Beruflich Dokumente

Kultur Dokumente

Biogas Calculator Template

Hochgeladen von

Alex Julian-Cooper0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

642 Ansichten27 SeitenThe document outlines worksheets created by Waterford County Council to calculate the energy potential from various waste streams. Worksheet 6 focuses on waste generated from industry. It provides tables to calculate biogas production from waste from a chicken processing plant, including offal, effluent, and litter. It also includes charts to guide local authorities in assessing energy potential of waste and determining appropriate processes.

Originalbeschreibung:

Copyright

© © All Rights Reserved

Verfügbare Formate

XLS, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThe document outlines worksheets created by Waterford County Council to calculate the energy potential from various waste streams. Worksheet 6 focuses on waste generated from industry. It provides tables to calculate biogas production from waste from a chicken processing plant, including offal, effluent, and litter. It also includes charts to guide local authorities in assessing energy potential of waste and determining appropriate processes.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als XLS, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

642 Ansichten27 SeitenBiogas Calculator Template

Hochgeladen von

Alex Julian-CooperThe document outlines worksheets created by Waterford County Council to calculate the energy potential from various waste streams. Worksheet 6 focuses on waste generated from industry. It provides tables to calculate biogas production from waste from a chicken processing plant, including offal, effluent, and litter. It also includes charts to guide local authorities in assessing energy potential of waste and determining appropriate processes.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als XLS, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 27

Author: Waterford County Council

Work Sheet 6 Calculates the Waste Generated from Industry

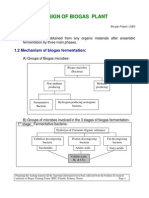

Phase 1: Assess the energy potential of the organic waste, by following the flow chart

EBIMUN: Evaluation of biomass resources for municipalities

(BIO-EN-AREA miniprogramme )

The aim of this calculator is for Local Authorities to calculate the energy

potential available to the LA and to assess the options in regards to the

energy potential of the product.

Work Sheet 1 Calculates the energy potential from Hose Hold Waste

Work Sheet 2 Calculates the energy potential from Agricultural Industry Waste

Work Sheet 7 Calculates the energy potential from Harvested Biomass

Work Sheet 3 Calculates the energy potential from Sludges

Work Sheet 4 Calculates the Energy potential from Energy Crops

Work Sheet 5 Calculates the energy potential from Catering Waste

Does the Local Authority have

access to a constant waste

stream

No

Can the waste product be used

with other products from

Agriculture / industry Yes

Flowchart for Local Authorities Assessing the Energy Potential of Waste

Wet Process

What Type of Process is best

suited and is this process

viable

Is there a suitable location

to locate such an

installation

Can a project progress with

raw product from private

industry

What Processes for energy production could the waste be used for

Flowchart for Local Authorities Assessing the Energy Potential of Waste

Can funding be sourced to

funding the installation and

is it economically justifable

Dry Process

What form of dry processes

can the waste be used for, is

there sufficient volumes of

product for an energy project

Can a building be located to

install technologies that can

be utalised the waste product

for energy purposes

Can funding be sourced to

funding the installation and is

it economically justifable

What Processes for energy production could the waste be used for

Flowchart for Local Authorities Assessing the Energy Potential of Waste

Proceed with installation

150 0

0

Energy Potential of Organic Waste Generated by Households

Typical range for organic waste to be generated by an persons ranges from 30 KG 100 KG, household organic waste generated per year

Range for biogas production per tonne of organic waste ranges from

Region Population

Organic Waste/person/year

(kg)

Potential biogas production m3

Avg. Biogas per ton of treated

waste (m3)

Tonnage Produced

Each Year

Avg. Biogas/tonne M

3

Annual Energy Potential

of Biogas

Abattoir Gastro-

Intestinal Waste

56 50 2,800

Abbatoir Fatty Waste 2 110 220

Animal By-Products

(Pasteurised)

45 100 4,500

Slaughter House

Waste Mixture

6 140 840

Animal Slaughtering 70 0

Tanneries 70 0

TOTAL 8,360

Useable waste from Cappoquin Chickens Ltd

Type Tonnes Dry solids/yr (tds)

Offal, Blood, Feathers 721

Effluent Plant Sludge 27

Cardboard 45

Chicken Litter 12,500

Energy Potential of Organic waste from Agricultural Industry

Meat Processing Waste

Waste/animal

(Nm3/year)

Number Animal

Total slurry production

(m3/year)

Tonnes dry solids

(tds/year)

Total 13,293

cappoquin chickens ltd

Number Waste/1000 birds m tonnes dry solid/1000 Tonnes dry solids Avg. Biogas/tonne

broiler chickens tonne per annum birds (tds/a) Nm

9,620,000 3.25 1.3 12,506 100

Energy Potential of Organic waste from Agricultural Industry

Meat Processing Waste

Avg. Biogas/tonne

m3

Potential Biogas

production m3

Potential Biogas

Production m

1250600

Biogas Potential from Sludges

Note 1: Typical Sludges from treatment of Sewerage have a typical output of . Per tonne dry solids

Note 2: Typical output from sludges from municipal water treatment have an output of . Per tonne dry solids

Avg. Biogas/tonne m3 Tonnes dry solids tds

Volume m3 /

year

Sludges type

Biogas Potential from Sludges

Note 1: Typical Sludges from treatment of Sewerage have a typical output of . Per tonne dry solids

Note 2: Typical output from sludges from municipal water treatment have an output of . Per tonne dry solids

Potential Biogas production

m3

Energy Crops Ton

Potential biogas prod m3 /

ton

Biogas Potential from Energy Crops

* Biogas produced from AD is assumed to have 60% Methane (CH4) content, with a calorific value of 6kWh/m

Output of the typical Biogas CHP plant is assumed to have a heat to electricity ratio of 2:1

Total potential biogas prod

m3

* Biogas produced from AD is assumed to have 60% Methane (CH4) content, with a calorific value of 6kWh/m

Output of the typical Biogas CHP plant is assumed to have a heat to electricity ratio of 2:1

Type of waste Energy potential MJ/tonne

Paper 13,500

Wood residues 20,000

Medical waste 21,000

Organic Waste Generated by Commerical Industry

Region Waste type

Annual Tonnage of

waste Generated

Avg. energy potential

MJ/tonne

Organic Waste Generated by Commerical Industry

Potential energy production

MJ

Fat 950

Bakery 500

Corn 190

Grass 175

Waste type type Biogas per ton (m3)

Avg. Biogas

Organic Waste Generated by Industrial Processes

Waste type Total amount (ton) Region

Potential

Biogas Production m3

Organic Waste Generated by Industrial Processes

Region Biomass Type

Process Under

Taken

Tonnage

harvested /

collected dry

Energy

Content / ton

(MJ)

Overall

Energy

Potential (MJ)

Total 0

http://www.biomassenergycentre.org.uk/portal/page?_pageid=75,163182&_dad=portal&_schema=PORTAL

Net Calorific Value

(CV) by mass

Net Calorific

Value (CV) by

mass

Bulk density

Energy density

by volume

Energy density

by volume

GJ/tonne kWh/kg kg/m

3

MJ/m

3

kWh/m

3

Wood chips (30%

MC)

12.5 3.5 250 3.1 870

Log wood (stacked -

air dry: 20% MC)

14.7 4.1 350-500 5,200-7,400 1,400-2,000

Wood (solid - oven

dry)

19 5.3 400-600 7,600-11,400 2,100-3,200

Wood pellets 17 4.8 650 11 3.1

Miscanthus (bale -

25% MC)

13 3.6 140-180 1,800-2,300 500-650

House coal 27-31 7.5-8.6 850 23,000-26,000 6,400-7,300

Anthracite 33 9.2 1.1 36.3 10.1

Heating oil 42.5 11.8 845 36 10

Natural gas (NTP) 38.1 10.6 0.9 35.2 9.8

LPG 46.3 12.9 510 23.6 6.6

kg/GJ kg/MWh kg

Hard coal 29 75 134 484 9680

Oil 42 85 97 350 7000

Natural gas 38 75 75 270 5400

LPG 46 82 90 323 6460

Wood chips

(25% MC) Fuel

only

Wood chips

(25% MC)

Including boiler

Wood pellets

14

17 15

37.5

45 4 300

7 25 500

7 140

These represent figures for the carbon or carbon dioxide emitted by full combustion of each fuel, per unit of energy. Note that life cycle CO

2

emissions depend

strongly upon details of supply chains, production techniques, forestry or agricultural practice, transport distances, etc.

Fuel

Approx. life cycle CO

2

emissions

(including production)

See note 1

14 37.5 2

Energy Potential from harvested biomass by Local Authorities

Fuel

Net calorific value

(MJ/kg)

Carbon content

(%)

Annual total CO

2

emissions to heat a

typical house

(20,000 kWh/yr)

(10% MC

starting from dry

wood waste)

See note 3

Wood pellets

(10% MC)

Including boiler

See note 3

Grasses/straw

(15% MC)

9 33 660 45

108 to 300 38

Notes:

1. Life cycle analysis data from: Carbon and energy balances for a range of biofuels options Elsayed, MA, Matthews, R, Mortimer, ND. Study for DTI URN

03/836 and: Comparison of energy systems using life cycle assessment A special report for the World Energy Council July 2004

2. www.electricity-guide.org.uk/fuel-mix.html

3. These figures for wood pellets include the hammer mill and pelleting process, however do not include sourcing the feedstock and any pre-processing such

as drying. If starting from green wood then drying could be a very major component, however pellets are often made from dry waste wood that has been

dried for another purpose, such as joinery. These figures also do not include transport (which is included in the figures for wod chips).

17

1.5 to 4 5.4 to 15

17

14.5

15 45 4 300

http://www.biomassenergycentre.org.uk/portal/page?_pageid=75,163182&_dad=portal&_schema=PORTAL

kg saved

compared

with oil

kg saved

compared

with gas

-2680 -4280

0 -1600

1600 0

540 -1060

5100

4900 6500

6700

These represent figures for the carbon or carbon dioxide emitted by full combustion of each fuel, per unit of energy. Note that life cycle CO

2

emissions depend

strongly upon details of supply chains, production techniques, forestry or agricultural practice, transport distances, etc.

5260 6860

Annual total CO

2

emissions to heat a

typical house

(20,000 kWh/yr)

5292 to

5100

6340

Notes:

1. Life cycle analysis data from: Carbon and energy balances for a range of biofuels options Elsayed, MA, Matthews, R, Mortimer, ND. Study for DTI URN

03/836 and: Comparison of energy systems using life cycle assessment A special report for the World Energy Council July 2004

2. www.electricity-guide.org.uk/fuel-mix.html

3. These figures for wood pellets include the hammer mill and pelleting process, however do not include sourcing the feedstock and any pre-processing such

as drying. If starting from green wood then drying could be a very major component, however pellets are often made from dry waste wood that has been

dried for another purpose, such as joinery. These figures also do not include transport (which is included in the figures for wod chips).

5100

6892 to

6700

4740

6700

Energy Potential from Local

Authority Waste

Biogas volume year Nm3

WS1

Work Sheet 1 Calculates the

energy potential from House Hold

Waste

0

WS2

Work Sheet 2 Calculates the

energy potential from Agricultural

Industry Waste

8360

WS3

Work Sheet 3 Calculates the

energy potential from Sludges

0

WS4

Work Sheet 4 Calculates the

Energy potential from Energy

Crops

0

WS5

Work Sheet 5 Calculates the

energy potential from commercial

industry

WS6

Work Sheet 6 Calculates the

Waste Generated from Industrial

processes

0

WS7

Work Sheet 7 Calculates the

energy potential from Harvested

Biomass

Overall Biogas Potential

Overall Bioenergy Potential

0

20

40

60

80

100

120

WS1 WS2 WS3

Total bioenergy distribution

Methane mass year tonnes Energy production / year(MJ) Energy production / year (MWh)

0 0 0

3 150000 41.66666667

0 0 0

0 0 0

0 0

0 0 0

0 0

150000 41.66666667

150000 41.66666667

WS4 WS5 WS6 WS7

Total bioenergy distribution

% of total

0 0

100

0

0

0

0

0

Das könnte Ihnen auch gefallen

- Biogas Plant: Biogas Digester Design, Gas Production and PurificationVon EverandBiogas Plant: Biogas Digester Design, Gas Production and PurificationNoch keine Bewertungen

- Design of Biogas DigestersDokument22 SeitenDesign of Biogas DigestersSharath Chandra100% (5)

- Detailed Project Report For Biogas Power PlantDokument132 SeitenDetailed Project Report For Biogas Power PlantShubham Jain100% (2)

- Waste To EnergyDokument9 SeitenWaste To Energyherb089Noch keine Bewertungen

- Calculations Biogas ProductionDokument4 SeitenCalculations Biogas ProductionTony Deligiorgis100% (5)

- Biogas Material BalanceDokument8 SeitenBiogas Material BalanceEngr Muhammad ArslanNoch keine Bewertungen

- Biogas Calculation Guide v3.0 - )Dokument98 SeitenBiogas Calculation Guide v3.0 - )swordprakashNoch keine Bewertungen

- Comparing Different Biogas Upgrading TechniquesDokument56 SeitenComparing Different Biogas Upgrading Techniquesengrabdulhanan100% (5)

- Biogas Calculation From CodDokument41 SeitenBiogas Calculation From CodReuben Malambugi100% (1)

- Biogas PlantDokument42 SeitenBiogas PlantPradeepLokhande100% (1)

- Publications - Design Biogas PlantDokument12 SeitenPublications - Design Biogas Planttssa100% (15)

- 4601423133391success Story of Biomethanation Projects-Dr - Bharat B NagarDokument16 Seiten4601423133391success Story of Biomethanation Projects-Dr - Bharat B Nagarpuja MangalNoch keine Bewertungen

- Danish Centralised Biogas PlantsDokument28 SeitenDanish Centralised Biogas PlantsXazolNoch keine Bewertungen

- Proposal Biogas RohulDokument13 SeitenProposal Biogas RohulIman SatriaNoch keine Bewertungen

- Techno Commercial Aspects of bio-CNG From 100 TPD Press Mud PlantDokument12 SeitenTechno Commercial Aspects of bio-CNG From 100 TPD Press Mud Plantpriyank sharmaNoch keine Bewertungen

- Biogas Plant Designs and Engery CalculationsDokument22 SeitenBiogas Plant Designs and Engery CalculationsHussein El Zikry88% (17)

- Mass Balance For Biomass and Biogas Production From Organic WasteDokument14 SeitenMass Balance For Biomass and Biogas Production From Organic WastedavidchemwenoNoch keine Bewertungen

- Anaerobic Treatment and Biogas GenerationDokument54 SeitenAnaerobic Treatment and Biogas GenerationvenkieeNoch keine Bewertungen

- Biomass - Power PlantDokument16 SeitenBiomass - Power PlantVinay MishraNoch keine Bewertungen

- Biogas Generation A Study: By: Madhav Mohan Bsc. Physics (Hons.) Ii Year Roll Number: 1815052Dokument17 SeitenBiogas Generation A Study: By: Madhav Mohan Bsc. Physics (Hons.) Ii Year Roll Number: 1815052Madhav Mohan100% (1)

- Extraction of Methane From Biogas - FinalDokument23 SeitenExtraction of Methane From Biogas - FinaldhanushNoch keine Bewertungen

- Process Simulation and Design of Biogas Plant Using Food Waste As FeedstockDokument27 SeitenProcess Simulation and Design of Biogas Plant Using Food Waste As FeedstockInternational Journal of Innovative Science and Research Technology0% (1)

- Anaerobic Digestor DesignDokument36 SeitenAnaerobic Digestor DesignChanelNoch keine Bewertungen

- Biogas HandbookDokument124 SeitenBiogas HandbookDaniel Gonzalo Herrera Peña100% (6)

- Biomass Gasification For Hydrogen ProductionDokument9 SeitenBiomass Gasification For Hydrogen ProductionCris CrisNoch keine Bewertungen

- Biogas Power PlantDokument130 SeitenBiogas Power PlantRahul Tomar100% (3)

- ICED OJK Overview of Biogas Power 160926 BK FinDokument57 SeitenICED OJK Overview of Biogas Power 160926 BK FinDigdo Setyaji100% (1)

- Paul GreeneDokument27 SeitenPaul GreeneLiuJaluNoch keine Bewertungen

- Anaerobic Digester Design and CalculationDokument42 SeitenAnaerobic Digester Design and CalculationDavid Lambert60% (5)

- Project ReportDokument25 SeitenProject ReportROHITNoch keine Bewertungen

- SWOT AnalysisDokument41 SeitenSWOT AnalysisMohamed Tarek KamarNoch keine Bewertungen

- Wood Gasification (Final)Dokument43 SeitenWood Gasification (Final)ratontopNoch keine Bewertungen

- Bio-Fuel: BY: K. Pramod E11-0031Dokument29 SeitenBio-Fuel: BY: K. Pramod E11-0031Nurul HudaNoch keine Bewertungen

- Business PlanDokument34 SeitenBusiness PlanSuratman Blanck MandhoNoch keine Bewertungen

- Hydrogen Production From Biomass.Dokument82 SeitenHydrogen Production From Biomass.tanmayrajNoch keine Bewertungen

- 9 Energy Balance and GHG Inventory SpreadsheetDokument202 Seiten9 Energy Balance and GHG Inventory SpreadsheetLok SewaNoch keine Bewertungen

- Pyrolysis 2014017017 ChelseaDokument24 SeitenPyrolysis 2014017017 ChelseaerkiruthirajNoch keine Bewertungen

- Exhaust and Jacket Water Heat Recovery From GeneratorDokument8 SeitenExhaust and Jacket Water Heat Recovery From GeneratorMuhammad Abdul Samad50% (2)

- Optimization of Biogas Generation From Press Mud in Batch ReactorDokument6 SeitenOptimization of Biogas Generation From Press Mud in Batch Reactorscm996Noch keine Bewertungen

- POME Plant CostDokument8 SeitenPOME Plant Costtamil vaanan100% (1)

- Wood Pyrolysis To Biochar: Submitted To: Engineering Physics Review Board Submitted By: Chris AlkireDokument20 SeitenWood Pyrolysis To Biochar: Submitted To: Engineering Physics Review Board Submitted By: Chris AlkireMyriah WilsonNoch keine Bewertungen

- Economics Tyre RecyclingDokument63 SeitenEconomics Tyre Recyclingapi-26693536100% (1)

- Biomass ReportDokument94 SeitenBiomass ReportRajat Negi100% (1)

- 2mw Biomass Gasification Gas Power Plant ProposalDokument9 Seiten2mw Biomass Gasification Gas Power Plant ProposalAnthony WoodardNoch keine Bewertungen

- Biogas Production and UtilizationDokument98 SeitenBiogas Production and UtilizationAhmed AwadenNoch keine Bewertungen

- 5 Economics of BiomassBoilersDokument20 Seiten5 Economics of BiomassBoilersmcalidonio5656Noch keine Bewertungen

- New Gas Fired Power Plant at Ressano Garcia - CER - Calculation - v5Dokument11 SeitenNew Gas Fired Power Plant at Ressano Garcia - CER - Calculation - v5rym romdhanNoch keine Bewertungen

- PyrolysisDokument7 SeitenPyrolysisconfirm@100% (1)

- Sector Handbook BiogasDokument39 SeitenSector Handbook BiogasMann HumanNoch keine Bewertungen

- A Presentation ON Biogas Power Plant: Submitted By: Gaurangi Saxena 1212240091Dokument30 SeitenA Presentation ON Biogas Power Plant: Submitted By: Gaurangi Saxena 1212240091ratgauriNoch keine Bewertungen

- Biogas Plants MonitoringDokument12 SeitenBiogas Plants MonitoringDeepak Dev BurmanNoch keine Bewertungen

- Emerging Technologies and Biological Systems for Biogas UpgradingVon EverandEmerging Technologies and Biological Systems for Biogas UpgradingNabin AryalBewertung: 5 von 5 Sternen5/5 (1)

- Biogas Calculator TemplateDokument26 SeitenBiogas Calculator TemplateRana BiswasNoch keine Bewertungen

- Methane To EnergyDokument5 SeitenMethane To EnergyMohammed HammadNoch keine Bewertungen

- 9) BiomassDokument64 Seiten9) BiomassDerrick VazquezNoch keine Bewertungen

- Biorefinery - The Worldwide Status at The Beginning of 2006Dokument62 SeitenBiorefinery - The Worldwide Status at The Beginning of 2006José Augusto Travassos ToméNoch keine Bewertungen

- Tannery ReportDokument6 SeitenTannery ReportdevajithNoch keine Bewertungen

- BiomassDokument7 SeitenBiomassJhonatan Romero HuarcayaNoch keine Bewertungen

- Pratica 11Dokument3 SeitenPratica 11Alex Julian-CooperNoch keine Bewertungen

- NegotiationDokument17 SeitenNegotiationnagaraj200481Noch keine Bewertungen

- Lemon Cream SauceDokument2 SeitenLemon Cream SauceAlex Julian-CooperNoch keine Bewertungen

- NegotiationDokument17 SeitenNegotiationnagaraj200481Noch keine Bewertungen

- Tarea Verano Concreto As y CorDokument3 SeitenTarea Verano Concreto As y CorAlex Julian-CooperNoch keine Bewertungen

- Elements of Soil Mechanics, 8th Edition Bearing Capacity FactorsDokument14 SeitenElements of Soil Mechanics, 8th Edition Bearing Capacity Factors3cesNoch keine Bewertungen

- Event BudgetDokument4 SeitenEvent BudgetAlex Julian-CooperNoch keine Bewertungen

- The Moment - Distribution MethodDokument30 SeitenThe Moment - Distribution MethodJovanne LanggaNoch keine Bewertungen

- Sample Lab Report PacketDokument16 SeitenSample Lab Report PacketAlex Julian-CooperNoch keine Bewertungen

- Feedstock Recycling and Pyrolysis of Waste PlasticsDokument792 SeitenFeedstock Recycling and Pyrolysis of Waste PlasticsNP100% (18)

- D86 and TBPDokument27 SeitenD86 and TBPJulio Cesar Fernadez Estela0% (1)

- PRINT - Axens - P-13, 14Dokument24 SeitenPRINT - Axens - P-13, 14D K SNoch keine Bewertungen

- 44 Cooling-System-Flush EN-1Dokument2 Seiten44 Cooling-System-Flush EN-1Jenkeiz KhanNoch keine Bewertungen

- Diesel Generator (4,000 Maintenance Work Order No: Inspection Date: Diesel Generator No: Diesel Gen Run HrsDokument2 SeitenDiesel Generator (4,000 Maintenance Work Order No: Inspection Date: Diesel Generator No: Diesel Gen Run HrsMohamed AfsalNoch keine Bewertungen

- Unit Engine Model Serial No. Code No. Model: Beri Tanda " V " Jika Kondisi Baik Dan " X " Jika Kondisi Tidak BaikDokument6 SeitenUnit Engine Model Serial No. Code No. Model: Beri Tanda " V " Jika Kondisi Baik Dan " X " Jika Kondisi Tidak BaikkkmechNoch keine Bewertungen

- HH EnglishDokument8 SeitenHH EnglishAamer Manzoor AhmadNoch keine Bewertungen

- Heat Economy in Textile MillsDokument6 SeitenHeat Economy in Textile MillsshariqfareedNoch keine Bewertungen

- Airem Energy 1.8MW Turbine Genset BrochureDokument4 SeitenAirem Energy 1.8MW Turbine Genset BrochureestebanNoch keine Bewertungen

- SO10374 Parts Catalogue: 6BTAA5.9-G2Dokument83 SeitenSO10374 Parts Catalogue: 6BTAA5.9-G2highNoch keine Bewertungen

- EWP - T&C Warranty Kia Forte 5 YearsDokument3 SeitenEWP - T&C Warranty Kia Forte 5 Yearsfaizal_aieNoch keine Bewertungen

- enDokument2 SeitenenMahmoud Reda ElSherifNoch keine Bewertungen

- Dokumen - Tips - Kubota d1105 E4bg Diesel Engine Service Repair Manual 1585667024Dokument21 SeitenDokumen - Tips - Kubota d1105 E4bg Diesel Engine Service Repair Manual 1585667024Juan LauNoch keine Bewertungen

- Diesel Fire Hydrant Booster PumpDokument1 SeiteDiesel Fire Hydrant Booster PumpAsep SaepullohNoch keine Bewertungen

- Automobile Engineering NotesDokument120 SeitenAutomobile Engineering Notesakshay2992Noch keine Bewertungen

- Fuel Oil SystemDokument2 SeitenFuel Oil SystemLawLietNoch keine Bewertungen

- Puma Belt Drive Instruction Manual 2020 09 04Dokument52 SeitenPuma Belt Drive Instruction Manual 2020 09 04MarcosNoch keine Bewertungen

- Motor Caterpillar 3044ctDokument2 SeitenMotor Caterpillar 3044ctOscar Pardo Pardo67% (3)

- Survey Report-Jack Up RigDokument67 SeitenSurvey Report-Jack Up Rigifebrian80% (5)

- Tabela Iso MateriaisDokument5 SeitenTabela Iso MateriaisMarcelo ColomboNoch keine Bewertungen

- Biodiesel From Animal Fat and OilDokument10 SeitenBiodiesel From Animal Fat and Oilmert tıglıNoch keine Bewertungen

- Continuously Variable Valve TimingDokument12 SeitenContinuously Variable Valve TiminggamerpipeNoch keine Bewertungen

- DEUTZ PowerSolutions PDFDokument9 SeitenDEUTZ PowerSolutions PDFAli ButtNoch keine Bewertungen

- (DownSub - Com) Chevrolet Bolt EV High Voltage ComponentsDokument24 Seiten(DownSub - Com) Chevrolet Bolt EV High Voltage Componentsabhi_cat16Noch keine Bewertungen

- Gx340 Gx390 Assembly GuideDokument1 SeiteGx340 Gx390 Assembly GuideSarmad Shah100% (1)

- Ling Whey Ethanol Overview 2007Dokument27 SeitenLing Whey Ethanol Overview 2007mclarkdaleNoch keine Bewertungen

- CAT - C10-C12-MBJ-MBL-Diesel-Engine-Service-ManualDokument286 SeitenCAT - C10-C12-MBJ-MBL-Diesel-Engine-Service-ManualCristina90% (41)

- Natural ResourcesDokument24 SeitenNatural ResourcesdoudouthekillerNoch keine Bewertungen

- Ford Eec Iv2168Dokument76 SeitenFord Eec Iv2168dardo100% (2)

- Tamson-Products PPSXDokument79 SeitenTamson-Products PPSXIan JoeNoch keine Bewertungen