Beruflich Dokumente

Kultur Dokumente

04 C.1.1-4.

Hochgeladen von

hulkco2Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

04 C.1.1-4.

Hochgeladen von

hulkco2Copyright:

Verfügbare Formate

Actual Trends in Development of Power System Protection and Automation

Yekaterinburg, 03.06 07.06, 2013

Implementation of a current transformer model in Simulink based on the

Hysteresis Theory of Gilet-Eserton

O. BAGLEYBTER

ALSTOM GRID UK LTD

United Kingdom

oleg.bagleybter@alstom.com

KEYWORDS

CT model, Jiles-Atherton hysteresis, Simulink, saturation, protection performance, CT requirements

1 INTRODUCTION

Correct and predictable performance of current transformers (CTs) is crucial for reliability of

protective relays connected to these CTs. The straightforward testing of HV and EHV current

transformers together with protective relays is constrained by the size and capabilities of test devices,

which does not allow using the primary current injection methods in most practical situations.

Therefore, manufacturers of numerical protection IEDs have been using various CT models for a long

time.

The accuracy of these models has an immediate impact on security and dependability of

protection devices. For example, if a specific CT model does not reproduce some important physical

phenomena, then a saturation detector or a waveform recovery algorithm developed and tested using

this model might fail in a real application.

CT models based on Jiles-Atherton theory of hysteresis have become an industry standard since

they were implemented in RTDS and PSCAD systems. These models are essentially fixed CTs +

leads + burden constructs, because the secondary current waveform is obtained as a solution to a set

of combined equations describing both the internal CT physics and the electrical network of the

burden [1]. Such an approach naturally limits the range of available CT schemes and burden options.

For example, one might need to model the following protection scheme (admittedly,

uncommon):

B A

I I

Figure 1: Complex CT arrangement

In this scheme the serial connection of the CTs increases their combined effective knee-point

voltage, while the subtractive connection of phases A and C allows protecting an MV feeder from

phase-to-phase faults using a relay with a single analogue input (the sensitivity, obviously, depends on

the faulty phases).

Another more common example is a high-impedance busbar protection, where the burden

includes a non-linear resistor. For such a scheme a new CTs + burden module would have to be

added in RTDS or PSCAD, especially considering the fact that non-linear resistors from different

manufacturers can have different characteristics.

1

Actual Trends in Development of Power System Protection and Automation

Yekaterinburg, 03.06 07.06, 2013

In this paper a Simulink model of CT is presented, which is based on Jiles-Atherton theory of

hysteresis from [2] with minor adjustments. The main advantage of this model is that it is decoupled

from the burden network. Hence, using Simulink, several CT models can be interconnected together

with other electrical elements from SymPowerSystems library in any imaginable combination.

2 JILES-ATHERTON (J-A) MODEL OF FERROMAGNETIC HYSTERESIS

2.1 Jiles-Athertom (J-A) model of ferromagnetic hysteresis

The model was originally proposed by D. C. Jiles and D. L. Atherton in their paper [3]. Unlike

the phenomenological Preisach model [4], it is based on the physics of the ferromagnetic materials,

namely on energy dissipation within a magnetic material resulting from changes in its magnetization.

A comparison between Preisach and J-A models of hysteresis can be found in [5]. The authors

demonstrated the similar performance of both approaches; however the JA hysteresis model offers a

higher computational efficiency according to [6].

An interpretation of the J-A model adopted in this paper generally follows the existing

implementation in RTDS and PSCAD, which in turn is based on [2]. The following enhancements

to the original J-A model formulation in [3] were proposed in [2]:

- an improved anhysteretic function instead of the Langevin function;

- dynamic adjustment of the Domain Pinning Parameter.

Equations (1-10) briefly summarize the variation of the J-A model presented in [2].

( ) H M B + =

0

, (1)

where B magnetic flux density; M magnetization; H magnetic field intensity.

If ( ) 0 M M

an

: (2)

e

an

an

an

e

an

dH

dM

c

c

M M k

M M

dH

dM

c

dH

dM

+

=

1

1

) (

0

mod

,

(3)

otherwise:

e

an

e

an

dH

dM

c

dH

dM

c

dH

dM

=

1

, (4)

where anhysteretic magnetization;

an

M , J-A model parameters. c

=

dt

dH

sign , (5)

b

e e

b

e e

s an

H H a a

H H a

M M

+ +

+

=

2 3

1

, (6)

M H H

e

+ = , (7)

If 0 H : (8)

=

2

mod

1

s

M

M

k k , (9)

otherwise

k k =

mod

. (10)

2

Actual Trends in Development of Power System Protection and Automation

Yekaterinburg, 03.06 07.06, 2013

where J-A model parameter, k coefficient of adjustment. k

Now let us adapt the equations (1-10) for efficient implementation in the Simulink

environment.

First of all, condition (8) is replaced by (11), the explanation given in section 3.1 of this paper.

If 0 M : (11)

The original equation (6) for anhysteretic magnetization is only valid for positive values

of and , therefore it needs to be modified as follows:

an

M

e

H

an

M

b

e e

b

e e

s e an

H H a a

H H a

M H M

+ +

+

=

2 3

1

) sign( . (12)

The derivative of with respect to (used in (3) and (4)) can be also calculated explicitly

as per [2]:

an

M

e

H

( )

2

2 3

1 2

1

3 3 1

) )( 1 (

b

e e

b

e

b

e

s

e

an

H H a a

H a a b H ba a a

M

dH

dM

+ +

+ +

=

.

(13)

Equations (3, 4) represent continuous-time relationship between magnetization M and magnetic

field intensity H. Implementing this model in Simulink requires its discrete-time modification (the

time step can be either variable or fixed).

At any step in time the input variables for the model are:

- the present value of the instantaneous excitation voltage

e

v ;

- the present value of the magnetization M ;

- the present value of the magnetic field intensity H and its previous value

PREV

H .

Using the discrete values of H and equation (5) can be replaced by (14):

PREV

H

( )

PREV

H H = sign . (14)

The models output variables are:

- time derivative of the magnetic field intensity dt dH ;

- time derivative of the magnetization dt dM .

Several ancillary equations are used in the process:

Area N

v

dt dB

e

2

= ,

(15)

+

=

1

0

dH

dM

dt dB

dt dH

,

(16)

dt dH

dt dB

dt dM =

0

.

(17)

The obtained time derivatives of the magnetic field intensity and magnetization are

subsequently passed through integrators, thus determining the transition to the next time step.

Having calculated the value of the magnetic field intensity H , the secondary current to be

injected into the CT burden network can be found using the following equation:

2

i

2 2

1

1 2

N

Length

H

N

N

i i = .

(18)

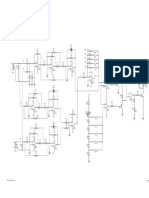

A flowchart in Fig. 2 shows the sequence of calculations executed at every step in time.

3

Actual Trends in Development of Power System Protection and Automation

Yekaterinburg, 03.06 07.06, 2013

e

v

dt dB

H

PREV

H

mod

k

H

M

) (n

an

M

e

H

e

H

H

M

e

H

e

an

dH

dM

dH

dM M

e

an

dH

dM

an

M

dt dH

dH

dM

dt dM

s

1

M

H

s

1

mod

k

dt

dB

dt

dH

dt

dM

2

i

1

i

2

i

e

v

Figure 2: CT model flowchart

The two integrators {1} and {2} in the flowchart are critically important for the Simulink

implementation of J-A hysteresis model. It would be possible to implement the same equations in

Simulink without integrators but this would most likely lead to the occurrence of multiple algebraic

loops (for a more detailed description of algebraic loops in Simulink see [7]). The in-built

Simulink loop solver is generally robust, but sometimes it may not converge and also significantly

reduces the simulation speed.

The integrators effectively break the direct feedthrough links and therefore eliminate the

algebraic loops. The calculations at each time step are thus reduced to a number of sequentially

executed instructions, speeding up the simulation and ensuring the models convergence.

3 PROBLEMS FACED AND SOLUTIONS PROPOSED

3.1 Adjustment of the Domain Pinning Parameter k

The original condition (8) for k adjustment was first taken from [2] and implemented in

Simulink as is. This led to several cases of poor numerical performance of the model, namely

inaccurate results (with high Relative Tolerance setting of Simulink solver, 1e-4) or unacceptably

slow simulation speed (with the same tolerance parameter set to lower value, 1e-7).

After some investigations the cause of such poor performance was pinned down to the sudden

change of the derivative dH dM (see the breaking point in Fig. 3), which is evidently non-physical.

The proposed condition (11), on the contrary, does not result in such undesirable behaviour of M-H

function, while still doing the job for which the adjustment of k was introduced in the first place it

reduces the width of the simulated hysteresis loop in the shoulder area [2].

4

Actual Trends in Development of Power System Protection and Automation

Yekaterinburg, 03.06 07.06, 2013

-10 -5 0 5 10

1.12

1.14

1.16

1.18

1.2

1.22

1.24

1.26

1.28

1.3

1.32

x 10

6

0 H

0 M

Figure 3: M-H characteristics with different adjustment conditions

It is worth mentioning that in [2] the authors proved that the dynamic adjustment of k does not

make any noticeable effect on the secondary current waveform. However, this adjustment was

preserved in the CT model described here (with condition (8) replaced by (11)) in order to unify it

with existing models in RTDS and PSCAD.

3.2 The models behaviour under heavy saturation conditions.

It can be seen from the flowchart in Fig. 2 that the values of H and M are calculated by

integrating their respective time derivatives. When a CT model is pushed into heavy saturation, the

integrators become prone to numerical errors, see Fig. 4 and Fig. 5. This can have two effects on the

CT simulation, both adverse:

- the errors may accumulate, yielding the simulation results completely invalid;

- the irregular shape of the M-H curve slows the calculations down in the Continuous

simulation mode (see the first line in Table 2).

The first problem can be overcome by reducing the Relative Tolerance setting to 1e-7, but this,

unfortunately, makes the simulation speed much slower (see the second line in Table 3).

H, A/m

M, A/m

H, A/m

M, A/m

Figure 4: M-H hysteresis loop under heavy saturation

5

Actual Trends in Development of Power System Protection and Automation

Yekaterinburg, 03.06 07.06, 2013

a) Original behaviour under heavy saturation

b) Simplified behaviour under heavy saturation

Figure 5: M-H characteristics under heavy saturation

At the same time it is obvious that once the saturation reaches a certain limit, , the difference

between ascending and descending branches of the hysteresis loop becomes negligible (see Fig. 4).

Hence switching to a simplified anhysteretic model can be introduced as described in equations (19-

21).

s

H

If

s

H H : (19)

an

M M = , (20)

e

an

e

an

an

dH

dM

dH

dM

dH

dM

dH

dM

= =

1

. (21)

Equation (20) resets the corresponding integrator {2} in the flowchart Fig. 2 and, therefore,

eliminates the numerical error seen in Fig. 5.a.

The fact that is a function of (12), while itself is a function of

an

M

e

H

e

H M (7), makes

obtaining a close-form solution of M with respect to H a challenging task.

A simple iterative procedure was proposed to calculate M based on a known value of H :

1. Assume ,

s

M M =

2. Calculate using equation (7),

e

H

3. Calculate new value of using equation (12),

an

M M =

4. Repeat steps 2-3 N times.

Table 1 below shows that after maximum two iterations the error becomes negligible.

H = 1000 A/m

M

true

= 1518043.45 A/m

H = 2000 A/m

M

true

= 1559462.85 A/m

H = 20000 A/m

M

true

= 1684462.19 A/m

Iteration

number

M

iter

Error, % M

iter

Error, % M

iter

Error, %

0 1720000 13.3 1720000 10.3 1720000 2.1

1 1518188.59 9.6e-3 1559530.88 4.4e-3 1684462.90 4.3e-5

2 1518043.55 6.9e-6 1559462.88 1.8e-6 1684462.19 0

3 1518043.45 0 1559462.85 0 1684462.19 0

Table 1: Accuracy of iterations

6

Actual Trends in Development of Power System Protection and Automation

Yekaterinburg, 03.06 07.06, 2013

The simplified saturation behaviour is implemented as a configurable option that significantly

increases the simulation speed. The default threshold is 2000 A/m (based on the default hysteresis

parameters from [2]), the corresponding relative difference between the major loop branches is

(1.5606e+6 - 1.5592e+6) / 1.5592e+6 * 100 = 0.09%

s

H

H, A/m

M, A/m

Original

Simplified

Figure 6: M-H characteristics under heavy saturation

A comparison between different simulation modes can be found in the table below. Timing tests

were performed using a laptop with Intel Core2 Duo CPU P8400 @ 2.26GHz with 2GB of RAM.

Simplified

saturation behaviour

Relative Tolerance Accuracy

Execution time (per one

second of simulation)

Disabled 1e-4 Bad 1.16 s

Disabled 1e-7 Good 1.96 s

Enabled 1e-4 Good 0.59 s

Table 2: Simulation results

3.3 Connecting the CT model to inductive burden.

The CT model in Simulink uses a controlled current source as its output, which is consistent

with the MATLAB Help guidelines for modelling of non-linear elements [8]. A current source,

obviously, cannot be connected in series with an inductor. To allow connecting non-linear elements to

inductors MATLAB Help recommends paralleling the current source with a relatively high resistance;

that is why the R_Loss resistor is introduced in the scheme below.

Figure 7: Internal connections of the CT model

7

Actual Trends in Development of Power System Protection and Automation

Yekaterinburg, 03.06 07.06, 2013

The recommended value of the R_Loss resistance is about 1000-10000 times the total burden

impedance. This would introduce an additional error of 0.01-0.1% that can be ignored in real-life

scenarios.

4 UTILIZING SIMULINK CT MODELS PRACTICAL EXAMPLES

4.1 Implementation of the scheme from Fig. 1.

The example below shows the implementation of the scheme described in section 1

INTRODUCTION and proves the idea of decoupling CT model from its burden. The RL burden in

Fig. 8 can be easily replaced with any kind of custom-built nonlinear electrical elements.

The primary and secondary current waveforms in Fig. 9 (measured at one of the CTs) clearly

demonstrate the phenomenon of saturation.

Figure 8: Implementation of a complex CT scheme

t, s

C

u

r

r

e

n

t

,

A

Figure 9: Illustration of saturation in the complex CT scheme

4.2 Using CT models in the development of new protection algorithms

According to [9] and [10], Simulink is now becoming the main tool for the development of

new protection and control algorithms. Though the final stage of such development process is still

Hardware-In-the-Loop (HIL) testing, the ability to test those algorithms within Simulink

environment is absolutely critical for fast delivery of the project.

Testing protection relays for CT requirements is extremely time-consuming. A brief description

of the testing procedure adopted in ALSTOM GRID and of the efforts involved can be found in [11].

In that particular project of Current Differential protection with Transient Biasing the Simulink CT

model was used extensively. This helped to significantly speed up the development by refining the

algorithm even before it was actually implemented in the protection device.

Obviously, testing new protection algorithms with CT models in Simulink does not take into

account many hardware-related factors, and as such needs to be considered as preparatory to RTDS

8

Actual Trends in Development of Power System Protection and Automation

Yekaterinburg, 03.06 07.06, 2013

testing. For example, during the development described in [11] thousands of faults with various

characteristics were first injected into Simulink CT models connected to the model of the relay. Only

when the algorithms performance was considered satisfactory, the project proceeded into the final

HIL testing using RTDS equipment.

5 CONCLUSION

The CT model presented in this paper was created to facilitate the development (and especially

validation) of new protection algorithms in Simulink. The main goals were to make this new model

as flexible, accurate and fast as possible without sacrificing its unification with existing CT models in

RTDS and PSCAD. A well-proven variation of J-A theory of ferromagnetic hysteresis was taken

from [2] and subjected to some minor modifications. The resulting Simulink CT model was

successfully used in two recent development projects the Transient Biasing for Current Differential

mentioned above (already available in ALSTOM GRID product range) and another Current

Differential improvement that is now going through its final testing stages.

The major constraint of the developed CT model is that it needs to be executed in Continuous

simulation mode (powergui block setting) and, therefore, the solvers type has to be Variable-step.

The simulation speed in Continuous mode is sufficient for small protection scheme containing 1-10

CTs. For example, the scheme with 4 CTs presented in Fig. 8 takes 0.66 seconds of real time per 1

second of simulation (check section 3.2 for details on the PC used). However, for large schemes with

tens of CTs connected to a common burden network the simulation speed is not satisfactory.

One way of improving the model might be switching to Discrete simulation mode and Fixed-

step solver type. So far the authors attempts to do so have not succeeded the discrete variation of

the same Simulink model exhibited poor accuracy and low reliability, especially with inductive

burden connected.

Another direction for future work is implementation of the J-A hysteresis model in a universal

electromagnetic element using Simulink SimScape. This universal element would represent the

relations between its windings electrical parameters and its cores magnetic parameters. Several such

elements could be connected together (meaning electrical connection of windings and magnetic

connection of cores/gaps) to model any complex multi-winding/multi-core electromagnetic system

transformer, autotransformer, reactor etc.

REFERENCES

[1] PSCAD On-Line Help System, https://pscad.com/products/pscad/free_downloads, Manitoba

HVDC Research Centre Inc. (accessed: 13 Aug 2012).

[2] U. D. Annakkage, P. G. McLaren, E. Dirks, R. P. Jayasinghe and A. D. Parker, A Current

Transformer Model Based on the Jiles-Atherton Theory of Ferromagnetic Hysteresis, IEEE

Transactions On Power Delivery, vol. 15, No. 1, pp. 57-61, Jan 2000.

[3] D. C. Jiles and D. L. Atherton, Ferromagnetic hysteresis, IEEE Trans. Magn., vol. 19, No. 5,

pp. 21832185, Sep. 1983.

[4] I. D. Mayergoyz, Mathematical Models of Hysteresis and Their Application, 2nd ed.

Amsterdam, The Netherlands: Elsevier, 2003.

[5] A. Benabou, S. Clenet, and F. Piriou, Comparison of Preisach and Jiles-Atherton models to

take into account hysteresis phenomenon for finite element analysis, J. Magn. Magn. Mater.,

No. 261, pp. 139160, 2003.

[6] S. Rosenbaum, M. Ruderman, T. Strhla, and T Bertram, Use of JilesAtherton and Preisach

Hysteresis Models for Inverse Feed-Forward Control, IEEE Trans. Magn., vol. 46, No. 12, pp.

3984-3989, Dec. 2010.

[7] Simulink User's Guide, http://www.mathworks.nl/help/toolbox/simulink/ug/f7-8243.html, The

MathWorks, Inc. (accessed: 13 Aug 2012).

9

Actual Trends in Development of Power System Protection and Automation

Yekaterinburg, 03.06 07.06, 2013

10

[8] SimPowerSystems User's Guide,

http://www.mathworks.nl/help/toolbox/physmod/powersys/ug/f1-7758.html, The MathWorks,

Inc. (accessed: 13 Aug 2012).

[9] C. Apostolopoulos, G. Korres, Real-time implementation of digital relay models using

MATLAB/SIMULINK and RTDS, Euro. Trans. Electr. Power, vol. 20, issue 3, pp. 290305,

Apr. 2010.

[10] B. Kirby, H. Kang, Model Based Design for Power Systems Protection Relays, Using Matlab

& Simulink, Proceedings of the 9th International Conference on Developments in Power

Systems Protection, 17-20 Mar. 2008, Glasgow, UK.

[11] O. Bagleybter, S. Subramanian, Enhancing differential protection stability during CT saturation

with Transient Bias, Proceedings of the 11th International Conference on Developments in

Power Systems Protection, 23-26 Apr. 2012, Birmingham, UK.

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Ijeev4n1 9Dokument20 SeitenIjeev4n1 9hulkco2Noch keine Bewertungen

- Paper 4 Paniput ICACCT2011Dokument5 SeitenPaper 4 Paniput ICACCT2011tariq76Noch keine Bewertungen

- Ijeev4n1 9Dokument20 SeitenIjeev4n1 9hulkco2Noch keine Bewertungen

- Modeling and Testing of a Digital Distance Relay Using MATLAB/SIMULINKDokument7 SeitenModeling and Testing of a Digital Distance Relay Using MATLAB/SIMULINKhulkco2Noch keine Bewertungen

- Livewire - Professional Edition - 87G - 5 - 270113Dokument1 SeiteLivewire - Professional Edition - 87G - 5 - 270113hulkco2Noch keine Bewertungen

- 04 C.1.1-4.Dokument10 Seiten04 C.1.1-4.hulkco2Noch keine Bewertungen

- Analysis of Modern Digital Differential Protection For Power Transformer-128Dokument8 SeitenAnalysis of Modern Digital Differential Protection For Power Transformer-128hulkco2Noch keine Bewertungen

- Paper 4 Paniput ICACCT2011Dokument5 SeitenPaper 4 Paniput ICACCT2011tariq76Noch keine Bewertungen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Classification of Lung Cancer Detection Using Convolution Neural Network (CNN)Dokument11 SeitenClassification of Lung Cancer Detection Using Convolution Neural Network (CNN)dataprodcsNoch keine Bewertungen

- Syllabus of BMRIT-1Dokument19 SeitenSyllabus of BMRIT-1Megha NaithaniNoch keine Bewertungen

- CancerDokument228 SeitenCancerCrystal Grace100% (1)

- Cancer vs CarcinogensDokument20 SeitenCancer vs CarcinogensChelzy Catabas100% (2)

- What Is A Tandem IsolatorDokument3 SeitenWhat Is A Tandem Isolatordebasis_cpp123100% (2)

- Cameron - IPMNDokument8 SeitenCameron - IPMNPaulNoch keine Bewertungen

- Multidetector-Row CT Angiography PDFDokument218 SeitenMultidetector-Row CT Angiography PDFJaime BonillaNoch keine Bewertungen

- Hispeed Dual Theory of OperationDokument139 SeitenHispeed Dual Theory of OperationJoel Inacio100% (1)

- Guide to eLicensing Radiation AppsDokument33 SeitenGuide to eLicensing Radiation AppsdrmohangNoch keine Bewertungen

- Managing Penetrating Abdominal TraumaDokument5 SeitenManaging Penetrating Abdominal TraumaAziil LiizaNoch keine Bewertungen

- ScintCare CT 128 en 202202 Rev.EDokument296 SeitenScintCare CT 128 en 202202 Rev.EMerzak BoukiNoch keine Bewertungen

- Dual Energy CTDokument11 SeitenDual Energy CTdeadcorpsesNoch keine Bewertungen

- Access CT Brochure - HR - FINALDokument12 SeitenAccess CT Brochure - HR - FINALAlin Mircea PatrascuNoch keine Bewertungen

- WWW - Medicaldelta.ro Cabinet Medical Mercado Tulcea Tomograf Somaton BalanceDokument17 SeitenWWW - Medicaldelta.ro Cabinet Medical Mercado Tulcea Tomograf Somaton BalancekowykoNoch keine Bewertungen

- Edge Enhancement Based Transformer For Medical Image Denoising PDFDokument8 SeitenEdge Enhancement Based Transformer For Medical Image Denoising PDFMohammed KharbatliNoch keine Bewertungen

- TCRT 2012 500394Dokument12 SeitenTCRT 2012 500394WALTERNoch keine Bewertungen

- Characteristics of SiO2-TiO2Dokument17 SeitenCharacteristics of SiO2-TiO2Isna NurhidayatiNoch keine Bewertungen

- ENGLISHDokument8 SeitenENGLISHJohn Michael LapasaNoch keine Bewertungen

- CT Scan Ref-Brampton CivicDokument1 SeiteCT Scan Ref-Brampton CivicalikuniNoch keine Bewertungen

- White Paper Bone Suppression Chest 201403Dokument6 SeitenWhite Paper Bone Suppression Chest 201403ShinjaKarasumoriNoch keine Bewertungen

- LightSpeed 3.X Technical Reference Manual - UM - 2302180-100 - 8Dokument172 SeitenLightSpeed 3.X Technical Reference Manual - UM - 2302180-100 - 8Ian Bruno Rodriguez CenturionNoch keine Bewertungen

- Dse7310mkii Dse7320mkii Operations ManualDokument170 SeitenDse7310mkii Dse7320mkii Operations ManualPHÁT NGUYỄN THẾNoch keine Bewertungen

- Pancreatic Cystic Lesions English 2019Dokument25 SeitenPancreatic Cystic Lesions English 2019Worku KifleNoch keine Bewertungen

- Cranioplasty With Custom-Made Titanium Plates-14 Years ExperienceDokument10 SeitenCranioplasty With Custom-Made Titanium Plates-14 Years Experiencethanhnhat5521Noch keine Bewertungen

- Siemens CT - Low - Dose - GuideDokument66 SeitenSiemens CT - Low - Dose - GuideSyazwanee Nasir100% (1)

- TMEIC Directo-Matic LCI 2011 Low-Res 1312294547Dokument8 SeitenTMEIC Directo-Matic LCI 2011 Low-Res 1312294547Parameswararao BillaNoch keine Bewertungen

- BTS Bronchiectasis Guideline PDFDokument54 SeitenBTS Bronchiectasis Guideline PDFnazarNoch keine Bewertungen

- Enhanced Precision in The OR: Answers For LifeDokument20 SeitenEnhanced Precision in The OR: Answers For LifeHeidi BlueNoch keine Bewertungen

- Tumor Celulas GigantesDokument7 SeitenTumor Celulas GigantesGabyNoch keine Bewertungen