Beruflich Dokumente

Kultur Dokumente

HAZOP Exercise

Hochgeladen von

kefeinzel0%(1)0% fanden dieses Dokument nützlich (1 Abstimmung)

2K Ansichten8 SeitenHAZOP Exercise

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenHAZOP Exercise

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0%(1)0% fanden dieses Dokument nützlich (1 Abstimmung)

2K Ansichten8 SeitenHAZOP Exercise

Hochgeladen von

kefeinzelHAZOP Exercise

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 8

1

HAZOP Analysis Exercise

Submit report to Assignment Box in the department Thursday 11 Sep, 5 pm

Process Section: Phosphoric Acid Feed Line to the DAP Reactor

Design Intention: Feed phosphoric acid at a controlled rate to the DAP Reactor

Guide Word: No

Process Parameter: Flow

Deviation: No Flow

Causes: (1) No feed material in the phosphoric acid storage tank

(2) Flow indicator/controller fails high

(3) Operator sets the flow controller too low

(4) Phosphoric acid control valve B fails closed

(5) Plugging of the line

(6) Leak or rupture of the line

Consequences: (1) Excess ammonia in the reactor, leading to...

(2) Unreacted ammonia in the DAP storage tank, with

subsequent...

(3) Release of unreacted ammonia from the DAP storage tank to

the enclosed work area

(4) Loss of DAP production

Safeguards: (1) Existing safeguard is the Flow Indicator.

Actions: (1) Consider adding an alarm/shutdown of the system for low

phosphoric acid flow to the reactor

(2) Ensure that periodic maintenance and inspection for valve B

are adequate

(3) Consider using a closed tank for DAP storage.

(4) Period maintenance of valve B.

2

This process is repeated with other guide word/process parameter combinations then the

study continues with the next node in the design. Every process section is evaluated, and

the relevant information is recorded in a HAZOP study table.

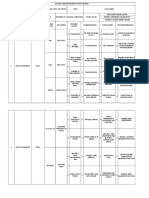

HAZOP Project

Team: HAZOP Team #N Drawing Number 70-0BP-57100

Meeting Date: 20/08/04 Revision Number: 3

Item

No.

1.0 Vessel - Ammonia solution storage tank. Safely contain ammonia feed at ambient temperature and

pressure.(Design Intention)

High Level (Deviation)

2.0 Line - Ammonia feed line to the DAP reactor. Deliver ammonia to reactor at y gpm and z psig.(Design

Intention)

High Flow (Deviation)

3.0 Vessel - Phosphoric acid solution storage tank. Safely contain acid feed at ambient temperature and

pressure(Design Intention)

Low concentration of phosphoric acid (Deviation)

4.0 Vessel DAP reactor. Contain the reaction at x C and y psig (Design Intention)

Loss of agitation (Deviation)

5.0 Draw the fault Tree of AMMONIA RELEASES TO WORKPLACE ENVIRONMENT as top event.

3

HAZOP Project

Team: HAZOP Team #N Drawing Number 70-0BP-57100

Meeting Date: 20/08/04 Revision Number: 3

4

PROCESS INFORMATION (optional)

You may report here a brief process description, process physical data, hazardous

properties of materials, assumptions, and any additional information used.

5

HAZOP ANALYSIS WORKSHEET (1 for each deviation)

Process Section:

Design Intention:

Guide Word:

Process Parameter:

Deviation:

Causes:

Consequences:

Safeguards:

Actions:

6

HAZOP ANALYSIS WORKSHEET (1 for each deviation)

Process Section:

Design Intention:

Guide Word:

Process Parameter:

Deviation:

Causes:

Consequences:

Safeguards:

Actions:

7

HAZOP ANALYSIS WORKSHEET (1 for each deviation)

Process Section:

Design Intention:

Guide Word:

Process Parameter:

Deviation:

Causes:

Consequences:

Safeguards:

Actions:

8

HAZOP ANALYSIS WORKSHEET (1 for each deviation)

Process Section:

Design Intention:

Guide Word:

Process Parameter:

Deviation:

Causes:

Consequences:

Safeguards:

Actions:

Das könnte Ihnen auch gefallen

- Hazop ExampleDokument2 SeitenHazop ExampleMARCOPOLO24Noch keine Bewertungen

- Hazop Example PDFDokument2 SeitenHazop Example PDFhappale200286% (7)

- HAZOP STUDY Report (Kutch Chemical Industries Limited)Dokument82 SeitenHAZOP STUDY Report (Kutch Chemical Industries Limited)kanakarao173% (11)

- HazopDokument66 SeitenHazopBlack WidowNoch keine Bewertungen

- HAZOP ExampleDokument5 SeitenHAZOP ExampleAnonymous QqE5tcEa100% (5)

- HAZOPDokument32 SeitenHAZOPMaximiano Ferraz71% (14)

- HAZOP Study (Part II)Dokument18 SeitenHAZOP Study (Part II)Saad Ahmed100% (14)

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesVon EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNoch keine Bewertungen

- Hazop.1092475 Appendix 30.hazopDokument67 SeitenHazop.1092475 Appendix 30.hazopAudrey Patrick Kalla50% (2)

- HAZOP ProcedureDokument10 SeitenHAZOP Proceduresharjeel39100% (3)

- Hazop StudyDokument8 SeitenHazop StudyNavaganesh KannappenNoch keine Bewertungen

- HAZOP AnalysisDokument35 SeitenHAZOP AnalysisGopi Krish100% (3)

- Senior HazopDokument113 SeitenSenior HazopKongWeiHern100% (7)

- Hazard and Operability Study (Hazop) : Dr. M. Azam SaeedDokument39 SeitenHazard and Operability Study (Hazop) : Dr. M. Azam SaeedMuhammad Bilal100% (2)

- HAZOP ExerciseDokument12 SeitenHAZOP Exerciseshawalina07Noch keine Bewertungen

- 3.2 HazopDokument66 Seiten3.2 Hazops sanjai100% (1)

- HAZOP Study (Part I)Dokument4 SeitenHAZOP Study (Part I)Saad Ahmed100% (1)

- Methanol Production Plant Feed Inlet Into Reformer, R-01 Supply Heat To FeedDokument12 SeitenMethanol Production Plant Feed Inlet Into Reformer, R-01 Supply Heat To FeedAin SyuhadaNoch keine Bewertungen

- HAZOPDokument18 SeitenHAZOPMark GuevarraNoch keine Bewertungen

- Tutorial Hazop: Node Guide Word Deviation Possible Cause Consequences Action RequiredDokument3 SeitenTutorial Hazop: Node Guide Word Deviation Possible Cause Consequences Action RequiredSyafiyatulMunawarahNoch keine Bewertungen

- HAZOP FinalDokument2 SeitenHAZOP Finalchiang95100% (3)

- HAZOPDokument43 SeitenHAZOPChemsys Mail100% (1)

- 10.1 HazopDokument15 Seiten10.1 HazopEdna TanNoch keine Bewertungen

- HAZOP TrainingDokument131 SeitenHAZOP Trainingtamilnaduchennai100% (14)

- HAZOP Study Training CourseDokument55 SeitenHAZOP Study Training CourseDobrescu Cristian100% (1)

- Application HAZOP LOPA Figueroa 2015Dokument225 SeitenApplication HAZOP LOPA Figueroa 2015ravisankar100% (1)

- Sample HAZOP Study Worksheet (P&ID 100-002)Dokument5 SeitenSample HAZOP Study Worksheet (P&ID 100-002)Mikee Felipe88% (8)

- HAZOP Analysis of Group 15: Isaac Law Shek Xiang Harvind Rajamanickam Shanmugam MuthusamyDokument2 SeitenHAZOP Analysis of Group 15: Isaac Law Shek Xiang Harvind Rajamanickam Shanmugam Muthusamyvijaymoorthy14Noch keine Bewertungen

- HAZOP GuidelinesDokument43 SeitenHAZOP GuidelinesKhan Lala100% (3)

- HazopDokument4 SeitenHazopbaaziz2015Noch keine Bewertungen

- 01-HAZOP Worksheet Formaldehyde - (Corrosion)Dokument8 Seiten01-HAZOP Worksheet Formaldehyde - (Corrosion)Muhammad Zarif Amir100% (1)

- Hazop & Hazid Report - CNG Gas Plant - Tambak Lorok Rev BDokument110 SeitenHazop & Hazid Report - CNG Gas Plant - Tambak Lorok Rev BDenstar Ricardo Silalahi94% (16)

- Lecture HAZOP ExampleDokument29 SeitenLecture HAZOP ExampleIbtida SultanaNoch keine Bewertungen

- HazopDokument75 SeitenHazopavanish.v100% (1)

- Updated Technical SafetyDokument122 SeitenUpdated Technical SafetyElla Agbettor100% (2)

- HAZOP Write UpDokument3 SeitenHAZOP Write UpGlacier RamkissoonNoch keine Bewertungen

- HAZOP ReactorDokument9 SeitenHAZOP ReactorChadGayle100% (9)

- Basics of HAZOPDokument26 SeitenBasics of HAZOPNg JoshuaNoch keine Bewertungen

- Process Hazard Analysis: Study Node Parameter Guide Word Deviation Causes Consequence Action RequiredDokument22 SeitenProcess Hazard Analysis: Study Node Parameter Guide Word Deviation Causes Consequence Action Requiredvinod kumar100% (2)

- HAZOP WorksheetDokument5 SeitenHAZOP WorksheetchristyleneNoch keine Bewertungen

- HAZOPDokument30 SeitenHAZOPgandalalake2002Noch keine Bewertungen

- Annexure - 1 - Propane - Hazop WorksheetDokument25 SeitenAnnexure - 1 - Propane - Hazop WorksheetsugandhajayaswalNoch keine Bewertungen

- HAZOPDokument7 SeitenHAZOPfairusNoch keine Bewertungen

- Layer of Protection AnalysisDokument6 SeitenLayer of Protection Analysishmatora72_905124701Noch keine Bewertungen

- Process Safety Enhancement in Chemical Plant Design by Exploiting Accident KnowledgeDokument88 SeitenProcess Safety Enhancement in Chemical Plant Design by Exploiting Accident KnowledgeAnonymous ocCa18RNoch keine Bewertungen

- Hazop ReportDokument188 SeitenHazop ReportTri Anugrah Kurniawan100% (6)

- HAZOP Saudi Aramco HAZOP GuidelinesDokument92 SeitenHAZOP Saudi Aramco HAZOP Guidelinesjakejohns100% (15)

- ChE 534 - Module 3Dokument34 SeitenChE 534 - Module 3Precious JamesNoch keine Bewertungen

- Vol V Esia Vol 3 Part 2a-2g HazopDokument15 SeitenVol V Esia Vol 3 Part 2a-2g HazopSalahBouzianeNoch keine Bewertungen

- Hazard and Operability Studies (HAZOP)Dokument28 SeitenHazard and Operability Studies (HAZOP)anpuselvi125100% (1)

- HAZOP ExampleDokument3 SeitenHAZOP ExampleN KannanNoch keine Bewertungen

- 2 4 Hazop 1Dokument14 Seiten2 4 Hazop 1barbarojNoch keine Bewertungen

- 2 4 HazopDokument14 Seiten2 4 HazopIMPG077080Noch keine Bewertungen

- 2 4 HazopDokument14 Seiten2 4 HazopwarlindaekaNoch keine Bewertungen

- Li LiDokument27 SeitenLi LiSardar PerdawoodNoch keine Bewertungen

- Hazard and Operability StudyDokument21 SeitenHazard and Operability StudyMohd HisammudinNoch keine Bewertungen

- ADMF - Reverse Phase HPLC For Asfotase AlfaDokument12 SeitenADMF - Reverse Phase HPLC For Asfotase Alfahlasdu sdhNoch keine Bewertungen

- Chapter No.10 MSDS & HAZOPDokument7 SeitenChapter No.10 MSDS & HAZOPAli AhsanNoch keine Bewertungen

- Xid-7772937 2Dokument44 SeitenXid-7772937 2kefeinzelNoch keine Bewertungen

- Xid-7772938 2Dokument26 SeitenXid-7772938 2kefeinzelNoch keine Bewertungen

- HYSYS Tutorial 1 Material & Energy BalancesDokument1 SeiteHYSYS Tutorial 1 Material & Energy BalancesJxinLeeNoch keine Bewertungen

- CH4801 SyllabusDokument3 SeitenCH4801 SyllabuskefeinzelNoch keine Bewertungen

- Palf PDFDokument16 SeitenPalf PDFKamal Nadh TammaNoch keine Bewertungen

- Cheap TBE Inverter TeardownsDokument33 SeitenCheap TBE Inverter TeardownsWar Linux92% (12)

- EngineCleaningAndVolcanicAsh InternDokument69 SeitenEngineCleaningAndVolcanicAsh InternLucio Portuguez AlmanzaNoch keine Bewertungen

- Factory OverheadDokument2 SeitenFactory OverheadKeanna Denise GonzalesNoch keine Bewertungen

- Rar Vol11 Nro3Dokument21 SeitenRar Vol11 Nro3Valentine WijayaNoch keine Bewertungen

- Userguide SW-MC V2 2015-W45 EN S034308Dokument131 SeitenUserguide SW-MC V2 2015-W45 EN S034308ReneNoch keine Bewertungen

- Traditional vs. Enterprise Risk Management - How Do They DifferDokument4 SeitenTraditional vs. Enterprise Risk Management - How Do They DifferJaveed A. KhanNoch keine Bewertungen

- Denagard-CTC US Knowledge ReportDokument4 SeitenDenagard-CTC US Knowledge Reportnick224Noch keine Bewertungen

- Ifm Product Innovations PDFDokument109 SeitenIfm Product Innovations PDFJC InquillayNoch keine Bewertungen

- Sudheer Kumar CVDokument3 SeitenSudheer Kumar CVGujjar Dhayki valeNoch keine Bewertungen

- Drug Development: New Chemical Entity DevelopmentDokument6 SeitenDrug Development: New Chemical Entity DevelopmentDeenNoch keine Bewertungen

- Extraordinary GazetteDokument10 SeitenExtraordinary GazetteAdaderana OnlineNoch keine Bewertungen

- Project PlanDokument55 SeitenProject PlanAlfredo SbNoch keine Bewertungen

- Indiana Administrative CodeDokument176 SeitenIndiana Administrative CodeMd Mamunur RashidNoch keine Bewertungen

- ScienceDokument17 SeitenScienceTambong HailyNoch keine Bewertungen

- Cooling SistemadeRefrigeracion RefroidissementDokument124 SeitenCooling SistemadeRefrigeracion RefroidissementPacoNoch keine Bewertungen

- SUPERHERO Suspension Training ManualDokument11 SeitenSUPERHERO Suspension Training ManualCaleb Leadingham100% (5)

- Kebersihan, Fungsi Sanitasi Dan Drainase - BAHASA INGGRIS - VII - Semester IDokument5 SeitenKebersihan, Fungsi Sanitasi Dan Drainase - BAHASA INGGRIS - VII - Semester IRiska AyuNoch keine Bewertungen

- Assistive TechnologyDokument3 SeitenAssistive Technologyapi-547693573Noch keine Bewertungen

- DSM-5 Personality Disorders PDFDokument2 SeitenDSM-5 Personality Disorders PDFIqbal Baryar0% (1)

- Practical Cookery 14th Edition SAMPLEDokument16 SeitenPractical Cookery 14th Edition SAMPLETendaiNoch keine Bewertungen

- Basic Operation Electrical - Total - Eng - Prot PDFDokument439 SeitenBasic Operation Electrical - Total - Eng - Prot PDFdidik setiawan100% (2)

- NSTP1 MODULE 3 Disaster Awareness Preparedness and ManagementDokument16 SeitenNSTP1 MODULE 3 Disaster Awareness Preparedness and Managementrenz dave100% (2)

- AQ-101 Arc Flash ProtectionDokument4 SeitenAQ-101 Arc Flash ProtectionYvesNoch keine Bewertungen

- Practice Problems Mat Bal With RXNDokument4 SeitenPractice Problems Mat Bal With RXNRugi Vicente RubiNoch keine Bewertungen

- Community Medicine DissertationDokument7 SeitenCommunity Medicine DissertationCollegePaperGhostWriterSterlingHeights100% (1)

- Full Bridge Phase Shift ConverterDokument21 SeitenFull Bridge Phase Shift ConverterMukul ChoudhuryNoch keine Bewertungen

- 2017 LT4 Wiring DiagramDokument10 Seiten2017 LT4 Wiring DiagramThomasNoch keine Bewertungen

- HumareaderDokument37 SeitenHumareaderStefan JovanovicNoch keine Bewertungen

- Coles Recipe MagazineDokument68 SeitenColes Recipe MagazinePhzishuang TanNoch keine Bewertungen