Beruflich Dokumente

Kultur Dokumente

Wheat Straw Gasification by Bubbling Fluidized Bed Reactor

Hochgeladen von

Anonymous 4PuFzAR0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

83 Ansichten2 SeitenShort introduction on gasification and future research path.

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenShort introduction on gasification and future research path.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

83 Ansichten2 SeitenWheat Straw Gasification by Bubbling Fluidized Bed Reactor

Hochgeladen von

Anonymous 4PuFzARShort introduction on gasification and future research path.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

TITLE: Wheat Straw Gasification by Bubbling Fluidized Bed Reactor

Energy is a strategic input necessary for socio-economic development. It helps in meeting

basic human needs. In fact energy propels the society. The standard of living is correlated with

per capita energy consumption. The sources of energy are renewable and non-renewable ones.

The fascination of renewable energy is that it is not dwindling, rather non-depleting and that it

does not damage environment rather it contributes towards a hazard-free safe environment.

Renewable energy sources have proven their reliability and competitiveness in comparison with

conventional sources of energy.

The rapid depletion of petroleum fuels and their ever increasing costs have led to an

intensive search for alternative fuels. This research has been accelerated after the 1973 oil

embargo. As per one of the study within 40 years, the present reservation of the petroleum fuel

including diesel will deplete at an increased consumption rate estimated to be order of 3% per

annum.

The new emerging technology of gasification is a demand of time. A large number of

research works for fuels by gasification have been carried out particularly in the USA, Canada

and EC. Recently the Asian countries like Malaysia and India have given their attention towards

this technology. The results of these researches have proved their feasibility of this technology.

Amongst various thermochemical conversion processes, gasification is considered as an

emerging technology for liquid oil production. Gasification for energy conversions from the

carbonaceous material is defined as the incomplete combustion of organic matter in the presence

of 1/5 to 1/3 theoretical amount of oxygen for complete combustion to produce gasses.

Among the various organic feed materials, biomass is one of the most abundant

renewable energy sources in the world. Biomass is actually a product of solar energy that has

been stored by the photosynthetic activity of plants. The plants remove CO

2

from the atmosphere

and combine it with water to produce biomass. Biomass is in many common waste products,

such as:

1. agricultural waste

2. forest waste

3. municipal waste

4. food processing waste

Conversion of solid biomass into combustible gas has all the advantages associated with

using gaseous and liquid fuels such as clean combustion, compact burning equipment, high

thermal efficiency and a good degree of control. In locations, where biomass is already available

at reasonable low prices or in industries using fuel wood, gasifier systems offer definite

economic advantages. Biomass gasification technology is also environment-friendly, because of

the firewood savings and reduction in CO

2

emissions. Biomass gasification technology has the

potential to replace diesel and other petroleum products in several applications, foreign

exchange. Currently biomass contributes on average 14% of total energy demand of the world.

The relative proportions of the gasification products depend on both process parameters

as well as the composition of the feedstock. The most important process parameters are the

operating temperature, feed particle size, equivalence ratio, steam to biomass ratio, and the

presence of catalyst. The physical and chemical constituent of the feedstock such as volatile,

moisture and ash contents also affect the product yield. Other process parameters such as the

feed rate, gasification atmosphere and operating pressure have also been reported to have some

influences on the product yields.

1

For this study wheat straw will be used as the feed material for gasification. As a prairie

province, Saskatchewan's economy is associated with agriculture, however increasing challenges

has meant that agriculture, fishing, hunting and forestry together make up 6.8% of the province's

GDP. Saskatchewan grows 45% of Canada's grain. Wheat is the most known crop here, and

perhaps the one stereotypically associated with the province. Hence it is appropriate to use wheat

straw as feed for gasification.

Among the various gasification technologies, fluidized bed technology is one of the best

gasification technologies. Here intimate mixing and contact between reactants increase the heat

and mass transfer and reduces time of reaction, plant size and power required. The advantages of

the fluidized bed reactor are as follows:

1. Higher throughput

2. Improved heat and mass transfer from fuel

3. High heating value

4. Reduced char

5. Simple ash removal

6. Most high-ash content fuels can be gasified

7. Suitable for biomass, municipal solid waste and lignite

8. Can be operated on different types of fuels or mixture of fuels

There is a bubbling fluidized bed in the University of Regina which will be used for the

experiments. The objectives of the study are:

1. To study the physical, elemental and thermal characteristics of wheat straw

2. To study the literatures about gasification

3. To design the experiments.

4. To do the leak test and heat test for the reactor and to check the hopper.

5. To do some commissioning if required.

6. To do some pre-experimental runs.

7. To carry out the experimental investigations at different process conditions.

8. To analysis the product gas through GC

9. To analyze the data that will be obtained by experiments.

So far step 1 to step 6 is done. But some commissioning and the pre-experimental runs are

required and step 2 is also required more. This commissioning is regarding the solid state relay

of the air heater controller.

2

Das könnte Ihnen auch gefallen

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityVon EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityBewertung: 3 von 5 Sternen3/5 (2)

- Energy Optimization in Fischer-Tropsch Process: Department of Chemical Engineering, Government Engineering CollegeDokument32 SeitenEnergy Optimization in Fischer-Tropsch Process: Department of Chemical Engineering, Government Engineering CollegeAdithyaNoch keine Bewertungen

- Use of Biomethane As A Sustainable FuelDokument35 SeitenUse of Biomethane As A Sustainable FuelVedant KarnatakNoch keine Bewertungen

- Final Year Report AfnanDokument57 SeitenFinal Year Report AfnanJr BagaporoNoch keine Bewertungen

- Use of Biogas As Alternative Fuel For Tobacco Curing: Case For ZimbabweDokument11 SeitenUse of Biogas As Alternative Fuel For Tobacco Curing: Case For ZimbabweLawrence ChibvuriNoch keine Bewertungen

- Energies: Pyrolysis of Municipal Green Waste: A Modelling, Simulation and Experimental AnalysisDokument20 SeitenEnergies: Pyrolysis of Municipal Green Waste: A Modelling, Simulation and Experimental Analysisbirg MF MelNoch keine Bewertungen

- Sustainable Energy Expansion Tactics in The Sub Sahara Botswana Design and Development of An Advanced Biogas DigesterDokument7 SeitenSustainable Energy Expansion Tactics in The Sub Sahara Botswana Design and Development of An Advanced Biogas DigesterIJMTERNoch keine Bewertungen

- Biogas Project ReportDokument69 SeitenBiogas Project ReportKetan V. JoshiNoch keine Bewertungen

- 2020-Optimization of The Oxidative Fast Pyrolysis Process of Sugarcane Straw byDokument7 Seiten2020-Optimization of The Oxidative Fast Pyrolysis Process of Sugarcane Straw byShafira RiskinaNoch keine Bewertungen

- Thermochemical Biomass GasificationDokument40 SeitenThermochemical Biomass Gasificationjambo98Noch keine Bewertungen

- Reduced Local Emissions and Long-Term Carbon Storage Through Pyrolysis of Agricultural Waste and Application of Pyrolysis Char For Soil ImprovementDokument10 SeitenReduced Local Emissions and Long-Term Carbon Storage Through Pyrolysis of Agricultural Waste and Application of Pyrolysis Char For Soil ImprovementShubham VarshneyNoch keine Bewertungen

- Jagjeet Research PaperDokument7 SeitenJagjeet Research PaperHarminder Singh PandherNoch keine Bewertungen

- GabissaDokument19 SeitenGabissaAshenafiNoch keine Bewertungen

- An Overview of Recent Developments in Biomass PyroDokument23 SeitenAn Overview of Recent Developments in Biomass PyroJulien MicoliNoch keine Bewertungen

- Synopsis PDFDokument7 SeitenSynopsis PDFankitrajeNoch keine Bewertungen

- Chemical Approaches To Cleaner FuelsDokument7 SeitenChemical Approaches To Cleaner FuelsMaria Donessa C. CayasNoch keine Bewertungen

- Report ContentDokument36 SeitenReport Contentredranger1804Noch keine Bewertungen

- Qualitative and Quantitative Feasibility of Biogas Production From Kitchen WasteDokument1 SeiteQualitative and Quantitative Feasibility of Biogas Production From Kitchen WasteHaftu GebretsadikNoch keine Bewertungen

- Chapter 9KSRDokument19 SeitenChapter 9KSRBryan xavier medina rodriguezNoch keine Bewertungen

- The Anila Stove, Linking Agriculture To EnergyDokument39 SeitenThe Anila Stove, Linking Agriculture To EnergyRaymond KatabaziNoch keine Bewertungen

- A Mini Review On Pyrolysis and Anaerobic Digestion An OptionalDokument10 SeitenA Mini Review On Pyrolysis and Anaerobic Digestion An OptionalNDUNGUTSE JEAN MAURICENoch keine Bewertungen

- Materials Today: Proceedings: Prashant Sharma, Bhupendra Gupta, Mukesh Pandey, Keshav Singh Bisen, Prashant BaredarDokument9 SeitenMaterials Today: Proceedings: Prashant Sharma, Bhupendra Gupta, Mukesh Pandey, Keshav Singh Bisen, Prashant BaredarRoberto Macias NNoch keine Bewertungen

- Ayhan DemirbasDokument8 SeitenAyhan DemirbasLalta PrasadNoch keine Bewertungen

- A Review of Technology Assessment of Green Gasoline ProcessingDokument9 SeitenA Review of Technology Assessment of Green Gasoline Processingdocument nugrohoNoch keine Bewertungen

- Renewable and Sustainable Energy Reviews: SciencedirectDokument26 SeitenRenewable and Sustainable Energy Reviews: SciencedirectMuhammad Farizan PraeviaNoch keine Bewertungen

- Biomass GasificationDokument26 SeitenBiomass GasificationlalejanNoch keine Bewertungen

- Z-Tar 2Dokument44 SeitenZ-Tar 2tamil thendralNoch keine Bewertungen

- s13399 020 01104 2Dokument15 Seitens13399 020 01104 2lunarNoch keine Bewertungen

- Biogas EnergyDokument6 SeitenBiogas EnergyHayan JanakatNoch keine Bewertungen

- Innovative Energy Conversion from Biomass WasteVon EverandInnovative Energy Conversion from Biomass WasteArif DarmawanNoch keine Bewertungen

- Resurch PaperDokument4 SeitenResurch PapershubhamNoch keine Bewertungen

- Biogas Production-A Review On Composition, Fuel Properties, Feed Stock and Principles of Anaerobic DigestionDokument13 SeitenBiogas Production-A Review On Composition, Fuel Properties, Feed Stock and Principles of Anaerobic DigestionTrần Thanh SơnNoch keine Bewertungen

- Effect of Swirl Flow, Loading Height, Primary Aeration and Semi-Confined Combustion Flame, On Overall Efficiency and Pollution Emissions From Domestic Gas BurnersDokument20 SeitenEffect of Swirl Flow, Loading Height, Primary Aeration and Semi-Confined Combustion Flame, On Overall Efficiency and Pollution Emissions From Domestic Gas BurnersAklilu BahetaNoch keine Bewertungen

- Effect of Rice Husk Ash Mass On Sustainability Pyrolysis Zone of Fixed Bed Downdraft Gasifier With Capacity of 10 KgHour-AIP (2017)Dokument9 SeitenEffect of Rice Husk Ash Mass On Sustainability Pyrolysis Zone of Fixed Bed Downdraft Gasifier With Capacity of 10 KgHour-AIP (2017)Hafif DafiqurrohmanNoch keine Bewertungen

- Waste Management: Marco Tomasi Morgano, Hans Leibold, Frank Richter, Dieter Stapf, Helmut SeifertDokument9 SeitenWaste Management: Marco Tomasi Morgano, Hans Leibold, Frank Richter, Dieter Stapf, Helmut SeifertCarlos AlvarezNoch keine Bewertungen

- Biogas Fro Chicken WasteDokument8 SeitenBiogas Fro Chicken WasteSekarNTutyNoch keine Bewertungen

- Biogas DigesterDokument35 SeitenBiogas DigesterXylester Kenn FabreNoch keine Bewertungen

- Biomass: The Ultimate Source of Bio Energy: Sushmita Mohapatra, Kasturi GadgilDokument4 SeitenBiomass: The Ultimate Source of Bio Energy: Sushmita Mohapatra, Kasturi GadgilRaghu RamNoch keine Bewertungen

- Biomass Conversion PDFDokument8 SeitenBiomass Conversion PDFVivek Rajkumar GNoch keine Bewertungen

- Press MUd To Bio GasDokument5 SeitenPress MUd To Bio GasAyush AgrawalNoch keine Bewertungen

- Into&lit ROSSAYE&SANDOORAMDokument11 SeitenInto&lit ROSSAYE&SANDOORAMshah shakeel rssNoch keine Bewertungen

- Analytical Methods for Biomass Characterization and ConversionVon EverandAnalytical Methods for Biomass Characterization and ConversionNoch keine Bewertungen

- RERA Volume1 Issue1 Pages27-45Dokument20 SeitenRERA Volume1 Issue1 Pages27-45Nur Ain MunirahNoch keine Bewertungen

- Final (ENG) - Overview of Biogas Development As Alternative Energy in IndonesiaDokument22 SeitenFinal (ENG) - Overview of Biogas Development As Alternative Energy in IndonesiaBudi SetyawanNoch keine Bewertungen

- Website Leelar@emirates - Net.aeDokument10 SeitenWebsite Leelar@emirates - Net.aeMohamed El GhandourNoch keine Bewertungen

- A Comprehensive Review On Thermochemical, and Biochemical Conversion Methods of Lignocellulosic Biomass Into Valuable End ProductDokument9 SeitenA Comprehensive Review On Thermochemical, and Biochemical Conversion Methods of Lignocellulosic Biomass Into Valuable End ProductAndreNoch keine Bewertungen

- The Problem and Its BackgroundDokument17 SeitenThe Problem and Its BackgroundRenzo M. JognoNoch keine Bewertungen

- Introduction To Dual Fuel InjectionDokument8 SeitenIntroduction To Dual Fuel InjectionAbhiNoch keine Bewertungen

- Ankur 2Dokument14 SeitenAnkur 2John TauloNoch keine Bewertungen

- Literature Review On Production of BiogasDokument8 SeitenLiterature Review On Production of Biogasea83ahc5100% (1)

- ANAEROBIC DIGESTION, Gasification, Pyrolysis of WasteDokument22 SeitenANAEROBIC DIGESTION, Gasification, Pyrolysis of WasteJoao Minho100% (1)

- Enhancement of Production and Upgradation of Biogas Using Different Techniques-A ReviewDokument17 SeitenEnhancement of Production and Upgradation of Biogas Using Different Techniques-A ReviewZainul Fikri TampengNoch keine Bewertungen

- Potential To Produce Biogas From Tannery Waste: SSRN Electronic Journal July 2018Dokument6 SeitenPotential To Produce Biogas From Tannery Waste: SSRN Electronic Journal July 2018sasabarnicNoch keine Bewertungen

- Jurnal Tim Boiler - EnglishDokument24 SeitenJurnal Tim Boiler - EnglishBung HaFiedNoch keine Bewertungen

- Analysis of Syngas Quality From Portuguese Biomasses: An Experimental and Numerical StudyDokument12 SeitenAnalysis of Syngas Quality From Portuguese Biomasses: An Experimental and Numerical StudyNuno CoutoNoch keine Bewertungen

- Article-On Waste To EnergyDokument4 SeitenArticle-On Waste To EnergyUsman HasnainNoch keine Bewertungen

- Nkwo Project 2021 Chap 1Dokument4 SeitenNkwo Project 2021 Chap 1Godwin NkwoNoch keine Bewertungen

- Material Science Lab - Manual PDFDokument18 SeitenMaterial Science Lab - Manual PDFUmashankarPrajapatiNoch keine Bewertungen

- The Lotos-Eaters by Alfred, Lord Tennyson - Poetry FoundationDokument5 SeitenThe Lotos-Eaters by Alfred, Lord Tennyson - Poetry FoundationAnonymous 4PuFzARNoch keine Bewertungen

- Reading 1.2 Lanford The Idea of A University Summary 2019Dokument6 SeitenReading 1.2 Lanford The Idea of A University Summary 2019Anonymous 4PuFzARNoch keine Bewertungen

- The Idea of A University: John Henry NewmanDokument3 SeitenThe Idea of A University: John Henry NewmanAnonymous 4PuFzARNoch keine Bewertungen

- Salt Spray Chamber - KORROX III: Years YearsDokument2 SeitenSalt Spray Chamber - KORROX III: Years YearsAnonymous 4PuFzARNoch keine Bewertungen

- Rust-Free, Metal-Free Products: Nuaire, Inc. 2100 Fernbrook Lane Plymouth, MN 55447 U.S.A. 763.553.1270Dokument28 SeitenRust-Free, Metal-Free Products: Nuaire, Inc. 2100 Fernbrook Lane Plymouth, MN 55447 U.S.A. 763.553.1270Anonymous 4PuFzARNoch keine Bewertungen

- Measurement of Crushing Strength of Coal AgglomeraDokument5 SeitenMeasurement of Crushing Strength of Coal AgglomeraAnonymous 4PuFzARNoch keine Bewertungen

- Lectrure Thermal AnalysisDokument36 SeitenLectrure Thermal Analysisaanfebrianto1993Noch keine Bewertungen

- Compliance Made Easy and Faster - ASTM C114-15 Norm With SumXcore at 1 KWDokument2 SeitenCompliance Made Easy and Faster - ASTM C114-15 Norm With SumXcore at 1 KWAnonymous 4PuFzARNoch keine Bewertungen

- SmsDokument2 SeitenSmsAnonymous 4PuFzARNoch keine Bewertungen

- Mat Sci Homework 7 FA2014Dokument6 SeitenMat Sci Homework 7 FA2014Anonymous 4PuFzARNoch keine Bewertungen

- Gender in Nepal ProjectDokument3 SeitenGender in Nepal ProjectAnonymous 4PuFzARNoch keine Bewertungen

- Laboratory Methods For Predicting Coal PerformanceDokument26 SeitenLaboratory Methods For Predicting Coal PerformanceAnonymous 4PuFzARNoch keine Bewertungen

- 2015 Evaluation AnandDokument63 Seiten2015 Evaluation AnandAnonymous 4PuFzARNoch keine Bewertungen

- Calcination of Nickel-Alumina CatalystsDokument4 SeitenCalcination of Nickel-Alumina CatalystsAnonymous 4PuFzAR100% (1)

- ECS Trans. 2015 Tomomichi 2819 29Dokument11 SeitenECS Trans. 2015 Tomomichi 2819 29Anonymous 4PuFzARNoch keine Bewertungen

- Study On The Characteristics of Waste Wood Ash: Ek. Serafimova, M. Mladenov, I. Mihailova, Y. PelovskiDokument4 SeitenStudy On The Characteristics of Waste Wood Ash: Ek. Serafimova, M. Mladenov, I. Mihailova, Y. PelovskiAnonymous 4PuFzARNoch keine Bewertungen

- Unit04 HandoutDokument68 SeitenUnit04 HandoutAnonymous 4PuFzARNoch keine Bewertungen

- Chemical Engineering 374: Fluid MechanicsDokument7 SeitenChemical Engineering 374: Fluid MechanicsAnonymous 4PuFzARNoch keine Bewertungen

- Agricultural Biomass Torre Faction Research Program: Ceati Soig Project 0538Dokument20 SeitenAgricultural Biomass Torre Faction Research Program: Ceati Soig Project 0538Anonymous 4PuFzARNoch keine Bewertungen

- Gasification Vs Pyrolysis Vs IncinerationDokument7 SeitenGasification Vs Pyrolysis Vs IncinerationAJ Conde100% (1)

- ManualsDokument71 SeitenManualsAnonymous 4PuFzARNoch keine Bewertungen

- Gasification Technology Option - Ronald Schoff, EPRIDokument34 SeitenGasification Technology Option - Ronald Schoff, EPRIAnonymous 4PuFzARNoch keine Bewertungen

- Fluid MechanicDokument20 SeitenFluid MechanicteknokolikNoch keine Bewertungen

- Requirements For New Application of Permit To Operate (Duly Notarized, Triplicate Copies)Dokument2 SeitenRequirements For New Application of Permit To Operate (Duly Notarized, Triplicate Copies)norlyn esguerraNoch keine Bewertungen

- Estimating Biofilter Size For Ras SystemsDokument9 SeitenEstimating Biofilter Size For Ras SystemstongaiNoch keine Bewertungen

- 2017 - RA 9275 - Clean Water ActDokument68 Seiten2017 - RA 9275 - Clean Water ActaseascanNoch keine Bewertungen

- 2015 02 27 CV EUROPASS Cristina - Avila PDFDokument7 Seiten2015 02 27 CV EUROPASS Cristina - Avila PDFAini ZahraNoch keine Bewertungen

- Advanced Waste Water TreatmentDokument1 SeiteAdvanced Waste Water TreatmentMoises FriasNoch keine Bewertungen

- PriceListHirePurchase Normal 1Dokument55 SeitenPriceListHirePurchase Normal 1Muhammad HajiNoch keine Bewertungen

- EE367 New and Renewable Energy SystemsDokument2 SeitenEE367 New and Renewable Energy SystemsSREEHARI S JNoch keine Bewertungen

- CBSE NCERT Notes Class 12 Biology Microbes in Human WelfareDokument3 SeitenCBSE NCERT Notes Class 12 Biology Microbes in Human WelfareAshique MontazNoch keine Bewertungen

- SCIENCE 9 - 7. W3-4 LAS Geothermal EnergyDokument1 SeiteSCIENCE 9 - 7. W3-4 LAS Geothermal EnergyAPRIL MULANoch keine Bewertungen

- Environmental Science ReviewerDokument3 SeitenEnvironmental Science ReviewerCAMACHO, Clarissa May D.Noch keine Bewertungen

- Hydraulics and Hydrology of Hydropower Solved Problems and AssignmentDokument16 SeitenHydraulics and Hydrology of Hydropower Solved Problems and AssignmentFola BayanNoch keine Bewertungen

- Waste Water TreatmentDokument28 SeitenWaste Water TreatmentSKRY RAYONoch keine Bewertungen

- Anaerobic Digestion of Wastewater Sludge: (Nazaroff & Alvarez-Cohen, Section 6.E.3)Dokument4 SeitenAnaerobic Digestion of Wastewater Sludge: (Nazaroff & Alvarez-Cohen, Section 6.E.3)AhmedSalemNoch keine Bewertungen

- Jul. 25 - Aug. 24, 2018Dokument2 SeitenJul. 25 - Aug. 24, 2018MichaelNoch keine Bewertungen

- Base Load and Peak LoadDokument4 SeitenBase Load and Peak LoadEr Umar RashidNoch keine Bewertungen

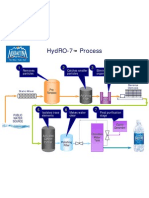

- Aqua Fin A Purification DiagramDokument1 SeiteAqua Fin A Purification DiagramPEPITOPULNoch keine Bewertungen

- No Sludge, No Odor Green Patent-A: Environmentally Effective Economically EfficientDokument9 SeitenNo Sludge, No Odor Green Patent-A: Environmentally Effective Economically EfficientHugoNoch keine Bewertungen

- Tutorial Sheet - Water PollutionDokument8 SeitenTutorial Sheet - Water PollutionAbdoo YasserNoch keine Bewertungen

- Group-1 Research-Proposal FinalDokument17 SeitenGroup-1 Research-Proposal Finalyechale tafereNoch keine Bewertungen

- Ecosistemas AcuticosDokument41 SeitenEcosistemas AcuticosProfesor Denis VijilNoch keine Bewertungen

- Septic System Design PDFDokument47 SeitenSeptic System Design PDFAshok Kumar Jena100% (1)

- Indicator Fact Sheet: (WQ1) Water Exploitation IndexDokument8 SeitenIndicator Fact Sheet: (WQ1) Water Exploitation IndexMourad LovelNoch keine Bewertungen

- Miles Biochar Production 02.07Dokument22 SeitenMiles Biochar Production 02.07fscripcaNoch keine Bewertungen

- Arief Sabdo Yuwono - Produksi Mulsa Dan Kompos Skala BesarDokument42 SeitenArief Sabdo Yuwono - Produksi Mulsa Dan Kompos Skala BesarGeorgius KoeyNoch keine Bewertungen

- BR 2007-322 - EUF (Wastewater Charge System)Dokument8 SeitenBR 2007-322 - EUF (Wastewater Charge System)Pacific SpectrumNoch keine Bewertungen

- Sustainable Production and ConsumptionDokument2 SeitenSustainable Production and ConsumptionPraharsh ShahNoch keine Bewertungen

- Floodplain Management Authorities of NSW 44 Annual Conference May 11-14 2004 - Coffs HarbourDokument7 SeitenFloodplain Management Authorities of NSW 44 Annual Conference May 11-14 2004 - Coffs HarbourFranchezka Lei MagtiraNoch keine Bewertungen

- Pilot Scale Reverse Osmosis Refinery Wastewater TreatmentDokument13 SeitenPilot Scale Reverse Osmosis Refinery Wastewater Treatmentmsantosu000Noch keine Bewertungen

- Basic Design of Desalination PDFDokument216 SeitenBasic Design of Desalination PDFShubham BansalNoch keine Bewertungen

- Discover NC River Basins BookletDokument16 SeitenDiscover NC River Basins Bookletapi-290100812Noch keine Bewertungen