Beruflich Dokumente

Kultur Dokumente

ChemE 140 Design Project 2

Hochgeladen von

Shyam BhaktaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

ChemE 140 Design Project 2

Hochgeladen von

Shyam BhaktaCopyright:

Verfügbare Formate

Shyam Bhakta

Reimer

ChmEng 140

10 December 2012

Demonstration of the Mechanical Equivalent of Heat

I: A major motivating factor for the birth of thermodynamics in the 19

th

century and the

supersession of the caloric theory of heat by the kinetic theory of heat was the discovery of a

mechanical equivalent of heat, which established that mechanical energy and internal energy

are interconvertible; a certain amount of mechanical work is required to produce a certain

amount of heat. Prior to the kinetic theory, it had been thought that a self-repelling, massless

gas called caloric flows from warmer to cooler bodies, transmitting heat. Inspired by the

proposition of the kinetic theory of heat by his predecessors, J ames J oule made a pivotal

contribution to the preponderance of the kinetic theory by his work in establishing precisely

how much work is necessary to raise the temperature of water by a certain amount. The

establishment of work-heat equivalence gave rise to the theory of conservation of energy.

Here, we attempt to simulate J oules pivotal experiment and in doing so learn something

about thermodynamics.

II: m =mass

= density

V =volume

g =gravitational acceleration on

surface

h =displacement from

surface

C

P

=(H/T)

P

=specific heat capacity *

T =temperature

U

g

=gravitational potential energy

U

thermal

=thermal energy

n =number of drops of the weight

(

,

,

)

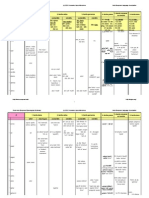

1.134 kg 9.81

m

s

2

6.5 m =

0.92g

mL

250 mL 2.177

J

g

19

= 6.9245

= 6.9245 for

= 1

= 1.44 for n = 10

Calculation of the specific heat capacity of canola oil was obtained by using a cubic function,

C

P

=-7E-08T

3

+2E-05T

2

+0.0009T +2.1536, R =0.9999, to fit the data in the following

publication in order to find the specific heat capacity at 19C.

* O.O. Fasina, Z. Colley. Viscosity and specific heat of vegetable oils as a function of

temperature: 35 to 180 C. Inter. J. Food Prop., 11 (4) (2008), pp. 738746

III: The apparatus, used to convert

mechanical energy to thermal energy of

the oil, consists of a Thermos

vacuum flask with a carved, fitted

Styrofoam lid through which the

mercury thermometer and paddle are

passed into the flask. The paddle is a

wooden paint sampler taped to a bolt

passing through a lid-protecting washer

outside the lid, terminating at a fixed

half of the locking mechanism. This

locking mechanism accommodates the

grooves of the upper half of the

mechanism, which is glued to a long bolt

wound with fishing wire to form the

spool. The bolt passes through a metal

loop and duct tape loop taped to

horizontal beams of wooden paint

samplers, taped to a vertical dowel. The

loops hold the bolt vertically with

minimal rotational restriction for the

purpose of resisting the tension on the

fishing wire from the metal disc weight it

is tied and taped to. Another wooden

dowel is used to guide the wire over the ledge of the window as the disc weight falls down. After

the weight has fallen, it is pulled up to the ledge, and the spool is spun to rewind the wire before

subsequent drops of the trial.

IV: A) The design had to be inexpensive and simple enough to construct in a short time due to

limited funds and human capital, and it had to be operable without external power sources.

Under these criteria, the design also had to maximize the conversion of mechanical energy to the

thermal energy of the oil and minimize passage of energy to other bodies and conversion of

energy to other forms. The first set of criteria prompted the choice of an apparatus mimicking

that of J oulesa falling weight inducing the agitation of a chosen liquid by a paddle. The

rotating mechanism to produce agitation had to be limited in mass in order for rotational work to

be negligible, and friction in the design had to be avoided and minimized wherever possible.

Reliability of the apparatus had to be minimized to the minimum necessary to conduct the three

trials in order to minimize wastage of money and human capital. Directions restricted the heat

collection material to be restricted to water and oil. Canola oil was chosen due to its lower

specific heat capacity than waters 4.186 J /gK.

B) & C) As per the calculations, ~7 drops should have raised the oils temperature by 1C,

which is the theoretical maximum for a 100% efficient apparatus. We decided to do 10 drops,

knowing there would be energy loss. Even after ten drops of the weight, the temperature was

only raised by 0.3C, 20.8% of the expected 1.44C from ten drops, giving our apparatus a

20.8% efficiency for conversion of mechanical energy to the oils thermal energy. The apparatus

performed suboptimally. We were hoping for at least 70-80% efficiency. J oules results were far

more accurate when compared to modern calculations of the specific heat capacity of water than

our experiment would have been in calculating the specific heat capacity of canola oil.

D) Detraction of mechanical energy to thermal energy of bodies other than oil was found in the

significant friction between the bolt and the loops supporting it vertically, between the wire and

the dowel, between the lid and the washer protecting its breakage, and between the paddle and

the orifice in the lid. The heavy bolt and locking mechanisms and the paddle and wire deducted

rotational energy while being spun. Perhaps the most significant error was acquired in the ~2 min

required to disjoin the locking mechanism and rewind the apparatus for subsequent drops. In that

time, thermal energy of the oil was lost to the container and the air above it, which was able to

circulate with the air outside through the space around the paddles widening hole in the lid.

E) We considered dropping the weight from a height seven story height, which would mean only

a single drop per trial was necessary to, under 100% efficiency, raise the oil temperature by 1C,

and would remove the need of rewinding the apparatus for subsequent drops in the trial,

significantly reducing heat loss. This option was attractive, but ruled out due to safety issues with

dropping a 2.5 lb metal disc weight from such a height. It was also considered that the paddle be

attached to gears on an axle of a cart, such that when the cart is rolled down an incline,

mechanical energy from the rotation of the wheels is used to turn the paddle in the oil. This

would, however, be less efficient than dropping a weight to drive the paddle, as rotational work

on the wheels contributes to the energy loss in addition to the rotational work on the paddle.

F) With infinite time and resources, I would improve the principle of this design by designing

the device to operate with a horizontal paddle, such that the wooden dowel and its friction would

be eliminated due to not having to redirect the wire. The bolt would be replaced with a thin

carbon fiber rod (strong, yet light) with two magnetic bands at the interface of the rod and the

loops supporting it. The metal and tape loops supporting the spool would be replaced with

opposite pole magnets, so that the tension force can be counteracted by the frictionless magnetic

force. The rod would pass into a vacuum-sealed chamber with walls packed with a silica rogel,

one of the best insulators. The volume of the chamber would be precisely 250 mL plus the

volume of a thin, multi-paneled carbon fiber paddle, passing through a vacuum tight orifice.

Residual air would be vacuumed out. A digital temperature probe inside the chamber would

relay the temperature. The apparatus would be positioned horizontally off a 45 m height in a

climate controlled facility before releasing the weight. Rotational work and heat loss through the

container would be calculated and deducted from the expected temperature.

All other materials were procured from the preexisting belongings of group members.

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Universalism and Animal CultureDokument27 SeitenUniversalism and Animal CultureShyam BhaktaNoch keine Bewertungen

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Separation of Organic Compounds Using Liquid-Liquid ExtractionDokument5 SeitenSeparation of Organic Compounds Using Liquid-Liquid ExtractionShyam BhaktaNoch keine Bewertungen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- A Scientist's ViewDokument1 SeiteA Scientist's ViewShyam BhaktaNoch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- Proto-Indo-European Etymological DictionaryDokument283 SeitenProto-Indo-European Etymological DictionarywoodwyseNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Flash ChromatographyDokument3 SeitenFlash ChromatographyHanyu ZhangNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Amino Acid Acidic PropertiesDokument1 SeiteAmino Acid Acidic PropertiesShyam BhaktaNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Don't Turn Your Back On Science - An Open LetterDokument15 SeitenDon't Turn Your Back On Science - An Open LetterShyam BhaktaNoch keine Bewertungen

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Organic Compound Separation Using Liquid-Liquid ExtractionDokument8 SeitenOrganic Compound Separation Using Liquid-Liquid ExtractionShyam BhaktaNoch keine Bewertungen

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- RICHARD DAWKINS - Religion of ScienceDokument23 SeitenRICHARD DAWKINS - Religion of Scienceanon-991322100% (11)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- ChemE 140 Design Project 1Dokument5 SeitenChemE 140 Design Project 1Shyam BhaktaNoch keine Bewertungen

- A Scientist's ViewDokument1 SeiteA Scientist's ViewShyam BhaktaNoch keine Bewertungen

- All Our YesterdaysDokument4 SeitenAll Our YesterdaysShyam BhaktaNoch keine Bewertungen

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Thermodynamic and Kinetic Control: Reaction ADokument2 SeitenThermodynamic and Kinetic Control: Reaction AShyam BhaktaNoch keine Bewertungen

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Tips For StereochemistryDokument1 SeiteTips For StereochemistryShyam BhaktaNoch keine Bewertungen

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- NMR Worksheet 1 KeyDokument2 SeitenNMR Worksheet 1 KeyShyam BhaktaNoch keine Bewertungen

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Properties & Reactions of AlkenesDokument2 SeitenProperties & Reactions of AlkenesShyam BhaktaNoch keine Bewertungen

- NMR Worksheet 1 CorrectionsDokument1 SeiteNMR Worksheet 1 CorrectionsShyam BhaktaNoch keine Bewertungen

- Review Reactivity of Functional Groups and ReagentsDokument1 SeiteReview Reactivity of Functional Groups and ReagentsShyam BhaktaNoch keine Bewertungen

- NMR Worksheet 2 KeyDokument4 SeitenNMR Worksheet 2 KeyShyam BhaktaNoch keine Bewertungen

- NMR Worksheet 4 CorrectionsDokument1 SeiteNMR Worksheet 4 CorrectionsShyam BhaktaNoch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Problem 2-Kolbe Reaction: Created by Hanna Key Grinnell CollegeDokument1 SeiteProblem 2-Kolbe Reaction: Created by Hanna Key Grinnell CollegeShyam BhaktaNoch keine Bewertungen

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- NMR Worksheet 4 KeyDokument3 SeitenNMR Worksheet 4 KeyShyam BhaktaNoch keine Bewertungen

- Grignard Reaction Formal Report InstructionsDokument2 SeitenGrignard Reaction Formal Report InstructionsShyam BhaktaNoch keine Bewertungen

- NMR Worksheet 2Dokument5 SeitenNMR Worksheet 2Shyam BhaktaNoch keine Bewertungen

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- NMR Worksheet Analysis and PredictionsDokument14 SeitenNMR Worksheet Analysis and PredictionsShyam BhaktaNoch keine Bewertungen

- Common Arrow Pushing MistakesDokument1 SeiteCommon Arrow Pushing MistakesShyam BhaktaNoch keine Bewertungen

- NMR Worksheet 1Dokument2 SeitenNMR Worksheet 1Shyam BhaktaNoch keine Bewertungen

- Cuprate AdditionDokument2 SeitenCuprate AdditionShyam BhaktaNoch keine Bewertungen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Edman Degradation IIDokument1 SeiteEdman Degradation IIShyam BhaktaNoch keine Bewertungen

- HW3 Molecular Polymorphism SolutionDokument2 SeitenHW3 Molecular Polymorphism SolutionMiriam KaufmanNoch keine Bewertungen

- Physics NET/JRF Practice QuestionsDokument44 SeitenPhysics NET/JRF Practice QuestionsSibadatta MaharanaNoch keine Bewertungen

- Geography Final Objective Life TimeDokument109 SeitenGeography Final Objective Life Timegowrishankar nayanaNoch keine Bewertungen

- Topics1 12chem230Dokument450 SeitenTopics1 12chem230MelissaNoch keine Bewertungen

- Petroleum Systems of MEDokument10 SeitenPetroleum Systems of MEDiya Disha100% (1)

- Site AnalysisDokument11 SeitenSite AnalysisVerina IskanderNoch keine Bewertungen

- Energy Efficient School DesignDokument31 SeitenEnergy Efficient School DesignXando FredericoNoch keine Bewertungen

- Petroleum Systems of South Atlantic Marginal BasinsDokument13 SeitenPetroleum Systems of South Atlantic Marginal Basinszulma_anayaNoch keine Bewertungen

- Activity 9.1: OIL Eeming With IFEDokument16 SeitenActivity 9.1: OIL Eeming With IFEAlisha ChopraNoch keine Bewertungen

- GTU BE Semester VI Exam on Wind and Solar EnergyDokument1 SeiteGTU BE Semester VI Exam on Wind and Solar Energyfeyayel990Noch keine Bewertungen

- Phytoremediation: From Theory Toward Practice: Vimal Chandra Pandey and Omesh BajpaiDokument49 SeitenPhytoremediation: From Theory Toward Practice: Vimal Chandra Pandey and Omesh BajpaiMalik HopeNoch keine Bewertungen

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Panduan Geologi Struktur TGL FT UGMDokument37 SeitenPanduan Geologi Struktur TGL FT UGMKhansamutiayNoch keine Bewertungen

- Y9 HT3 Holiday Homeworkbonding No AnswersDokument8 SeitenY9 HT3 Holiday Homeworkbonding No Answersaqeelf146Noch keine Bewertungen

- Unit 1 Scientific Investigation - Chapter 1 Thinking Like A ScientistDokument2 SeitenUnit 1 Scientific Investigation - Chapter 1 Thinking Like A ScientistKayla OsbornNoch keine Bewertungen

- Planetary Atmospheric ElectricityDokument521 SeitenPlanetary Atmospheric ElectricityArmando Heilmann100% (1)

- Environmental Impact of Cement ProductionDokument2 SeitenEnvironmental Impact of Cement ProductionRahul SainiNoch keine Bewertungen

- Biology ProjectDokument19 SeitenBiology ProjectShriti Sikta Panda100% (1)

- Hydrogen ApplicationDokument66 SeitenHydrogen ApplicationHisham Zainal AbidinNoch keine Bewertungen

- Heat of Combustion of Liquid Hydrocarbon Fuels by Bomb CalorimeterDokument10 SeitenHeat of Combustion of Liquid Hydrocarbon Fuels by Bomb CalorimetersaderfendeNoch keine Bewertungen

- Geopolitics and Current Affairs Handwritten Notes For UPSCDokument22 SeitenGeopolitics and Current Affairs Handwritten Notes For UPSCNarendranNoch keine Bewertungen

- ElectricityDokument121 SeitenElectricityKhairul Hazwan100% (3)

- Lecture 1 1489485680Dokument52 SeitenLecture 1 1489485680Dato TevzadzeNoch keine Bewertungen

- CORSIKA A Monte Carlo Code To Simulate Extensive Air ShowersDokument98 SeitenCORSIKA A Monte Carlo Code To Simulate Extensive Air ShowersRadovan KovacevicNoch keine Bewertungen

- Introduction To Heat TransferDokument15 SeitenIntroduction To Heat TransferRishabh KumarNoch keine Bewertungen

- 3540660208Dokument223 Seiten3540660208Iswahyudi AlamsyahNoch keine Bewertungen

- Chap 3 BDokument32 SeitenChap 3 BMike BelayNoch keine Bewertungen

- Energy Conservation Tips Under 40 CharactersDokument21 SeitenEnergy Conservation Tips Under 40 CharactersRajesh SattiNoch keine Bewertungen

- Experiment 8 - Report - Specific HeatDokument3 SeitenExperiment 8 - Report - Specific HeatRami HammoudNoch keine Bewertungen

- Mitsubishi Lossnay Energy Recovery Ventilator (ERV) BrochureDokument20 SeitenMitsubishi Lossnay Energy Recovery Ventilator (ERV) Brochuree-ComfortUSA100% (1)

- Climate Change 11 FactsDokument4 SeitenClimate Change 11 Factsfahadraja78Noch keine Bewertungen

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsVon EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNoch keine Bewertungen

- Guidelines for Implementing Process Safety ManagementVon EverandGuidelines for Implementing Process Safety ManagementNoch keine Bewertungen

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisVon EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisBewertung: 5 von 5 Sternen5/5 (1)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsVon EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsBewertung: 4 von 5 Sternen4/5 (11)

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeVon EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNoch keine Bewertungen

- A Complete Guide to Safety Officer Interview Questions and AnswersVon EverandA Complete Guide to Safety Officer Interview Questions and AnswersBewertung: 4 von 5 Sternen4/5 (1)

- Guidelines for Auditing Process Safety Management SystemsVon EverandGuidelines for Auditing Process Safety Management SystemsNoch keine Bewertungen

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesVon EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesBewertung: 5 von 5 Sternen5/5 (1)

- Introduction to Petroleum Process SafetyVon EverandIntroduction to Petroleum Process SafetyBewertung: 3 von 5 Sternen3/5 (2)