Beruflich Dokumente

Kultur Dokumente

T Z40e

Hochgeladen von

arness22Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

T Z40e

Hochgeladen von

arness22Copyright:

Verfügbare Formate

Wrtsil Italy, Service

Subject Engine type Ref. Date Document No. DLC Issue Page

High pressure fuel pipe ZA40S WIT-S 18.02.2003 T-ZA40S.0014.GB 162 03 1/5

Wrtsil Italia SpA Bagnoli della Rosandra, 334 Telephone : +39 040 319 5000

Service 34018 San Dorligo Della Valle (TS) ITALY Fax : +39 040 319 5647

qb`ekf`^i

_riibqfk

ZAS-14.3

High-pressure Fuel Pipe

1 Introduction

This Technical Bulletin supersedes previous Service Bulletin ZAS-14.2 and its purpose is to declare

superseded previous high-pressure pipe Type 808.

It still informs you about different types of high-pressure fuel pipe together with tightening instructions and

guidelines to be observed when changing the type of high-pressure fuel pipe on a cylinder unit.

2 Superseded Fuel Pipe Types

2.1 Original Type 714

The following Type 714 high-pressure pipe was originally introduced on the first ZA40S engines in 1986.

Its main features were: flat seal between pressure pipe, fuel stud and fuel pump cover as well as a

corrugated protection tube with metal gauze jacketed around the high pressure pipe.

It has been superseded because of possible friction between corrugated protection tube and pipe. Type

714 is not interchangeable with Type 723.

2.2 Intermediate Type 808

The first type of high-pressure fuel pipe introduced with conical seal was Type 808 in 1995. It also

presents a solid protection tube surrounding the pipe.

Type 808 type has already a double shielded high-pressure fuel pipe and it has been declared

superseded because of a tendency for cavitation at upper end. Type 808 is interchangeable with

Type 723 under the specific conditions of paragraph 4.2 of the present document.

2.3 Alternative Type 111

The retrofit package Type 111 was also introduced in 1995 in order to profit from the benefits of the new

Type 808 design, without changing the fuel pump cover.

It has been declared superseded because of the tendency for cavitation at the upper end might be

increased. Type 111 is not interchangeable with Type 723.

Wrtsil Italy, Service

Subject Engine type Ref. Date Document No. DLC Issue Page

High pressure fuel pipe ZA40S WIT-S 18.02.2003 T-ZA40S.0014.GB 162 03 2/5

Wrtsil Italia SpA Bagnoli della Rosandra, 334 Telephone : +39 040 319 5000

Service 34018 San Dorligo Della Valle (TS) ITALY Fax : +39 040 319 5647

qb`ekf`^i

_riibqfk

3 Present Fuel Pipe Type 723

Type 723 high-pressure fuel pipe is the present standard, introduced since February 1998.

Compared to Type 808, the Type 723 has:

(a) a shorter pipe, and

(b) an inner diameter of the pipe enlarged

(from 6 mm) to 7 mm in order to

minimise any tendency for cavitation at

the upper end.

4 Up-grading recommendations

4.1 Summary of present status

Type Status Remarks

714 Superseded Original type, no longer available

808 Superseded Intermediate type, no longer available

111 Superseded Alternative retrofit set for Type 714, no longer available

723 Present standard -

4.2 Conditional maintenance for existing superseded types

If the installed fuel pipe is a superseded type and doesn't show any leaking or cavitation problems,

it can be kept on the engine only if applying the following conditional maintenance follow-up.

Wrtsil Italy, Service

Subject Engine type Ref. Date Document No. DLC Issue Page

High pressure fuel pipe ZA40S WIT-S 18.02.2003 T-ZA40S.0014.GB 162 03 3/5

Wrtsil Italia SpA Bagnoli della Rosandra, 334 Telephone : +39 040 319 5000

Service 34018 San Dorligo Della Valle (TS) ITALY Fax : +39 040 319 5647

qb`ekf`^i

_riibqfk

4.2.1 Parameters to follow

In order to identify if a problem exist on the installed superseded fuel pipe, the fuel pressure should

be followed-up and within the limits, as per Technical Bulletin T-ZAS-22:

Fuel oil service pressure at engine inlet....................................................................................................8-10 bar

Dp across the engine fuel injection pump at engine stand-still - 550 kW.................................... 0.8 bar

- 600 kW.................................... 0,9 bar

- 660 kW.................................... 1,1 bar

- 720 kW.................................... 1,3 bar

In case of deviation from the above information, the hereunder conditional recommendations of

your installed fuel pipe should be performed.

4.2.2 Condition checking

for Type 714

Control of the flat sealing surfaces: check if leaking.

Control of inner pipe: check if crack are present on the internal pipe surface resulting from a

friction between corrugated protection tube and fuel pipe.

for Type 808

Control of inner pipe: check if traces of cavitation are present inside the pipe at the upper end.

for Type 111

Control of inner pipe: check if traces of cavitation are present inside the pipe at the upper end.

4.2.3 Corrective action

If one of the above mentioned problem is found, the installed high-pressure fuel pipe should be up-

graded for a 723-Type.

5 Tightening instructions

Please find in the following table an overview of the tightening torques suitable for the different types.

Type Fuel stud (1) Delivery valve bolts (2) High pressure pipe cap nut (3)

714 290 Nm 28 Nm 170 Nm

111 290 Nm 28 Nm 250 Nm

808 300 Nm 28 Nm 250 Nm

723 300 Nm 28 Nm New 130-150 Nm (*)

(*) Notice: The threads of the 723 cap nut should be lubricated with Molykote 1000 or Copper Slip.

All other threads in this table remain oil lubricated.

Wrtsil Italy, Service

Subject Engine type Ref. Date Document No. DLC Issue Page

High pressure fuel pipe ZA40S WIT-S 18.02.2003 T-ZA40S.0014.GB 162 03 4/5

Wrtsil Italia SpA Bagnoli della Rosandra, 334 Telephone : +39 040 319 5000

Service 34018 San Dorligo Della Valle (TS) ITALY Fax : +39 040 319 5647

qb`ekf`^i

_riibqfk

Important All joint faces should be dry and clean.

6 Conversion from Types 714, 111, and 808 to present Type 723

6.1 Fuel Pipe up-grading

6.1.1 Solution for 714-Type and 111-Type

The 714-Type and 111-Type can be upgraded as per following indications:

Replacement of fuel injection pipe, fuel stud with delivery valve and accessories ........... KS27245

Replacement of fuel pump cover ..................................................................................................... KS55008

Replacement of fuel pump cover o-ring ......................................................................................... KS55036

Replacement of back-up ring ............................................................................................................. KS55038

6.1.2 Solution for the 808-Type

The 808-Type can be upgraded as per following indications:

Replacement of fuel pressure pipe................................................................................................... KS27248

Replacement of existing compression spring ............................................................................... KS27270

Replacement of fuel pump cover ..................................................................................................... KS55270

Replacement of fuel pump cover o-ring ......................................................................................... KS55036

Replacement of back-up ring ............................................................................................................. KS55038

The pump cover can also be up-graded by machining as per Technical Bulletin T-ZAS-32.

Index to Figure

(1) Fuel stud

(2) Delivery valve bolts

(Allen screw M8x20)

(3) High pressure pipe cap nut

Wrtsil Italy, Service

Subject Engine type Ref. Date Document No. DLC Issue Page

High pressure fuel pipe ZA40S WIT-S 18.02.2003 T-ZA40S.0014.GB 162 03 5/5

Wrtsil Italia SpA Bagnoli della Rosandra, 334 Telephone : +39 040 319 5000

Service 34018 San Dorligo Della Valle (TS) ITALY Fax : +39 040 319 5647

qb`ekf`^i

_riibqfk

6.2 Tool up-grading

If the fuel pump is equipped with the conical seal pump cover, the adjusting device 9455.02 can

only be used if the following tool parts are added:

Additional flange and gasket ............................................................................................................... 9455.09

Measuring pin (174 mm instead of 143 mm)........................................................................... 9455.05.004

6.3 Spare part kits

Up-grading set of parts are presented in the Spare Part Notice P-ZAS-01, paragraphs 3.1 and 3.2.

7 Distribution

Wrtsil Italy Service Wrtsil Service Network Owners of engines concerned

8 Liability

NO LIABILITY WHETHER DIRECT, INDIRECT, SPECIAL INCIDENTAL OR CONSEQUENTIAL, IS

ASSUMED WITH RESPECT TO THE INFORMATION CONTAINED HEREIN. THIS PUBLICATION IS

CONFIDENTIAL AND INTENDED FOR INFORMATION PURPOSES ONLY.

9 Validity

This general instruction is valid until further notice.

Das könnte Ihnen auch gefallen

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualVon EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualNoch keine Bewertungen

- Upgrading of Camshaft: Improved Performance For Old WÄRTSILÄ Vasa 32 Diesel EnginesDokument2 SeitenUpgrading of Camshaft: Improved Performance For Old WÄRTSILÄ Vasa 32 Diesel EnginesAlexanderNoch keine Bewertungen

- Petrobras Marine Aprov Sulzer Z and ZaDokument12 SeitenPetrobras Marine Aprov Sulzer Z and ZaozakyusNoch keine Bewertungen

- P Za40Dokument2 SeitenP Za40arness22Noch keine Bewertungen

- EASA-TCDS-E.012 Rolls - Royce Plc. RB211 Trent 900 Series Engines-06-11122013 PDFDokument10 SeitenEASA-TCDS-E.012 Rolls - Royce Plc. RB211 Trent 900 Series Engines-06-11122013 PDFmakumba1972Noch keine Bewertungen

- I-W38B 0044 GB-01 Piston OverhaulDokument8 SeitenI-W38B 0044 GB-01 Piston OverhaulRonald Bienemi Paez100% (1)

- I-W38B 0044 GB-01 Piston Overhaul PDFDokument8 SeitenI-W38B 0044 GB-01 Piston Overhaul PDFRonald Bienemi PaezNoch keine Bewertungen

- Bell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDokument20 SeitenBell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDenis JimenezNoch keine Bewertungen

- Technical Information: JB Probjbkq Ob'loaDokument33 SeitenTechnical Information: JB Probjbkq Ob'loaJan Scharlett BechNoch keine Bewertungen

- Service Manual. YANGFAN 2058 BOW 1Dokument239 SeitenService Manual. YANGFAN 2058 BOW 1Oleksandr RakshaNoch keine Bewertungen

- Bulletin Technique Jaguar 3.4 38 1960Dokument63 SeitenBulletin Technique Jaguar 3.4 38 1960AlfajagNoch keine Bewertungen

- All Unified PL On SR RequestDokument87 SeitenAll Unified PL On SR RequestRohit Kumar SinghNoch keine Bewertungen

- Tid 0000108 01 PDFDokument1 SeiteTid 0000108 01 PDFjoaojitoNoch keine Bewertungen

- Cylinder Head Assembly: Pbosf'b IbqqboDokument3 SeitenCylinder Head Assembly: Pbosf'b IbqqboRonald Bienemi PaezNoch keine Bewertungen

- Brosur Pompa KSB Type CLTDokument20 SeitenBrosur Pompa KSB Type CLThenryhh111Noch keine Bewertungen

- Grundfos NKDokument121 SeitenGrundfos NKSam Wang Chern PengNoch keine Bewertungen

- Continental Ignition SystemsDokument60 SeitenContinental Ignition SystemsCristhian342Noch keine Bewertungen

- STD Line: Product DescriptionDokument16 SeitenSTD Line: Product DescriptionrpmNoch keine Bewertungen

- Pump Info ReferenceDokument42 SeitenPump Info ReferenceingenieroNoch keine Bewertungen

- Pompe Perkins 3340f261t PDFDokument2 SeitenPompe Perkins 3340f261t PDFKamel BelhibaNoch keine Bewertungen

- Imo ACGDokument16 SeitenImo ACGMiguel Ponce100% (1)

- Mejora Ventilador Dumper Caterpillar 730Dokument11 SeitenMejora Ventilador Dumper Caterpillar 730Edwin VacaNoch keine Bewertungen

- Comefri - TLZ-THLZ Fan Catalogue 04-08Dokument46 SeitenComefri - TLZ-THLZ Fan Catalogue 04-08João Guilherme Raimundo GarciaNoch keine Bewertungen

- en WHB Hatz W35 PDFDokument76 Seitenen WHB Hatz W35 PDFpricopdaniel100% (3)

- SEBF8164 - Specification For Liner Measurement and Salvage of 3500 Series EnginesDokument19 SeitenSEBF8164 - Specification For Liner Measurement and Salvage of 3500 Series Enginesyahmanmahira4Noch keine Bewertungen

- EASA-TCDS-E.012 Rolls - Royce Plc. RB211 Trent 900 Series Engines-06-11122013Dokument10 SeitenEASA-TCDS-E.012 Rolls - Royce Plc. RB211 Trent 900 Series Engines-06-11122013Smit PatelNoch keine Bewertungen

- T BlackbookDokument6 SeitenT BlackbookMORTEMNoch keine Bewertungen

- Holden VT 2000 Service TechlinesDokument177 SeitenHolden VT 2000 Service Techlinescosky071% (7)

- A002E1S1Dokument1 SeiteA002E1S1381tutNoch keine Bewertungen

- W38B New Bolts For Charge Air CoolerDokument3 SeitenW38B New Bolts For Charge Air CoolerD.PoljachihinNoch keine Bewertungen

- TC Kta50 Clearances Extended - CompressedDokument57 SeitenTC Kta50 Clearances Extended - CompressedSebastian Nicușor PărăoanuNoch keine Bewertungen

- Ih Navistar Dt466e 530e Service ManualDokument206 SeitenIh Navistar Dt466e 530e Service Manualaviseur100% (3)

- B3887BHF1Dokument4 SeitenB3887BHF1xianmingNoch keine Bewertungen

- Guia - Aplicacion - Frenos Jacobs - Detroit DieselDokument18 SeitenGuia - Aplicacion - Frenos Jacobs - Detroit DieselJorge Castillo HdzNoch keine Bewertungen

- Pump Polaris SeriesDokument47 SeitenPump Polaris SeriesDANIZACHNoch keine Bewertungen

- Service Manual. YANGFAN 2058 BOW 2Dokument238 SeitenService Manual. YANGFAN 2058 BOW 2Oleksandr RakshaNoch keine Bewertungen

- Grundfos MTS Screw Spindle PumpDokument68 SeitenGrundfos MTS Screw Spindle PumpAnonymous lswzqlo100% (1)

- Service Bulletin RL-7.2: 18.05.99 Technical Information To All Owners / Operators of Sulzer RL Diesel EnginesDokument20 SeitenService Bulletin RL-7.2: 18.05.99 Technical Information To All Owners / Operators of Sulzer RL Diesel Engineszbkt07100% (1)

- STT 330 ManuelDokument183 SeitenSTT 330 ManuelOzzyNoch keine Bewertungen

- en WHB Hatz W35Dokument76 Seitenen WHB Hatz W35Guido Giovanni Franco Rodriguez100% (1)

- Overhaul (Major) : Manual de Operación y MantenimientoDokument3 SeitenOverhaul (Major) : Manual de Operación y Mantenimientozona amrullohNoch keine Bewertungen

- 1ZVN460100-C Operation ManualDokument206 Seiten1ZVN460100-C Operation Manualmetha.d8070100% (1)

- CPGK S 00000207 - I0 - 201504 VTA28 G5 Frequency ConversionDokument3 SeitenCPGK S 00000207 - I0 - 201504 VTA28 G5 Frequency ConversionPieroNoch keine Bewertungen

- RSE 220-01-777 - Parts ListDokument106 SeitenRSE 220-01-777 - Parts ListCentrifugal Separator100% (1)

- H4800 Lubrication & Hydraulic Oil Tank Spare Part ListDokument71 SeitenH4800 Lubrication & Hydraulic Oil Tank Spare Part ListAndres Rivera100% (1)

- Abib 0107r2Dokument4 SeitenAbib 0107r2Miry Lu DNoch keine Bewertungen

- Fuel Leakage On LP Pipes W38B.0007.GB - 03Dokument2 SeitenFuel Leakage On LP Pipes W38B.0007.GB - 03Ronald Bienemi PaezNoch keine Bewertungen

- International Navistar Works KitDokument7 SeitenInternational Navistar Works Kithuskerchamps100% (1)

- Flygt PumpsDokument104 SeitenFlygt PumpsAchira Chanaka Peiris0% (1)

- AVL Schrick Camshaft Catalog 2011 EDokument34 SeitenAVL Schrick Camshaft Catalog 2011 EHernan SeilikovichNoch keine Bewertungen

- 0106-7 Section C-DDokument129 Seiten0106-7 Section C-DPartsGopher.comNoch keine Bewertungen

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualVon EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualBewertung: 2.5 von 5 Sternen2.5/5 (2)

- VW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Von EverandVW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)Noch keine Bewertungen

- High-Performance GM LS-Series Cylinder Head GuideVon EverandHigh-Performance GM LS-Series Cylinder Head GuideBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Von EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Bewertung: 5 von 5 Sternen5/5 (1)

- How to Build Max-Performance Chevy LT1/LT4 EnginesVon EverandHow to Build Max-Performance Chevy LT1/LT4 EnginesBewertung: 3 von 5 Sternen3/5 (1)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesVon EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNoch keine Bewertungen

- User ManualDokument44 SeitenUser Manualarness22Noch keine Bewertungen

- Fcp190N60 / Fcpf190N60: N-Channel Superfet Ii MosfetDokument10 SeitenFcp190N60 / Fcpf190N60: N-Channel Superfet Ii Mosfetarness22Noch keine Bewertungen

- TEKTRONIX THS3024 DatasheetDokument13 SeitenTEKTRONIX THS3024 Datasheetarness22Noch keine Bewertungen

- The Journey of A Signal - Inside Your OscilloscopeDokument1 SeiteThe Journey of A Signal - Inside Your Oscilloscopearness22Noch keine Bewertungen

- ASEE2000 AmplifiersDokument9 SeitenASEE2000 Amplifiersarness22Noch keine Bewertungen

- SC92F7352 7351 7350v0.1enDokument109 SeitenSC92F7352 7351 7350v0.1enarness22Noch keine Bewertungen

- 3W Ultra Low-EMI Anti-Clipping Stereo Class D Audio Power AmplifierDokument17 Seiten3W Ultra Low-EMI Anti-Clipping Stereo Class D Audio Power Amplifierarness22Noch keine Bewertungen

- 0302 - Test3 - Instruction ManualDokument2 Seiten0302 - Test3 - Instruction Manualarness22Noch keine Bewertungen

- MT1898EDokument1 SeiteMT1898Earness22Noch keine Bewertungen

- Designing For High Common-Mode Rejection in Balanced Audio InputsDokument7 SeitenDesigning For High Common-Mode Rejection in Balanced Audio Inputsarness22Noch keine Bewertungen

- Belts PDFDokument1 SeiteBelts PDFarness22Noch keine Bewertungen

- MY81SPK02M2: Bluetooth 3.0+EDR Stereo Audio ModuleDokument5 SeitenMY81SPK02M2: Bluetooth 3.0+EDR Stereo Audio Modulearness22Noch keine Bewertungen

- Engin'e Air Starters: Tditurbostarttwd™Dokument1 SeiteEngin'e Air Starters: Tditurbostarttwd™arness22Noch keine Bewertungen

- Turbdstart Two™: WarningDokument1 SeiteTurbdstart Two™: Warningarness22Noch keine Bewertungen

- Airst 4Dokument1 SeiteAirst 4arness22Noch keine Bewertungen

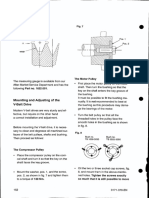

- Mounting of The V-Belt Drive: Kept Parallel With The Compres-Sor, Which Can Be Checked by Means ofDokument1 SeiteMounting of The V-Belt Drive: Kept Parallel With The Compres-Sor, Which Can Be Checked by Means ofarness22Noch keine Bewertungen

- Fig. 6 - Wear On Belt Grooves Fig. 7: Mounting and Adjusting of The V-Belt DriveDokument1 SeiteFig. 6 - Wear On Belt Grooves Fig. 7: Mounting and Adjusting of The V-Belt Drivearness22Noch keine Bewertungen

- Turbdstart TWD"™: Tech DevelopmentDokument1 SeiteTurbdstart TWD"™: Tech Developmentarness22Noch keine Bewertungen

- Tdi Turbdstart Two™: Tech Development IncDokument1 SeiteTdi Turbdstart Two™: Tech Development Incarness22Noch keine Bewertungen

- Magnetic Field in The Airgap of The Three-Phase Synchronous Generator Connected On RectifiersDokument4 SeitenMagnetic Field in The Airgap of The Three-Phase Synchronous Generator Connected On Rectifiersarness22Noch keine Bewertungen

- Build These Circuits That Can Amplify, Filter, Generate White Noise, Flash Lamps, Locate Hidden Metal - and Perhaps Even Detect Lies.Dokument2 SeitenBuild These Circuits That Can Amplify, Filter, Generate White Noise, Flash Lamps, Locate Hidden Metal - and Perhaps Even Detect Lies.arness22Noch keine Bewertungen

- 1SDC210004D0203 PDFDokument280 Seiten1SDC210004D0203 PDFarness22Noch keine Bewertungen

- Transistors TutorialDokument9 SeitenTransistors Tutorialarness22Noch keine Bewertungen

- Toro Groundsmaster 7200-7210 Service ManualDokument248 SeitenToro Groundsmaster 7200-7210 Service ManualPaulNoch keine Bewertungen

- Elequench: Fike Elevator Flameless Venting DeviceDokument18 SeitenElequench: Fike Elevator Flameless Venting DevicemcgteccadNoch keine Bewertungen

- Description Assembly Order No.: Static DataDokument30 SeitenDescription Assembly Order No.: Static DataMROstop.comNoch keine Bewertungen

- Workshop Manual Engine 47712292 enDokument139 SeitenWorkshop Manual Engine 47712292 enjames100% (1)

- SB As350-67.00.73eDokument31 SeitenSB As350-67.00.73eanon_847285754Noch keine Bewertungen

- Terrano 6.4 GX Parts Catalog 2018Dokument94 SeitenTerrano 6.4 GX Parts Catalog 2018Juli PNoch keine Bewertungen

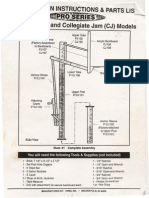

- Hoosier Hoops Installation Instructions and Parts ListDokument4 SeitenHoosier Hoops Installation Instructions and Parts ListPatrick BothwellNoch keine Bewertungen

- ChildCraft Crib'N'Double BedDokument14 SeitenChildCraft Crib'N'Double BedBren SchliepNoch keine Bewertungen

- Towers ErectionDokument60 SeitenTowers Erectionshoaib100% (1)

- Parts List: Band Knife Cutting MachineDokument16 SeitenParts List: Band Knife Cutting MachinekelvinNoch keine Bewertungen

- Radial GatesDokument26 SeitenRadial Gatesrs2operNoch keine Bewertungen

- TDS Dismantling JointsDokument5 SeitenTDS Dismantling JointsTanmoy DuttaNoch keine Bewertungen

- Adjust Valve GH8Dokument21 SeitenAdjust Valve GH8Ab Dila LueNoch keine Bewertungen

- Major Overhaul Procedure Chart (Using Remanufactured Components)Dokument2 SeitenMajor Overhaul Procedure Chart (Using Remanufactured Components)carlos gallego100% (1)

- Bolt Length Check ISO 4014Dokument30 SeitenBolt Length Check ISO 4014ValentinNoch keine Bewertungen

- Mesin RumputDokument32 SeitenMesin Rumputaep77Noch keine Bewertungen

- Forklift Checklist BROC EN 46491254Dokument32 SeitenForklift Checklist BROC EN 46491254ikperha jomafuvweNoch keine Bewertungen

- Ashok Leyland ReportDokument7 SeitenAshok Leyland ReportJay Surya100% (1)

- F 002 A0z 755 Spare PartsDokument17 SeitenF 002 A0z 755 Spare PartsGowtham100% (1)

- Cameron Riser Slip JointDokument118 SeitenCameron Riser Slip JointНикита ПромиснкийNoch keine Bewertungen

- B13T-2, B15T-2, B18T-2 Service ManualDokument451 SeitenB13T-2, B15T-2, B18T-2 Service Manualmarjan mircevski100% (1)

- Acoustic Pipe SupportsDokument6 SeitenAcoustic Pipe Supportsnamdq-1Noch keine Bewertungen

- Propeller Shaft and Axle PDFDokument76 SeitenPropeller Shaft and Axle PDFduongpn100% (1)

- Rear Shock Rebuild On A GL1200 GoldwingDokument28 SeitenRear Shock Rebuild On A GL1200 GoldwingValdir GomieroNoch keine Bewertungen

- MP513ENDokument132 SeitenMP513ENAnonymous H3I29yjNoch keine Bewertungen

- Husky 715 Diaphragm Pump Instructions PartslistDokument28 SeitenHusky 715 Diaphragm Pump Instructions Partslistgulam husseinNoch keine Bewertungen

- Flowmotion XL Flowmotion XL: Construction ManualDokument46 SeitenFlowmotion XL Flowmotion XL: Construction ManualMike and JimNoch keine Bewertungen

- Fresadora Makita 710w Pinza 6 8mm SarDokument104 SeitenFresadora Makita 710w Pinza 6 8mm SarAlvaro GordilloNoch keine Bewertungen

- Manual Motor k21 - k25Dokument48 SeitenManual Motor k21 - k25Emmanuel mejia100% (2)

- MR365MEGANE7Dokument97 SeitenMR365MEGANE7Natasa DurdaNoch keine Bewertungen