Advani100% (1)

- PAS 99 - Integrated Management SystemDokument24 SeitenPAS 99 - Integrated Management SystemluvongaNoch keine Bewertungen

- Kukmc 0376 UsDokument12 SeitenKukmc 0376 Usaiyubi2Noch keine Bewertungen

- Kukmc 0378 UsDokument2 SeitenKukmc 0378 Usaiyubi2Noch keine Bewertungen

- Kukmc 0377 UsDokument2 SeitenKukmc 0377 Usaiyubi2Noch keine Bewertungen

- C-Line - Front & Back CoversDokument4 SeitenC-Line - Front & Back Coversaiyubi2Noch keine Bewertungen

- 200 60 IndustrialDokument8 Seiten200 60 Industrialaiyubi2Noch keine Bewertungen

- Kukmc 0328 UsDokument8 SeitenKukmc 0328 Usaiyubi2Noch keine Bewertungen

- Kukmc 0375 UsDokument4 SeitenKukmc 0375 Usaiyubi2Noch keine Bewertungen

- Kukmc 0328 UsDokument8 SeitenKukmc 0328 Usaiyubi2Noch keine Bewertungen

- MS100-00 (M-MA Series Meter Specs)Dokument6 SeitenMS100-00 (M-MA Series Meter Specs)aiyubi2Noch keine Bewertungen

- 400-20 (Meter Manual)Dokument28 Seiten400-20 (Meter Manual)edwinramonNoch keine Bewertungen

- Kukmc 0258 UsDokument2 SeitenKukmc 0258 Usaiyubi2Noch keine Bewertungen

- Hose Clamps and Ferrules for Assembly of Different FittingsDokument6 SeitenHose Clamps and Ferrules for Assembly of Different Fittingsaiyubi2Noch keine Bewertungen

- Heavy duty fifth wheel couplings JSK 38 C-1-2Dokument2 SeitenHeavy duty fifth wheel couplings JSK 38 C-1-2aiyubi2Noch keine Bewertungen

- Crosby G-2130Dokument1 SeiteCrosby G-2130AekJayNoch keine Bewertungen

- DRIV-LOK Press Fit FastenersDokument28 SeitenDRIV-LOK Press Fit Fastenersaiyubi2Noch keine Bewertungen

- Wire Rope ThimblesDokument1 SeiteWire Rope Thimblesaiyubi2Noch keine Bewertungen

- DODGE Torque-Arm Speed Reducer Feature BenefitDokument4 SeitenDODGE Torque-Arm Speed Reducer Feature Benefitaiyubi2Noch keine Bewertungen

- A-344, A-347 Master LinkDokument1 SeiteA-344, A-347 Master LinkAekJayNoch keine Bewertungen

- A-344 & A347 Welded Master Link - ImperialDokument1 SeiteA-344 & A347 Welded Master Link - Imperialaiyubi2Noch keine Bewertungen

- Tranz Couplings CatalogDokument4 SeitenTranz Couplings Catalogaiyubi2Noch keine Bewertungen

- Universal JointsDokument10 SeitenUniversal JointsshashanksekharNoch keine Bewertungen

- APEX U-Joint CatalogDokument28 SeitenAPEX U-Joint Catalogaiyubi2Noch keine Bewertungen

- Iso 9001 - 2015 ALISONDokument5 SeitenIso 9001 - 2015 ALISONAymane LAKHALNoch keine Bewertungen

- ISO 9001:2015 Quality Management System ExplainedDokument3 SeitenISO 9001:2015 Quality Management System ExplainedShailesh GuptaNoch keine Bewertungen

- Lancier Hydraulik Katalog 2011 GBDokument44 SeitenLancier Hydraulik Katalog 2011 GBChup AlaNoch keine Bewertungen

- Soal Ujian ISO 9001Dokument20 SeitenSoal Ujian ISO 9001Budi SusantoNoch keine Bewertungen

- ISO RegistrationDokument4 SeitenISO RegistrationSweta MorNoch keine Bewertungen

- Garrison Lecture Chapter 2 - Cost ConceptsDokument80 SeitenGarrison Lecture Chapter 2 - Cost Conceptsnahid mushtaqNoch keine Bewertungen

- Cat DPCV 07 15 Wafer Type Check ValveDokument24 SeitenCat DPCV 07 15 Wafer Type Check Valvemoorthymech1979100% (1)

- Quality Cost and TQMDokument7 SeitenQuality Cost and TQMAnand MauryaNoch keine Bewertungen

- Iso Program Guide 2006Dokument20 SeitenIso Program Guide 2006Adriana Dobrila100% (1)

- BOKE LED Driver Catalog 2022 Q3 ENDokument40 SeitenBOKE LED Driver Catalog 2022 Q3 ENIvan Rudolf De FretesNoch keine Bewertungen

- Kinh Do of ReportDokument23 SeitenKinh Do of ReportKhoi Duy Anh NguyenNoch keine Bewertungen

- 1 - What Is ASES, 2 - Explanation of The QuestionnaireDokument50 Seiten1 - What Is ASES, 2 - Explanation of The QuestionnaireCarlos AguilarNoch keine Bewertungen

- Appolo 2012Dokument70 SeitenAppolo 2012hhaiderNoch keine Bewertungen

- ©the Mcgraw-Hill Companies, Inc., 2004Dokument27 Seiten©the Mcgraw-Hill Companies, Inc., 2004kate sultanNoch keine Bewertungen

- Globalproductmbpdfresourceseaflex PDFDokument48 SeitenGlobalproductmbpdfresourceseaflex PDFTee Shi FengNoch keine Bewertungen

- Iso 12944Dokument4 SeitenIso 12944Kiran Kumar Yanmangandla100% (2)

- Thesesaastu 2019 261Dokument95 SeitenThesesaastu 2019 261abraha gebruNoch keine Bewertungen

- Ghana Trade & Investment Gateway ProjectDokument138 SeitenGhana Trade & Investment Gateway ProjecttogolonginusNoch keine Bewertungen

- Curriculum Vitae: Ranjan BesekarDokument4 SeitenCurriculum Vitae: Ranjan BesekarIqbalAsifNoch keine Bewertungen

- ATAD Brochure August 10 2018 PDFDokument127 SeitenATAD Brochure August 10 2018 PDFHai Tran0% (1)

- CV - HR OfficerDokument3 SeitenCV - HR OfficerswathyedayathNoch keine Bewertungen