Beruflich Dokumente

Kultur Dokumente

Work in Progress - Developing Warm-Up Questions For Strength of Materials

Hochgeladen von

Heidi Ray0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

13 Ansichten2 Seitengfggsgd

gs

g

gs

g

h

sthystnytytr

Originaltitel

1110

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldengfggsgd

gs

g

gs

g

h

sthystnytytr

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

13 Ansichten2 SeitenWork in Progress - Developing Warm-Up Questions For Strength of Materials

Hochgeladen von

Heidi Raygfggsgd

gs

g

gs

g

h

sthystnytytr

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

Session M4H

978-1-4244-4714-5/09/$25.00 2009 IEEE October 18 - 21, 2009, San Antonio, TX

39

th

ASEE/IEEE Frontiers in Education Conference

M4H-1

Work in Progress - Developing Warm-Up

Questions for Strength of Materials

Janet M. Braun and Jeffrey L. Newcomer

Western Washington University, Janet.Braun@wwu.edu, Jeff.Newcomer@wwu.edu

Abstract This paper outlines our preliminary efforts to

develop warm-up questions for Strength of Materials.

These are conceptual questions that students answer

before the topics the questions cover are introduced in

class. The warm ups give instructors an idea of what

students conceptions are before discussion begins, so the

instructor can directly address students specific difficul-

ties as the topic is introduced. The questions that we are

developing are still in flux, but our preliminary results

indicate that while students remember some relevant

information from the prerequisite Materials Science

course, they have trouble knowing when to apply it.

Index Terms up to four words

INTRODUCTION

Understanding students conceptual difficulties with engi-

neering topics is necessary to allow faculty to improve

course materials and teaching methods [1]. There have been

widespread and significant efforts to develop concept inven-

tories for different engineering topics for use in assessment,

such as the Statics Concept Inventory [2]-[3]. These concept

questions, however, are also useful if employed throughout

the duration of a course to provide faculty with insight into

students specific difficulties [4]. Warm up questions are a

well established method for gaining this information [5].

To this end, we are in the process of developing a set of

conceptual warm-up questions for Strength of Materials

(SOM). These questions cover nine topic areas that are

synchronized with the course lecture. At Western Washing-

ton University (WWU), students enrolled in Manufacturing

Engineering Technology (ET), Plastics ET, and Industrial

Technology with specialization in either Vehicle Design or

CAD/CAM are required to take SOM. Students complete

the warm-up questions prior to the topic being covered in

class, so faculty are able to use the students responses to

address specific difficulties that are common as new material

is introduced. We are currently developing the second itera-

tion of these questions, incorporating what we learned from

the first iteration.

A few others have attempted to develop concept

questions for or to more thoroughly understand students

conceptual difficulties with SOM, but the attempts are very

preliminary, focused differently than our efforts, or have

been abandoned [6]-[8]. Our initial results indicate that

students bring with them certain biases, most likely from

their introductory Materials Science course that, along with

Physics, Calculus, and Statics, is a pre-requisite for SOM.

Within the ET department, extensive research has been con-

ducted by Kitto on methods to improve conceptual under-

standing of Materials Science [9]. One example where this

understanding of a Materials Science concept may have

created a bias in students response is that heating a part is

more strongly associated with the material softening than the

part expanding and that stress and deflection are not strongly

related as being proportional to each other. We are, howev-

er, continuing to modify the questions and collect student

responses in order to confirm that we are building valid

models of common specific difficulties. We will describe

the topics, two of the questions, and some of the findings

from our preliminary work.

WARM-UP TOPICS

The goal of the warm ups is to provide the course instructor

with some idea of student conceptions on a topic before the

topic is covered. That way the instructor can directly ad-

dress any common difficulties that appear in the students

responses. As such, the warm-up topics were selected to

match the lecture topics. The warm-up topics are:

1. Thermal stress and expansion

2. Shear due to torsion

3. Shear forces and bending moments in beams

4. The effect of beam cross sections on stress and def-

lection

5. Axial stress distribution in beams

6. Shear stress distribution in beams

7. Beam deflection

8. Combined loadings

9. Buckling

PRELIMINARY FINDINGS

The majority of the warm ups contained two or three ques-

tions for students to answer. The questions are open-ended

rather than multiple-choice. We are developing multiple

choice questions, using students incorrect answers to help

us develop the distractors. Here are two examples of res-

ponses to warm up that we believe provide some insight into

student thinking.

Figure 1 shows the image for Warm Up 1. The question

asked students to consider the changes to stress and deflec-

tion in both beams as the temperature increased, with beam

A free to expand, but beam B constrained at both ends. The

Session M4H

978-1-4244-4714-5/09/$25.00 2009 IEEE October 18 - 21, 2009, San Antonio, TX

39

th

ASEE/IEEE Frontiers in Education Conference

M4H-2

students responses regarding the stresses were mildly inter-

esting. Of the thirty-two students who completed this warm

up, thirteen correctly identified that beam B would see an

increase in stress, but beam A would not; seven indicated

that temperature changes do not affect stress, for stress is

force over area; and seven indicated that the material would

soften as it heated, so the beams would start to sag. This last

group of students increased to fifteen when they were asked

to consider deflection, while only eight students answered

the question correctly. The students concerned with the

material softening highlighted a focus in their thinking.

They were all aware that materials will eventually soften as

the temperature gets high enough, and with gravity pulling

perpendicular to the main axis of the beam the beam will

eventually sag, and they were more concerned with this than

with stress and elongation. In the second iteration we li-

mited the amount of temperature change and reoriented the

picture so that the beams are vertical, and student responses

were more focused on the issues of interest.

FIGURE 1

BEAMS FOR WARM UP 1.

Figure 2 shows the figure for Warm Up 4. The ques-

tions asked students to consider if the three different cross

sections, that all have the same area, would lead to different

stress or deflection for the simply supported and loaded

beam. Of the twenty-six students who completed this warm

up, nineteen indicated that the deflection would vary due to

the different distribution of areas, with general agreement

that cross section 2 would deflect the most, but some disa-

greement as to whether cross section 1 or 3 would deflect the

least. The results for stress, however, were very different.

Fourteen students indicated that the stress would be the same

for all three cross sections, since the areas are the same, yet

ten of these fourteen students indicated that the deflections

would be different for the different cross sections. This

result is consistent with student responses on the first warm

up and with findings in [6]. Many students know that stress

is force over area, but they do not understand the idea well

enough to know how to apply it in indirect loading situa-

tions. Moreover, none of the students thought to relate stress

to strain or deflection through the material stiffness, so the

question did not invoke them to think about that relationship

and the possible contradiction of having the same stress but

different deflections.

FIGURE 2

LOADING AND BEAM CROSS-SECTIONS FOR WARM UP 4.

It seems clear from these two warm ups, and it was rein-

forced by others, that students remember some things from

their prerequisite engineering materials class very well, but

many of them to do not know when to apply them.

FUTURE WORK

Our intention at this point is to continue to refine the warm

ups so that we can create a stable set that can be used to

reliably inform instructors as to what specific difficulties

students have as a new SOM topic is introduced. Once we

have stable questions we will begin to collect data to see if

there are consistent patterns in different groups of students.

REFERENCES

[1] Wankat, P. C., Improving Engineering and Technology Education by

Applying What is Known About How People Learn, J. of SMET Ed.,

Vol. 3, No. 1&2, Jan.-June 2002, pp. 3-8

[2] Evans, D., et. al., Panel Discussion: Progress on Concept Inventory

Assessment Tools, Proc. of the 33rd ASEE/IEEE FIE Conf., Boulder,

Co., November 5-8, 2003, pp. T4G-1-8

[3] Steif, P. S., and Dantzler, J. A., A Statics Concept Inventory: Devel-

opment and Psychometric Analysis, J. of Eng. Ed., Vol. 94, No. 4,

Oct. 2005, pp. 363-371

[4] Newcomer, Jeffrey L., Many Problems, One Solution Method:

Teaching Statics without Special Cases, Proc. of the 36

th

ASEE/IEE

FIE Conf., San Diego, CA, Oct. 2006, pp. S2D-7-12

[5] Patterson, E., and Novak, G., Just-In-Time Teaching, 1999-2006,

http://webphysics.iupui.edu/jitt/jitt.html

[6] Brown, S., Findley, K., and Montfort, D., Student Understanding of

States of Stress in Mechanics of Materials, ASEE 2007 An. Conf. &

Expo., Honolulu, HI, June 2007

[7] Edwards, R., Englund, R., and Sweeny, S., Direct Assessment of

Mechanics of Materials Learning with Concept Inventory, ASEE

2007 An. Conf. & Expo., Honolulu, HI, June 2007

[8] Richardson, J., Stief, P., Morgan, J., and Dantzler, J., Development

of a Concept Inventory for Strength of Materials, Proc. of the 33rd

ASEE/IEEE FIE Conf., Boulder, Co., November 5-8, 2003, pp. T3D-

29-33

[9] Kitto, K., Developing and Assessing Conceptual Understanding in

Materials Engineering Using Written Research Papers and Oral Poster

Presentations, Proc. of the 38

th

ASEE/IEE FIE Conf., Saratoga

Springs, NY, Oct. 2008, pp. F4A-1-6

F

1

2 3

A

B

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- (Newspaper Analysis) SEPTEMBER-2015: Monthly GK CapsuleDokument24 Seiten(Newspaper Analysis) SEPTEMBER-2015: Monthly GK CapsuleHeidi RayNoch keine Bewertungen

- Kajdafasdf A Sa VDokument80 SeitenKajdafasdf A Sa VHeidi RayNoch keine Bewertungen

- Conveyors and Conveying EquipmentDokument64 SeitenConveyors and Conveying EquipmentHeidi RayNoch keine Bewertungen

- Data InterpretationDokument12 SeitenData InterpretationAbhayMenonNoch keine Bewertungen

- 7.8 Cutting Tool Materials CompleteDokument15 Seiten7.8 Cutting Tool Materials CompleteNikhil Batham67% (6)

- Memory Mentor Maths TipsDokument16 SeitenMemory Mentor Maths TipsSameer PandeyNoch keine Bewertungen

- Data InterpretationDokument12 SeitenData InterpretationAbhayMenonNoch keine Bewertungen

- 1322578Dokument1 Seite1322578Heidi RayNoch keine Bewertungen

- Air Around Us: Activity 1 Activity 2Dokument8 SeitenAir Around Us: Activity 1 Activity 2Heidi RayNoch keine Bewertungen

- Fesc 114Dokument11 SeitenFesc 114Heidi RayNoch keine Bewertungen

- HiDokument220 SeitenHiHeidi RayNoch keine Bewertungen

- HiDokument220 SeitenHiHeidi RayNoch keine Bewertungen

- HiDokument220 SeitenHiHeidi RayNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Guided-Discovery Learning Strategy and Senior School Students Performance in Mathematics in Ejigbo, NigeriaDokument9 SeitenGuided-Discovery Learning Strategy and Senior School Students Performance in Mathematics in Ejigbo, NigeriaAlexander DeckerNoch keine Bewertungen

- E-Mobility and SafetyDokument77 SeitenE-Mobility and SafetySantosh KumarNoch keine Bewertungen

- Academic Socialization and Its Effects On Academic SuccessDokument2 SeitenAcademic Socialization and Its Effects On Academic SuccessJustin LargoNoch keine Bewertungen

- Fortigate Firewall Version 4 OSDokument122 SeitenFortigate Firewall Version 4 OSSam Mani Jacob DNoch keine Bewertungen

- Sales Forecast Template DownloadDokument9 SeitenSales Forecast Template DownloadAshokNoch keine Bewertungen

- Manual de Operacion y MantenimientoDokument236 SeitenManual de Operacion y MantenimientoalexNoch keine Bewertungen

- 21 Tara Mantra-Wps OfficeDokument25 Seiten21 Tara Mantra-Wps OfficeAlteo FallaNoch keine Bewertungen

- RPH Week 31Dokument8 SeitenRPH Week 31bbwowoNoch keine Bewertungen

- Music 9 Q3 Mod4 Musical Elements of Given Romantic Period PiecesDokument19 SeitenMusic 9 Q3 Mod4 Musical Elements of Given Romantic Period PiecesFinn Daniel Omayao100% (1)

- Income Tax and VATDokument498 SeitenIncome Tax and VATshankar k.c.100% (2)

- MolnarDokument8 SeitenMolnarMaDzik MaDzikowskaNoch keine Bewertungen

- Daewoo 710B PDFDokument59 SeitenDaewoo 710B PDFbgmentNoch keine Bewertungen

- Multimedia System DesignDokument95 SeitenMultimedia System DesignRishi Aeri100% (1)

- Generalized Class of Sakaguchi Functions in Conic Region: Saritha. G. P, Fuad. S. Al Sarari, S. LathaDokument5 SeitenGeneralized Class of Sakaguchi Functions in Conic Region: Saritha. G. P, Fuad. S. Al Sarari, S. LathaerpublicationNoch keine Bewertungen

- Beyond Models and Metaphors Complexity Theory, Systems Thinking and - Bousquet & CurtisDokument21 SeitenBeyond Models and Metaphors Complexity Theory, Systems Thinking and - Bousquet & CurtisEra B. LargisNoch keine Bewertungen

- Brahms Symphony No 4Dokument2 SeitenBrahms Symphony No 4KlausNoch keine Bewertungen

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Dokument1 SeiteS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)BaytolgaNoch keine Bewertungen

- I Pmtea 2020 HandoutDokument94 SeitenI Pmtea 2020 HandoutAbhijeet Dutta100% (1)

- KundaliniDokument3 SeitenKundaliniAlfred IDunnoNoch keine Bewertungen

- Spring 2010 - CS604 - 1 - SolutionDokument2 SeitenSpring 2010 - CS604 - 1 - SolutionPower GirlsNoch keine Bewertungen

- Lightning Protection Measures NewDokument9 SeitenLightning Protection Measures NewjithishNoch keine Bewertungen

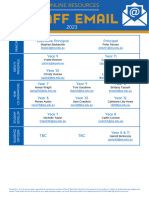

- 2023 Teacher Email ListDokument5 Seiten2023 Teacher Email ListmunazamfbsNoch keine Bewertungen

- Women Are Better Managers Than MenDokument5 SeitenWomen Are Better Managers Than MenCorazon ValdezNoch keine Bewertungen

- Web-Based Attendance Management System Using Bimodal Authentication TechniquesDokument61 SeitenWeb-Based Attendance Management System Using Bimodal Authentication TechniquesajextopeNoch keine Bewertungen

- Art of War Day TradingDokument17 SeitenArt of War Day TradingChrispen MoyoNoch keine Bewertungen

- G1000 Us 1014 PDFDokument820 SeitenG1000 Us 1014 PDFLuís Miguel RomãoNoch keine Bewertungen

- Analytics Designer - Comment Deletion - SAP CommunityDokument6 SeitenAnalytics Designer - Comment Deletion - SAP CommunityARPITA BISWASNoch keine Bewertungen

- SecurityFund PPT 1.1Dokument13 SeitenSecurityFund PPT 1.1Fmunoz MunozNoch keine Bewertungen

- Duo Interpretation Class PresentationDokument31 SeitenDuo Interpretation Class PresentationPlanetSparkNoch keine Bewertungen

- Taoist Master Zhang 张天师Dokument9 SeitenTaoist Master Zhang 张天师QiLeGeGe 麒樂格格100% (2)