Beruflich Dokumente

Kultur Dokumente

Typical Joint Detailing of Steel Hollow Sections

Hochgeladen von

Syed Mohd MehdiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Typical Joint Detailing of Steel Hollow Sections

Hochgeladen von

Syed Mohd MehdiCopyright:

Verfügbare Formate

TYPICAL JOINT DETAILING OF STEEL

HOLLOW SECTIONS

JOINT DETAILING OF STEEL HOLLOW SECTIONS

Detailing of joints in steel structure is as much important as detailing of main structural

members. Ultimately loads from structures are transferred to different structural

members through joints. So, a good detailing of joints in steel structure is required to

make the structure safe for the given loads.

Here we will discuss about the types of joints commonly used for structural steel hollow

sections. Hollow sections are of three types, Rectangular Hollow Sections (RHS) and

Square Hollow Sections (SHS) and Circular Hollow Sections (CHS).

Following are the joint details for structural steel hollow sections (RHS and

SHS) commonly used:

1. K Type Joints:

K Type joints in steel structures are formed when the centroidal axis of horizontal

member and two lateral bracings meet with the central axis of top chord. Following

figure shows K-Type joint:

It should be ensured that the ends of hollow sections are always closed. If any ends of a

hollow section does not get closed due to more width, then a plate is welded on that end

so that the ends gets closed and also the connection with other members are made good

by effective sealing of the members. This also prevents internal corrosion of the hollow

sections.

K-type of joints in structural steel members is simplest and most economical.

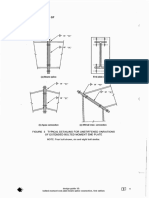

2. Knee Type Joint:

To increase the stability of connection between vertical and horizontal members of

structure, knee-type joint is used.

In welded knee-joint, the top chord is directly welded to the main column and then a

suitably cut haunch is welded to the vertical and as well as to the chord member for

better stiffening. The knee-type joint is shown below:

3. N Type Joint:

N-type joint is formed as per the adopted configuration, for connecting web members to

top and bottom chords. Typical details of one of the joints are given below:

i) In this joint, first the vertical member is put in place and directly welded to top and

bottom chords.

ii) Afterwards, the other inclined diagonal member, with suitable double cuts at the ends,

is directly welded to top and bottom chords and also to the vertical.

iii) These connections, of vertical and diagonal members to top and bottom chords

directly, help in eliminating the gusset plates thus resulting in automatic sealing of

member ends. Direct jointing, of vertical and diagonal members to top and bottom

chords, eliminates gusset plates.

4. Gap Joint:

When two smaller sections are to be joined with a bigger section, a gap between two

smaller sections remains. When the intersection of centroidal axes of two smaller size

members lies in the centroidal axis of larger size member i.e. bottom boom of landing,

this type of joint is formed.

Following figure shows Gap Joints Details:

In this arrangement, single cut bracings are directly welded to floor beam. This joint is

used in the column bracings.

5. Overlap Joint:

This type of joint is used in elevation for connecting three smaller size members so that

two members are in close touch with each other and also the intersection of their

centroidal axes lies on the axis of third member.

Following figure shows typical details of Overlap Joints between hollow sections:

In this arrangement, both the diagonal bracing members have double cut at the ends

and directly welded to horizontal bracings. This is a symmetrical layout.

6. Vierendeel Joint:

In this type of joint the vertical member is directly welded to the top chord by fillet weld.

Following figure shows typical details of Vierendeel Joints between hollow sections:

In this type of Vierendeel joint the width of the vertical member is less than the chord

members. This is a most suitable joint.

Das könnte Ihnen auch gefallen

- Model Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionVon EverandModel Analysis of Plane Structures: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNoch keine Bewertungen

- Title Page and ContentsDokument11 SeitenTitle Page and ContentsAshlin AarthiNoch keine Bewertungen

- Graitec Com en Ad Steel Connection Design ASPDokument7 SeitenGraitec Com en Ad Steel Connection Design ASPpatrickNX9420Noch keine Bewertungen

- Computer Aided Engineering Space Gass Tutorial Questions (Beam Frames Trusses)Dokument9 SeitenComputer Aided Engineering Space Gass Tutorial Questions (Beam Frames Trusses)April IngramNoch keine Bewertungen

- Unistrut CatalogDokument12 SeitenUnistrut CatalogElia Nugraha AdiNoch keine Bewertungen

- Tapered Column DesignDokument79 SeitenTapered Column DesignfostbarrNoch keine Bewertungen

- Steel Connections.Dokument40 SeitenSteel Connections.Mahmoud YehiaNoch keine Bewertungen

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 13Dokument1 SeiteASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 13Anonymous 0x2pwMCWgjNoch keine Bewertungen

- Portal Frame Footings and Slab - 4ed - bk180Dokument12 SeitenPortal Frame Footings and Slab - 4ed - bk180NivarNoch keine Bewertungen

- Beam To Column ConnectionsDokument15 SeitenBeam To Column ConnectionsKevinManuelNoch keine Bewertungen

- Some Info On TrussesDokument9 SeitenSome Info On TrussesameensderajNoch keine Bewertungen

- Beam Formulas With Shear and Mom PDFDokument16 SeitenBeam Formulas With Shear and Mom PDFPanagiotis StamatisNoch keine Bewertungen

- Temporary StructuresDokument65 SeitenTemporary StructuresnisfibolahenkNoch keine Bewertungen

- Anchor Bolts D-000-1320-003 - E3 - 001Dokument1 SeiteAnchor Bolts D-000-1320-003 - E3 - 001Ahmed FitryMusa100% (1)

- Effect of Backstay On 3B+G+20 Storey RC BuildingDokument5 SeitenEffect of Backstay On 3B+G+20 Storey RC Buildingdharashah28Noch keine Bewertungen

- Structural Steel Design Project: Calculation SheetDokument30 SeitenStructural Steel Design Project: Calculation SheetLynzerNoch keine Bewertungen

- Steel Connections EnuDokument92 SeitenSteel Connections Enumparmi4725Noch keine Bewertungen

- Topic - Connections - Typical JointsDokument75 SeitenTopic - Connections - Typical JointsvijeshrajNoch keine Bewertungen

- Double Angle CleatsDokument6 SeitenDouble Angle CleatsKaushal KishoreNoch keine Bewertungen

- Beam Column ConnectionDokument2 SeitenBeam Column ConnectionHAZIRACFS SURATNoch keine Bewertungen

- Design of BeamsDokument28 SeitenDesign of BeamsNayan Fatania100% (2)

- 7-Bolted Connections PDFDokument18 Seiten7-Bolted Connections PDFKellen BrumbaughNoch keine Bewertungen

- Space Structures - Principles and Practice - Subramanian Narayan - Volulmul 2Dokument72 SeitenSpace Structures - Principles and Practice - Subramanian Narayan - Volulmul 2herohue67% (3)

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsVon EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsNoch keine Bewertungen

- Steelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiesDokument56 SeitenSteelwork Design Guide To BS 5950 Vol 1 Part B1 Dimensions & PropertiessubamanivelNoch keine Bewertungen

- Steel Members DesignDokument195 SeitenSteel Members DesignStephen JamesNoch keine Bewertungen

- Limit State Design of Steel Members To AS4100Dokument20 SeitenLimit State Design of Steel Members To AS4100Sam ThomasNoch keine Bewertungen

- Bolted ConnectionsDokument49 SeitenBolted Connectionsabhijithshettyk100% (1)

- Truss DesignDokument16 SeitenTruss DesignRabindraUpretiNoch keine Bewertungen

- 1992 - 04 Designing For Cost Efficient FabricationDokument8 Seiten1992 - 04 Designing For Cost Efficient FabricationHenry HoyosNoch keine Bewertungen

- (Eng) Steel Connection 14Dokument89 Seiten(Eng) Steel Connection 14HENGKIMHACHNoch keine Bewertungen

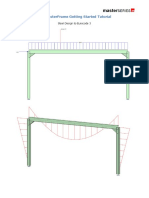

- T00 MasterFrame Getting Started Tutorial PDFDokument36 SeitenT00 MasterFrame Getting Started Tutorial PDFJEMAYERNoch keine Bewertungen

- StruCad Evolution Getting Started TutorialDokument41 SeitenStruCad Evolution Getting Started Tutorialnifty25Noch keine Bewertungen

- Sherman - Extended Shear TabsDokument148 SeitenSherman - Extended Shear TabsRohan KarandeNoch keine Bewertungen

- Gusset Plate Connection DesignDokument3 SeitenGusset Plate Connection DesignMin Khant KyawNoch keine Bewertungen

- T01-1 MasterFrame Tutorial - The BasicsDokument68 SeitenT01-1 MasterFrame Tutorial - The BasicsMartinNoch keine Bewertungen

- Frame ExamplesDokument4 SeitenFrame ExamplesXet FatNoch keine Bewertungen

- Rev - Office Proposal - 6.11.2014-ModelDokument1 SeiteRev - Office Proposal - 6.11.2014-ModelChandra ShekarNoch keine Bewertungen

- Design of Tension Member - Gusset Plates Lug Angles and Tension SplicesDokument28 SeitenDesign of Tension Member - Gusset Plates Lug Angles and Tension SplicesDarsHan MoHanNoch keine Bewertungen

- MasterSeries Student Masonry Retaining EtcDokument21 SeitenMasterSeries Student Masonry Retaining EtcekaNoch keine Bewertungen

- Con 1302Dokument12 SeitenCon 1302Sanket Arun More100% (1)

- Tied Foundations-Portal FrameDokument3 SeitenTied Foundations-Portal FrameJaime Manalili LandinginNoch keine Bewertungen

- Welded ConnectionsDokument16 SeitenWelded ConnectionsAnkit SinghNoch keine Bewertungen

- Design of Steel ColumnDokument22 SeitenDesign of Steel ColumnN.S.M.RAVI KUMARNoch keine Bewertungen

- S&T Purlins & Girts Catalogue PDFDokument36 SeitenS&T Purlins & Girts Catalogue PDFNguyen Duc CuongNoch keine Bewertungen

- RAM Conncetion Standalone Manual PDFDokument34 SeitenRAM Conncetion Standalone Manual PDFThanit ThanadirekNoch keine Bewertungen

- Lattice TowerDokument15 SeitenLattice TowerAmlan DasNoch keine Bewertungen

- Review of AISI Design Guide For Cold-Formed Steel Purlin Roof FraDokument17 SeitenReview of AISI Design Guide For Cold-Formed Steel Purlin Roof FraguillermoNoch keine Bewertungen

- Magazines o o o oDokument14 SeitenMagazines o o o oTemesgenAbiyNoch keine Bewertungen

- Steel ConnectionDokument34 SeitenSteel ConnectionDiana100% (1)

- Software Verification: AISC-360-16 Example 001Dokument4 SeitenSoftware Verification: AISC-360-16 Example 001alejandro mantillaNoch keine Bewertungen

- Software Verification: Example 17Dokument8 SeitenSoftware Verification: Example 17sancloudNoch keine Bewertungen

- Reinforced Concrete Design Theory P Bhatt Thomas Joseph MacGinleyDokument1 SeiteReinforced Concrete Design Theory P Bhatt Thomas Joseph MacGinleyjason_gernale2011Noch keine Bewertungen

- Steel - : "The Right Choice"Dokument20 SeitenSteel - : "The Right Choice"Anh Linh LeNoch keine Bewertungen

- CHH LVL Portal Frame Design Example - Sept 2008Dokument92 SeitenCHH LVL Portal Frame Design Example - Sept 2008podderickNoch keine Bewertungen

- Steel Connection Guide 211 EnuDokument64 SeitenSteel Connection Guide 211 EnuAnonymous TRthlKkWWNoch keine Bewertungen

- Extra Item Rate HQDokument9 SeitenExtra Item Rate HQSyed Mohd MehdiNoch keine Bewertungen

- REV01 CEILING ELECTRICAL-Model PDFDokument1 SeiteREV01 CEILING ELECTRICAL-Model PDFSyed Mohd MehdiNoch keine Bewertungen

- Consumer Lighting Price ListDokument80 SeitenConsumer Lighting Price ListSyed Mohd MehdiNoch keine Bewertungen

- Final Sustainable Sand Mining Management Guidelines 2016Dokument101 SeitenFinal Sustainable Sand Mining Management Guidelines 2016Salil86Noch keine Bewertungen

- Time Extension Letter. (24.09.2016) DocxDokument1 SeiteTime Extension Letter. (24.09.2016) DocxSyed Mohd MehdiNoch keine Bewertungen

- Furniture Layout Plan - ModelDokument1 SeiteFurniture Layout Plan - ModelSyed Mohd MehdiNoch keine Bewertungen

- Walls - Types, Features and Design ConceptDokument2 SeitenWalls - Types, Features and Design ConceptSyed Mohd MehdiNoch keine Bewertungen

- A3 JAL NIGAM HEAD Office Last Final 12.08.15-ModelDokument1 SeiteA3 JAL NIGAM HEAD Office Last Final 12.08.15-ModelSyed Mohd MehdiNoch keine Bewertungen

- Dissertation Phase 1Dokument33 SeitenDissertation Phase 1Syed Mohd Mehdi100% (1)

- ACI Journal - Evaluation of Ratio Between Splitting Tensile StrengthDokument10 SeitenACI Journal - Evaluation of Ratio Between Splitting Tensile StrengthSyed Mohd MehdiNoch keine Bewertungen

- 1) MouldingDokument1 Seite1) MouldingSyed Mohd MehdiNoch keine Bewertungen

- Concrete Mix DesignDokument5 SeitenConcrete Mix Designkom1984Noch keine Bewertungen

- Stone Dust & RubberDokument64 SeitenStone Dust & RubberSyed Mohd Mehdi100% (1)

- Analysis of RatesDokument5 SeitenAnalysis of Ratesakstrmec23Noch keine Bewertungen

- How To Make A Building GreenDokument5 SeitenHow To Make A Building GreenSyed Mohd MehdiNoch keine Bewertungen

- Save Environment With Green BuildingsDokument2 SeitenSave Environment With Green BuildingsSyed Mohd MehdiNoch keine Bewertungen

- Green Building Site and Landscape PlanningDokument3 SeitenGreen Building Site and Landscape PlanningSyed Mohd MehdiNoch keine Bewertungen

- Performance of Various Types of Buildings During EarthquakeDokument5 SeitenPerformance of Various Types of Buildings During EarthquakeSyed Mohd Mehdi100% (1)

- Selection of Green Building MaterialsDokument3 SeitenSelection of Green Building MaterialsSyed Mohd MehdiNoch keine Bewertungen

- Building Orientation For Hot & Dry ClimateDokument2 SeitenBuilding Orientation For Hot & Dry ClimateSyed Mohd Mehdi75% (4)

- Concrete Without CementDokument2 SeitenConcrete Without CementSyed Mohd MehdiNoch keine Bewertungen

- Is 15109 (Part 2) - 2002 Iso 11269 - 1995 - Determination of The Effects of Pollutants On Soil Flora - Part 2 Effects of Chemicals On The Emergence and Growth Higher PlantsDokument10 SeitenIs 15109 (Part 2) - 2002 Iso 11269 - 1995 - Determination of The Effects of Pollutants On Soil Flora - Part 2 Effects of Chemicals On The Emergence and Growth Higher PlantsPrapa KaranNoch keine Bewertungen

- Concrete Mix Design Comparison Between BIS and ACIDokument7 SeitenConcrete Mix Design Comparison Between BIS and ACIPraveen JainNoch keine Bewertungen

- Green Roofing - A Step Towards SustainabilityDokument4 SeitenGreen Roofing - A Step Towards SustainabilitySyed Mohd MehdiNoch keine Bewertungen

- Sustainability in Construction & Civil EngineeringDokument4 SeitenSustainability in Construction & Civil EngineeringSyed Mohd MehdiNoch keine Bewertungen

- Indian Standard 16 - Part 1Dokument6 SeitenIndian Standard 16 - Part 1sdmelNoch keine Bewertungen

- CV PDFDokument4 SeitenCV PDFSyed Mohd MehdiNoch keine Bewertungen

- Cement Chemistry and Types of CementDokument9 SeitenCement Chemistry and Types of CementSyed Mohd MehdiNoch keine Bewertungen

- 2r - Rules For RoundingDokument18 Seiten2r - Rules For Roundingসন্দীপ চন্দ্রNoch keine Bewertungen

- Determination of Specific Gravity of CementDokument1 SeiteDetermination of Specific Gravity of CementSyed Mohd MehdiNoch keine Bewertungen

- Comparing Dell Compellent Network-Attached Storage To An Industry-Leading NAS SolutionDokument19 SeitenComparing Dell Compellent Network-Attached Storage To An Industry-Leading NAS SolutionPrincipled TechnologiesNoch keine Bewertungen

- Donato BramanteDokument5 SeitenDonato Bramantejanhavi28Noch keine Bewertungen

- Mill Roller Lowering HydraulicsDokument22 SeitenMill Roller Lowering HydraulicsTirath TmsNoch keine Bewertungen

- Draft Openconfig Netmod Model StructureDokument8 SeitenDraft Openconfig Netmod Model Structuresafyh2005Noch keine Bewertungen

- Solving The WebGoat Labs Draft V2Dokument5 SeitenSolving The WebGoat Labs Draft V2vishalscribd77Noch keine Bewertungen

- Cuadro Comparativo Versiones PostgressDokument4 SeitenCuadro Comparativo Versiones PostgressAlejo GutiérrezNoch keine Bewertungen

- Drafting TechnologyDokument80 SeitenDrafting Technologyong0625Noch keine Bewertungen

- NetAct PlanEditor & CM Guidelines v1.0Dokument105 SeitenNetAct PlanEditor & CM Guidelines v1.0Anonymous g8YR8b950% (2)

- Curriculum Vitea Roshan Spa VijayawadaDokument2 SeitenCurriculum Vitea Roshan Spa Vijayawadajai_swetaNoch keine Bewertungen

- SystemVerilog Switch Lab FinalDokument6 SeitenSystemVerilog Switch Lab FinalmanchuricoNoch keine Bewertungen

- Urban AtriumDokument10 SeitenUrban AtriumrashmigodhaNoch keine Bewertungen

- Pre Stressed BeamsDokument127 SeitenPre Stressed BeamsjaffnaNoch keine Bewertungen

- Sap BasisDokument6 SeitenSap BasisMadhusudhan AkulaNoch keine Bewertungen

- Alcatel-Lucent Omnipcx Office Technical Bulletins & Release Notes Table of ContentDokument6 SeitenAlcatel-Lucent Omnipcx Office Technical Bulletins & Release Notes Table of ContentKleanthis KleanthousNoch keine Bewertungen

- MUB 100 630D4-L MultiboxDokument5 SeitenMUB 100 630D4-L MultiboxognadNoch keine Bewertungen

- Scan ErrorDokument5 SeitenScan Errorhientran1018Noch keine Bewertungen

- 10 1 1 475 5570Dokument7 Seiten10 1 1 475 5570joni indoNoch keine Bewertungen

- Convert HEIC To PNGDokument3 SeitenConvert HEIC To PNGEjaz AlamNoch keine Bewertungen

- Porosity and AbsorptionDokument4 SeitenPorosity and AbsorptionEhsan RehmanNoch keine Bewertungen

- Itramas Street LightDokument4 SeitenItramas Street Lightchandimas10Noch keine Bewertungen

- Ex 3 - TCP Udp Chat ServerDokument3 SeitenEx 3 - TCP Udp Chat ServerrmuthusamiNoch keine Bewertungen

- TDS Euco Diamond HardDokument2 SeitenTDS Euco Diamond HardJim HaigNoch keine Bewertungen

- Modine Heating CalculationDokument4 SeitenModine Heating CalculationAnonymous imDtTMNoch keine Bewertungen

- DeconstructivismDokument14 SeitenDeconstructivismNajah Abdul RahmanNoch keine Bewertungen

- Common Administrative Commands in Red Hat Enterprise Linux 5, 6, 7, and 8Dokument4 SeitenCommon Administrative Commands in Red Hat Enterprise Linux 5, 6, 7, and 8hoadiNoch keine Bewertungen

- Long Span Structure London VelodromeDokument20 SeitenLong Span Structure London VelodromeArjun Nambiar67% (3)

- The Design of The Millau Viaduct: Jean-Pierre MARTIN Claude SERVANTDokument23 SeitenThe Design of The Millau Viaduct: Jean-Pierre MARTIN Claude SERVANTAmirhossein AbbasiNoch keine Bewertungen

- 808 PC Software InterfaceDokument2 Seiten808 PC Software InterfaceJohn GarnetNoch keine Bewertungen

- 1P Dungeon NamesDokument1 Seite1P Dungeon NamesJohn BewleyNoch keine Bewertungen