Beruflich Dokumente

Kultur Dokumente

1 Basic Manta Ray Installation With Photos

Hochgeladen von

Arnaldo BenitezOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1 Basic Manta Ray Installation With Photos

Hochgeladen von

Arnaldo BenitezCopyright:

Verfügbare Formate

INSTALLATION INSTRUCTIONS

1.0 Description

Manta Ray earth anchors are driven tipping plate soil anchors. The most common anchor models

are shown in figure 1. They have working load capacities up to 12 tons and all use the same

anchor rod and eye nut or termination hardware. Figure 2 shows how they work. This document

describes a basic hand held and mechanized installation of the most common Manta Ray anchors.

Deeper installations differ only by requiring longer anchor rods and more drive steel.

Fig. 1 MR-SR for soft soil MR-1 for medium soil MR-2 for hard soil

Fig. 2 How they work

The Manta Ray anchor is designed to be driven into the ground with a 90 lb (41kg.). hydraulic

pavement breaker (hammer). After the anchor has been driven to the depth of the anchor rod, the

driving tool (called drive steel) is removed. The anchor is then tipped from its edgewise-driving

position to its load locked position. This is done with a hydraulic jack called the Load Locker,

and provides an immediate proof test of each anchor. The direct reading gauge on the Load Locker

makes the proof test easy and fast. There is no guesswork; if the soil is too soft the installer

immediately knows to install a second anchor, use a larger anchor, or install to a greater depth.

1

2.0 Required Tools

All of the required tools fit easily in a small pick up truck.

2.1 Hydraulic Hammer: A 90lb. (41kg.) hand held hydraulic pavement breaker (hammer) is

required. Typical performance specifications are 1200 blows per minute at 8gpm and 1500 psi (30

lpm/140 bar). The HB90-14 anchor driving hammer pictured below with 1 hex x 6 (32mm x

152mm) chuck and HTMA flush face couplers is available from a Manta Ray Distributor.

2.2 Hydraulic Power unit: A hydraulic power unit and hydraulic hoses to power the hammer are

required. Typical specifications are 18hp, 8gpm, 2000 psi (30 lpm/140 bar) with hydraulic oil

cooler. The GPU18-8CE hydraulic power unit pictured below is available from a Manta Ray

Distributor.

2.3 Hydraulic hoses: Should be (12.5mm) nominal size and 25 (7.6m) length with HTMA

flush face couplers. 2 sets of hoses may be coupled together to provide a 50 foot (15.2m) reach

from the power unit to the anchor installation. HC-16-25 hydraulic hoses that meet all these

requirements are available from a Manta Ray Distributor.

2

2.4 Drive steel

Available from your Manta Ray Distributor, is required. The Manta Ray drive steel is a patented

design made of high performance materials. It allows the anchor to be driven to depth in discrete

increments to allow installation in tight spaces while the operators remain safely on the ground.

The SGC-14 Drive steel kit is the preferred starting set. It is composed of short (about 3 foot

long) pieces that are coupled together during installation: The shank (or striking bar) has a 1

hex x 6 (32mm hex x 152mm) shank configuration on one end to match the HB90-14 hammer

and is threaded on the other. The radius tip piece is rounded on one end to fit into the Manta Ray

anchor and threaded on the other. Extensions are threaded on both ends. The couplers join the

different pieces together. The SGC-14 kit includes 1 shank, 1 radius tip, 2 extensions, 3 couplers,

an extractor bar, and a carrying bag. This is enough to drive Manta Ray anchors to about 8(2.4m)

depth. The extractor bar is included to allow the Load locker to be used to extract the drive steel if

it gets stuck. Refer to stuck drive steel in the special cases section.

Left: The drive steel kit includes the drive steel pieces, an extractor bar and a carrying bag.

Right: Close up of the Shank, Couplers, Radius Tip and Extensions.

The patented Manta Ray SG drive steel uses a partial left hand thread that allows very efficient

impact energy transfer from the hammer to the anchor. All joints should be lubricated with light

oil or spray lubricant prior to assembly. After installing an anchor the drive steel joints should be

cleaned of dirt which will enter the couplers during driving. Failure to clean and lubricate the

drive steel and couplers will result in premature failure. Drive steel parts are available separately

and come in lengths of 3, 6, 8 feet (.9, 1.8, 2.4m). Medium and heavy duty couplers are also

available. Contact your Manta Ray distributor.

3

2.5 LL-1 Load Locker

The Manta Ray LL-1 Load Locker is required to load lock and proof test the anchor. It is a double

acting hollow hydraulic jack with a base reaction plate and a direct reading gage. Use of this tool

provides an immediate proof test of each Manta Ray anchor. It is designed to be powered by the

same GPU18-8CE hydraulic power unit that is used to power the HB90-14 anchor driving

hammer. The LL-1 uses quick release gripping jaws that grip an Adapter Setting Bar (ASB) that

passes through the center of the jack. The ASB extends the anchor rod and precludes any damage

to the anchor rod from the gripping jaws. Different models of LL-1 Load lockers to accommodate

different anchor rod thread patterns (with different Adapter Setting Bars and gripping jaws) are

available. Contact your Manta Ray distributor for the proper model of LL-1 Load Locker. The

base plate is designed for anchors that are installed at an angle to the ground: it has a large and a

small cross member. For angled guy anchors the shorter of the two cross members should be

placed toward the tower and perpendicular to the axis of the anchor rod. The Load locker and

base are designed to self align to the actual angle between the anchor and the ground. The vertical

legs of the Base cut into the soil during use to help keep the base from skidding. When load

locking angled anchors the knife edges of the Load Locker jack should engage the square tabs on

the base that are closest to the short cross member.

The LL-1 Load Locker kit includes adapter setting bar, Gripping Jaws and Metal Box. It does not

include the Hydraulic Power Unit.

4

3.0 Step by Step Installation Instructions

CAUTIONS:

ALL SUBSURFACE UTILTIY LOCATION PRECAUTIONS MUST BE OBSERVED

PRIOR TO INSTALLATION. DO NOT DRIVE MANTA RAY ANCHORS WITHOUT

AN UNDERGROUND UTILITY LOCATION REPORT.

PERSONNEL MUST USE SAFETY GEAR INCLUDING BUT NOT LIMITED TO:

HARD HATS, GLOVES, STEEL TOE BOOTS, EYE AND HEARING PROTECTION.

3.1. Assemble the anchor

Thread the anchor rod into the anchor shackle and tighten with a wrench. There are several styles

of anchor rods and some require the use of a pipe wrench. Place the anchor at the required

location. For guy anchors the anchor should point away from the tower and the anchor rod should

point directly at the tower.

This picture shows a Utility Style anchor rod with a wrench hex. Some anchor rods are

fully threaded with no hex so a pipe wrench is used to tighten the rod into the shackle.

5

3.2. Assemble the first section of drive steel

The shank, a coupler and the radius tip are threaded together. Remember the drive steel system

has left handed partial threads. When connected properly, the coupler should move back and forth

freely (called free float). Always check for this free float. If the coupler is not completely

threaded into the free float position it will break when the hammer is turned on. Lubricate the

threads prior to assembly with light oil or spray lubricant, then connect shank and radius drive

steel tip together with a coupler.

3.3 At anchor location, put drive steel in hammer, put anchor on drive steel

Place the hammer on the ground behind the anchor and insert the drive steel shank into the

hammer. Place the anchor onto the radius tip. Position the anchor at the point of entry into the

ground.

6

3.4 Make hydraulic power connections

Connect the hammer to the power unit with the hoses, start the power unit and turn the hydraulic

circuit on.

3.5 Drive the first section

Raise the hammer to the proper angle and begin to drive the anchor. To avoid skidding at the

start of angled drives, start closer to vertical, then lower the hammer to the proper angle as the

anchor begins to penetrate the ground. The installer must support the weight of the hammer. Do

not let the weight of the hammer apply a side load on the drive steel or premature drive steel

failure will occur. Drive the anchor until the first drive steel coupler is approximately at ground

level.

3.6 Add drive steel extensions

Open the hammer latch and remove the hammer from the shank, being careful not to remove the

radius drive tip from the anchor. CAUTION: THE DRIVE STEEL, ESPECIALLY THE

COUPLERS, CAN BE HOT. WEAR GLOVES. Remove the drive steel shank from the coupler.

Remember the drive steel has a left hand partial thread. It helps to hold the coupler and pull

upward on the shank while turning clockwise (as viewed from above) to the get the partial threads

to engage. Place a drive steel extension and another coupler between the original tip and shank.

Remember to lubricate the drive steel joints prior to assembly. Replace the hammer on the shank

and continue driving the anchor until the second coupler is at ground level. Repeat this step with

the second drive steel extension (or as many drive steel extensions as required to achieve the depth

required). Drive times for most normal soils are approximately 3 5 minutes per 3 foot (.9m)

long drive steel section. If at any time the anchor stops moving, perform what is called the 5

minute test. Make a visible mark on the anchor rod and drive the anchor for 5 minutes. If the

anchor moves less than (12.5mm) in 5 minutes this is called refusal. Refer to anchor refusal in

the special cases section.

7

3.7 Attach Adapter Setting Bar (ASB) and countersink

When the top of the anchor rod is at ground level, stop driving and thread the Load Locker

Adapter Setting Bar (ASB) onto the anchor rod. The purpose of the ASB is to extend the anchor

rod so the Load Locker can grip it. Because the anchors pull back upward during load locking,

some experience is required to properly estimate how far to drive the anchors to achieve the

required minimum finished depth. A good rule of thumb is the anchor will pull back

approximately 1 to 2 times its length. After threading on the ASB, drive the anchor until the top

of the anchor rod is below grade by approximately the length of the anchor. This is called

countersinking the anchor. The ability to estimate how much to countersink comes only with

experience. Softer soils and larger anchors require greater countersink. Some very soft soils will

require the installer to countersink 18-36 inches (.45 .9m). Harder soils require less if any

countersink. Some conservative installers drive all anchors 36 (.9m) beyond the minimum

required finished depth to be sure to meet the finished depth requirement. This may require

additional drive steel extensions and couplers.

Top of anchor rod at grade, and Adapter Setting Bar (ASB) being installed.

8

3.8 Remove the drive steel.

In most cases the drive steel is simply removed by an upward pull on the hammer. A very rapid

upward pull usually breaks the drive steel free. After the steel is broken free, remove the hammer

and pull the drive steel out of the hole by hand. CAUTION: THE DRIVE STEEL,

ESPECIALLY THE COUPLERS, CAN BE HOT. WEAR GLOVES. If the steel does not break

free easily, pull upward while operating the hammer to vibrate the steel free. After the steel has

broken free, remove the hammer and pull the drive steel out of the hole by hand. In some gravelly

or rocky soils the drive steel can become stuck. If this happens, the Load Locker can be used to

remove the drive steel. Refer to stuck drive steel in the special cases section.

Note: This picture shows the installer removing the drive steel by hand after it has broken free. It

does not show the adapter Setting Bar (ASB) on the anchor rod, but normally it would be on the

anchor rod as shown in the previous picture.

9

3.9 Set up the Load Locker.

Place the base plate over the Adapter Setting Bar (ASB) with the shorter cross member toward the

tower and perpendicular to the axis of the ASB. Align and adjust the position of the base plate so

that the ASB is even with the square steel tabs closest to the small cross member. Slide the Load

Locker jack over the ASB so the knifed edges on the jack engage the square tabs on the base.

Place the gripping jaws around the ASB and into the tapered rod end of the jack. Use light oil or

spray lubricant on the outside surfaces of the gripping jaws to help them release. New jaws have a

tendency to stick. Connect the hydraulic jack to the power unit and turn on the hydraulic circuit.

10

3.10 Load Lock the anchor.

CAUTION: NEVER STAND IN LINE WITH THE ANCHOR ROD DURING LOAD

LOCKING.

Be certain that nothing is underneath any part of the base plate. Push the valve handle toward the

jack to extend the cylinder and tip the anchor. When the cylinder reaches the top of its stroke it

will stop automatically on its own internal stops. When it does, pull the valve handle away from

the jack to retract the jack. New jaws have a tendency to stick, so dont be surprised. To release

them retract the jack about halfway and give the ASB a very swift side to side jerk. This should

release the jaws and the jack should fall back onto the base plate. Fully retract the jack and reset

the jaws. A good rule of thumb is to apply 3 full strokes of the jack to the anchor to insure that it

is fully tipped.

3.11 Proof test the anchor

Proof test the anchor to the required load. This is done by re setting the jack and the jaws and

gradually increasing the load on the anchor to find out the maximum it will hold without

movement. With practice and installer can carefully control the pressure on the anchor with the

control valve. Hold the load on the anchor as measured on the direct reading gage and monitor the

movement of the anchor. If the anchor holds the required load for 1 minute with no more than

(12.5mm) of movement then the anchor has passed the proof test. A common way to measure the

movement of the anchor is to use a tape measure between the top of the cylinder portion of the

Jack and the bottom of the tapered barrel that holds the gripping jaws. The manual included with

the Load locker manual has more detail on proof testing methods.

In softer soil the base plate can be set on top of timbers for increased surface area so that any

sinking tendency will be eliminated.

Load locker base is placed on timbers in soft soil, and finished anchor with eye nut installed.

11

4.0 Special Cases

4.1 Refusal

Refusal is defined a s a penetration rate of 1/2 (12.5 mm) or less in 5 minutes of driving. This

can indicate extremely hard soil or an impenetrable object.

4.1.1 Hard soil

The use of a hand held hydraulic auger to drill a pilot hole can help significantly. The hydraulic

auger shown below is available from a Manta Ray distributor. Called the LB-1 earth auger it is

powered by the same hydraulic power unit and comes with enough 4 (102mm) diameter augers

and extensions to drill an 8 foot (2.4m) deep pilot hole.

Deeper pilot holes can be drilled by the addition of more extensions. The Manta Ray can then be

driven down the pilot hole to achieve a much faster installation. Always use the auger tailings to

backfill and tamp after the anchor has been driven down the pilot hole. Some installers use

(6mm) gravel to backfill after driving the anchors. The use of a pilot hole in hard soils can

significantly increase the life of the SG drive steel. In some extremely hard soils the use of a pilot

hole and the MR-2 anchor is the right choice. The MR-2 will penetrate the pilot hole with

virtually no resistance. The MR-1 and MR-SR anchors can be driven down the pilot hole but the

wings will provide some resistance. In most cases, if the soil is hard enough to warrant the use of

a pilot hole, the holding capacity is not an issue and the anchors will proof test to their maximum

capacity. Because all soils are different, some experimentation is required to effectively use pilot

holes. In some extremely hard soils the MR-2 will tend to slide back up the pilot hole during load

locking. Sometimes this can be avoided by good backfilling and tamping. Sometimes it cant be

avoided, and the possible solutions are: drive the anchor beyond the end of the pilot hole if

possible, or try a larger diameter pilot hole. Different diameters augers and extensions are

available.

12

4.1.1 Impenetrable object

If the anchor has hit an impenetrable object the installer has two options:

4.1.1.1 Abandon the anchor but save the anchor rod by unthreading it. Then try a slightly different

location or angle with a new anchor to attempt to miss the object.

4.1.1.2 Retrieve the anchor with the Load Locker. This is done by removing the hammer from

the drive steel but leaving the drive steel in the anchor. Then place the LL-1 Load locker over the

anchor rod and use it to pull the anchor out. Leaving the drive steel in the anchor prevents it from

tipping and locking when the LL-1 pulls on the anchor rod. Be careful to stop pulling with the

when the anchor gets close to the bottom of the Load Locker. In most cases a bit of shovel work

is required to retrieve the anchor. After retrieval try a slightly different location or angle with a

new anchor to attempt to miss the object.

4.2 Stuck drive steel

Some gravelly soils or very wet, muddy soils will collapse around the drive steel during driving

and make it very difficult to break free by hand. This can also happen when a the anchor hits a

small obstruction and penetrates on a slightly curved path. For this reason a Drive Steel Extractor

Bar (SG-X) is included with each drive steel set. It is threaded on one end to fit into the drive

steel couplers. The other end is designed to be gripped by the gripping jaws of the LL-1 Locker.

If steel does not manually break free, simply remove the hammer from the shank, remove the

shank piece from the coupler, and thread in SG-X ( remember the left hand partial thread). Use

the load locker to pull up on the SG-X to break the steel sections free. Usually after the steel

breaks free it can be pulled out by hand. The drive steel will fit through the center of the Load

locker, but be careful. Sometimes the edges of the couplers can get stuck on the bottom of the

load locker jack or base plate.

4.3 Alternate Tools

Pneumatic pavement breakers can be used to drive the anchors, but be sure to use a 90 lb. (41kg.)

hammer and the proper compressor. Most installers have found that the hydraulic hammers

outperform the pneumatics for driving Manta Rays, especially in the harder soils. A hydraulic

power unit will still be required to run the Load Locker and the earth auger. Contact your Manta

Ray distributor for details.

4.4 Other Options

Manta Ray anchors can be threaded for many different types of anchor rods and smaller Manta

Ray anchors are also available. Contact your Manta Ray distributor for details.

13

5.0 Driving the anchors with Mounted Hammers

A Hammer mounted to a skid steer, backhoe or excavator makes driving Manta Ray anchors very

easy. Be careful to maintain proper alignment as the anchor penetrates the ground. It is easy to

move the arms of the vehicle too fast and cause severe misalignment which will cause premature

drive steel failure. Many installers use an equipment operator and a helper who can stand to the

side for a better view to signal to the operator how to move the arms of the vehicle.

5.1.1 Skid Steer

A Hammer mounted to a skid steer makes driving Manta Ray anchors very easy. 500 ft-lb (369

Joule) rated hammers are common and perform well for driving Manta Ray anchors. A blunt (flat

end) tool in the hammer is required. The picture at right shows the socket adapter that threads

onto Manta Ray SG drive steel. Socket adapters are sized for the diameter of the blunt tool in the

hammer. 6 foot long drive steel pieces are typically used. Use a chain around the socket adapter

to remove the drive steel with the vehicle.

The use of optional Medium or Heavy duty Drive steel couplers is recommended. A Heavier Duty

SG150 drive steel system is also available. Contact your Manta Ray distributor for details.

14

5.1.1 Backhoe or Excavator

Use the same socket adapter and drive steel as used with the skid steer method. Note the helpers

stand to the side to watch the alignment and signal to the operator.

6.0 Holding Capacities

The holding capacity of Manta Ray anchors is dependant on the soil into which they are placed.

Use the charts of Section 6.1 to estimate capacities based upon the Standard Penetration Test

(SPT) Blow count, N. The capacities listed in the charts are Ultimate Capacity. In the harder

soils the Ultimate holding capacity is the actual Breaking strength of the anchor. In the softer soils

the ultimate capacity is the ultimate strength of the soil. In general Manta Ray anchors perform

best in mixed soils with Blow counts in the 10 40 range. The values listed in the charts represent

estimated capacities for anchors with a minimum of 6 feet embedment into the soil in question.

15

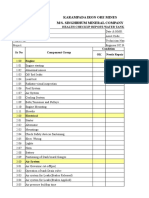

6.1 Holding Capacity Charts for Manta Ray Anchors

Capacities in KIPS (kilopounds, or 1000s of pounds)

Soil Description Blow

count

(N)

MR-2

KIPS

MR-1

KIPS

MR-SR

KIPS

Very dense/cemented sands;

Coarse gravel and cobbles

60-100+ 28-40

(1,3,4)

40

(1,3,5)

40

(5)

Dense fine compacted sands,

very hard silts or clays

45-60 21-28

(2,4)

36-40

(1,3,4)

40

(1,3,5)

Dense Clays, Sands and

gravels, hard silts and clays

35-50 15-22

(2,4)

24-36

(2,4)

32-40

(2,3,4)

Medium dense sandy gravel,

stiff to hard silts and clays.

24-40 12-18

(4)

18-20

(2,4)

24-34

(2,4)

Medium Dense Coarse sandy

gravel, Stiff to Very stiff silts

and Clays

14-25 9-12

(4)

15-20

(4)

18-24

(4)

Loose to Medium Dense Fine

to Coarse Sand: Firm to Stiff

Clays and Silts

7-14 7-10

(4)

10-15

(4)

14-18

(4)

Loose Fine Sand, Alluvium,

Soft Clays, Fine saturated

Silty Sand

4-8 5-8

(4,6)

8-12

(4,6)

9-14

(4,6)

Peat, Organic Silts: Inundates

Silts Fly Ash

0-5 2-5

(4,6)

3-8

(4,6)

4-12

(4,6)

Capacities in kN (kilonewtons, or 1000s of Newtons)

Soil Description Blow

count

(N)

MR-2

KIPS

MR-1

KIPS

MR-SR

KIPS

Very dense/cemented sands;

Coarse gravel and cobbles

60-100+ 125 - 178

(1,3,4)

178

(1,3,5)

178

(5)

Dense fine compacted sands,

very hard silts or clays

45-60 93 - 125

(2,4)

168 - 178

(1,3,4)

178

(1,3,5)

Dense Clays, Sands and

gravels, hard silts and clays

35-50 67 - 98

(2,4)

107 - 160

(2,4)

142 - 178

(2,3,4)

Medium dense sandy gravel,

stiff to hard silts and clays.

24-40 53 - 80

(4)

80 - 89

(2,4)

107 - 151

(2,4)

Medium Dense Coarse sandy

gravel, Stiff to Very stiff silts

and Clays

14-25 40 - 53

(4)

67- 89

(4)

80 - 107

(4)

Loose to Medium Dense Fine

to Coarse Sand: Firm to Stiff

Clays and Silts

7-14 31 - 44

(4)

44 - 67

(4)

62 - 80

(4)

Loose Fine Sand, Alluvium,

Soft Clays, Fine saturated

Silty Sand

4-8 22 - 36

(4,6)

36 - 53

(4,6)

40 - 62

(4,6)

Peat, Organic Silts: Inundates

Silts Fly Ash

0-5 9 - 22

(4,6)

13-36

(4,6)

18 - 53

(4,6)

Notes: 1) Drilled pilot hole required for efficient installation

2) Ease of installation may be improved by drilling a pilot hole.

3) Holding capacity limited by ultimate strength of anchors

4) Holding capacity limited by soil failure.

5) Not recommended in these soils

6) Wide variation in soil properties reduces prediction accuracy.

16

Das könnte Ihnen auch gefallen

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheVon EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheBewertung: 4.5 von 5 Sternen4.5/5 (2)

- 4L80E Build Tips and TricksDokument5 Seiten4L80E Build Tips and TricksSjoling8211Noch keine Bewertungen

- IFR CalculationDokument15 SeitenIFR CalculationSachin5586Noch keine Bewertungen

- Sany Piling RigDokument66 SeitenSany Piling RigRajan Mullappilly100% (2)

- Ku Electric HandbookDokument132 SeitenKu Electric HandbookArnaldo BenitezNoch keine Bewertungen

- TDBFP ManulDokument266 SeitenTDBFP ManulJackSparrow8678% (9)

- Shimano Ultegra 6700 Shifters Double Owners ManualDokument2 SeitenShimano Ultegra 6700 Shifters Double Owners ManualTimNoch keine Bewertungen

- Manual Operation XQ114-6BDokument33 SeitenManual Operation XQ114-6BrogerNoch keine Bewertungen

- IBPS Clerk Pre QUANT Memory Based 2019 QuestionsDokument8 SeitenIBPS Clerk Pre QUANT Memory Based 2019 Questionsk vinayNoch keine Bewertungen

- Mechanical SectionDokument16 SeitenMechanical SectionFrancis DimeNoch keine Bewertungen

- BT Series Owners Manual - CombinedDokument142 SeitenBT Series Owners Manual - Combinedalejandro777_eNoch keine Bewertungen

- Manual Book XQ29-1.8B Sucker Rod Power Tong PDFDokument31 SeitenManual Book XQ29-1.8B Sucker Rod Power Tong PDFadi Julianto100% (1)

- Rockwell Collins RDRDokument24 SeitenRockwell Collins RDRMatty Torchia100% (5)

- Connecting Rod ReplacementDokument11 SeitenConnecting Rod Replacementfjafarvand100% (1)

- Hydrogeological Survey and Eia Tor - Karuri BoreholeDokument3 SeitenHydrogeological Survey and Eia Tor - Karuri BoreholeMutonga Kitheko100% (1)

- Manual Mantenimiento Mission 40Dokument8 SeitenManual Mantenimiento Mission 40Daygor Martinez SabucoNoch keine Bewertungen

- Pioneer Single Trip Retreival SystemDokument13 SeitenPioneer Single Trip Retreival SystemRight S AlexNoch keine Bewertungen

- Ginger Final Report FIGTF 02Dokument80 SeitenGinger Final Report FIGTF 02Nihmathullah Kalanther Lebbe100% (2)

- Maintenance For Model Master Rotary TableDokument7 SeitenMaintenance For Model Master Rotary Tablejdk3dNoch keine Bewertungen

- Clutch Manual 2013 PDFDokument16 SeitenClutch Manual 2013 PDFArnaldo BenitezNoch keine Bewertungen

- 5370Dokument300 Seiten5370Arnaldo BenitezNoch keine Bewertungen

- Av Vibrating Screens PDFDokument2 SeitenAv Vibrating Screens PDFArnaldo BenitezNoch keine Bewertungen

- Casing Scraper ManualDokument8 SeitenCasing Scraper ManualMinnyeong YoonNoch keine Bewertungen

- MODEL XQ140/20 Hydraulic Power Tong: Parts and Operation ManualDokument57 SeitenMODEL XQ140/20 Hydraulic Power Tong: Parts and Operation ManualCarlos Antonio Fontalvo Carrascal100% (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementVon EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNoch keine Bewertungen

- Digital SLR AstrophotographyDokument366 SeitenDigital SLR AstrophotographyPier Paolo GiacomoniNoch keine Bewertungen

- Atlas 4350 Hacksaw ManualDokument6 SeitenAtlas 4350 Hacksaw Manualf4d711Noch keine Bewertungen

- Briquettes Handbook-FAO PDFDokument134 SeitenBriquettes Handbook-FAO PDFArnaldo Benitez100% (2)

- En 50124 1 2001Dokument62 SeitenEn 50124 1 2001Vivek Kumar BhandariNoch keine Bewertungen

- Shimano XTR M980 Shift Lever Set ManualDokument4 SeitenShimano XTR M980 Shift Lever Set ManualNick SpeisNoch keine Bewertungen

- M-S-215 Static Cone PenetrometerDokument4 SeitenM-S-215 Static Cone PenetrometerJunpieter GultomNoch keine Bewertungen

- OWI 1000 DrawworksDokument54 SeitenOWI 1000 DrawworksÖnder Büyükişcan100% (1)

- H2000 5-10t Service and Operation ManualDokument111 SeitenH2000 5-10t Service and Operation ManualArnaldo Benitez100% (1)

- Tetra IntroductionDokument65 SeitenTetra Introductionuniversidaddistrital100% (2)

- KHT5500 ManualDokument56 SeitenKHT5500 ManualFernando EncisoNoch keine Bewertungen

- Conveyor Control Using Programmable Logic ControllerDokument7 SeitenConveyor Control Using Programmable Logic ControllerWann RexroNoch keine Bewertungen

- Benko Gambit-Jacobs and Kinsman, 1999Dokument163 SeitenBenko Gambit-Jacobs and Kinsman, 1999johnson Greker100% (3)

- X30592Dokument16 SeitenX30592CTN2010Noch keine Bewertungen

- Vibratory Feeders and Conveyors PDFDokument14 SeitenVibratory Feeders and Conveyors PDFArnaldo BenitezNoch keine Bewertungen

- Manta Ray in Depth Installation Guide 05-04-2022 FINALDokument8 SeitenManta Ray in Depth Installation Guide 05-04-2022 FINALotmani.yanissNoch keine Bewertungen

- TM 300BK21Dokument4 SeitenTM 300BK21Oscar GuaricalloNoch keine Bewertungen

- KPS03 Installation InstructionsDokument12 SeitenKPS03 Installation InstructionsHybrid RacingNoch keine Bewertungen

- Operation Manual: Model Xq114/6B Hydraulic Power Tong PartsDokument33 SeitenOperation Manual: Model Xq114/6B Hydraulic Power Tong PartsJohan PorrasNoch keine Bewertungen

- Transcriptor Skeleton Turntable Owners ManualDokument20 SeitenTranscriptor Skeleton Turntable Owners ManualMatt RichmondNoch keine Bewertungen

- Ela Rotors Adjust 2015 1604 PDFDokument11 SeitenEla Rotors Adjust 2015 1604 PDFJoffre Lautaro Benavides SeminarioNoch keine Bewertungen

- Manual Rosq - enDokument10 SeitenManual Rosq - enRobinson JimenezNoch keine Bewertungen

- Month Marine Engineering at The Operational LevelDokument79 SeitenMonth Marine Engineering at The Operational LevelMum ZetaNoch keine Bewertungen

- DrivetrainDokument43 SeitenDrivetrainfuckoffalreadyNoch keine Bewertungen

- Roller Chain Coupling: Features 1. Simple Structure 1. Advantages of HousingDokument5 SeitenRoller Chain Coupling: Features 1. Simple Structure 1. Advantages of Housingsyaifularifin33Noch keine Bewertungen

- SANY Heavy Industry Co., Ltd. Quality Changes The WorldDokument66 SeitenSANY Heavy Industry Co., Ltd. Quality Changes The Worldavtonika38Noch keine Bewertungen

- Shaft 141118092812 Conversion Gate02Dokument14 SeitenShaft 141118092812 Conversion Gate02Aso SerwanNoch keine Bewertungen

- Tech Write-Up New ...Dokument2 SeitenTech Write-Up New ...Dheeraj Kapoor /QOGIL/QuippoworldNoch keine Bewertungen

- K-Swap Bolt-In Shifter Install GuideDokument8 SeitenK-Swap Bolt-In Shifter Install GuideHybrid RacingNoch keine Bewertungen

- Lycoming Starter AdapterDokument11 SeitenLycoming Starter AdapterakNoch keine Bewertungen

- General Series Overhead Crane: User ManualDokument27 SeitenGeneral Series Overhead Crane: User ManualjokoNoch keine Bewertungen

- KHT5500 Power Tong ManualDokument46 SeitenKHT5500 Power Tong ManualSon DDarrellNoch keine Bewertungen

- Steering SystemDokument22 SeitenSteering SystemAlexanderNoch keine Bewertungen

- Unidad Rotacion Serie l30Dokument22 SeitenUnidad Rotacion Serie l30Raphael Ruiz RamosNoch keine Bewertungen

- Pneumatic Actuators Firesafe: Type and Design The Principle and Application of The Scotch Yoke ConstructionDokument4 SeitenPneumatic Actuators Firesafe: Type and Design The Principle and Application of The Scotch Yoke ConstructionreliableplacementNoch keine Bewertungen

- 7.0 Reference: 7.1 Engine Room LayoutDokument3 Seiten7.0 Reference: 7.1 Engine Room LayoutCarlos MenaNoch keine Bewertungen

- Rewind Motor BrushlessDokument11 SeitenRewind Motor Brushlesssharingiscaring69Noch keine Bewertungen

- Bow Thruster Installation InstructionsDokument9 SeitenBow Thruster Installation InstructionsRovert AlonzoNoch keine Bewertungen

- Bulk Roller Chain and AccessoriesDokument16 SeitenBulk Roller Chain and AccessoriesArmorNoch keine Bewertungen

- Shimano AlivioDokument1 SeiteShimano AlivioBrent MitchellNoch keine Bewertungen

- CouplingDokument9 SeitenCouplingPrabir Kumar PatiNoch keine Bewertungen

- ER-56-03 EN Packager Standards Skid Design and FabricationDokument4 SeitenER-56-03 EN Packager Standards Skid Design and FabricationCamilo Andres Cardozo FajardoNoch keine Bewertungen

- What Are SprocketsDokument9 SeitenWhat Are SprocketsTarcool KingsoftNoch keine Bewertungen

- CAPT CouplingsDokument33 SeitenCAPT Couplingshermes alberto consuegra gonzalezNoch keine Bewertungen

- CADCAM Laboratory VivaDokument6 SeitenCADCAM Laboratory VivasivaeinfoNoch keine Bewertungen

- RC Shark User Manual v1.0Dokument6 SeitenRC Shark User Manual v1.02gb46fvsvdNoch keine Bewertungen

- Wireline Operations, Drilling, GeophysicsDokument60 SeitenWireline Operations, Drilling, GeophysicsGheorghe AndreiNoch keine Bewertungen

- IronRidge Flush Mount Installation ManualDokument12 SeitenIronRidge Flush Mount Installation ManualAnonymous nrE2hFsvNoch keine Bewertungen

- Manual Hidraulico Montacargas Yale Gp060rcDokument52 SeitenManual Hidraulico Montacargas Yale Gp060rcPepe AlNoch keine Bewertungen

- Synopsis Pedal HacksawDokument13 SeitenSynopsis Pedal Hacksawbalbir100% (1)

- Torque Motor1Dokument4 SeitenTorque Motor1pepenitoNoch keine Bewertungen

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeVon EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNoch keine Bewertungen

- Catalogo de BornesDokument150 SeitenCatalogo de Bornesvrv01Noch keine Bewertungen

- Catalogo General BDHDokument576 SeitenCatalogo General BDHArnaldo BenitezNoch keine Bewertungen

- Technical Assessment For Solar Powered Pumps Final For Public With Logos (Final)Dokument68 SeitenTechnical Assessment For Solar Powered Pumps Final For Public With Logos (Final)Arnaldo BenitezNoch keine Bewertungen

- In Search of Chip Quality & Financial Return: NalyzeDokument53 SeitenIn Search of Chip Quality & Financial Return: NalyzeArnaldo BenitezNoch keine Bewertungen

- Spheerol LMMDokument2 SeitenSpheerol LMMArnaldo BenitezNoch keine Bewertungen

- CA6110TH2 (11m) PDFDokument1 SeiteCA6110TH2 (11m) PDFArnaldo BenitezNoch keine Bewertungen

- Basics of Shutdowns, Turnarounds, and OutagesDokument9 SeitenBasics of Shutdowns, Turnarounds, and OutagesArnaldo BenitezNoch keine Bewertungen

- 884519Dokument289 Seiten884519Arnaldo BenitezNoch keine Bewertungen

- Mma 1210-Uk PDFDokument24 SeitenMma 1210-Uk PDFArnaldo BenitezNoch keine Bewertungen

- Business Statistic Handout Bba - Sem 2Dokument7 SeitenBusiness Statistic Handout Bba - Sem 2hanirveshNoch keine Bewertungen

- Usm 1Dokument47 SeitenUsm 1Abhishek KumarNoch keine Bewertungen

- Water Tanker Check ListDokument8 SeitenWater Tanker Check ListHariyanto oknesNoch keine Bewertungen

- Product Specifications Product Specifications: LLPX411F LLPX411F - 00 - V1 V1Dokument4 SeitenProduct Specifications Product Specifications: LLPX411F LLPX411F - 00 - V1 V1David MooneyNoch keine Bewertungen

- Chem Resist ChartDokument13 SeitenChem Resist ChartRC LandaNoch keine Bewertungen

- Avid Final ProjectDokument2 SeitenAvid Final Projectapi-286463817Noch keine Bewertungen

- M.Plan SYLLABUS 2022-24Dokument54 SeitenM.Plan SYLLABUS 2022-24Mili DawsonNoch keine Bewertungen

- Le Chatelier's Principle Virtual LabDokument8 SeitenLe Chatelier's Principle Virtual Lab2018dgscmtNoch keine Bewertungen

- Practical Cs Xii Mysql 2022-23 FinalDokument9 SeitenPractical Cs Xii Mysql 2022-23 FinalHimanshu GuptaNoch keine Bewertungen

- Redirection & PipingDokument16 SeitenRedirection & PipingPraveen PatelNoch keine Bewertungen

- Internship ReportDokument36 SeitenInternship ReportM.IMRAN0% (1)

- Jurnal Ekologi TerestrialDokument6 SeitenJurnal Ekologi TerestrialFARIS VERLIANSYAHNoch keine Bewertungen

- Contoh Assignment PDFDokument18 SeitenContoh Assignment PDFSiti Fatimah A Salam67% (3)

- Morse Potential CurveDokument9 SeitenMorse Potential Curvejagabandhu_patraNoch keine Bewertungen

- Freshers Jobs 26 Aug 2022Dokument15 SeitenFreshers Jobs 26 Aug 2022Manoj DhageNoch keine Bewertungen

- NHM Thane Recruitment 2022 For 280 PostsDokument9 SeitenNHM Thane Recruitment 2022 For 280 PostsDr.kailas Gaikwad , MO UPHC Turbhe NMMCNoch keine Bewertungen

- The Piano Lesson Companion Book: Level 1Dokument17 SeitenThe Piano Lesson Companion Book: Level 1TsogtsaikhanEnerelNoch keine Bewertungen

- Manual Ares-G2 2Dokument78 SeitenManual Ares-G2 2CarolDiasNoch keine Bewertungen

- A SURVEY OF ENVIRONMENTAL REQUIREMENTS FOR THE MIDGE (Diptera: Tendipedidae)Dokument15 SeitenA SURVEY OF ENVIRONMENTAL REQUIREMENTS FOR THE MIDGE (Diptera: Tendipedidae)Batuhan ElçinNoch keine Bewertungen

- Lect.1-Investments Background & IssuesDokument44 SeitenLect.1-Investments Background & IssuesAbu BakarNoch keine Bewertungen