Beruflich Dokumente

Kultur Dokumente

Gs Oxygen Sensor

Hochgeladen von

curublackCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Gs Oxygen Sensor

Hochgeladen von

curublackCopyright:

Verfügbare Formate

Revised 06/05 1

TECHNICAL INFORMATION FOR KE-SERIES

Technical Information for GS Oxygen Sensor KE-Series

The GS Oxygen Sensor KE-Series

is a unique galvanic cell type

oxygen sensor which provides a

linear output voltage signal relative

to percent oxygen present in a

particular atmosphere. The sensor

features long life expectancy,

excellent chemical durability, and it

is not inuenced by CO2, making

it ideal for oxygen monitoring.

Page

Introduction...............................................................................................2

Basic Information and Specications

Features...............................................................................................2

Applications.......................................................................................2

Structure and Operating Principle.................................................2

Specifications.........................................................................2

Absolute Maximum Operating and Storage Conditions............3

Dimensions.................................................................................3

Manufacturing Code Number...........................................................4

Typical Sensitivity Characteristics

Sensitivity to Oxygen...........................................................................4

Response Speed..............................................................................4

Inuence from Various Gases...........................................................4

Effects of Pressure Change......................................................5

Humidity Dependency...........................................................5

Temperature Dependency..................................................................6

Reliability

Inuence of Organic Solvents.....................................................6

Life Expectancy.................................................................................6

Relationship of Expected Life and O2 Concentration..............6

Relationship of Expected Life and Storage Temperature.........6

Long Term Stability...........................................................................7

Handling Instructions.......................................................................................7

Warranty...........................................................................................................9

a

n

I

S

O

9

0

0

1

/

1

4

0

0

1

c

o

m

p

a

n

y

Revised 06/05 2

TECHNICAL INFORMATION FOR KE-SERIES

1. Introduction

The GS Oxygen Sensor KE series (KE-25 and KE-50) is

a unique galvanic cell type oxygen sensor which

was developed in Japan in 1985. Its most notable

features are a long life expectancy, excellent chemical

durability, and it is not inuenced by CO2. The

KE series oxygen sensor is ideal to meet the ever-

increasing demand for oxygen monitoring in various

fields such as combustion gas monitoring, the

biochemical eld, medical applications, domestic

combustion appliances, etc.

2. Basic Information and Specications

2-1 Features

* Long life (KE-25 - 5 years / KE-50 - 10 years)

* Virtually no inuence from CO2, CO, H2S, NOx, H2

* Low cost

* Operates in normal ambient temperatures

* Stable output signal

* No external power supply required for sensor

operation

* No warm-up time is required

2-2 Applications

* Medical - Anesthetic instruments, respirators,

oxygen-enrichers

* Biotechnology - Oxygen incubators

* Food industry - Refrigeration, greenhouses

* Safety - Air conditioners, oxygen detectors, re

detectors

2-3 Structure and operating principle

The KE series sensor is a lead-oxygen battery which

incorporates a lead anode, an oxygen cathode made of

gold, and a weak acid electrolyte. Oxygen molecules

enter the electrochemical cell through a non-porous

uorine resin membrane and are reduced at the gold

electrode with the acid electrolyte. The current

which ows between the electrodes is proportional

to the oxygen concentration in the gas mixture

being measured. The terminal voltages across the

thermistor (for temperature compensation) and

resistor are read as a signal, with the change in

output voltages representing the change in oxygen

concentration.

The following chemical reactions which take place

in KE sensors:

Cathodic reaction: O2 + 4H

+

+ 4e

-

2H2O

Anodic reaction: 2Pb + 2H2O 2PbO + 4H

+

+ 4e

-

Total reaction: O2 + 2Pb 2PbO

A small volume air bubble is contained inside the sensor

body in order to compensate for internal inuence from

pressure changes. The sensor's electrolyte is primarily

composed of acetic acid with a pH of approximately 6.

The sensor's body is made of ABS resin.

Both the KE-25 and the KE-50 sensors are based on

identical design and performance principles. The

basic difference between these two models is in the

thickness of the uorine resin membrane. This affects

the diffusion speed of oxygen molecules and, as a

result, the response speed and life of the sensor. Each

model shows basically the same performance in the

various conditions described in the technical data, e.g.

inuence by other gases, pressure dependency, etc.

2-4 Specications

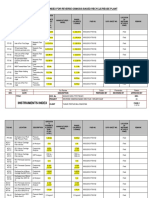

Table 1 (see following page) shows the specications

of the KE series oxygen sensors.

Notes:

1) When calibrated at both 0% and 100% of O2, accuracy

in the range from 0-100% O2 shall be within 1% of

full scale for KE-25 and 2% of full scale for KE-50.

2) Va = output voltage at 21% O2

V0 = output voltage at 0% O2

V100 = output voltage at 100% O2

3) Va = output voltage at 25C

VH = output voltage at 40C

VL = output voltage at 5C

4) Sensors should be used under conditions where

the air exchange is greater than 200~300ml per

minute in order to obtain the response speed as

specied in Table 1.

Fig. 1 - Structure of KE-25/KE-50

Bottom Lid

Compensating

Resistor

Air Bubble

Electrolyte

Lead Electrode

(Anode)

Lead Wire (-)

Lead Wire (+)

Thermistor

Titanium

Lead Wire

Current

Collector

O-Ring

Inner Lid

Outer Lid

Oxygen Permeable

Membrane

Gold Electrode

(Cathode)

Revised 06/05 3

TECHNICAL INFORMATION FOR KE-SERIES

m e t I m e t I m e t I m e t I m e t I

l e d o M l e d o M l e d o M l e d o M l e d o M

5 2 - E K 5 2 - E K 5 2 - E K 5 2 - E K 5 2 - E K 0 5 - E K 0 5 - E K 0 5 - E K 0 5 - E K 0 5 - E K

e g n a r t n e m e r u s a e M O % 0 0 1 ~ 0 2

( y c a r u c c A 1 e t o N ) ) e l a c s l l u f ( % 1 ) e l a c s l l u f ( % 2

s n o i t i d n o c g n i t a r e p O

e r u s s e r p c i r e h p s o m t A a P h 6 1 2 1 ~ a P h 1 1 8

e r u t a r e p m e T C 0 4 ~ 5

y t i d i m u h e v i t a l e R ) n o i t a s n e d n o c o n ( . H . R % 0 9 ~ 0 1

( ) % 0 9 ( e m i t e s n o p s e R 4 e t o N ) 4 1 s d n o c e s 2 0 6 s d n o c e s 5

s n o i t i d n o c t s e t d r a d n a t s r e d n u e g a t l o v t u p t u o l a i t i n I V m 5 . 5 1 ~ 0 . 0 1 V m 5 6 ~ 7 4

s n o i t i d n o c t s e t d r a d n a t S

s a g t s e T O % 1 2 2

e r u s s e r p c i r e h p s o m t A 3 1 0 1 a P h 5

e r u t a r e p m e T C 5 2 C 1

y t i d i m u h e v i t a l e R 0 6 % 5

y t i r a e n i L

V - a V ( 0 V ( / ) 0 0 1 V - 0)

( 2 e t o N )

1 2 . 0 2 0 . 0

e g a t l o v t e s f f O V0 V m 5 . 0 V m 0 . 6

e r u t a r e p m e T

( s c i t s i r e t c a r a h c 3 e t o N )

VH a V / 9 0 . 1 ~ 1 9 . 0

VL a V / 9 0 . 1 ~ 1 9 . 0

2-5 Absolute maximum operating and storage conditions

The accumulated total duration of exposure to the

absolute maximum conditions listed in Table 2 should

be limited to no more than 24 hours.

Cautions:

1) Beneath the lower pressure limit, sensor life may

Table 1 - Specications of KE-25/KE-50

m e t I m e t I m e t I m e t I m e t I t i m i l r e w o L t i m i l r e w o L t i m i l r e w o L t i m i l r e w o L t i m i l r e w o L t i m i l r e p p U t i m i l r e p p U t i m i l r e p p U t i m i l r e p p U t i m i l r e p p U

e r u s s e r P ( a P h 7 0 5 1 e t o N ) ( a P h 0 2 5 1 2 e t o N )

e r u t a r e p m e T ( C 0 2 - 3 e t o N ) ( C 0 6 4 e t o N )

y t i d i m u h e v i t a l e R ( H R % 0 5 e t o N ) H R % 0 0 1

Table 2 - Absolute maximum operating and storage conditions

of KE-25/KE-50

become shorter due to excessive evaporation of the

liquid electrolyte.

2) At pressure in excess of the upper limit, sensor

output may become unstable due to excessive air

entering through the o-ring.

3) Below -20C, the electrolyte will freeze and

the sensor will not function. KE sensors are not

damaged by freezing of the electrolyte and will

resume functioning after the electrolyte thaws to a

liquid state.

4) At temperatures in excess of the upper limit, the

ABS resin casing may deteriorate.

5) If used for a long period in an extremely dry

environment, sensor life may be shortened due to

excessive evaporation of the liquid electrolyte.

2-6 Dimensions (see Fig. 2)

Figure 2 - Dimensions of KE-25/KE-50

OXYGEN

KE-

NO.94

JAPANSTORAGE

280.5

2

2

.

5

0

.

3

805

42

4

7

.

3

0

.

5

5

23.20.5

15

9

M16 x P1.0

8

1

.

5

4

.

5

2

.

5

1

5

Lead wire

4

7

.

3

0

.

5

5

23.20.5

15

9

23.20.5

9

16

16.6

5

0

0

.

5

5

7

0

.

5

Unit = mm

22.70.5

2

3

0

.

5

KE-25/KE-50 standard version KE-25F1 (w/o flange) KE-25F3 (threaded top) KE-25F4 (O-ring top)

1

3

1

3

22.70.5

2

3

0

.

5

22.70.5

2

3

0

.

5

Revised 06/05 4

TECHNICAL INFORMATION FOR KE-SERIES

2-7 Manufacturing code number

The manufacturing code number shown on the side

of the sensor body indicates the manufacturing Year/

Month/Lot No. (since September 1990).

Example: 02 09 01

Year Month Lot No.

2002 Sept. 01

3. Typical Sensitivity Characteristics

3-1 Sensitivity to oxygen

Figures 3a and 3b show the sensitivity characteristics

of the KE sensors. The Y-axis indicates the output

voltage of the sensor.

3-2 Response time

Figure 4 demonstrates the response pattern of the

sensor's output voltage. The Y-axis indicates the

output voltage ratio(%) to saturated voltage. Typical

response time to 90% of saturated response is 14

seconds for KE-25 and 60 seconds for KE-50.

3-3 Inuence of various gases

The inuence on KE sensors from various gases is

shown in Table 3. The 'interference level' shown in

the table indicates the change ratio between sensor

output in an air (20.7% O2) and gas mixture compared

to sensor output in normal air (20.7% O2). For

example, if the interference level of SO2 is considered

to be 3%, that would indicate that the sensor's output

voltage in normal air (20.7% O2) would correspond

to a concentration of 21.3% O2 (20.7% x 1.03).

Fig. 3b - KE-50 sensitivity characteristics

Fig. 3a - KE-25 sensitivity characteristics

0

20

40

60

80

100

120

0 30 60 90 100 110 120

Time (sec.)

O

u

t

p

u

t

r

a

t

i

o

(

%

)

KE-25

KE-50

Fig. 4 - Response speed of KE sensors to oxygen

s a G s a G s a G s a G s a G n o i t a r t n e c n o C n o i t a r t n e c n o C n o i t a r t n e c n o C n o i t a r t n e c n o C n o i t a r t n e c n o C l e v e L e c n e r e f r e t n I l e v e L e c n e r e f r e t n I l e v e L e c n e r e f r e t n I l e v e L e c n e r e f r e t n I l e v e L e c n e r e f r e t n I

e d i x o n o m n o b r a C % 0 0 1 - 0 t c e f f e o n

e d i x o i d n o b r a C % 0 0 1 - 0 t c e f f e o n

e d i x o n o m c i r t i N % 1 - 0 t c e f f e o n

e d i x o i d n e g o r t i N % 1 - 0 t c e f f e o n

e d i x o i d r u f l u S % 3 - 0 % 3

e d i f l u s n e g o r d y H % 3 - 0 t c e f f e o n

a i n o m m A % 3 - 0 % 1

n e g o r d y H % 0 0 1 - 0 t c e f f e o n

e d i r o l h c n e g o r d y H % 3 - 0 % 1

e n e z n e B m p p 0 0 1 - 0 % 1

e n a h t e M % 0 0 1 - 0 t c e f f e o n

Table 3 - Inuence of various gases on KE-series sensors

Oxygen concentration (%)

O

u

t

p

u

t

v

o

l

t

a

g

e

(

m

V

)

0

70

60

50

40

30

20

10

0 10 20 30 40 50 60 70 80 90 100

80

max.

min.

typ.

0

0

Oxygen concentration (%)

O

u

t

p

u

t

v

o

l

t

a

g

e

(

m

V

)

300

250

200

150

100

50

10 20 30 40 50 60 70 80 90 100

max.

min.

typ.

Revised 06/05 5

TECHNICAL INFORMATION FOR KE-SERIES

3-4 Effects of pressure change

The pressure dependency of KE-50 can be seen in

Figure 5. In this range of atmospheric pressure, sensor

output voltage maintains a linear relationship when

compared with atmospheric pressure. This same

tendency can be seen in all models of KE sensors.

3-5 Humidity dependency

Figure 6 displays an example of humidity dependency

for KE-50. The Y-axis shows sensor output voltage. The

sensor itself is not inuenced by humidity, but its output

voltage may show some variation to the extent that O2

is displaced by humidity, as indicated in Figure 7.

Fig. 5 - KE-50 response of output voltage to

ambient pressure changes

(at 25C/60%RH)

Fig. 6 - KE-50 effect of humidity on output voltage

(at 25C in ambient air)

Fig. 7 - Effect of humidity on O2 concentration

0 20 40 60 80 100

Humidity (%RH)

O

2

c

o

n

c

e

n

t

r

a

t

i

o

n

(

%

)

21.0

20.5

19.5

19.0

20.0

5

o

C

15

o

C

40

o

C

35

o

C

30

o

C

25

o

C

20

o

C

10

o

C

30

45

60

75

90

800 900 1000 1100 1200 1300

S

e

n

s

o

r

o

u

t

p

u

t

(

m

V

)

Atmospheric pressure (hPa)

max.

min.

typ.

30

40

50

60

70

20 40 60 80

S

e

n

s

o

r

o

u

t

p

u

t

(

m

V

)

Humidity (%RH)

max.

min.

typ.

100

Revised 06/05 6

TECHNICAL INFORMATION FOR KE-SERIES

3-6 Temperature dependency

The standard KE sensor has a built-in temperature

compensation circuit which uses a thermistor that is

mounted inside the sensors body (see Fig. 1). The

temperature dependency of the KE series with this

built-in compensation circuit is shown in Figs. 8a

and 8b.

The KE sensor may show some transient char-

acteristics if the ambient temperature changes very

widely and quickly. This is caused by the difference in

response speed to temperature changes between the

sensor compartment and the built-in thermistor. A

quick rise in ambient temperature temporarily makes

output voltage high and vice versa for a quick fall in

temperature. Such temporary drift disappears after

the sensor's temperature reaches equilibrium with the

ambient temperature. For avoiding this problem, the

sensor should be protected from quick temperature

changes (such as direct exposure to sunlight or wind)

by some kind of enclosure.

In addition, temperature should be kept uniform

throughout the sensor's structure in order to avoid

improper compensation caused by differences

in temperature between the sensing area and the

thermistor location.

4. Reliability

4-1 Inuence of organic solvents

Exposure to organic solvents such as toluene,

benzene, xylene, acetone, methyl ethyl ketone, methyl

chloride, kerosene, gasoline, naphtha and gas oil may

cause the sensor's external housing (ABS resin) to

degenerate and degrade, resulting in unstable output

voltage. Condensation of such solvents on the sensor

would cause adverse inuence on output voltage and

response speed. To reduce potential risk of exposure

to these solvents, installation of a lter or condenser

on the sensor is recommended.

4-2 Life expectancy

The life expectancy of the KE oxygen sensor is

expressed in %-hours as follows:

[Oxygen Concentration (%)] x [Exposure Time (hours)]

Accordingly, the life of KE-50 is approximately

1,800,000 %-hours, and the KE-25 is 900,000 %-hours.

The end of life for KE sensors is specied as the point at

which output voltage is reduced to 70% from the initial

Fig. 9a - Relationship of life expectancy vs.

O2 concentration (Lo = life at 20.7% O2)

0

0.5

1.0

1.5

2.0

2.5

0 10 20 30 40 50 60 70 80 90 100

O2 concentration (%)

L

i

f

e

e

x

p

e

c

t

a

n

c

y

r

a

t

i

o

(

L

/

L

o

)

Fig. 8a - KE-25 temperature dependency

of output voltage

Fig. 8b - KE-50 temperature dependency

of output voltage

6

7

8

9

10

11

12

13

14

15

16

0 10 20 30 40

O

u

t

p

u

t

v

o

l

t

a

g

e

(

m

V

)

Temperature (C)

max.

min.

typ.

35

45

55

65

75

0 10 20 30 40 50

Temperature (C)

S

e

n

s

o

r

o

u

t

p

u

t

(

m

V

)

max.

min.

typ.

Revised 06/05 7

TECHNICAL INFORMATION FOR KE-SERIES

output voltage of the sensor. These facts indicate that

the expected life time in ambient conditions (21% O2

at 20C) is 10 years for KE-50 and 5 years for KE-25.

a) Relationship between expected life and O2 concentration

Figure 9a shows the relationship between life expectancy

and O2 concentration for KE sensors. The Y-axis

indicates the ratio of life expectancy in a given O2

concentration (L) to life expectancy in natural air (Lo).

The greater the O2 concentration, the shorter the life

expectancy. The inuence of atmospheric pressure

on life expectancy is estimated based on the O2

concentration in a given atmospheric pressure.

b) Relationship between expected life and storage temperature

Figure 9b shows the relationship between life

expectancy and ambient temperature. The Y-axis

indicates the ratio of life expectancy at a given

temperature (L) compared to life expectancy at 20C

(Lo). A correlation exists between the sensors life time

and its storage temperaturethe life time becomes

shorter as the storage temperature increases.

4-3 Long term stability

When used in normal air without any incidence of

improper use, both KE-25 and KE-50 show good long

term characteristics as illustrated in Figs. 10a and 10b

(see previous page).

Please note that there are various factors which may

inuence the life time of KE oxygen sensors in actual use

and that their life span can be variable.

5. Handling Instructions

5-1 Required oxygen amount

KE sensors consume a small amount of oxygen

during the detection process. It is recommended that

these sensors be used under conditions where the air

exchange is greater than 2~3ml per minute to offset

the sensor's oxygen consumption. Please note that

sensors should be used under conditions where the

air exchange is greater than 200~300ml per minute in

order to obtain response speed specied in Table 1.

5-2 Mechanical strength against shock and vibration

Since mechanical shock and vibration may potentially

inuence the sensitivity characteristics of the sensor,

these factors should be avoided in actual usage.

Temporary changes/instability in the sensor's output

signal may result due to these factors, but the signal

may recover to its original state after the sensor is

Fig. 10a - KE-25 long term stability

Fig. 10b - KE-50 long term stability

Fig. 9b - Relationship of life expectancy vs.

temperature (Lo = life at 20C)

0

0. 5

1.0

1.5

2.0

2.5

0 10 20 30 40 50 60

L

i

f

e

e

x

p

e

c

t

a

n

c

y

r

a

t

i

o

(

L

/

L

o

)

Temperature (C)

50

60

Time (hrs.)

S

e

n

s

o

r

o

u

t

p

u

t

(

m

V

)

0 1000 2000 3000 4000 5000 6000 7000 8000 9000

40

max.

min.

typ.

10

12

14

0 500 1000 1500 2000 2500 3000 3500 4000 4500

Time (hrs.)

S

e

n

s

o

r

o

u

t

p

u

t

(

m

V

)

max.

min.

typ.

Revised 06/05 8

TECHNICAL INFORMATION FOR KE-SERIES

kept motionless in natural air/room temperature

for between several hours to several days. If the

mechanical shock or vibration is great, an irreversible

change in the output signal may occur due to

structural damage within the sensor. Shock absorbing

measures should be used to protect the sensor during

transportation or when used for applications in which

shock/vibration is likely to occur.

5-3 Position dependency

At all times the sensor is recommended to be kept

either horizontal or in the normal vertical position

(refer to side view in Figure 2) in order to prevent the

cathode from drying out. If this were to occur, the

sensor's output signal would uctuate.

5-4 Low O2 concentration detection

When less than 1% O2 is measured, offset voltage

(which appears at close to 0% of O2) should be taken

into consideration when calculating O2 concentration.

For details, please refer to the document Application

Notes on Offset Voltage and Low Concentration

Measurement.

5-5 Storage conditions

To prolong the life expectancy of KE sensors,

storage at low temperature (in a refrigerator) and

at low oxygen concentration is recommended. Care

should also be taken to ensure that the lead wires are

not connected or shorted during storage as this may

cause slow response to oxygen.

If the sensor is stored in a 0% O2 environment for an

extended period of time, the sensor's offset voltage (see

Sec. 5-4) becomes lower and response speed to O2 will

become slower. In this case, the sensor will be able to

recover to normal response speed after exposure to a

normal environment for a period of 24 hours.

The absolute minimum storage temperature for

the sensor is -20C. Below this temperature, the

electrolyte will freeze. KE sensors are not damaged

by the freezing of the electrolyte, and they can be

used again after the electrolyte melts.

The specied maximum storage temperature is 60C.

This is a result of the temperature limitation of ABS resin,

the material which is used to make the sensors body.

5-6 Inuence of condensation

Measures should be taken to prevent condensation

on the sensor because the output signal will degrade

and response speed will decrease, causing inaccurate

measurement. However, once condensation

dissipates, sensor characteristics will recover to

their original state.

5-7 Recommended input impedance

The sensor must be connected to equipment which

has an input impedance of 1000k or greater. If not,

proper temperature compensation would not be

possible.

5-8 Sensor connection

The sensor must not have a counter-electromotive

force applied to it from any equipment to which it is

connected. Application of external electric potential

to the sensor's output terminals may cause temporary

instability in the output signal and reduced response

speed. However, removal of this condition and

subsequent aging in normal air for several days will

allow the sensor to recover to normal.

If reverse polarity or excessive voltage is applied

to the sensor, the characteristic change would be

irreversible due to the internal electrical damage

caused by this condition. For example, if several

10mV of reverse voltage were applied, the internal

electrode would be broken.

5-9 Disassembly or repair of the sensor

Disassembling or repair of the sensor should

be avoided because it will result in a change of

sensitivity characteristics. The reason for such a

change is related to the sensors structure. The most

important factor in determining sensitivity is the

condition of the cathode which is determined by

afxing the F.E.P. membrane with a suitable pressure

via tightening the plastic top. Loosening of the plastic

top will change the internal pressure and therefore

change the sensors sensitivity.

The plastic label covering the sensor's housing should

not be removed since the label is used as a seal to fasten

and immobilize the plastic top on the sensor's body.

5-10 Safety measures for electrolyte leakage

If the liquid electrolyte leaks due to sensor breakage,

care should be taken in handling the sensor, which

should immediately be placed into a plastic bag. The

liquid electrolyte is a weak aqueous acid solution

(pH=5~6) with an irritating odor. The liquid is non-

ammable. Since this solution contains lead acetate,

Revised 06/05 9

TECHNICAL INFORMATION FOR KE-SERIES

FIGARO GROUP

HEAD OFFICE

Figaro Engineering Inc.

1-5-11 Senba-nishi

Mino, Osaka 562 JAPAN

Tel.: (81) 72-728-2561

Fax: (81) 72-728-0467

email: garo@garo.co.jp

www.garo.co.jp

which is harmful to humans, contact with this liquid

should be avoided.

In case the liquid electrolyte contacts the skin or

clothing, wash with soapy water and rinse generously

with plain water. If the liquid electrolyte contacts

the eye, ush with water for at least 15 minutes

and obtain immediate medical assistance. In case of

breathing in of the electrolyte, ush the nasal cavity

thoroughly with water and seek immediate medical

assistance. If the electrolyte is swallowed, rinse the

mouth thoroughly with water and seek immediate

medical assistance.

6. Warranty

Sensors shall be warranted to meet the specications

shown in Table 1 for a period of one year after the

date of purchase from Figaro.

Figaro USA Inc. and the manufacturer, Figaro

Engineering Inc. (together referred to as Figaro)

reserve the right to make changes without notice to

any products herein to improve reliability, functioning

or design. Information contained in this document is

believed to be reliable. However, Figaro does not

assume any liability arising out of the application or

use of any product or circuit described herein; neither

does it convey any license under its patent rights, nor

the rights of others.

Figaros products are not authorized for use as criti-

cal components in life support applications wherein

a failure or malfunction of the products may result

in injury or threat to life.

OVERSEAS

Figaro USA Inc.

121 S. Wilke Rd. Suite 300

Arlington Heights, IL 60005 USA

Tel.: (1) 847-832-1701

Fax.: (1) 847-832-1705

email: garousa@garosensor.com

www.garosensor.com

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Landslide: Parts of A Typical SlideDokument14 SeitenLandslide: Parts of A Typical SlideShuvanjan Dahal100% (3)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- LECTURE 5-Measurement of Water Yield From WatershedDokument23 SeitenLECTURE 5-Measurement of Water Yield From WatershedChu DicksonNoch keine Bewertungen

- Coral20100304 DLDokument111 SeitenCoral20100304 DLMohd HazrickNoch keine Bewertungen

- Marine Bilge Water Treatment SystemDokument11 SeitenMarine Bilge Water Treatment Systemrobjsimon100% (3)

- Septic Tank CalculationDokument10 SeitenSeptic Tank Calculation8o54doNoch keine Bewertungen

- Project Report On Nicotine Based Products (Nicotine Alkaloid, Nicotine Usp, Nicotine Polacrilex, Bitartrate)Dokument7 SeitenProject Report On Nicotine Based Products (Nicotine Alkaloid, Nicotine Usp, Nicotine Polacrilex, Bitartrate)EIRI Board of Consultants and PublishersNoch keine Bewertungen

- Penilaian AuthenticDokument28 SeitenPenilaian AuthenticcurublackNoch keine Bewertungen

- Penilaian AuthenticDokument28 SeitenPenilaian AuthenticcurublackNoch keine Bewertungen

- Personal Data: Curriculum VitaeDokument3 SeitenPersonal Data: Curriculum VitaecurublackNoch keine Bewertungen

- CV Amirsyah - IT StudentDokument2 SeitenCV Amirsyah - IT StudentcurublackNoch keine Bewertungen

- CV Amirsyah - IT StudentDokument2 SeitenCV Amirsyah - IT StudentcurublackNoch keine Bewertungen

- Ashirvad Only PVC Product MRP - 1st Dec 2020Dokument68 SeitenAshirvad Only PVC Product MRP - 1st Dec 2020Ujwal Elijah GurramNoch keine Bewertungen

- Iso Octane Toluene 50 50 Astm d471Dokument4 SeitenIso Octane Toluene 50 50 Astm d471vkmsNoch keine Bewertungen

- VD1w2 1711 APOSTOL Stefania Sust2Dokument5 SeitenVD1w2 1711 APOSTOL Stefania Sust2Ştefania ApostolNoch keine Bewertungen

- Safety Data Sheet Neutral Disinfectant Cleaner: Section 1. Product and Company IdentificationDokument12 SeitenSafety Data Sheet Neutral Disinfectant Cleaner: Section 1. Product and Company IdentificationLast ShelterNoch keine Bewertungen

- Gate Valves in IndustryDokument3 SeitenGate Valves in IndustryKogulan SubramaniamNoch keine Bewertungen

- Twin-Tub Washing Machine User's Manual: This Manual Is For XPB60-CSDokument20 SeitenTwin-Tub Washing Machine User's Manual: This Manual Is For XPB60-CSTheMaskedOneNoch keine Bewertungen

- Solon Wants To Probe The Impact of The Fishing Ban in Visayan SeaDokument1 SeiteSolon Wants To Probe The Impact of The Fishing Ban in Visayan Seapribhor2Noch keine Bewertungen

- Definition of Terms:: Harvesting MethodsDokument5 SeitenDefinition of Terms:: Harvesting MethodsHero DiasNoch keine Bewertungen

- Evs ProjectDokument11 SeitenEvs ProjectUmesh TyagiNoch keine Bewertungen

- Instruments Index RO Plant YTMDokument8 SeitenInstruments Index RO Plant YTMSswahyudiNoch keine Bewertungen

- 128 Salicylic Rohdia MSDSDokument13 Seiten128 Salicylic Rohdia MSDSWike Wingtias ArnesaNoch keine Bewertungen

- (ACM) RG CatalogueDokument8 Seiten(ACM) RG Cataloguerazak shareefNoch keine Bewertungen

- Career Episode 2 - Waste Water Treatment PlantDokument11 SeitenCareer Episode 2 - Waste Water Treatment PlantMiyuranga W.H.D.D. en17081344Noch keine Bewertungen

- Wilkes-Barre Times Leader 3-12Dokument108 SeitenWilkes-Barre Times Leader 3-12The Times LeaderNoch keine Bewertungen

- 7 Effect of Thermal and Chemical Hydrolysis On Sludge Dewatering HartwigDokument57 Seiten7 Effect of Thermal and Chemical Hydrolysis On Sludge Dewatering HartwigBrian ThomasNoch keine Bewertungen

- RS PaperDokument29 SeitenRS PaperAstrid LirazanNoch keine Bewertungen

- Indian Standard: Specification FOR Precast Concrete Pipes (With and Without Reinforcement)Dokument45 SeitenIndian Standard: Specification FOR Precast Concrete Pipes (With and Without Reinforcement)Yashvardhan Singh SisodiyaNoch keine Bewertungen

- Methodology For Capliary Cut-OffDokument5 SeitenMethodology For Capliary Cut-OffMarees KumarNoch keine Bewertungen

- Interzone 5140: Epoxy PrimerDokument4 SeitenInterzone 5140: Epoxy PrimerTrịnh Minh KhoaNoch keine Bewertungen

- Ugc Net Paper-1 Weekly Magazine (Current Affairs, Mock Test, Reasoning) For December Exam Download PDFDokument65 SeitenUgc Net Paper-1 Weekly Magazine (Current Affairs, Mock Test, Reasoning) For December Exam Download PDFDiwakar Entertainment DoseNoch keine Bewertungen

- Waterproofing101 GMXDokument27 SeitenWaterproofing101 GMXJatinder BhatiaNoch keine Bewertungen

- Water Dispenser Manual Nov 2021Dokument10 SeitenWater Dispenser Manual Nov 2021ErGaurav KumarNoch keine Bewertungen

- Are Golf Courses Bad For The EnvironmentDokument4 SeitenAre Golf Courses Bad For The EnvironmentKyle M. SantosNoch keine Bewertungen

- Safety Data Sheet: 1. IdentificationDokument15 SeitenSafety Data Sheet: 1. IdentificationSaeed FNoch keine Bewertungen