Beruflich Dokumente

Kultur Dokumente

Schlumberger Oilfield Review

Hochgeladen von

Bahman MadadiCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Schlumberger Oilfield Review

Hochgeladen von

Bahman MadadiCopyright:

Verfügbare Formate

Winter 2010/2011

Enhanced Oil Recovery

Arctic Operations

Oil Shale

Oilfield Review

S

C

H

L

U

M

B

E

R

G

E

R

O

I

L

F

I

E

L

D

R

E

V

I

E

W

W

I

N

T

E

R

2

0

1

0

/

2

0

1

1

V

O

L

U

M

E

2

2

N

U

M

B

E

R

4

38607schD1R1.qxp:38607schD1R1 3/1/11 9:29 PM Page 1

11-OR-0001

38607schD1R1.qxp:38607schD1R1 3/1/11 9:29 PM Page 2

The global imbalance between supply and demand for oil

and gas is growing. This trend is pointed out in studies

from numerous organizations that watch the E&P industry,

including the International Energy Agency, Cambridge

Energy Research Associates and the World Petroleum

Council. Some studies indicate that the decline rate of

existing oil elds is increasing signicantly over time, so

additional production is becoming progressively more cru-

cial to bridge the supply and demand gap.

In my opinion, neither we, as professionals in the oil and

gas industry, nor the resource owners can be satised with

recovery factors that average well below 40%. We need to

do better. Enhanced oil recovery (EOR) is a vital means to

achieve additional production and recovery from new and

existing elds. In addition, several sizable resources, such

as extra-heavy oil elds, cannot be developed without EOR

techniques. The high capital investments for offshore and

deepwater projects warrant a reassessment of development

philosophies because production options once considered

tertiary now need to be considered as possibilities in initial

development stages.

EOR techniques employ fundamental physical and chem-

ical rock and uid interactions to improve reservoir sweep

and reduce residual oil saturations (see Has the Time Come

for EOR? page 16). Of the three basic EOR processes

thermal, gas injection and chemicalused to achieve

these ends, thermal and gas injection are the most mature.

Chemical EOR is advancing rapidly in the use of mobility

improvements (polymer and steam), residual saturation

reducers (surfactants and designer waterooding) or com-

binations thereof (alkali-surfactant-polymer ooding).

Extensive customization, fundamental to ensure that an

EOR process will be successful for a specic eld, contrib-

utes signicantly to the complexity and cost of EOR projects.

This customization usually includes detailed laboratory

studies, eld trials, pilots and phased developments, all

needed to reduce project risk before sanction. Unfortunately,

this also leads to quite long development times and higher

up-front investment, hence, longer payback times. Faster

maturation workows are required, which can be enabled

by technological solutions to speed up appraisal and devel-

opment. The scal regimes that work well for primary and

secondary developments in several countries stand in the

way of economic EOR projects, thus change of the scal

frameworks is required as well.

Enhanced recovery comes at a price. The technical costs

in dollars per barrel produced are notably higher than

those of primary or secondary recovery methods. In addi-

tion, the environmental footprint of some EOR techniques

Enhanced Oil Recovery: Here to Stay

1

can be signicant and necessitates mitigation, also adding

to the costs. EOR processes developed in the past are not

necessarily the solutions we need for today and tomorrow.

We therefore need continued investment in EOR technology

development, from the processes and fundamental concepts,

to new engineering solutions, to surveillance techniques

that improve sweep efciency.

Recent research efforts have greatly advanced the funda-

mental understanding of the rock and uid interface in

chemical EOR. This understanding has opened up new

opportunities that have lower costs and higher recovery

efciencies. It has also increased the scope for recovery to

domains that were previously thought to be unattractive

as targets for EOR. However, more work is required. If we

want to reduce the EOR technology timeline and deploy

projects earlier, we must encourage wider cooperation

between industry, academia and resource holders. There

must be sharing of risk, data and knowledge while address-

ing and overcoming potential blocks such as intellectual

property ownership and other commercial aspects.

I am therefore pleased that Schlumberger and Shell

have recently agreed to start a signicant landmark

research partnership. The research is aimed at discovering

and developing new methodologies and technologies for

enhancing recovery, with the aim of addressing many of

the challenges mentioned above. Enhanced oil recovery is

here to stay.

Jeroen Regtien

Vice President, Hydrocarbon Recovery Technologies

Innovation, Research & Development

Shell International Exploration and Production

Jeroen Regtien leads the improved oil recovery/enhanced oil recovery, smart

field, CO

2

storage and rock and fluid science research and development

activities in the Shell Projects and Technology Group. His extensive career in

the upstream oil and gas industry has included roles as technical manager,

chief petroleum engineer, manager of strategy and planning, head of geother-

mal energy, asset manager and development manager during assignments in

Brunei, Australia, Oman, the USA and The Netherlands. He is a member of

the World Petroleum Council and International Advisory Board of the Oman

Research Council. Jeroen is an experimental physicist with an MSc degree

from the University of Groningen, The Netherlands.

38607schD2R1.indd 1 2/21/11 9:22 PM

www.slb.com/oilfieldreview

Schlumberger

Oilfield Review

1 Enhanced Oil Recovery: Here to Stay

Editorial contributed by Jeroen Regtien, Vice President, Hydrocarbon Recovery Technologies

Innovation, Research & Development; Shell International Exploration and Production

4 Coaxing Oil from Shale

Oil shale contains copious amounts of immature organic

material. Heating the rock accelerates the normal maturation

process to generate oil and gas. Historically, oil shales were

mined, crushed and heated at the surface, but companies are

finding it may be more efficient to access these formations

through boreholes, heat the subsurface and bring the oil to

the surface.

16 Has the Time Come for EOR?

Enhanced oil recovery (EOR) methods are designed to

produce additional oil beyond what is obtainable through

traditional methods of pressure depletion and simple

pressure maintenance. EOR techniques include miscible

gasflooding, chemical flooding and thermal recovery.

This article describes the basics of these methods; field

examples illustrate their application.

Executive Editor

Mark A. Andersen

Advisory Editor

Lisa Stewart

Senior Editors

Matt Varhaug

Rick von Flatern

Editors

Vladislav Glyanchenko

Tony Smithson

Contributing Editors

Rana Rottenberg

Ginger Oppenheimer

Design/Production

Herring Design

Steve Freeman

Illustration

Chris Lockwood

Mike Messinger

George Stewart

Printing

Wetmore Printing Company

Curtis Weeks

Oilfield Review is published quarterly and

printed in the USA.

Visit www.slb.com/oilfieldreview for

electronic copies of articles in multiple

languages.

2011 Schlumberger. All rights reserved.

Reproductions without permission are

strictly prohibited.

For a comprehensive dictionary of oilfield

terms, see the Schlumberger Oilfield

Glossary at www.glossary.oilfield.slb.com.

About Oilfield Review

Oilfield Review, a Schlumberger journal,

communicates technical advances in

finding and producing hydrocarbons

to employees, clients and other oilfield

professionals. Contributors to articles

include industry professionals and experts

from around the world; those listed with

only geographic location are employees

of Schlumberger or its affiliates.

On the cover:

Engineers prepare a slim tube for a test

of minimum miscibility pressure at the

Schlumberger Reservoir Fluids Center in

Houston. The sand-filled metal coil

provides sufficient length for a multiple-

contact miscibility condition to develop

between a crude oil in the coil and an

injected gas. Miscible gas injection is

one of several enhanced oil recovery

methods used to sweep post-waterflood

residual oil from a reservoir (inset ).

2

38607schD3R1.qxp:38607schD3R1 2/21/11 10:58 PM Page 2

Winter 2010/2011

Volume 22

Number 4

ISSN 0923-1730

50 Contributors

52 New Books and Coming in Oilfield Review

54 Annual Index

3

36 Petroleum Potential of the Arctic:

Challenges and Solutions

Although constituting only about 6% of the Earths surface,

the Arctic potentially contains a significant portion of the

worlds undiscovered petroleum resources and, thus, is

attracting the growing attention of oil and gas companies.

However, this region poses numerous challenges, including a

harsh climate, short operational season, complex surface and

shallow-subsurface conditions and increasing environmental

restrictions. Operators and service companies are improving

existing technologies and developing new ones to address the

unique challenges of this remote region.

Abdulla I. Al-Kubaisy

Saudi Aramco

Ras Tanura, Saudi Arabia

Dilip M. Kale

ONGC Energy Centre

Delhi, India

Roland Hamp

Woodside Energy Ltd.

Perth, Australia

George King

Apache Corporation

Houston, Texas, USA

Richard Woodhouse

Independent consultant

Surrey, England

Advisory Panel

Editorial correspondence

Oilfield Review

5599 San Felipe

Houston, Texas 77056 USA

(1) 713-513-1194

Fax: (1) 713-513-2057

E-mail: editorOilfieldReview@slb.com

Subscriptions

Client subscriptions can be obtained

through any Schlumberger sales office.

Clients can obtain additional subscrip-

tion information and update subscription

addresses at www.slb.com/oilfieldreview.

Distribution inquiries

Tony Smithson

Oilfield Review

12149 Lakeview Manor Dr.

Northport, Alabama 35475 USA

(1) 832-886-5217

Fax: (1) 281-285-0065

E-mail: DistributionOR@slb.com

Paid subscriptions are available from

Oilfield Review Services

Lane End Farm, Kelsall Road

Ashton Hayes, Chester CH3 8BH UK

Fax: (44) 1829 759163

E-mail: subscriptions@oilfieldreview.com

Current subscription rates are available

at www.oilfieldreview.com.

38607schD3R1.qxp:38607schD3R1 2/21/11 10:58 PM Page 3

4 Oileld Review

Oilfield Review

Winter 10

Oil Shale Fig. Opener

ORWIN10-OilShl Fig. Opener

Coaxing Oil from Shale

Oil shale is plentiful, but producing its petroleum can be complicated. Since the

1800s, these rocks have been mined and fed into surface facilities where liquid

hydrocarbons were extracted. Now, operators are developing methods to heat the

rock in situ and pipe the liberated oil to the surface. They are also adapting oileld

technology to evaluate these deposits and estimate their uid yields.

Pierre Allix

Total

Pau, France

Alan Burnham

American Shale Oil LLC

Rie, Colorado, USA

Tom Fowler

Shell International Exploration and Production

Houston, Texas, USA

Michael Herron

Robert Kleinberg

Cambridge, Massachusetts, USA

Bill Symington

ExxonMobil Upstream Research Company

Houston, Texas

Oileld Review Winter 2010/2011: 22, no. 4.

Copyright 2011 Schlumberger.

For help in preparation of this article, thanks to Neil Bostrom,

Jim Grau, Josephine Mawutor Ndinyah, Drew Pomerantz

and Stacy Lynn Reeder, Cambridge, Massachusetts; John

R. Dyni, US Geological Survey, Denver; Martin Kennedy,

University of Adelaide, South Australia, Australia; Patrick

McGinn, ExxonMobil Corporation, Houston; Eric Oudenot,

London; Kenneth Peters, Mill Valley, California, USA; and

Carolyn Tucker, Shell Oil, Denver.

ECS and RST are marks of Schlumberger.

CCR is a mark of American Shale Oil LLC.

Electrofrac is a mark of ExxonMobil.

Rock-Eval is a mark of the Institut Franais du Ptrole.

Oil shale is the term given to very ne-grained

sedimentary rock containing relatively large

amounts of immature organic material, or kero-

gen. It is essentially potential source rock that

would have generated hydrocarbons if it had

been subjected to geologic burial at the requisite

temperatures and pressures for a sufcient time.

In nature, it can take millions of years at

burial temperatures between 100C and 150C

[210F and 300F] for most source rocks to gen-

erate oil. But the process can be accelerated by

heating the kerogen-rich rock more quickly and

to higher temperatures, generating liquid hydro-

carbons in much shorter time: from a matter of

minutes to a few years.

1. Dyni JR: Geology and Resources of Some World

Oil-Shale Deposits, Reston, Virginia, USA: US Geological

Survey Scientic Investigations, Report 2005-5294, 2006.

Smith MA: Lacustrine Oil Shales in the Geologic

Record, in Katz BJ (ed): Lacustrine Basin Exploration:

Case Studies and Modern Analogs. Tulsa: The American

Association of Petroleum Geologists, AAPG Memoir 50

(1990): 4360.

38607schD4R1.indd 4 2/21/11 9:24 PM

Winter 2010/2011 5

Forcing petroleum products from immature

formations is one of the more difcult ways to

extract energy from the Earth, but that has not

kept people from trying. From prehistoric times

to the present, oil shale, like coal, has been

burned as fuel. Methods for coaxing oil from the

rock to produce liquid fuels have existed for hun-

dreds of years. The earliest such ventures mined

oil shale and heated it in processing facilities on

the surface to obtain liquid shale oil and other

petroleum products. More recently, methods

have been tested to heat the rock in situ and

extract the resulting oil in a more conventional

way: through boreholes. These approaches are

being developed, but the worlds oil shale

resources remain largely untapped.

Current estimates of the volumes recoverable

from oil shale deposits are in the trillions of

barrels, but recovery methods are complicated

and expensive. However, with todays sustained

high prices and predictions of future oil short-

ages in the coming decades, producing oil from

shale may soon become economically viable.

Therefore, several companies and countries are

working to nd practical ways to exploit these

unconventional resources.

This article explains how oil shales form, how

they have been exploited in various parts of the

world and which techniques are currently being

developed for tapping the energy they contain.

Examples from the western US illustrate innova-

tive applications of oileld technology for evaluat-

ing oil shale deposits and assessing their richness.

Oil Shale Formation

Oil shales form in a variety of depositional envi-

ronments, including freshwater and saline lakes

and swamps, near-shore marine basins and

subtidal shelves.

1

They may occur as minor sedi-

mentary layers or as giant accumulations hun-

dreds of meters thick, covering thousands of

square kilometers (above right).

As with other sedimentary rocks, composi-

tions of shales containing organic material range

from mostly silicates to mostly carbonates, with

varying amounts of clay minerals (right). Mineral

composition has little effect on oil yield, but it

can impact the heating process. Clay minerals

contain water, which may affect the amount of

heat required to convert the organic material to

petroleum. Carbonate shales, upon heating, gen-

erate additional CO

2

that must be considered in

any oil shale development program. Many depos-

its also contain valuable minerals and metals

such as alum, nahcolite, sulfur, vanadium, zinc,

copper and uranium, which may themselves be

targets of mining operations.

>

Outcropping oil shales. The oil shale of the Green River Formation in the Piceance Creek basin in

Colorado covers about 3,100 km

2

[1,200 mi

2

]. The inset (top) shows a hand specimen from that region,

with dark layers of rich oil shale interbedded with pale layers of lean shale. The white scale bar is

7.2 cm [2.8 in.] long. (Outcrop photograph courtesy of Martin Kennedy, University of Adelaide. Inset

photograph courtesy of John R. Dyni, US Geological Survey, Denver.)

Oilfield Review

Winter 10

Oil Shale Fig. 1

ORWIN10-OilShl Fig. 1

>

Shale mineralogy. Worldwide average shale composition regardless of organic content (black

diamond) is high in clay minerals and contains some quartz and feldspar with little or no calcite or

dolomite. Organic-rich shales (other diamonds and dots) tend to have a wider variety of compositions.

Oil shales from the Green River Formation are highlighted in dotted blue ovals. Those from the

Parachute Creek Member (green squares) have low clay-mineral content, while oil shales from the

Garden Gulch Member (red dots) are richer in clay minerals. Gray lines subdivide the triangle into

compositional regions. (Adapted from Grau et al, reference 32.)

Oilfield Review

Winter 10

Oil Shale Fig. 2

ORWIN10-OilShl Fig. 2

Clay

Minerals

Calcite and Dolomite

Siliceous

dolomite

Eagle Ford

Niobrara

Calcareous

or dolomitic

mudstone

Argillaceous

marlstone

Siliceous

marlstone

Argillaceous

mudstone

(traditional shale)

Siliceous

mudstone

Monterey

Montney

Muskwa

Barnett

Bakken

Haynesville

Lower

Marcellus

Siliceous shale

Monterey

porcellanite

Bazhenov

Average shale

Garden Gulch Member

Parachute Creek Member

Gas shales from Poland

Quartz and

Feldspar

Various other locations

38607schD4R1.indd 5 2/21/11 9:25 PM

6 Oileld Review

Interspersed between the grains of these

rocks is kerogeninsoluble, partially degraded

organic material that has not yet matured enough

to generate hydrocarbons. The kerogen in oil

shale has its origins predominantly in the

remains of lacustrine and marine algae, and con-

tains minor amounts of spores, pollen, fragments

of herbaceous and woody plants and remnants of

other lacustrine, marine and land ora and

fauna. The type of kerogen has a bearing on what

kind of hydrocarbon it will produce as it matures

thermally.

2

The kerogens in oil shale fall into the

Type I and Type II classications used by geo-

chemists (left).

The thermally immature kerogens in oil

shales have undergone low-temperature diagen-

esis but no further modications.

3

Some other

organic-rich shales may have reached thermal

maturity but not yet expelled all of their liquid

petroleum products. To distinguish them from oil

shales, for the purposes of this article, mature,

organic-rich shales that have not expelled all of

their oil are called oil-bearing shales. Examples

of these are the Bakken, Monterey and Eagle

Ford shales, which currently produce oil in the

US. Other organic-rich shales are more thermally

mature or of different kerogen type and contain

gas instead of oil, such as the Barnett, Fayetteville

and Marcellus shales, also in the US.

4

Many shales attain source-rock status, achiev-

ing full maturity and expelling their oil and natu-

ral gas, which then migrate, and under the proper

conditions, accumulate and become trapped

until discovered and produced. Some such shales

can manifest in several ways. For example, the

Kimmeridge Clay Formation is the main source

rock for the oil elds of the North Sea, but where

it outcrops in England it is an oil shale. Similarly,

the Green River shale, which is presumed to be

the source rock for the oil produced from the

Red Wash eld in Utah, USA, outcrops in the

same region. It also contains the worlds largest

reserves of shale oil.

Oil Shales in Time and Space

The earliest use of oil shale was as fuel for heat,

but there is also evidence of weaponry applica-

tions, such as aming, oil shaletipped arrows

shot by warriors in 13th-century Asia.

5

The rst

known use of liquid petroleum derived from shale

dates to the mid-1300s, when medical practitio-

ners in what is now Austria touted its healing

properties. By the late 1600s, several municipali-

ties in Europe were distilling oil from shale for

heating fuel and street lighting. In the 1830s,

mining and distillation activities began in France,

and reached commercial levels there and in

Canada, Scotland and the US by the mid-1800s.

The country with the longest history of commer-

cial shale oil production is Scotland, where mines

operated for more than 100 years, nally closing

in 1962.

6

Fuel shortages during the two World Wars

encouraged other countries to exploit their oil

shale resources. Tapping a kerogen-rich carbon-

ate sequence, Estonia began mining oil shale

from a deposit about 20 to 30 m [65 to 100 ft]

thick that covers hundreds of square kilometers

in the northern part of the country. The operation

continues today.

The shale, which occurs as 50 or so beds of

organic-rich shallow marine sediments alternat-

ing with biomicritic limestone, is produced from

open-pit mines at depths to 20 m. Where the shale

is buried deeper than that, down to 70 m [230 ft],

it is accessed by underground mines. Roughly

three-quarters of the mined rock supplies fuel for

electric power plants, providing 90% of the coun-

trys electricity. The remainder is used for heating

and as feedstock for petrochemicals. In the past

90 years, 1 10

9

metric tons [1 10

9

Mg, or

1.1 billion tonUS] of oil shale has been mined

from the primary Estonia deposit (left).

7

China has a signicant history of oil shale min-

ing as well, with shale oil production beginning in

the 1920s. In the Fushun area, extensive shale lay-

ers 15 to 58 m [49 to 190 ft] thick are mined along

with coal, both from Eocene lacustrine deposits.

The total resource of oil shale at Fushun is esti-

mated at 3.3 10

9

Mg [3.6 billion tonUS].

8

As of

1995, Fushuns petroleum production capacity

from shale was 66,000 m

3

/yr [415,000 bbl/yr].

Brazil began developing an oil shale mining

and processing industry in the 1960s. The national

oil company, Petrleo Brasileiro SA (Petrobras),

>

Kerogen maturation. The Type I and Type II

kerogens in most oil shales are not yet mature

enough to generate hydrocarbons. As these

kerogens matureusually through geologic burial

and the increased heat associated with itthey

transform into oil, and then with more heat, to gas.

Methods that accelerate the maturation process

attempt to control heat input, thereby producing

only the desired type of hydrocarbon.

Oilfield Review

Winter 10

Oil Shale Fig. 3

ORWIN10-OilShl Fig. 3

1.5

H

y

d

r

o

g

e

n

/

c

a

r

b

o

n

r

a

t

i

o

1.0

0.5

0 0.1 0.2

Type I

Type II

Type III

Type IV

Oxygen/carbon ratio

Dry gas

Increasing

maturation

CO

2

, H

2

O

Oil

Wet gas

No hydrocarbon

potential

Products Given

off from Kerogen

Maturation

>

More than a century of commercial oil shale mining. Tonnage of mined shale rose dramatically in the

1970s when oil prices were also rising; it peaked in 1980, but declined as oil prices made shale oil

noncompetitive. Several countries continue to mine oil shale as a source of heat, electricity, liquid fuel

and chemical feedstock. Since 1999, mined shale tonnage has started to increase again. (Data from

1880 to 1998 from Dyni, reference 1.)

Oilfield Review

Winter 10

Oil Shale Fig. 4

ORWIN10-OilShl Fig. 4

M

i

n

e

d

s

h

a

l

e

,

m

i

l

l

i

o

n

m

e

t

r

i

c

t

o

n

s

40

50

30

20

10

0

1880 1900 1920 1940 1960 1980 2000 1890 1910 1930 1950 1970 1990

Year

2010

Germany

China

Brazil

Scotland

Russia

Estonia

38607schD4R1.indd 6 2/21/11 9:25 PM

Winter 2010/2011 7

established the Shale Industrialization Business

Unit (SIX) to exploit the countrys several

large oil shale deposits. The Irati Formation,

which outcrops extensively in southern Brazil,

contains reserves of more than 1.1 10

8

m

3

[700 million bbl] of oil and 2.5 10

10

m

3

[880 Bcf]

of gas.

9

Surface facilities at So Mateus do Sul, in

the state of Paran, are capable of processing

7,100 Mg [7,800 tonUS] of shale per day to produce

fuel oil, naphtha, liqueed petroleum gas (LPG),

shale gas, sulfur and asphalt additives.

To date, almost all the oil extracted from the

worlds oil shale has been from rock that was

mined and then processed at surface facilities.

Mining is typically performed either through sur-

face mining or through underground mining

using the room-and-pillar method associated

with coal mining. After mining, oil shale is trans-

ported to a facilitya retortwhere a heating

process converts kerogen to oil and gas and sepa-

rates the hydrocarbon fractions from the mineral

fraction. This mineral waste, which contains sub-

stantial amounts of residual kerogen, is called

spent shale. After retorting, the oil must be

upgraded by further processing before being sent

to a renery.

Mining operations require handling massive

volumes of rock, disposing of spent shale and

upgrading the heavy oil. The environmental

impact can be signicant, causing disruption of

the surface and requiring substantial volumes of

water. Water is needed for controlling dust, cool-

ing spent shale and upgrading raw shale oil.

Estimates of water requirements range from 2 to

5 barrels of water per barrel of oil produced.

10

The worlds oil shale deposits are widely distrib-

uted; hundreds of deposits occur in more than 30

countries (above). Many formations are at depths

beyond mining capabilities or in environmentally

fragile settings. In these areas, heating the rocks in

place may offer the best method to hasten kerogen

maturation. If ways can be found to do this safely,

efciently and cost effectively, the potential prize is

immense. By conservative estimatebecause oil

shales have not been the target of modern explora-

tion effortsresources of the worlds shale oil total

about 5.1 10

11

m

3

[3.2 trillion bbl].

11

It is estimated

that more than 60% of this amountroughly

3 10

11

m

3

[2 trillion bbl]is located in the US.

Converting Oil Shale to Shale Oil

Translating volume of rock to volume of recover-

able oil requires information on oil shale proper-

ties, such as organic content and grade, which can

vary widely within a deposit. Traditionally, for the

purposes of surface retorting, oil shale grade is

determined by the modied Fischer assay method,

which measures the oil yield of a shale sample in

a laboratory retort.

12

A 100-g [0.22-lbm] sample is

crushed and sieved through a 2.38-mm [8] mesh

screen, heated in an aluminum retort to 500C

[930F] at a rate of 12C/min [22F/min] and

then held at that temperature for 40 min.

13

The

resulting distilled vapors of oil, gas and water are

condensed and then separated by centrifuge. The

quantities delivered are weight percentages of oil,

water and shale residue and the specic gravity of

the oil. The difference between the weight of the

products and that of the starting material is

2. Tissot BP: Recent Advances in Petroleum Geochemistry

Applied to Hydrocarbon Exploration, AAPG Bulletin 68,

no. 5 (May 1984): 545563.

3. For more on diagenesis: Ali SA, Clark WJ, Moore WR

and Dribus JR: Diagenesis and Reservoir Quality,

Oileld Review 22, no. 2 (Summer 2010): 1427.

4. Boyer C, Kieschnick J, Suarez-Rivera R, Lewis RL and

Waters G: Producing Gas from Its Source, Oileld

Review 18, no. 3 (Autumn 2006): 3649.

5. Moody R: Oil & Gas Shales, Denitions and Distributions

in Time & Space, presented at the Geological Societys

History of Geology Group Meeting, Weymouth, England,

April 2022, 2007, http://www.geolsoc.org.uk/gsl/cache/

offonce/groups/specialist/hogg/pid/3175;jsessionid=

4CC09ACD6572AE54454755DE4A9077DC (accessed

September 14, 2010).

6. Shale Villages: A Very Brief History of the Scottish Shale

Oil Industry, http://www.almondvalley.co.uk/V_

background_history.htm (accessed September 24, 2010).

>

Signicant oil shale deposits. Most of the known high-quality shale oil resources are in these 14 countries. (Data from Knaus et al, reference 11.)

Oilfield Review

Winter 10

Oil Shale Fig. 5

ORWIN10-OilShl Fig. 5

Brazil (4)

82

Canada (11)

15

United States (1)

2,085

France (12)

7

Italy (5)

73

Russia (2)

247

China (10)

16

Democratic

Republic of

Congo (3)

100

Australia (8)

31

Shale oil resource,

billion bbl

(global ranking)

Morocco (6)

53

Egypt (13)

5.7

Estonia (9)

16

Israel (14)

4

Jordan (7)

34

7. Sabanov S, Pastarus J-R and Nikitin O: Environmental

Impact Assessment for Estonian Oil Shale Mining

Systems, paper rtos-A107, presented at the

International Oil Shale Conference, Amman, Jordan,

November 79, 2006.

8. Dyni, reference 1.

9. Petrobras SIX Shale Industrialization Business Unit:

Shale in Brazil and in the World, http://www2.

petrobras.com.br/minisite/renarias/petrosix/ingles/oxisto/

oxisto_reservas.asp (accessed November 10, 2010).

10. Bartis JT, LaTourrette T, Dixon L, Peterson DJ and

Cecchine G: Oil Shale Development in the United States:

Prospects and Policy Issues. Santa Monica, California,

USA: The RAND Corporation, Monograph MG-414, 2005.

11. Knaus E, Killen J, Biglarbigi K and Crawford P: An

Overview of Oil Shale Resources, in Ogunsola OI,

Hartstein AM and Ogunsola O (eds): Oil Shale: A

Solution to the Liquid Fuel Dilemma. Washington, DC:

American Chemical Society, ACS Symposium

Series 1032 (2010): 320.

12. Dyni, reference 1.

13. Screen mesh of 8 means the particles can pass

through a wire screen with 8 openings per linear inch.

38607schD4R1.indd 7 2/21/11 9:25 PM

8 Oileld Review

recorded as gas plus loss. The oil yield is

reported in liters per metric ton (L/Mg) or gallons

per short ton (galUS/tonUS) of raw shale.

Commercially attractive oil shale deposits yield at

least 100 L/Mg [24 galUS/tonUS], and some reach

300 L/Mg [72 galUS/tonUS].

14

The Fischer assay method does not measure

the total energy content of an oil shale because

the gases, which include methane, ethane, pro-

pane, butane, hydrogen, H

2

S and CO

2

, can have

signicant energy content, but are not individu-

ally specied. Also, some retort methods, espe-

cially those that heat at a different rate or for

different times, or that crush the rock more nely,

may produce more oil than that produced by

the Fischer assay method. Therefore, the method

only approximates the energy potential of an oil

shale deposit.

15

Another method for characterizing organic

richness of oil shale is a pyrolysis test developed

by the Institut Franais du Ptrole, in Reuil-

Malmaison, France, for analyzing source rock.

16

The Rock-Eval test heats a 50- to 100-mg

[0.00011- to 0.00022-lbm] sample through several

temperature stages to determine the amounts of

hydrocarbon and CO

2

generated. The results can

be interpreted for kerogen type and potential for

oil and gas generation. The method is faster than

the Fischer assay and requires less sample material.

The reactions that convert kerogen to oil and

gas are understood generally, but not in precise

molecular detail.

17

The amount and composition

of generated hydrocarbons depend on the heating

conditions: the rate of temperature increase, the

duration of exposure to heat and the composition

of gases present as the kerogen breaks down.

Generally, surface-based retorts heat the

shale rapidly. The time scale for retorting is

directly related to the particle size of the shale,

which is why the rock is crushed before being

heated in surface retorts. Pyrolysis of particles on

the millimeter scale can be accomplished in

minutes at 500C; pyrolysis of particles tens of

centimeters in size takes hours.

In situ processes heat the shale more slowly.

It takes a few years to heat a block tens of meters

wide. However, slow heating has advantages.

Retorting occurs at a lower temperature so less

heat is needed. Also, the quality of the oil

increases substantially (above left). Coking and

cracking reactions in the subsurface tend to

leave the heavy, undesirable components in the

ground. As a result, compared with surface pro-

cessing, in situ heating can produce lighter liquid

hydrocarbons with fewer contaminants.

During in situ conversion, the subsurface acts

as a large reactor vessel in which pressure and

heating rate may be designed to maximize prod-

uct quality and quantity while minimizing pro-

duction cost. In addition to generating a superior

product relative to surface processing, in situ

methods have a reduced environmental impact in

terms of surface disturbance, water require-

ments and waste management.

Several companies have developed methods

for heating oil shale in situ to generate shale oil.

They are testing these techniques in the rich sub-

surface deposits of the western US.

The Epitome of Oil Shales

The Green River Formation at the intersection of

the states of Colorado, Utah and Wyoming, USA,

contains the most bountiful oil shale beds in the

world. Estimates of the recoverable shale oil

in this area range from 1.2 to 1.8 trillion bbl

[1.9 to 2.9 10

11

m

3

]. Nearly 75% of the resources

lie under land managed by the US Department of

the Interior.

The ne-grained sediments of this formation

were deposited over the course of 10 million years in

Early and Middle Eocene time, in several large lakes

covering up to 25,000 mi

2

[65,000 km

2

]. The warm

alkaline waters provided conditions for abundant

growth of blue-green algae, which are believed to be

the main component of the organic matter in the oil

shale.

18

The formation is now about 1,600 ft [500 m]

thick and in places has shale layers that contain

more than 60 galUS/tonUS [250 L/Mg] of oil (next

page).

19

A particularly rich and widespread layer,

called the Mahogany zone, reaches a thickness of

50 ft [15 m]. It contains an estimated 173 billion bbl

[2.8 10

10

m

3

] of shale oil. The Green River area has

been well studied, with more than 750,000 assay

tests performed on samples from outcrops, mines,

boreholes and core holes.

20

Settlers and miners began retorting oil from

the shale in the 1800s. The region experienced

mining and exploration booms from 1915 to 1920

and again from 1974 to 1982, each period fol-

lowed by busts.

21

In 1980, Unocal built a major

plant for mining, retorting and upgrading oil

shale in the Piceance Creek basin in Colorado; it

operated until 1991. During that time, the

company produced 4.4 million bbl [700,000 m

3

]

of shale oil.

22

Recently, oil price volatility and growing

energy needs have combined to again focus inter-

est on the region. In 2003, the US Bureau of Land

Management initiated an oil shale development

program and solicited applications for research,

development and demonstration (RD&D) leases.

Several companies applied for and received

lease awards to develop in situ heating techniques

on public lands, and some are testing methods

>

Improved oil quality with slow heating. Data

from the Shell in situ conversion process (ICP)

and Lawrence Livermore National Laboratory

(LLNL), in California, show a clear increase in oil

API gravity as heating rate decreases. The red

endpoint represents the results of typical

laboratory pyrolysis.

Oilfield Review

Winter 10

Oil Shale Fig. 6

ORWIN10-OilShl Fig. 6

S

h

a

l

e

o

i

l

,

d

e

g

r

e

e

A

P

I

g

r

a

v

i

t

y

20

24

28

32

36

40

1 10 100 1,000 10,000 100,000

Heating rate, C/d

ICP LLNL

>

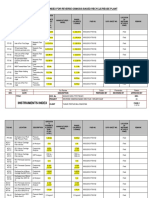

Shells thermal conduction pilot projects. Shell has performed seven eld pilots using the in situ

conversion process (ICP) to heat oil shale to conversion temperature. (Adapted from Fowler and

Vinegar, reference 24.)

Red Pinnacle

thermal conduction test

Mahogany field

experiment

Mahogany demonstration

project

Mahogany demonstration

project, South

Deep heater test

Mahogany isolation test

Freeze wall test

Project Name Primary Purpose Dates Heater

Holes

Total

Holes

Depth,

ft

ICP field demonstration

ICP field demonstration

ICP field demonstration,

recovery

ICP field demonstration,

recovery

Heaters

Freeze wall

Freeze wall

1996 to 1998

1981 to 1982

1998 to 2005

2003 to 2005

2001 to present

2002 to 2004

2005 to present

3

6

38

16

21

2

0

14

26

101

27

45

53

233

20

130

600

400

700

1,400

1,700

Oilfield Review

Winter 10

Oil Shale Fig. 9

ORWIN10-OilShl Fig. 9

38607schD4R1.indd 8 3/1/11 9:35 PM

Winter 2010/2011 9

on privately held land. Examples from three

companiesShell, ExxonMobil and American

Shale Oil LLC (AMSO)show the range of

concepts being applied to the challenges of in situ

retorting in the Green River oil shale.

Shell has done extensive laboratory and eld

work in efforts to demonstrate commercial viabil-

ity of in situ retorting using downhole electric

heaters.

23

The process follows a method developed

in Sweden during World War IIa technique used

until 1960, when cheaper supplies of imported oil

became available.

Shell participated in early mining and surface

retort attempts in the Green River area, but chose

to withdraw from those in the mid-1990s to focus

on an in situ method.

24

Years of laboratory testing,

thermal simulations and eld pilots contributed to

the development of Shells in situ conversion pro-

cess (ICP). Through seven eld pilot tests, Shell

has investigated a variety of heating methods

including injected steam and downhole heaters

and well congurations with patterns of wells of

varying depths for heating, producing and dewa-

tering (previous page, top right).

14. Knaus et al, reference 11.

15. Dyni JR, Mercier TJ and Browneld ME: Chapter 1

Analyses of Oil Shale Samples from Core Holes and

Rotary-Drilled Wells from the Green River Formation,

Southwestern Wyoming, in US Geological Survey Oil

Shale Assessment Team (ed): Fischer Assays of

Oil-Shale Drill Cores and Rotary Cutting from the

Greater Green River Basin, Southwestern Wyoming,

US Geological Survey, Open-File Report 2008-1152,

http://pubs.usgs.gov/of/2008/1152/downloads/Chapter1/

Chapter1.pdf (accessed October 8, 2010).

16. Pyrolysis is the controlled heating of organic matter in

the absence of oxygen to yield organic compounds such

as hydrocarbons.

Peters KE: Guidelines for Evaluating Petroleum Source

Rock Using Programmed Pyrolysis, AAPG Bulletin 70,

no. 3 (March 1986): 318329.

.

Lithology (center) and

grade (right) of the Green

River Formation. Oil shales in

the Parachute Creek Member

are carbonate rich, and the

underlying shales of the

Garden Gulch Member are

clay rich. High-grade (blue)

oil shales are interspersed

with lean layers (pink). Oil

yield from Fischer assay

measurement is plotted in

red. Total shale oil resources

contained in the various

layers are shown in the chart

(bottom left). (Lithology and

shale oil resources from

Dyni, reference 1; shale

grade from Johnson et al,

reference 19.)

Oilfield Review

Winter 10

Oil Shale Fig. 8

ORWIN10-OilShl Fig. 8

Sandstone, siltstone and some

marlstone and lean oil shale

Oil shale

Marlstone and low-grade oil shale

Leached oil shale; contains open solution

cavities and marlstone solution breccias

Nahcolite-bearing oil shale; contains nodules,

scattered crystals and beds of nahcolite

Clay-bearing oil shale

Interbedded halite, nahcolite and oil shale

Nahcolite and oil shale

A-groove

R-8 zone

Mahogany

zone

B-groove

R-6 zone

R-5 zone

R-4 zone

R-3 zone

L-5 zone

L-4 zone

L-3 zone

L-2 zone

R-2 zone

L-1 zone

R-1 zone

L-0 zone

R-0 zone

0 20 40 60 80 100

Shale oil yield,

galUS/tonUS

Anvil Points

Member

0

500

1,000

1,500

2,000

2,500

3,000

G

a

r

d

e

n

G

u

l

c

h

M

e

m

b

e

r

P

a

r

a

c

h

u

t

e

C

r

e

e

k

M

e

m

b

e

r

G

r

e

e

n

R

i

v

e

r

F

o

r

m

a

t

i

o

n

Generalized

Lithology Depth, ft

Rich oil shale zones, carbonate rich

Rich oil shale zones, clay rich

Lean oil shale zones, carbonate rich

Lean oil shale zones, clay rich

U

i

n

t

a

F

o

r

m

a

t

i

o

n

(

w

i

t

h

t

o

n

g

u

e

s

o

f

G

r

e

e

n

R

i

v

e

r

F

o

r

m

a

t

i

o

n

)

Shale Oil Resources

10

9

tonUS

Total

Mahogany

Zone

147.17

No data

1,008.10

No data

10

9

bbl

No data

No data

No data

No data

115.35

10.70

53.07

20.08

58.38

18.72

107.78

60.85

178.72

52.42

159.09

172.94

R-1

L-1

R-2

L-2

R-3

L-3

R-4

L-4

R-5

L-5

R-6

R-8

L-0

R-0

16.84

1.56

7.75

2.93

8.52

2.73

15.74

8.88

26.09

7.65

23.23

25.25

Espitalie J, Madec M, Tissot B, Mennig JJ and Leplat P:

Source Rock Characterization Method for Petroleum

Exploration, paper OTC 2935, presented at the Offshore

Technology Conference, Houston, May 25, 1977.

17. Burnham AK: Chemistry and Kinetics of Oil Shale

Retorting, in Ogunsola OI, Hartstein AM and Ogunsola O

(eds): Oil Shale: A Solution to the Liquid Fuel Dilemma.

Washington, DC: American Chemical Society, ACS

Symposium Series 1032 (2010): 115134.

18. Dyni, reference 1.

19. Johnson RC, Mercier TJ, Browneld ME, Pantea MP

and Self JG: Assessment of In-Place Oil Shale

Resources of the Green River Formation, Piceance

Basin, Western Colorado, Reston, Virginia, USA: US

Geological Survey, Fact Sheet 2009-3012, March 2009.

20. US Department of Energy: Secure Fuels from Domestic

Resources, http://www.unconventionalfuels.org/

publications/reports/SecureFuelsReport2009FINAL.pdf

(accessed November 12, 2010).

21. Hanson JL and Limerick P: What Every Westerner

Should Know About Oil Shale: A Guide to Shale

Country, Center of the American West, Report no. 10,

June 17, 2009, http://oilshale.centerwest.org (accessed

August 4, 2010).

22. Dyni, reference 1.

23. Ryan RC, Fowler TD, Beer GL and Nair V: Shells In Situ

Conversion ProcessFrom Laboratory to Field Pilots,

in Ogunsola OI, Hartstein AM and Ogunsola O (eds):

Oil Shale: A Solution to the Liquid Fuel Dilemma.

Washington, DC: American Chemical Society,

ACS Symposium Series 1032 (2010): 161183.

24. Fowler TD and Vinegar HJ: Oil Shale ICPColorado

Field Pilots, paper SPE 121164, presented at the SPE

Western Regional Meeting, San Jose, California,

March 2426, 2009.

38607schD4R1.indd 9 2/21/11 9:25 PM

10 Oileld Review

The ICP method uses closely spaced down-

hole electric heaters to gradually and evenly heat

the formation to the conversion temperature of

about 650F [340C]. Depending on heater spac-

ing and the rate of heating, the time projected to

reach conversion temperature in a commercial

project ranges from three to six years. Tests have

demonstrated liquid-recovery efciencies greater

than 60% of Fischer assay value, with the low-

value kerogen components left in the ground. The

resulting oil is of 25 to 40 degree API gravity. The

gas contains methane [CH

4

], H

2

S, CO

2

and H

2

.

Taking into account the oil equivalence

of the gas generated, the recovery efciency

approaches 90% to 100% of Fischer assay value.

From results of the pilot testing, a commercial-

scale project is expected to have an energy

gain close to 3, meaning the energy value of the

products is three times the energy input to

obtain them.

Commercialization of the ICP process

requires a method that prevents water inux to

the heated volume and contains the uid prod-

ucts, thereby maximizing recovery and protecting

local aquifers.

25

The Shell ICP process makes use

of a freeze wall, created by circulating coolants,

to isolate the heated formation from ground-

water. Use of a freeze wall is a relatively common

practice in some underground mining operations.

Inside the freeze wall, water is pumped from the

formation. The formation is heated, the oil is pro-

duced and the residual shale is cleaned of con-

taminants by ushing with clean water. The

recovered oil in one test had 40 degree API grav-

ity, similar to modeling results for oil produced at

heating rates of 1C/h [0.5F/h] and 27 MPa.

Pilot testing of the freeze wall began in 2002

with 18 freeze wells arranged in a circle 50 ft

across. One producer, two heating wells and eight

monitor wells were located within the freeze cir-

cle (left). After ve months of cooling, the freeze

wall was complete. This pilot showed that a

freeze wall could be established and could isolate

uids inside the circle from those outside.

Shell tested the freeze wall concept on a larger

scale starting in 2005, with an ambitious project

involving 157 freeze wells at 8-ft [2.4-m] intervals

to create a containment volume 224 ft [68 m]

across (next page, top). The operator began chill-

ing in 2007 by circulating an ammonia-water

solutioninitially at shallow depth and gradually

deepening. As of July 2009, the freeze wall was

continuing to form in the deeper zones, down to

1,700 ft [520 m]. The test is designed to evaluate

the integrity of the freeze wall, and will not involve

heating, or production of hydrocarbons.

ExxonMobil is also pursuing research and

development of a process for in situ oil shale con-

version. The companys Electrofrac process

hydraulically fractures the oil shale and lls the

fractures with an electrically conductive material,

creating a resistive heating element.

26

Heat is

thermally conducted into the oil shale, converting

the kerogen into oil and gas, which are then pro-

duced by conventional methods. Calcined petro-

leum coke, a granular form of relatively pure

carbon, is being tested as the Electrofrac conduc-

tant. By pumping this material into vertical

hydraulic fractures, ExxonMobil hopes to create a

series of parallel planar electric heaters (next

page, bottom). As in the Shell ICP method, the

resistive heat reaches the shale by thermal diffu-

sion. A potential advantage of the Electrofrac pro-

cess is that, compared with line sources, the

greater surface area of planar fracture heaters will

permit fewer heaters to be used to deliver heat to

the subsurface volume. The use of planar heaters

should also reduce surface disturbance when com-

pared with line sources or wellbore heaters.

25. Ryan et al, reference 23.

26. Symington WA, Kaminsky RD, Meurer WP, Otten GA,

Thomas MM and Yeakel JD: ExxonMobils Electrofrac

Process for In Situ Oil Shale Conversion, in Ogunsola

OI, Hartstein AM and Ogunsola O (eds): Oil Shale: A

Solution to the Liquid Fuel Dilemma. Washington, DC:

American Chemical Society, ACS Symposium Series 1032

(2010): 185216.

Symington WA, Olgaard DL, Otten GA, Phillips TC,

Thomas MM and Yeakel JD: ExxonMobils Electrofrac

Process for In Situ Oil Shale Conversion, presented at

the AAPG Annual Convention, San Antonio, Texas, USA,

April 2023, 2008.

>

Shell freeze wall isolation test. Using a technique dating to the 1880s, Shell

constructed a circular freeze wall 1,400 ft [430 m] deep by circulating

coolant in 18 freeze wells for 5 months. A 430-ft [130-m] interval of the

enclosed formation was then heated to generate shale oil. The test veried

that the freeze wall could conne produced uids.

Oilfield Review

Winter 10

Oil Shale Fig. 10

ORWIN10-OilShl Fig. 10

Plan View

Side View

22 ft

50 ft

8 ft

1,400-ft

freeze

interval

430-ft

heated

interval

Inside monitor (8)

Freeze (18)

Producer (1)

Heater (2)

Wells

38607schD4R1.indd 10 2/21/11 9:25 PM

Winter 2010/2011 11

>

Large-scale freeze wall test. In a step toward

supporting commercial viability of the ICP, Shell is

testing a large-scale freeze wall for isolation and

containment. In addition to the freeze wells shown

in the plan view (left) there are 27 observation

holes for geomechanical, pressure, uid level and

temperature measurements; 30 special-use holes

for venting, squeezing, water reinjection, water

production and hydraulic fracturing; and 40

groundwater monitoring holes. An artists

rendering (right) depicts the freeze wall in 3D.

Oilfield Review

Winter 10

Oil Shale Fig. 11

ORWIN10-OilShl Fig. 11

A

B

C

Plan View

Side View

Test

Section B

1,700-ft

freeze

interval

Test

Sections

A and C

1,500-ft

freeze

interval

224 ft

Freeze well 8 ft

B

C

A

Oilfield Review

Winter 10

Oil Shale Fig. 11

ORWIN10-OilShl Fig. 11

A

B

C

Plan View

Side View

Test

Section B

1,700-ft

freeze

interval

Test

Sections

A and C

1,500-ft

freeze

interval

224 ft

Freeze well 8 ft

B

C

A

>

The ExxonMobil Electrofrac process. Horizontal wells penetrate the oil shale. The horizontal sections are hydraulically

fractured (left) and lled with electrically conductive proppant made of calcined coke (bottom right). A 20/40 mesh proppant (top

right) is displayed for scale. Field testing has shown it is possible to create an electrically conductive fracture and heat it for

several months. The plus and minus signs indicate electric charge applied to heat the fractures. (Illustration and photographs

courtesy of ExxonMobil.)

20/40 Mesh Proppant

Calcined Coke

Toe connector well Production wells Electrofrac process

heater wells

Conductive heating and

oil shale conversion

Hydraulic fracture

with electrically

conductive material

Oilfield Review

Winter 10

Oil Shale Fig. 12

ORWIN10-OilShl Fig. 12

38607schD4R1.indd 11 2/21/11 9:26 PM

12 Oileld Review

Prior to embarking on eld research,

ExxonMobil conducted modeling and laboratory

studies addressing several important technical

issues for the Electrofrac process. These included

establishing the following:

That the conductant in the fracture can main-

tain its electrical continuity while the surround-

ing rock is heated to conversion temperatures.

That oil and gas generated by the process are

expelled from oil shale, not only at surface con-

ditions, but also under in situ stress conditions.

That a completion strategy can be designed to

create fractures that deliver heat effectively.

Based on these results, ExxonMobil advanced

to eld research to test the Electrofrac method in

situ.

27

The test site is at the company-owned

Colony oil shale mine in northwest Colorado. The

Colony mine provides a large, highly accessible

volume of rock for testing. ExxonMobil has cre-

ated two Electrofrac fractures at Colony by drill-

ing horizontally into the oil shale and pumping a

slurry of calcined petroleum coke, water and

portland cement at pressures sufcient to break

the rock. The larger of the two Electrofrac frac-

tures has been heavily instrumented to measure

temperature, voltage, electrical current and

rock movement. As a preliminary test of the

Electrofrac process, the fracture was heated

to relatively low temperatures. This low-

temperature experiment was not intended to

generate oil or gas. To date, the results of this

eld program have been encouraging. They

demonstrate that it is possible to create an elec-

trically conductive hydraulic fracture, to make

power connections to the fracture and to operate

it, at least at low temperature, for several months.

AMSO, 50% owned by Total, proposes to use

the CCR conduction, convection and reux pro-

cess to recover shale oil. By focusing the heating

effort on shales beneath an impermeable shale

caprock, this method isolates production zones

from protected sources of groundwater.

28

The company plans to drill two horizontal

wellsa heater below a producerin the bot-

tom of the illite shale at the base of the Green

River Formation (above left). Heat is delivered by

a downhole burner that eventually runs on pro-

duced gas. As the kerogen decomposes, the

lighter productshot vaporsrise and reux.

Heat is distributed through the formation by the

reuxing oil; thermomechanical fracturing, or

spalling, creates permeability for the convective

heat transfer.

The concept for commercial-scale produc-

tion uses an array of horizontal wells about

2,000 ft [600 m] long at 100-ft [30-m] intervals

(left). The formation is heated slowly, yielding

oil with lower concentrations of heteroatoms

and metals than that generated by surface pro-

cessing methods.

29

Meanwhile, the aromatic

portions of kerogen tend to stay in the rock

matrix as coke. More than enough gas is copro-

duced to provide the energy required to operate

a self-sustaining commercial retorting process,

and it is likely that most of the propane and

butane produced can be exported to market.

Computational studies show that heat deliv-

ery by convection and conduction is much more

effective than by conduction alone. The CCR pro-

cess is estimated to give a total energy gain

between 4 and 5, counting all the surface facility

requirements, including an oxygen plant for pro-

ducing pure CO

2

from the downhole burner. The

method is projected to use less than one barrel of

water per barrel of oil produced. No water is

needed to clean spent retorts because they

remain isolated from usable groundwater.

>

The AMSO CCR conduction, convection and reux process. Two horizontal wells target the illitic oil

shale beneath a nahcolitic caprock. The heating well is at the base and the production well is at the

top of the shale (left). As heat causes the kerogen to decompose, the lighter products rise and

condense (right), efciently heating a large volume of rock. Hydrocarbon uids are produced via the

production well.

D

e

p

t

h

,

f

t1,000

0

500

1,500

2,000

Low-salinity water

High-salinity water

Mahogany zone

Nahcolitic oil shale caprock

Illitic oil shale

Heating well

Production well

2,000 ft

Boiling oil

V

a

p

o

r

C

o

n

d

e

n

s

a

t

e

C

o

n

d

e

n

s

a

t

e

Heating well

Rubble-

filled

retort

Production well

Oilfield Review

Winter 10

Oil Shale Fig. 13

ORWIN10-OilShl Fig. 13

>

The AMSO concept for commercial-scale production. By using long

horizontal wells concentrated in a 200-ft corridor, drilling should impact

less than 10% of the surface area. While one 2,000-ft square panel is being

heated and converted in situ, wells will be drilled in an adjacent panel. The

operation is projected to produce about 1 billion bbl of shale oil over a

25-year period.

Oilfield Review

Winter 10

Oil Shale Fig. 14

ORWIN10-OilShl Fig. 14

2

0

0

ft

2

,

0

0

0

f

t

2

,0

0

0

ft

2

,0

0

0

f

t

Panel being drilled

Panel being retorted

38607schD4R1.indd 12 2/21/11 9:26 PM

Winter 2010/2011 13

AMSOs initial RD&D pilot test is currently

under construction and will begin in mid-2011.

Heating will take up to 200 days. The operation

will retort a formation volume equivalent to

4,000 tonUS [3,600 Mg] of oil shale and produce

up to 2,000 bbl [320 m

3

] of shale oil. Development

of a commercial operation will proceed in steps

up to 100,000 bbl/d [16,000 m

3

/d], with plans to

sustain that production for 25 years. That trans-

lates into about 1 billion bbl [1.6 10

8

m

3

] of oil

to be produced from an 8-mi

2

[20.8-km

2

] lease.

Evaluating Oil Shales

Companies are looking at ways to assess oil shale

richness and other formation properties without

having to take core samples and perform Fischer

assay analysis. Methods that show promise

include integration of several conventional log-

ging measurements, such as formation density,

magnetic resonance, electrical resistivity and

nuclear spectroscopy.

One way of quantifying kerogen content is by

combining density porosity and magnetic reso-

nance responses. In a formation with porosity

that is lled with both kerogen and water, the

density porosity measurement does not distin-

guish between kerogen- and water-lled porosity.

However, the magnetic resonance measurement

sees the kerogen as a solid, similar to the grains

of the rock, and so senses a lower porosity. The

difference between the magnetic resonance and

density readings gives kerogen volume.

30

The vol-

ume of kerogen can be related empirically to

Fischer assay values for oil shales in the region.

The method was tested in an AMSO oil shale

well in the Green River basin. Kerogen content

was calculated from density porosity and mag-

netic resonance logs (right). Using a correlation

between kerogen content and Fischer assay

27. Symington WA, Burns JS, El-Rabaa AM, Otten GA,

Pokutylowicz N, Spiecker PM, Williamson RW and

Yeakel JD: Field Testing of Electrofrac Process

Elements at ExxonMobils Colony Mine, presented at

the 29th Oil Shale Symposium, Colorado School of

Mines, Golden, Colorado, USA, October 1921, 2009.

28. Burnham AK, Day RL, Hardy MP and Wallman PH:

AMSOs Novel Approach to In-Situ Oil Shale Recovery,

in Ogunsola OI, Hartstein AM and Ogunsola O (eds):

Oil Shale: A Solution to the Liquid Fuel Dilemma.

Washington, DC: American Chemical Society,

ACS Symposium Series 1032 (2010): 149160.

29. Heteroatoms are atoms of elements other than hydrogen

and carbonthe components of pure hydrocarbons.

They commonly consist of nitrogen, oxygen, sulfur, iron

and other metals.

30. Kleinberg R, Leu G, Seleznev N, Machlus M, Grau J,

Herron M, Day R, Burnham A and Allix P: Oil Shale

Formation Evaluation by Well Log and Core

Measurements, presented at the 30th Oil Shale

Symposium, Colorado School of Mines, Golden,

Colorado, October 1822, 2010.

>

Kerogen content from porosity measurements in Green River oil shales. Neither gamma ray (Track 1,

dashed green) nor resistivity measurements (Track 2) show much correlation with kerogen content, but

porosity measurements are more useful. The difference between density porosity (Track 3, red) and

nuclear magnetic resonance (NMR) porosity (green) represents kerogen-lled porosity (gray). The

kerogen values can also be depicted as a log (Track 4) of total organic matter (TOM, red), which

compares favorably with laboratory Fischer assay results on core samples (black dots). Mineralogical

analysis incorporating ECS elemental capture spectroscopy measurements (Track 5) indicates the high

levels of calcite and dolomite in these shales, as well as the presence of rare minerals such as

dawsonite (light gray) and nahcolite (solid pink) in some intervals.

X,000

X,050

X,100

X,150

X,200

Depth,

ft

6 16 in.

Caliper

0 10

PEF

0 200 gAPI

Gamma

Ray

0.2 2,000 ohm.m

10-in. Array

0.2 2,000 ohm.m

20-in. Array

0.2 2,000 ohm.m

30-in. Array

0.2 2,000 ohm.m

60-in. Array

0.2 2,000 ohm.m

90-in. Array

Resistivity

NMR Porosity

45 % 15

Density Porosity

45 % 15

Porosity

0 % 50

TOM Log

0 % 50

Core Fischer Assay

Total Organic Matter Kerogen

Illite

Montmorillonite

Orthoclase

Pyrite

Dawsonite

Nahcolite

Albite

Quartz

Calcite

Dolomite

Bound water

Kerogen

Water

Oilfield Review

Winter 10

Oil Shale Fig. 15

ORWIN10-OilShl Fig. 15

38607schD4R1.indd 13 2/21/11 9:26 PM

14 Oileld Review

results on Green River shales, researchers com-

puted an estimated Fischer assay log based on

the wireline logging measurements (above). The

estimated Fischer assay values show excellent

agreement with those from laboratory measure-

ments on cores from the same interval.

Another approach distinguishes mineral from

organic content using spectroscopy data. The ECS

elemental capture spectroscopy sonde measures

concentrations of silicon [Si], aluminum [Al], cal-

cium [Ca], iron [Fe], sulfur [S], potassium [K],

sodium [Na], magnesium [Mg], titanium [Ti] and

gadolinium [Gd].

31

Grain mineralogy is computed

from these element concentrations.

The total carbon concentration comes from

the RST reservoir saturation tool. Of this concen-

tration, some carbon is inorganic and some

organic. The inorganic carbon combines with cal-

cium and other elements to form calcite and

dolomite, along with lesser-known minerals,

such as nahcolite [NaH(CO

3

)] and dawsonite

[NaAl(CO

3

)(OH

2

)], which are common in Green

River shales. The ECS concentrations of Ca, Mg

and Na are used to compute the inorganic car-

bon. The remainder, called total organic carbon

(TOC), makes up the kerogen.

Using this spectroscopy method, researchers

computed a TOC log for an AMSO well in the

Green River basin, showing a good match between

log-based results and core measurements (next

page).

32

The TOC log was converted to a Fischer

assay yield log using a correlation derived inde-

pendently by AMSO scientists. The Fischer assay

log exhibited excellent agreement with Fischer

assay tests performed on cores (above right). This

technique employing geochemical logs, along

with the complementary method using nuclear

magnetic resonance logs, provides reliable, ef-

cient means to characterize shale oil yield with-

out having to resort to core measurements.

Heating Elements

One of the most fundamental issues for oil shale

retorting is how to get the heat into the oil shale.

After early testing, steam injection was aban-

doned as other, more efcient techniques were

discovered. In situ combustion has also been

tried, but is difcult to control. Electric heaters,

electrically conductive proppant and downhole

gas burners have all been evaluated and reported

to be effective with varying degrees of efciency.

Another concept, heating by downhole radio-

frequency (RF) transmitters, has also been mod-

eled and has undergone laboratory testing.

33

Advantages of the RF method are that it heats the

interior of the formation instead of the borehole,

and it can be controlled to customize heating rate.

But like all electrical methods, it sacrices ef-

ciency, losing about half the heating value of the

fuel originally burned to produce the electricity.

It is important to note that all the current

projects to produce shale oil by in situ heating

methods are in test and pilot stages; none have

demonstrated large-scale commercial produc-

tion. Operators are still working to optimize their

heating technologies. For a given oil shale, the

>

Fischer assay estimates from wireline logs. Core measurements on Green

River shales show a strong correlation between total organic matter (TOM),

or kerogen, and Fischer assay values (top). Total organic matter is

calculated using the density

k

of the kerogen, bulk density of the formation

b

and the difference between density porosity

D

and magnetic resonance

porosity

MR

. Researchers computed a kerogen log from the difference

between density and NMR porosity, then used this linear correlation to

convert the kerogen log to a Fischer assay log (bottom). The log-based

Fischer assay estimates (black) show excellent agreement with values from

laboratory Fischer assay measurements on cores (red).

Oilfield Review

Winter 10

Oil Shale Fig. 16

ORWIN10-OilShl Fig. 16

F

i

s

c

h

e

r

a

s

s

a

y

,

g

a

l

U

S

/

t

o

n

U

S

20

0

40

60

80

X,000 X,050 X,100 X,150 X,200

Depth, ft

Core-measured Fischer assay values

Well log Fischer assay estimate

TOM =

D

MR

b

( )

Total organic matter

as fraction of ore weight

T

o

t

a

l

o

r

g

a

n

i

c

m

a

t

t

e

r

(

T

O

M

)

,

%

0

10

20

30

40

20 40 60 0

Modified Fischer assay, galUS/tonUS

TOM =

D

MR

b

( )

Total organic matter

as fraction of ore weight

>

Fischer yield from TOC. Fischer assay estimates

(black) from the TOC log exhibit an excellent

correlation with core Fischer assay results (red).

Oilfield Review

Winter 10

Oil Shale Fig. 19

ORWIN10-OilShl Fig. 19

D

e

p

t

h

,

f

t

X,200

X,000

X,400

X,600

X,800

Y,000

Y,200

Y,400

0 20 40 60

Shale oil yield, galUS/tonUS

TOC converted to

Fischer assay yield

Core Fischer assay

38607schD4R1.indd 14 2/21/11 9:26 PM

Winter 2010/2011 15

heating historyhow much heat and for how

longdetermines the amount and content of the

resulting uids. By controlling the heat input,

companies can ne-tune the output, essentially

designing a shale oil of desired composition.

Beyond heating methods, there are other

aspects of oil shale operations that have yet to

be fully addressed. Mechanical stability of the

heated formation is not well understood. All the

in situ heating techniques rely on some thermo-

mechanical fracturing within the shale to

release matured organic material and create

additional permeability for the generated uids

to escape the formation. With many oil shales

containing 30% or more kerogen, most of which

leaves the rock after in situ retorting, treated

formations may not be able to support their

newfound porosity. Overburden weight can help

drive production, but may also cause compac-

tion and subsidence, which in turn can affect

wellbore stability and surface structures.

It is also unclear how to deal with the CO

2

generated along with other gases. Companies

retorting oil shale in situ may need to investigate

ways to capture and use the CO

2

for enhanced oil

recovery or sequester it in deep storage zones. An

alternative, being explored by AMSO, is mineral-

ization of CO

2

in the spent shale formation.

34

This

option exploits the chemical properties of the

heat-treated shale. AMSO scientists expect the

depleted formation to have sufcient porosity to

accommodate all the generated and reinjected

CO

2

as carbonate minerals.

Work also remains to understand the kerogen-

maturation process. To optimize heating pro-

grams, operators would like to know when the

shale has been heated enough and if the subsur-

face volume has been heated uniformly. To this

end, scientists are conducting laboratory experi-

ments to monitor the products of kerogen pyroly-

sis.

35

To understand when the process should be

modied or stopped, researchers plan to analyze

the composition of an oil shale and its hydrocar-

bons as they evolve with time. In the future, it

may be possible to control and monitor oil shale

heating and production to obtain oil and gas of

desired compositions. LS

31. Barson D, Christensen R, Decoster E, Grau J, Herron M,

Herron S, Guru UK, Jordn M, Maher TM, Rylander E

and White J: Spectroscopy: The Key to Rapid, Reliable

Petrophysical Answers, Oileld Review 17, no. 2

(Summer 2005): 1433.

32. Grau J, Herron M, Herron S, Kleinberg R, Machlus M,

Burnham A and Allix P: Organic Carbon Content of the

Green River Oil Shale from Nuclear Spectroscopy Logs,

presented at the 30th Oil Shale Symposium, Colorado

School of Mines, Golden, Colorado, October 1822, 2010.

33. Burnham AK: Slow Radio-Frequency Processing of

Large Oil Shale Volumes to Produce Petroleum-Like Shale

>

Organic and inorganic carbon from logs and cores. Total carbon (left) is made up of inorganic and organic carbon, the latter of

which resides in kerogen. The inorganic carbon is present in mineral form, such as in carbonates and some exotic minerals

sometimes found in oil shales. Estimates of inorganic (middle left) and organic carbon (middle right) based on nuclear

measurements (black) correlate extremely well with laboratory measurements on cores (red). An expanded section (right) shows

the quality of the match across the bottom 150-ft interval.

0 20 40

Total carbon, weight percent

D

e

p

t

h

,

f

t