Beruflich Dokumente

Kultur Dokumente

QAP For Conical Strainer

Hochgeladen von

satishchidrewar0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

213 Ansichten2 SeitenThis quality control plan outlines the inspection and testing requirements for the fabrication of a conical vee wire type screen made of stainless steel 316L for a nuclear power plant project. It includes:

1) Raw material will undergo chemical, mechanical and dimensional testing to ensure it meets specifications. Welding procedures will also be qualified.

2) In process inspections include visual checks of fabrication and welding, as well as dimensional checks and DP testing of welds.

3) Final inspections consist of visual and dimensional checks to verify conformance to drawings, as well as documentation reviews to ensure compliance with purchase order requirements before dispatch.

4) Packing and shipping will also be visually inspected to quality control standards

Originalbeschreibung:

stage wise inspection for conical strainer

Originaltitel

QAP for Conical Strainer

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis quality control plan outlines the inspection and testing requirements for the fabrication of a conical vee wire type screen made of stainless steel 316L for a nuclear power plant project. It includes:

1) Raw material will undergo chemical, mechanical and dimensional testing to ensure it meets specifications. Welding procedures will also be qualified.

2) In process inspections include visual checks of fabrication and welding, as well as dimensional checks and DP testing of welds.

3) Final inspections consist of visual and dimensional checks to verify conformance to drawings, as well as documentation reviews to ensure compliance with purchase order requirements before dispatch.

4) Packing and shipping will also be visually inspected to quality control standards

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

213 Ansichten2 SeitenQAP For Conical Strainer

Hochgeladen von

satishchidrewarThis quality control plan outlines the inspection and testing requirements for the fabrication of a conical vee wire type screen made of stainless steel 316L for a nuclear power plant project. It includes:

1) Raw material will undergo chemical, mechanical and dimensional testing to ensure it meets specifications. Welding procedures will also be qualified.

2) In process inspections include visual checks of fabrication and welding, as well as dimensional checks and DP testing of welds.

3) Final inspections consist of visual and dimensional checks to verify conformance to drawings, as well as documentation reviews to ensure compliance with purchase order requirements before dispatch.

4) Packing and shipping will also be visually inspected to quality control standards

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

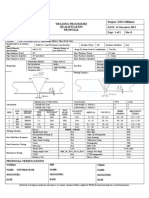

QUALITY CONTROL PLAN

Client : SULTANIA ENGINEERING SERVICE

Final Client : NUCLER POWER CORPORATION OF INDIA LIMITED

Name of the Project : TAPS 3& 4

Work order No. : JEW/SES/60 QC No.: QA/SES/ 13003 Rev : Page 1/2 Date: 20.06.14 ORDER No: SES/2011-2012/1078 DTD. 11.05.13

Drawing No. JE/SES/40713003 Description: CONICAL VEE WIRE TYPE SCREEN MOC SS 316L Amendment No. DTD.

Sr.

No.

Fabrication & Control Operation Operation Characteristic Class Type of Check

Quantum

of Check

Reference Document Acceptance Norm Record Format

Agency

Remarks

P W R H

A Preparation for Manufacturing

A1 WPS, PQR & WPQ Qualification of WPS, PQR & WPQ Major Visual 100% ASME Sec. IX ASME Sec. IX WPS, PQR & WPQ 3

B In Process Control

B1 Raw Material Checking & Testing

Visual, chemical & mechanical

Properties with comply with to

order

Major

FOR Plates: Chemical, tensile,

hardness, micro test in solution

annealed condition & IGC Practice

A as per ASTM A 262 no mill T.C

For pipes: Chemical, tensile,

hardness, micro test in solution

annealed condition & IGC Practice

A as per ASTM A 262 no mill T.C

For Screens: Chemical, tensile,

hardness, micro test in solution

annealed condition & IGC Practice

A as per ASTM A 262 check

testing of the round wires from

third party laboratories no mill T.C

Visual

100%

NPCIL/PLL

TDS & ASME Sec .II

Part A

NPCIL/PLL

TDS & ASME Sec .II

Part A

Internal Reports

& Test Certificate

3

B2 Manufacturing

Visual dimensional control &

identification of components

Major

Visual & Dimensional Checked

with measuring instruments

100% Approved Drawing Approved Drawing Inspection Report 3

B3 DP Test

DP test on accessible welds & Butt

weld ring ends preparation

Major

DP test on accessible welded &

butt weld ring ends preparation

100%

NPCIL/PLL

Approved procedure

NPCIL/PLL

Approved procedure

ASME, SEC III

DP Test Reports 3

Written By : Date:

A

g

e

n

c

y

P = ACTION PERFORM BY

A

g

e

n

c

y

1 = NPCIL or his Authorized Representative NPCL Remarks

A = APPROVED BY 2 = SES or his Authorized Representative Approved without Comment

Checked by &

Approved by

R = DOCUMENTS SUBMITTAL FOR REVIEW 3 = Jagtap Engineering Works Approved with Comment

H = HOLD POINT Not Approved

W= CONVOCATION FOR WITNESS

QUALITY CONTROL PLAN

Client : SULTANIA ENGINEERING SERVICE

Final Client : NUCLER POWER CORPORATION OF INDIA LIMITED

Name of the Project : TAPS 3& 4

Work order No. : JEW/SES/60 QC No.: QA/SES/ 13003 Rev : Page 2/2 Date: 20.06.14 ORDER No: SES/2011-2012/1078 DTD. 11.05.13

Drawing No. JE/SES/40713003 Description: CONICAL VEE WIRE TYPE SCREEN MOC SS 316L Amendment No. DTD.

Sr.

No.

Fabrication & Control Operation Operation Characteristic Class Type of Check

Quantum

of Check

Reference

Document

Acceptance Norm Record Format Agency

Remarks

P W R H

C. Final Inspection

C1 Visual Examination General Visual Aspect Major Visual 100%

NPCIL/PLL

Approved procedure

NPCIL/PLL

Approved procedure

Visual inspection Report 3 2,1

C2 Dimensional Inspection (AS-Built) Overall Dimension Major Measurement 100% Approved Drawing Approved Drawing

Dimensional Report & as

Built Drawing

3 2,1

C3

Examination of conformity with respect

to purchase order stipulations

Check compliance with clients

requirement as per PO

Major

Verification of clients

requirements & standards

100%

clients requirements &

standards

clients requirements &

standards

Certification 3 1,2

C4 Dispatch Clearance Inspection documents Major Verification of documents 100%

clients requirements &

standards

clients requirements &

standards

Inspection Release Note 3 1,2 (Hold)

D Packing & Forwarding

D1 Packing Packaging Major Visual 100%

NPCIL/PLL

Approved procedure

NPCIL/PLL

Approved procedure

Packing List

Written By : Date:

A

g

e

n

c

y

P = ACTION PERFORM BY

A

g

e

n

c

y

1 = NPCIL or his Authorized Representative NPCL Remarks

A = APPROVED BY 2 = SES or his Authorized Representative Approved without Comment

Checked by &

Approved by

R = DOCUMENTS SUBMITTAL FOR REVIEW 3 = Jagtap Engineering Works Approved with Comment

H = HOLD POINT Not Approved

W= CONVOCATION FOR WITNESS

General Note :

1 Co-related original material test certificate is acceptable. In absence of co-related original material test certificate, sample per lot (lot means, all material having same heat mark/material specification requirements) for chemical and physical test shall be drawn and witnessed by PLL. Chemical and

physical test shall be carried out in NPCIL approved labs only and PLL shall witness physical tests. PLL shall submit all material verification report as per material specification to NPCIL QS for checking / verification and clearance. NPCIL-QS Hold point is only review and clearance. Stamping of Raw

material and stamp transfer shall be done by PLL. NPCIL - QS however, reserves the right to physically verify such activities by surprise visits and by retesting the material at NPCILs cost. In case the test results are not in line with TC submitted/material specification the cost will have to be borne by

manufacturer/supplier.

2 Welding procedure shall be qualified as per Sec-IX, with additional requirement of Sec-III-NC/ND. (delta ferrite requirement in welding consumable and WPS qualification)

3 Pull out test of which to be conducted & value reported

4 Welding consumable and DP material shall be of NPCIL approved brand make.

5 Witness quantum for NPCIL, QA may be of 10% at random selection basis.

6 Raw material (Like, Vee wire, V wire screen cylinder, flange and Rod) shall be specified with full material specification in bill of material presently only grade is specified in bill of material.

Das könnte Ihnen auch gefallen

- Coke Crusher - Lubrication Pumps Run in TestDokument26 SeitenCoke Crusher - Lubrication Pumps Run in TestsayedNoch keine Bewertungen

- Cold Tap Coating Report 2Dokument1 SeiteCold Tap Coating Report 2Jamal BakhtNoch keine Bewertungen

- Hydro Test ReportDokument2 SeitenHydro Test ReportAnonymous a8oga83Noch keine Bewertungen

- MS For Fabrication of Above-Ground Storage TankDokument8 SeitenMS For Fabrication of Above-Ground Storage Tankdadz mingiNoch keine Bewertungen

- Test Report Portable Power SP (PW 768 2S)Dokument16 SeitenTest Report Portable Power SP (PW 768 2S)Pankaj PatilNoch keine Bewertungen

- Project:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportDokument4 SeitenProject:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportEngr Saeed AnwarNoch keine Bewertungen

- Circularity Inspection Report: Shell Course (LW) CW CWDokument14 SeitenCircularity Inspection Report: Shell Course (LW) CW CWaszlizaNoch keine Bewertungen

- 800D SeriesDokument3 Seiten800D Seriesvkeie0206Noch keine Bewertungen

- Chemical Resistance (LLDPE) PDFDokument24 SeitenChemical Resistance (LLDPE) PDFrubyshreeNoch keine Bewertungen

- Welder and Welder Operator Qualification Record FormDokument1 SeiteWelder and Welder Operator Qualification Record FormNanaba Nanayaw DwomohNoch keine Bewertungen

- Hydrostatic Test of Pandi WaterDokument7 SeitenHydrostatic Test of Pandi WaterOscar C. GabinayNoch keine Bewertungen

- Prosedur Penetran TestingDokument11 SeitenProsedur Penetran TestingIkhsan DalimuntheNoch keine Bewertungen

- BOLT Torquing ReportDokument4 SeitenBOLT Torquing ReportSumith Kumar S MNoch keine Bewertungen

- How To Calculate Hydrostatic Test Height in TanksDokument4 SeitenHow To Calculate Hydrostatic Test Height in TanksEric MagnayeNoch keine Bewertungen

- HDPE Butt Fusion Weld Inspection and Imaging PDFDokument19 SeitenHDPE Butt Fusion Weld Inspection and Imaging PDFelectroscribdNoch keine Bewertungen

- Ug PipingDokument1 SeiteUg PipingVinoth KumarNoch keine Bewertungen

- Welding Procedure Specification For GTAWDokument9 SeitenWelding Procedure Specification For GTAWraja reyhanNoch keine Bewertungen

- Lot Inspection Report For LPG New CylindersDokument3 SeitenLot Inspection Report For LPG New CylindersJagannath MajhiNoch keine Bewertungen

- Halliburton Multi Chem Batch Plant Project: Purchase Order/Contract NumberDokument7 SeitenHalliburton Multi Chem Batch Plant Project: Purchase Order/Contract NumberTahseen Ahmed100% (1)

- 13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)Dokument7 Seiten13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)SANDEEP100% (1)

- Burckhardt Compression (India) PVT - LTD.: 1.0 MaterialsDokument2 SeitenBurckhardt Compression (India) PVT - LTD.: 1.0 MaterialsYOGESHNoch keine Bewertungen

- Inspection and Test Plan FOR Filter Separator/CoalescerDokument6 SeitenInspection and Test Plan FOR Filter Separator/Coalescersumit kumarNoch keine Bewertungen

- Instrumentation and ControlsDokument2 SeitenInstrumentation and ControlsTrí NguyễnNoch keine Bewertungen

- Itp Electrical SwitchgearDokument4 SeitenItp Electrical SwitchgearpertmasterNoch keine Bewertungen

- DBB BNCPP B M v29 0015 Revb IfaDokument6 SeitenDBB BNCPP B M v29 0015 Revb IfaIzzadAfif1990Noch keine Bewertungen

- Daily Welding Report PLD LogoDokument1 SeiteDaily Welding Report PLD Logonike_y2kNoch keine Bewertungen

- WPS Sa 517Dokument2 SeitenWPS Sa 517DHANANNJAI SINGH -Noch keine Bewertungen

- INS T 004, Tol - OvalityDokument4 SeitenINS T 004, Tol - OvalityDeepakNoch keine Bewertungen

- Hydrotest QI304-sampleDokument3 SeitenHydrotest QI304-sampleHanuman Rao100% (1)

- Welding Procedure SpecificationDokument2 SeitenWelding Procedure SpecificationSAKDA MAPRADITKULNoch keine Bewertungen

- TopCoreBelco 101 FCDokument9 SeitenTopCoreBelco 101 FCCesar ArellanoNoch keine Bewertungen

- Made in Italy - EuropeDokument8 SeitenMade in Italy - EuropeenenickNoch keine Bewertungen

- Certificate of Origin Form F For China-Chile FTADokument2 SeitenCertificate of Origin Form F For China-Chile FTAinspectormetNoch keine Bewertungen

- Test Pack Clearance FormatDokument2 SeitenTest Pack Clearance FormatKarthikNoch keine Bewertungen

- Vessel Final BoxDokument14 SeitenVessel Final Boxmanoj thakkarNoch keine Bewertungen

- 1.13 Inspection & Test PlansDokument1 Seite1.13 Inspection & Test Plansabimanyubawono100% (2)

- Blasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateDokument3 SeitenBlasting and Painting Inspection Report: Achieved Profile Date of Report No: DFT Application DateLOPA THANDARNoch keine Bewertungen

- WPQP 6g Smaw API 5lx52 Od10inch 15.9mmDokument1 SeiteWPQP 6g Smaw API 5lx52 Od10inch 15.9mmufomskiNoch keine Bewertungen

- ITP For Piping SystemsDokument6 SeitenITP For Piping SystemsGia Minh Tieu TuNoch keine Bewertungen

- Hydrotest Form 1Dokument2 SeitenHydrotest Form 1jrod915Noch keine Bewertungen

- Package 2s E0001 - Jupiter DCR 30-10-2021Dokument96 SeitenPackage 2s E0001 - Jupiter DCR 30-10-2021senthilNoch keine Bewertungen

- Inspectation Test PlanDokument1 SeiteInspectation Test Planazimr157Noch keine Bewertungen

- Al-Uqlah Central Processing Facility Water Level & Settlement TableDokument12 SeitenAl-Uqlah Central Processing Facility Water Level & Settlement TableSantosh Kumar BogelaNoch keine Bewertungen

- Cable Tray InstallationDokument1 SeiteCable Tray InstallationNaeemNoch keine Bewertungen

- Gate & Globe PDFDokument0 SeitenGate & Globe PDFZoebairNoch keine Bewertungen

- 4.1 - ANX-1 Definition of Mechanical Completion PDFDokument18 Seiten4.1 - ANX-1 Definition of Mechanical Completion PDFLegend AnbuNoch keine Bewertungen

- 8 Material Inspection ReportDokument1 Seite8 Material Inspection Reportvinson bayNoch keine Bewertungen

- SOW Fabrikasi C-335-01 - 19.116.1Dokument1 SeiteSOW Fabrikasi C-335-01 - 19.116.1AlfanNoch keine Bewertungen

- Project Department Kuwait National Petroleum Company: Daily Welding Inspection ReportDokument1 SeiteProject Department Kuwait National Petroleum Company: Daily Welding Inspection ReportMuthazhagan SaravananNoch keine Bewertungen

- Painting ReportDokument29 SeitenPainting ReportDimas Afiefan AmirNoch keine Bewertungen

- 2G & 5GDokument2 Seiten2G & 5GRahul MoottolikandyNoch keine Bewertungen

- Factors Contributing To Foarming Crude OilDokument11 SeitenFactors Contributing To Foarming Crude OilSang Duong Van100% (1)

- PTDokument7 SeitenPTMohdHuzairiRusliNoch keine Bewertungen

- Radiation Safety Distance DiagramDokument3 SeitenRadiation Safety Distance DiagramEswaranNoch keine Bewertungen

- KBR Inspection Test Plan For Anchor Bolts: Level 1 Level 2 Level 3Dokument4 SeitenKBR Inspection Test Plan For Anchor Bolts: Level 1 Level 2 Level 3kamlNoch keine Bewertungen

- Approved Itp-Dss - 28 Sep 2016Dokument4 SeitenApproved Itp-Dss - 28 Sep 2016Selvakumar SubramanianNoch keine Bewertungen

- Neral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFDokument26 SeitenNeral Policy - Qualified Welding Procedure Specifications (QWPS) PROCESSPIPING PDFcarlosNoch keine Bewertungen

- ASME Buttweld Fittings ExplainedDokument13 SeitenASME Buttweld Fittings ExplainedMarine SleimanNoch keine Bewertungen

- Large Deformation BeamDokument10 SeitenLarge Deformation BeamAdimasu AyeleNoch keine Bewertungen

- Modern Control Design With MATLAB and SIMULINKDokument518 SeitenModern Control Design With MATLAB and SIMULINKPrajwal Bikram Thapa94% (17)

- Analytical Methods To DetermineDokument8 SeitenAnalytical Methods To DetermineRafael AlonsoNoch keine Bewertungen

- Master's Thesis - Quaternion-Based Control For Aggressive Trajectory Tracking With A Micro-Quadrotor UAVDokument113 SeitenMaster's Thesis - Quaternion-Based Control For Aggressive Trajectory Tracking With A Micro-Quadrotor UAVMarcus LimaNoch keine Bewertungen

- Astm E59Dokument20 SeitenAstm E59M Zeeshan HaiderNoch keine Bewertungen

- Meshing in ANSYS WorkbenchDokument5 SeitenMeshing in ANSYS Workbenchfr129834Noch keine Bewertungen

- OSA-06-Vibration Fatigue Analysis of Sheet Metal Mahindra2wheelerDokument11 SeitenOSA-06-Vibration Fatigue Analysis of Sheet Metal Mahindra2wheelerikramishereNoch keine Bewertungen

- Cuk Control PDFDokument57 SeitenCuk Control PDFPraveen PJNoch keine Bewertungen

- IAL Physics Jan 2017 Unit 4 QP PDFDokument24 SeitenIAL Physics Jan 2017 Unit 4 QP PDFsabreenNoch keine Bewertungen

- New Insights Into The Removal of Calcium SulfateDokument10 SeitenNew Insights Into The Removal of Calcium SulfatetsanshineNoch keine Bewertungen

- Abdulla Samin MV 14449: Lab Report Froth FlotationDokument4 SeitenAbdulla Samin MV 14449: Lab Report Froth FlotationKevin100% (1)

- SM Notes 1 by Civildatas - Blogspot.inDokument154 SeitenSM Notes 1 by Civildatas - Blogspot.inutsav_koshtiNoch keine Bewertungen

- Lesson Plan Hess Law 90 - From MR - TonoDokument14 SeitenLesson Plan Hess Law 90 - From MR - TonoSiti Aminah Al-Hadi100% (2)

- Aguilar Et Al, 2000Dokument8 SeitenAguilar Et Al, 2000Edgar SilveiraNoch keine Bewertungen

- Continuous Time Signals Part I Fourier SeriesDokument12 SeitenContinuous Time Signals Part I Fourier SeriesbusybeeNoch keine Bewertungen

- Behavior and Analysis of A Curved and Skewed I-Girder BridgeDokument17 SeitenBehavior and Analysis of A Curved and Skewed I-Girder BridgeaapennsylvaniaNoch keine Bewertungen

- JESD22 B110A Sub Assembly ShockDokument16 SeitenJESD22 B110A Sub Assembly ShockTan Long BinNoch keine Bewertungen

- Comparison of Digestion Methods For Determination of PB (II), CR (VI) and CD (II) Contents in Some Ethiopia Spices Using Atomic Absorption SpectrosDokument12 SeitenComparison of Digestion Methods For Determination of PB (II), CR (VI) and CD (II) Contents in Some Ethiopia Spices Using Atomic Absorption SpectrosijasrjournalNoch keine Bewertungen

- AutoRecovery 1 Save of Lab Report Template With Grading Rubric (1) .AsdDokument5 SeitenAutoRecovery 1 Save of Lab Report Template With Grading Rubric (1) .AsdMohammed ElnaggarNoch keine Bewertungen

- Private - Lost Secrets of The Sacred Ark (16288949)Dokument10 SeitenPrivate - Lost Secrets of The Sacred Ark (16288949)Gordon Scott TaylorNoch keine Bewertungen

- Mil HDBK 505 PDFDokument9 SeitenMil HDBK 505 PDFCORAL ALONSONoch keine Bewertungen

- MatrixDokument20 SeitenMatrixrohitjdbi83Noch keine Bewertungen

- Building Envelope - Group B (ETTV)Dokument47 SeitenBuilding Envelope - Group B (ETTV)Kyaw ZawNoch keine Bewertungen

- ThermodynamicsDokument3 SeitenThermodynamicsArslan JigarNoch keine Bewertungen

- DLM ValidationDokument7 SeitenDLM ValidationSandilya KambampatiNoch keine Bewertungen

- Introduction BearingDokument4 SeitenIntroduction BearingtonojsgpNoch keine Bewertungen

- Heat and TemperatureDokument33 SeitenHeat and Temperatureapi-3722337100% (1)

- E 1476 - 04 (2014)Dokument12 SeitenE 1476 - 04 (2014)iTuan Khai TruongNoch keine Bewertungen

- Methods For Assessing The Stability of Slopes During Earthquakes-A RetrospectiveDokument20 SeitenMethods For Assessing The Stability of Slopes During Earthquakes-A Retrospectiveilijarsk100% (1)

- P6 Part 5Dokument10 SeitenP6 Part 5Kenneth DuroNoch keine Bewertungen

- Arizona, Utah & New Mexico: A Guide to the State & National ParksVon EverandArizona, Utah & New Mexico: A Guide to the State & National ParksBewertung: 4 von 5 Sternen4/5 (1)

- New York & New Jersey: A Guide to the State & National ParksVon EverandNew York & New Jersey: A Guide to the State & National ParksNoch keine Bewertungen

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensVon EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNoch keine Bewertungen

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoVon EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoBewertung: 5 von 5 Sternen5/5 (1)

- The Bahamas a Taste of the Islands ExcerptVon EverandThe Bahamas a Taste of the Islands ExcerptBewertung: 4 von 5 Sternen4/5 (1)

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptVon EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptBewertung: 5 von 5 Sternen5/5 (1)